JR PCM9X II User manual

Add to My manuals32 Pages

JR PCM9X II is an advanced and versatile transmitter designed specifically for multi-function sailplanes. With its sophisticated programming software developed by leading sailplane pilots, it offers a level of control and customization not found in other sailplane systems. The JR PCM9X II allows for precise adjustments of various flight parameters, including camber, elevator, rudder, and aileron, through its intuitive menus and user-friendly interface. The device features 5 flight modes, each of which can be individually programmed to suit different flying conditions. It provides active digital flight trims for in-flight adjustments and automatic storage and recall of settings for each flight mode.

advertisement

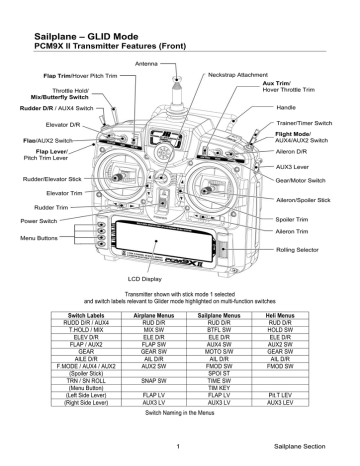

Sailplane – GLID Mode PCM9X II Transmitter Features (Front) Antenna Neckstrap Attachment Flap Trim/Hover Pitch Trim Aux Trim/ Hover Throttle Trim Throttle Hold/ Mix/Butterfly Switch Handle Rudder D/R / AUX4 Switch Trainer/Timer Switch Elevator D/R Flight Mode/ AUX4/AUX2 Switch Flap/AUX2 Switch Flap Lever/ Pitch Trim Lever Aileron D/R AUX3 Lever Rudder/Elevator Stick Gear/Motor Switch Elevator Trim Aileron/Spoiler Stick Rudder Trim Spoiler Trim Power Switch Aileron Trim Menu Buttons Rolling Selector LCD Display Transmitter shown with stick mode 1 selected and switch labels relevant to Glider mode highlighted on multi-function switches Switch Labels RUDD D/R / AUX4 T.HOLD / MIX ELEV D/R FLAP / AUX2 GEAR AILE D/R F.MODE / AUX4 / AUX2 (Spoiler Stick) TRN / SN ROLL (Menu Button) (Left Side Lever) (Right Side Lever) Airplane Menus RUD D/R MIX SW ELE D/R FLAP SW GEAR SW AIL D/R AUX2 SW Sailplane Menus RUD D/R BTFL SW ELE D/R AUX4 SW MOTO S/W AIL D/R FMOD SW SPOI ST TIME SW TIM KEY FLAP LV AUX3 LV SNAP SW FLAP LV AUX3 LV Heli Menus RUD D/R HOLD SW ELE D/R AUX2 SW GEAR SW AIL D/R FMOD SW Pit.T LEV AUX3 LEV Switch Naming in the Menus 1 Sailplane Section Sailplane Section 2 Contents – Glider Section PCM9X II Transmitter Features (Front) Sailplane- GLID Mode System Mode GLID Features Function Mode GLID Features System Mode – Functions Specific to GLID mode Device Select Flight Modes Device Select - Activating and Assigning Flight Modes Activating and Assigning Flight Modes (continued) Motor Function Flap and AUX Functions Wing Type Trim Step Function Mode D/R & EXP – Dual Rate and Exponential REV.SW – Servo Reversing SUB TRIM TRVL. ADJ – Travel Adjust Elevator-to-Flap Mix Aileron-to-Flap Mix Differential Flight Mode Delay Adjust Flaperon Mix Aileron-to-Rudder Mix Butterfly Mix (Landing Flaps) Flap Rate Motor Hold PROG MIX – Programmable Mixers Multi-Point Programmable Mixer Master Channel - (Multi-Point Mixer) Standard Programmable Mixer - (Std. Prog Mixer) PROG MIX - Programmable Mixers (continued) PROG MIX - Programmable Mixers (continued) Timer Servo Monitor 3 1 4 4 4 5 6 6 7 8 9 9 10 11 12 14 14 15 16 16 17 17 18 19 20 20 21 21 22 22 23 25 26 27 28 29 Sailplane Section Sailplane- GLID Mode The GLID mode is intended for multi-function sailplanes. The program software was developed by some of the world’s leading sailplane pilots and offers a level of sophistication not found in any other sailplane system. Up to 5 flight modes are available, each allowing virtually every parameter to be individually adjusted. Active flight mode digital trims allow in-flight adjustments of camber, elevator, rudder and aileron. Trim settings are automatically stored and recalled in each individual flight mode. Following is a list of sailplane specific programming menus and their primary functions: System Mode GLID Features System mode contains the foundational programming. System mode screens include model name, model reset, modulation, data transfer, etc.— functions that are typically set once and then are seldom changed or adjusted. • Trim Step–Allows the trim authority to be adjusted or even turned off. • Device Select–Flight modes, switch and lever locations and functions are programmed in this menu. • Wing Type–Allows the selection of V-tail and dual or single flap servos. Function Mode GLID Features Programs found in the function mode are more frequently used. Not only are these functions used during initial setup, but many of these are commonly adjusted at the field to change/optimize the flight characteristics and response of an aircraft. • Elevator-to-Flap–Allows two values of elevator-toflap mixing with independent up and down adjustments. Offset allows snap flaps to be programmed and the mix can be automatically selected in any desired flight mode or via several switch options. • Aileron-to-Flap–Allows two values of aileron-toflap mixing with independent right and left adjustment. This mix can be automatically selected in any desired flight mode or via several switch options. • Aileron and Flap Differential–Separate differential values (5) are available in each flight mode including reverse differential (for landing). Aileron and flap differentials are independently adjustable. • Flight Mode Delay adjust –A delay of up to 2 seconds can be programmed for each individual flight mode such that when switching flight modes, the camber and elevator presets transition smoothly. A break-off delay allows an elevator stick position to be used to override the delay, useful during launch when switching from launch to cruise mode for a zoom launch. • Flaperon Mix–Allows individual up and down flaperon and elevator values for each of the 5 flight modes to be adjusted via the side lever. • Aileron-to-Rudder Mix–Features separate right and left mix values for each of the 5 available flight modes. Sailplane Section • The Butterfly Menu–Provides 2 settings for flaps, flaperons and elevator values operated using the spoiler stick. Each value can be selected via flight modes or several available switches. • Flap Rate–Allows the flap camber up and down to be adjusted independently in each of the 5 flight modes via the side lever(s). • Programmable Mix 1–Spoiler-to-elevator curve mix allows non-linear elevator compensation when landing flap (butterfly/ crow) is deployed. A 6-point adjustable curve allows precise elevator input throughout flap travel avoiding unwanted pitching during landings. • 2 Timers–Are available and can be programmed as count up or down, and are assignable to various switches and buttons. • Active Digital Flight Trims–Allow presets of elevator, camber, rudder and aileron to be adjusted in flight and are automatically stored and recalled in each of the 5 flight modes. Note: The following section contains in-depth details regarding each of the available programming functions. If you’re just getting started, you’ll likely find it easier (and we recommend) using the programming guide for 6 servo sailplanes following the glider section of this manual. This step-by-step guide leads you through a typical 6-servo sailplane and even gives the keystrokes necessary to set up a sailplane, including flight modes, butterfly and side lever camber adjustment. We recommend referring to the section below when a more in-depth understanding of a specific programming feature is desired. 4 System Mode – Functions Specific to GLID mode System mode contains the foundational programming. System mode screens include model name, model reset, modulation, data transfer, etc.—functions that are typically set once and then are seldom changed or adjusted. This section describes system functions that are specific to the glider mode. The system functions that are common to all 3 model types are described in the common section at the front of this manual. To enter System Mode– Press ENT and hold while turning on the transmitter. The screen should appear as follows. System mode contains the following Glider specific screens: Device Select Pg. 5 Wing Type Pg 10 Trim Step Pg 11 5 Sailplane Section Device Select The device select screen is used to select the following: • To assign/activate flight modes to a variety of switches • To assign the motor function to the spoiler stick, levers or switches • To program the digital aileron and rudder trims so that they are common or separate in each flight mode • To assign the flap (camber) adjustment to one of the two available side levers • To assign the aux 2, 3 and 4 channels to various levers, switches or sticks • To activate or inhibit the motor, flap, aux 2, aux 3 and/or aux 4 channels Flight Modes adjustment of the side lever is programmed to give proportional camber changes to allow for last minute adjustments based on wind and winch conditions. • Aileron differential is set at 50%. All these (and many more) programming parameters can be selected by simply moving one switch. At the top of the launch you prepare to zoom by switching to the cruise mode. A single flip of the switch neutralizes the trailing edge while giving the correct elevator trim for cruise. Rudder-to-elevator and elevator-to-flap mixes automatically turn on the programmed values and the aileron differential is now at a much higher 75% for more coordinated thermal turns. At the flip of a single switch you’re ready for a zoom launch and for hunting thermals! And remember there are 3 more flight modes available. Once you start using flight modes, you’ll wonder how you ever flew without them. Flight modes allow nearly all of the parameters (i.e. dual rates, camber adjust values, preset trims, all types of mixing, etc.) to be programmed and then selected in flight via a switch(es). The PCM9X II offers up to 5 flight modes that include Launch, Land, Cruise, Speed and Thermal. Flight modes allow a sailplane’s programming to be optimized for up to five tasks. As an example, typically in launch mode: • The flaps and flaperons are preset with positive camber to give more lift. • An elevator preset trim position that gives the best climb is programmed. • A high rudder rate with reduced exponential to give authoritative steering control on launch is desired, while the elevator and aileron rates are set to give a medium response. • Aileron-to-rudder mix is turned off, as are landing flaps and elevator-to-flap mix while camber Sailplane Section 6 Device Select - Activating and Assigning Flight Modes In the factory default setting, all flight modes are inhibited. Flight modes are activated and assigned to the desired switch position using the SPEED and LAUN functions in the Device SEL screen. In system mode list rotate the Selector until Device SEL is highlighted. Press the Selector to access the Device Select screen. To activate the launch, cruise, and land mode, rotate the Selector until LAUN is highlighted and then press the Selector. The following screen will appear: At this point, you must decide which 2- or 3-position switch you prefer to assign the launch/land flight modes to. If a 2-position switch is selected, launch and cruise will be active. If a 3-position switch is selected, the launch, cruise and land will be activated. We recommend starting with the Flap (left 3 position) switch, as this is a convenient place. Rotate the Selector until the desired switch is highlighted and press to select. Trims may be selected to be either common (COM) or individual for each flight mode. Refer to the TRIM:COM function in the ACRO section of this manual for a full description. AIL D/R ELE D/R RUD D/R BTFL SW FMOD SW AUX4 SW MOTO SW 7 Aileron dual rate switch Elevator dual rate switch Rudder dual rate switch Butterfly switch (labelled Gear) Right 3-position Flight Mode switch Left 3-position Flap switch Mix switch Sailplane Section Activating and Assigning Flight Modes (continued) To activate the speed and thermal flight modes, highlight SPEED and press the Selector to select the desired switch position. Important: When the speed and thermal flight modes are activated, launch mode always has priority. Any time launch is selected it will override speed, thermal or cruise. To access speed or thermal, the launch switch Switch A Land Cruise Launch(Has Priority) must be in the cruise position. Try selecting the various flight modes several times while looking at the main info screen and you’ll quickly become familiar with the switch priority. Note: On the main info screen, the flight mode that is activated will be displayed on the top center of the screen. enables At this point, you must decide which 3-position switch you prefer to assign the speed and thermal flight modes to. We recommend starting with the Flight Mode (right 3 position) switch, as this is a convenient place. Rotate the Selector until the desired switch is highlighted and press to select. Sailplane Section Switch B Speed Cruise Thermal FMOD SW AUX4 SW 8 Right 3-position Flight Mode switch Left 3-position Flap switch Motor Function The motor function can be assigned to operate from several different switches, buttons or the throttle stick. In device select, highlight MOTO and press the Selector to access the available switches that can be programmed to operate the motor. Select the desired switch by highlighting it and press the Selector. Note: If dual flaps are activated in Wing Type in system mode, the motor function is not assigned to a channel. It will be necessary to use a programmable mix to mix MOTO to any open auxiliary channel in order to operate the throttle when dual flaps are activated. Also see Motor Hold on page 21 for more details. AIL D/R ELE D/R RUD D/R BTFL SW FMOD SW AUX4 SW MOTO SW TIME SW SPOI ST Aileron dual rate switch Elevator dual rate switch Rudder dual rate switch Mix (Butterfly) switch Right 3-position Flight Mode switch Left 3-position Flap switch Gear (Motor) switch Trainer/Snap Roll/Timer switch Spoiler stick Flap and AUX Functions The Flap and Auxiliary functions can be assigned to operate from several different switches, levers or the throttle stick. In device select, highlight the desired flap or aux function and press the Selector to access the available switches that can be programmed to operate each function. Select the desired switch by highlighting it and press the Selector. Refer to the table under Motor Function above for a mapping of menu switch names to the actual switch labels. 9 Sailplane Section Highlight the desired ACT/INH below the appropriate channel. Press the Selector to inhibit or activate the channel. Activating / Inhibiting Channels Channels 6–9 can be inhibited, allowing them to be used as slave channels, in programmable mixes. Wing Type This screen allows the selection of V-tail, dual flap and, when dual flaps are activated, aileron-to-flap trim. To access Wing type in System mode list, rotate the Selector to highlight Wing TYPE. Press the Selector to access the wing type screen. If your sailplane has a V-tail, activate the V-tail function by highlighting INH and pressing the Selector. Sailplane Section If your sailplane has dual flaps, activate the dual flap function by highlighting INH and pressing the Selector. Making dual flaps active also activates the AILEFLAP trim function in the function menu, which allows aileron trim to also affect the flaps. 10 Trim Step Use a fairly coarse setting such as 4–6 when test flying an aircraft in order to be able to trim the aircraft quickly, and then use a finer setting such as 3–1 for final precision trimming. 1. Highlight and select TRIM STEP in the Device SEL display of the SYSTEM Menu to acquire the TRIM STEP display. 2. Highlight and select the trim that is to be changed and use the Selector to set a value of 1–10 (1 = finest, 10 = coarsest). 3. Repeat for other trims as desired. The Trim Step function provides for adjusting the sensitivity of the trim levers. It is useful during and after initial trimming of the aircraft, in order to trim the aircraft quickly at first and then to make very precise adjustments to aircraft trim. When adjusting the digital trims (SPOI, AILE, ELEV, RUDD), the total trim travel does not change—only the number of increments (beeps) changes, which makes for finer or coarser trim movements. The digital trims may have a setting of 0– 10 with 10 being the coarsest adjustment. When the value is set to 10, there are only 10 trim increments from center to each end. When set to 5, there are 20 trim increments from center to each end. When set to 4 there are 25 increments. When set to 3 there are 34 increments and when set to 1 there are 100 trim increments. When set to 0 the trim levers cease to function and can no longer be used to change the trim of the aircraft. When adjusting the analog spoiler trim, however, the total trim travel is actually reduced when set to less than 100%. 4. Select the type of trim required. On a normal trim, adjustment of the trim will affect the end points. On L.S.T (Limit Stroke Trim), the end points will NOT be affected by the trim, this prevents the trim from overdriving the servos. 11 Sailplane Section Function Mode Programs found in the function mode are more frequently used. Not only are these functions used during initial setup, but many of these are commonly adjusted at the field to change/optimize the flight characteristics and response of an aircraft. Note that the Fail Safe and Trainer functions are covered in the general section at the front of this manual. To enter function modes, turn on the transmitter then press the ENT button. To enter the function list mode, press the list mode after the function mode has been selected. Note: The Aileron to Flap Mix option is only displayed if the Dual Flaps option has been enabled in the Wing TYPE setup in the System Menu. Similarly, the Motor Hold option is only displayed if the motor function has been assigned in the System Menu. The Fail Safe function is available only when SPCM has been selected as the Modulation Type in the System Menu. Function mode contains the following screens: Dual Rate and Exponential Pg. 14 Elevator-to-Flap Mix Pg. 16 Reversing Switch Pg. 14 Aileron-to-Flap Mix Pg. 16 Sub Trim Pg. 15 Differential Pg. 17 Travel Adjust Pg. 16 Flight mode delay adjust Pg. 18 Sailplane Section 12 Flaperon Mix Pg. 19 Programmable Curve Mix Pg. 22 Aileron-to-Rudder Mix Pg. 20 Programmable Mix Pg. 25 Butterfly Mix Pg. 20 Timer Pg. 28 Flap Rate Pg. 21 Servo Monitor Pg. 29 Motor Hold Pg. 21 13 Sailplane Section D/R & EXP – Dual Rate and Exponential Three dual and exponential rates are available and are selectable via flight modes or selected switches. Dual and Expo rates are independently adjustable in each direction by moving the appropriate stick in the desired direction. For an in-depth description of D/R and Exponential, please refer to the Dual Rates and Exponential Curves article in the General Section of this manual. 1. Highlight and select D/R & EXP in te FUNC.LIST to obtain the D/R & EXP display. If Flight Modes were activated earlier in the Devic.SEL function and D/R was set to FM in the same function, there will be 3 sets of values displayed for each channel – Aileron, Elevator and Rudder. 2. Use the Selector to change between Aileron, Elevator and Rudder. Then use it to set dual rate and exponential values. 3. You may also assign a dual rate setting to a flight mode using the automatic switching function, which is accessed by scrolling the cursor to the right. REV.SW – Servo Reversing The servo reverse screen allow the direction of each servo to be selected. 1. Highlight and select REV.SW in the FUNC.LIST to obtain the servo reversing display. 2. Use the Selector to highlight and select those channels that need to be reversed. Pressing the Selector toggles the channel between Normal and Reverse. Note: Channel labels may vary due to channel assignments, eg. RUD = RFL and MOT = LFL Sailplane Section 14 SUB TRIM Use Sub Trims to fine-tune the alignment of servo arms. 1. Highlight and select Sub Trim in the FUNC.LIST to obtain the Sub Trim Display. 2. Highlight and select the channels where the sub trims must be adjusted. Once a channel is selected, rotate the Selector until the servo arm is in the desired position. Note that channel names may vary depending on channel assignments. Note: Typical flap geometry requires that the sub trim be significantly offset to provide adequate down flap throw. This issue exists because flaps typically have a large travel down (80 to 90 degrees) but very little travel up (less than 15 degrees). To achieve proper flap travel, it is necessary that the right flap sub trim be set at 225 down and the left flap sub trim be set at 225 up as a starting point. Then when attaching the flap servo arms be sure the spoiler stick is in the up position and camber lever is in the middle position. Install the flap servo horns such that they are angled approximately 30˚ toward the trailing edge, then adjust the flap linkage such that the flaps are level. 15 Sailplane Section TRVL. ADJ – Travel Adjust Travel Adjust allows from 0-150% (0 degrees to 60 degrees) independent adjustment of servo travel for each direction of servo travel. For more information on Servo Travel and Mechanical Advantage please refer to the Sub Trim Usage and Mechanical Advantage article contained in the General Section. 1. Highlight and select TRVL ADJ. in the FUNC.LIST to obtain the Travel Adjust display. 2. Use the Selector to highlight and select each channel and adjust the travel in each direction by rotating the Selector. The direction of travel is changed by moving the stick/switch/lever back and forth. Elevator-to-Flap Mix menu. Note that two elevator-to-flap mix values are available, Pos0 and Pos1 and the elevator-to-flap values can be independently adjusted up and down. Also the offset (the stick position where the mixing changes from up to down) can be adjusted. This offset allows the programming of snap-flaps, a common sailplane function that gives greater full up elevator pitch authority for tighter turns. If you choose to program snap-flaps, the offset adjustment range is -200 to +200. Negative values move the offset in the up elevator direction. Switches are available at the bottom of the screen that allow the selection of Pos0 or Pos1. Note: Position 1 always has priority over position 0. Press the LIST button to return to the Function Mode screen. Elevator-to-flap mix is normally used to give several degrees of down flap when up elevator is applied. This gives more pitch authority than would elevator alone, and is commonly used for slope racers to improve highspeed turns and in thermal sailplanes to allow increased maneuverability for tight thermal turns. An offset is available that allows the programming of snapflaps. With snap-flaps, no flap mixing occurs during small to medium up elevator inputs, but at about 80% up elevator, the flaps are mixed to give down flaps, causing greater up pitch authority. For more detail on setting up snap-flaps, see step #25 in the glider setup guide following the glider section of this manual. To access Elevator-to-flap mix, in Function Mode list, rotate the Selector until ELEFLP M is highlighted. Press the Selector to access the Elevator-to-Flap mix BTF MOT Sailplane Section 16 Mix (Butterfly) switch Gear (Motor) switch Aileron-to-Flap Mix Aileron-to-flap mix causes the flaps to move in unison with the ailerons. This function gives added roll response by mixing ailerons to flaps such that the entire trailing edge functions as an aileron. To access aileron-to-flap mix, in FUNC.LIST rotate the Selector until AILFLP M is highlighted. Press the Selector to access the Aileron-to-Flap mix. Note: Two aileron-to-flap mix values are available— Pos0 and Pos1. Switches are available at the bottom of the screen that allow the selection of Pos0 or Pos1. Note that position 1 always has priority over position 0. The Aileron to Flap Mix option is only displayed if dual flaps have been enabled in the Wing TYPE setup in the System Menu. Press the LIST button to return to the Function Mode screen. Differential Differential (typically more up aileron travel than down) is utilized to reduce adverse yaw and to improve the turning/ handling characteristics. Aileron and flap differentials can be adjusted for each of the 5 flight modes. To access Differential, in FUNC.LIST rotate the Selector until DIFFEREN. is highlighted. Press the Selector to access the Aileron differential menu. Rotate the Selector to highlight the desired flight mode and aileron or flap value, and then press the Selector to access that value. With the flight mode switch in the corresponding mode, give a full right aileron command and rotate the Selector to achieve the desired aileron or flap differential. Pressing the Selector will store the value. Press the LIST button to return to the Function Mode screen. 17 Sailplane Section Flight Mode Delay Adjust Device Select Pg. 6 and Servo Monitor pg. 29 for more details. The flight mode delay adjust screen allows a delay of up to 2 seconds to be programmed to each of the 5 flight modes. This delay affects the flap, flaperon and elevator (and rudder and aileron if activated) presets such that when switching from one flight mode to another the servos don’t rapidly change to their intended preset position. A break-off function is available for each flight mode that bypasses the delay at a given programmed elevator stick position. This is useful during launch when you my wish to switch from the launch flight mode to cruise for zoom and need the delay to be overridden. In this case, the break-off can be set for slight down elevator in the cruise mode. Note: In order for the flight mode delay adjustment to operate, flight modes must be programmed in device select and each must have different trim presets. See Sailplane Section To access flight mode delay adjust, in FUNC.LIST rotate the Selector until FM Delay is highlighted. Press the Selector to access the flight mode delay adjust menu. Rotate the Selector to highlight the launch delay value, and then press the Selector to access this value. Rotate the Selector to adjust the value. Values from inhibit to 2 seconds are available. To access the breakoff value, rotate the Selector to highlight the desired break-off flight mode then press the Selector to access this value. To access the elevator stick position, rotate the Selector to highlight ELEV Stick then press the Selector to access this value. Press the Selector to store the value. Press the LIST button to return to the Function Mode screen. 18 Flaperon Mix pilots prefer the neutral position to be in the lever up position. (Offset +170) To access flaperon mix, in FUNC.LIST rotate the Selector until Flaprn MX is highlighted. Press the Selector to access the Flaperon Mix menu. Rotate the Selector to highlight the desired value then press the Selector to access this value. With the flight mode switch in the corresponding mode, move the programmed side lever to the appropriate position and adjust the value to the desired position. Press the Selector to store the value. Repeat the process for all flight modes. Press the LIST button to return to the Function Mode screen. Note: The Offset value determines the point at which the side lever changes from the up value to the down value. If the desired lever neutral position is in the middle a 0 value is needed. This will allow up and down FPRN and ELEV values to the programmed. If an up lever position is desired then the offset value of +170 is used. This will allow only the down values to be operational. Important: Flaperon mix values are based on a percentage of the value programmed in Flap Rate (see page 21). If no values are programmed in flap rate (default setting) then flaperon mix values will have no effect. It’s recommended that the flap rate values be programmed first before programming camber or reflex mix values. Also be aware that whenever changing flap rate values, the travel of these camber or reflex mix settings will also be affected. Flaperon mix allows the independent adjustment of flaperon (ailerons up and down) and elevator with the lever that camber mix is assigned to (flap lever on the left or Aux 3 lever on the right) in Device Select (pg. 5) for each of the flight modes. An offset is provided that allows pilots to choose the neutral position for the side lever. Some pilots prefer the lever’s neutral position be in the center position when the trailing edge is at neutral (offset at 0). This offers the advantages of being able to add camber (trailing edge down) or reflex (trailing edge up) in each flight mode using the side lever. Some 19 Sailplane Section Aileron-to-Rudder Mix Aileron-to-rudder mix causes the rudder to move in unison with ailerons. It is utilized to reduce adverse yaw and to improve the turning/ handling characteristics. Aileron-to-rudder mix values can be independently adjusted right and left for each of the 5 flight modes. To access Aileron-to-Rudder mix, in FUNC.LIST rotate the Selector until AILRUD M is highlighted. Press the Selector to access the aileron-to-rudder mix menu. Rotate the Selector to highlight the desired value corresponding to the flight mode and desired direction and then press the Selector to access that value. With the flight mode switch in the corresponding mode, give an aileron command and rotate the Selector to achieve the desired rudder value. Pressing the Selector will store the value. Press the LIST button to return to the Function Mode screen. Butterfly Mix (Landing Flaps) setting is the BTF or butterfly switch. To access the various values, rotate the Selector to highlight them then depress the Selector to access the value. Move the spoiler stick to the full down position and adjust the value by rotating the Selector until the desired position is achieved. Press the Selector to store the value. You may wish to adjust the SPOIELEV, however, there is a curve mix in P-mix 1 that will allow several points on a curve to be adjusted for flap-to-elevator mixing that we will be covering in programmable mix 1. Press the LIST button to return to the Function Mode screen. The Butterfly Mix is the landing program that mixes the flaps, flaperons (ailerons as flaps) and elevator to the spoiler (throttle) stick. Two values are available, Pos0 and Pos1, and each can be assigned to several different switches or flight modes. An offset is provided to allow the user’s preference for the neutral position (normally stick up). Note: The default setting for offset is at +170%. With this setting, the flap’s neutral position (trailing edge level) occurs when the spoiler stick is in the full up position. If you choose to locate the neutral position in the down position, the value would be –170%. Rotate the Selector to highlight SW select and press the Selector to access the available switches. The default Sailplane Section 20 Flap Rate Flap Rate allows the independent up and down adjustment of flaps with the lever that camber mix is assigned to (flap lever on the left or Aux. 3 lever on the right) in Device Select (pg. 5) for each of the flight modes. The lever-offset position is established in Flaperon Mix above, allowing pilots to choose the neutral position for the side lever and this offset is in effect in the flap rate menu (see Flaperon Mix for more details). It’s important to first program these values before proceeding to the Flaperon (camber) mix menu, as the camber mix values are based on a percentage of the flap values. To access Flap Rate in FUNC.LIST rotate the Selector until FLAP RATE is highlighted. Press the Selector to access the Flap Rate menu. Rotate the Selector to highlight the desired value then press the Selector to access this value. With the flight mode switches in the corresponding flight mode, move the left side lever to the appropriate position and adjust the value to the desired flap position. Repeat this for all desired flight modes and flap positions. Press the LIST button to return to the Function Mode screen. Motor Hold program holds the throttle in the desired position (usually motor off). To access Motor Hold in FUNC.LIST rotate the Selector until MOTO. HOLD is highlighted. Press the Selector to access the Motor Hold menu. Rotate the Selector to highlight desired flight mode or switch, and then press the Selector to access on or off. Adjust the motor value to achieve the desired throttle position for that flight mode or switch. Press the LIST button to return to the Function Mode screen. Note: This function is only available when the motor is programmed to the spoiler stick in the device select menu. See Device Select Pg. 6. The Motor Hold feature allows the spoiler stick to be used for multiple functions. In one mode (launch mode, for example) it can be used as a proportional throttle for an electric motor and switching to another mode (landing) the spoiler can be used as landing flaps. The motor hold function is used in conjunction with a programmable mix by mixing motor to an AUX channel. When the motor hold mix is on, the throttle hold 21 Sailplane Section PROG MIX – Programmable Mixers The PCM9X II System provides 2 Multi-Point programmable mixers (PROG.MIX1 & PROG.MIX2) and 4 Standard programmable mixers (PROG.MIX3 PROG.MIX6). Programmable mixers are used whenever the pilot wants a channel to react or move as a result of providing input to another channel, or to simply cause a channel to move by moving a switch or lever. Multi-Point Mixing provides the ability to define a customized “curve” of travel that the Slave channel will follow as it reacts to the Master channel. It is different from Normal Mixing in the sense that Normal Mixing results in a linear movement of the Slave channel in relation to the Master. With Multi-Point Mixing there are 7 points (including end points) along the travel of the Master channel that can be adjusted to control the action of the Slave channel (more or less travel in the same/opposite direction) providing the ability to deviate from a linear mixing action. The channel that receives the original input from the pilot is called the Master channel, while the channel that reacts to the Master is called the Slave channel. Mixing occurs when the pilot provides an input to the Master channel by moving a stick, switch, or lever. The transmitter automatically generates an input for the Slave channel based on the pilot’s input to the Master channel and the parameters defined in the programmable mixer. Mixes are programmable, allowing any of the 9 channels to be Master, Slave or both. Other mixing parameters are also programmable and include the direction of travel of the Slave channel; the amount of travel for the Slave channel; the Offset (where the mix starts and changes direction) and the switches/levers/sticks that are used to turn a mixer on and off. All of these elements are adjustable in Programmable Mixers. Note: Programmable Mix 1 is defaulted to SpoilerElevator mix. This program when used in conjunction with Butterfly allows for pitch compensation during landings. Programmable Mix 1 can be changed to use any master or slave channel if so desired. Multi-Point Programmable Mixer There are 2 Multi-Point Programmable Mixers in the GLID system. They are Prog.Mix1 and Prog.Mix2. They differ from the standard mixers in that they allow a nonlinear mix response from the Master to the Slave. This is possible because the mixer uses 7 points to define how the slave channel moves as the Master is moved. As the Master comes across each point, the Slave response can be defined in terms of deflection and direction independent of other point settings. This results in extreme flexibility in the movement of the Slave channel relative to the Master channel. TO INHIBIT A MIXER (TURN IT OFF ENTIRELY) Highlight either the Master or Slave and press the CLR button to completely disable a mixer. Sailplane Section 22 Master Channel - (Multi-Point Mixer) This is the Master channel that receives input from the pilot. The Master channel is selected by highlighting and selecting this parameter to obtain a list of channels and then selecting the Master channel from the list. There are 4 channels that appear more than once. They are Flap, Aileron, Elevator and Rudder. Since these channels can be influenced by Dual Rate, Exponential, and Throttle Curve settings, they are included in the list twice - once where the D/R and EXP settings are in effect and again where the D/R and EXP settings are ignored. The second time they are listed, there is a special designator to indicate that these channels can also be used as a Master while bypassing any Dual Rate and Exponential settings that may be associated with them. They are designated by a “#” (hash) in front of the name - #FLP, #AIL, #ELE, and #RUD. When one of these channels is selected as the Master, all D/R, EXP and Curve settings associated with the Master are ignored during the mixing operation. Instead, the mixer reads only the physical position of the stick to perform mixing. A (+) behind the channel indicates a trim include function. By selecting a channel with the (+) the trim lever effects both the master and slave channels. BTF Mix (Butterfly) switch MOT Gear (Motor) switch deflection in the other direction. A value of 0 indicates the Slave’s center or neutral position. The overall travel of the slave channel is determined by the Travel settings described earlier in the TRVL ADJ. function. A point value of INH can also be set for points 1, 2, 4, and 5. When set to INH the point takes on a value represented by the intersection of the cursor and the Curve/Line between the 2 adjacent points. For instance, if Point-1 is set to -67, Point-2 is set to INH and Point-3 is set to 0, then Point-2, which is inhibited, takes on a value of -34, which is midway between points 1 and 3. The value for a point can be changed by highlighting and selecting the Point Name to the left of the point value and then dialing-in the desired value. Pressing the CLR button when a point value is highlighted resets the point to original settings. The original settings are: Point-0 -100 Point-1 INH Point-2 INH Point-3 0 Point-4 INH Point-5 INH Point-6 +100 Slave Channel - (Multi-Point Mixer) This is the Slave channel that will move according to the program mix in relation to the Master channel. The Slave channel is selected by highlighting and selecting this parameter to obtain a list of channels and then selecting the Slave channel from the list. The list contains each of the 9 channels in the system. Point Names/Numbers - (Multi-Point Mixer) The points that can be adjusted are listed vertically by name and are also displayed by number along the bottom of the graph. Change the value of a point by highlighting and selecting the point name and dialing-in the desired percentage. Current Point Setting - (Multi-Point Mixer) This list shows the setting for each of the 7 adjustable points (Point-0, 1, 2, 3, 4, 5, 6). The value of each point determines where the point is positioned vertically on the graph, which dictates the Slave servo position. The point values can be set from -100 to +100 with -100 being full deflection in one direction and +100 being full 23 Sailplane Section Master Channel - (Multi-Point Mixer) continued Cursor - (Multi-Point Mixer) Slave Channel Position - (Multi-Point Mixer) The cursor shows the current Master channel position. When the Master channel is deflected fully in one direction, the cursor is to the extreme left over Point-0, when it is at neutral it is in the center over Point-3 and when it is fully deflected in the other direction the cursor is at the extreme right of the graph over Point-6. The cursor moves across the 7 points as the Master is moved from one extreme to the other. Where the cursor intersects the Curve/Line over a given point defines the amount of Slave servo deflection, which is equal to the value assigned to the point. For example, if Point-2 is set to 30% then the servo will deflect 30% from neutral when the Master is advanced so the cursor is over that point. The Slave servo position next to OUT at the bottom left of the display is expressed in values from -100 to +100, with 0 being neutral or center. It represents the servo travel that corresponds to the present Master Channel position. Note: When the mixer is switched OFF, the out value will change to OFF instead of displaying the Slave position. This is how to determine if the mixer is ON or OFF. Master Channel Position - (Multi-Point Mixer) The Curve/Line is the line that results from connecting all of the points together based upon their point values. The Master channel position is shown on the bottom line of the display next to IN and is expressed in values from 0 to 100 with 50 being the center or neutral position. It represents the present Master channel position. Graph - (Multi-Point Mixer) Select Switch - (Multi-Point Mixer) The graph illustrates the mixing curve. The X-Axis (horizontal plane) represents Master channel movement. The Y-Axis (vertical plane) represents the Slave servo movement where the bottom 1/2 of the graph is one direction from neutral and the top portion of the graph is the other direction. There are 2 switches that can be always used to switch between the Pos0 and Pos1 settings (if the upper and lower settings for Pos0 or Pos1 are left at 0% the mixer can be turned on and off with the switch). They are the Butterfly switch and the Motor switch. In addition, if Flight Modes are activated in the Devic.SEL function, then 5 more switch positions may be selected: Cruise, Speed, Thermal, Launch and Land, which correspond to the various flight modes. To select a switch that will switch between the Pos0 and Pos1 values, highlight and select the switch name and it will toggle between pos0 and pos1. Set the desired switch(es) to pos1. Curve/Line - (Multi-Point Mixer) Points That Can Be Adjusted - (MultiPoint Mixer) The points that can be adjusted are listed vertically by name and are also displayed by number along the bottom of the graph. Use the numbers along the bottom of the graph to determine which point(s) need adjustment. Change the value of a point by highlighting and selecting the Point Name and dialing-in the desired percentage. CLR Button - (Multi-Point Mixer) Pressing the CLR button while a modifiable parameter is selected will reset the parameter to its default value. Note: Pressing the CLR button when either the Master or Slave is highlighted inhibits the entire mixer and it is no longer functional. Exponential - (Multi-Point Mixer) This parameter smoothes the Curve/Line between all of the points on the graph to provide a smoother mixing response. The default value is OFF. To turn it on and smooth the mixing curve, highlight and select OFF and it will toggle to ON. LIST Button - (Multi-Point Mixer) Press the LIST button to return to the FUNCTION List, or rotate the rotary selector until LST appears next to LIST and select it to return to the SYSTEM Menu. ENT Button - (Multi-Point Mixer) Pressing the ENT button returns to the Main Display. Sailplane Section 24 Standard Programmable Mixer - (Std. Prog Mixer) The PCM9X II has 4 standard programmable mixers that allow for linear mixing of a Master channel to a Slave channel. The standard mixers are PROG.Mix 3, 4, 5 and 6. The mixer provides for 2 sets of mixing values named Pos0 and Pos1. If one set of values is set to 0% then the mixer can be turned On and Off with a stick, switch or lever. Each set of mixing values is comprised of 2 percentages to accommodate movement of the Master channel in both directions. This is shown in the illustration below where there is an upper and lower percentage for both Pos0 and Pos1. A mixer can be made to always be on by setting Pos0 values only and not selecting any switches to switch between the Pos0 and Pos1 values. BTF MOT Mix (Butterfly) switch Gear (Motor) switch reads only the physical position of the stick to perform mixing. A (+) behind the channel indicates a trim include function. By selecting a channel with the (+) the trim lever effects both the master and slave channels. Master Channel - (Std. Prog Mixer) This is the Master channel that receives input from the pilot. The default for both the Master and the Slave channel is FPRN. The Master channel is selected by highlighting and selecting this parameter to obtain a list of channels and then selecting the Master channel from the list. There are 4 channels that appear more than once. They are Flap, Aileron, Elevator and Rudder. Since these channels can be influenced by Dual Rate and Exponential settings, they are included in the list twice once where the D/R and EXP settings are in effect and again where the D/R and EXP settings are ignored. The second time they are listed, there is a special designator to indicate that these channels can also be used as a Master while bypassing any Dual Rate and Exponential settings that may be associated with them. They are designated by a “#” (hash) in front of the name - #FLP, #AIL, #ELE, and #RUD. When one of these channels is selected as the Master, all D/R, EXP and Curve settings associated with the Master are ignored during the mixing operation. Instead, the mixer Slave Channel - (Std. Prog Mixer) This is the Slave channel that will move according to the program mix in relation to the Master channel. The default for both the Master the Slave channel is FPRN. The Slave channel is selected by highlighting and selecting this parameter to obtain a list of channels and then selecting the Slave channel from the list. The list contains each of the 9 channels in the system. Current Switch Position - (Std. Prog Mixer) Indicates the current switch position of the switch (if any) that controls the mixer. 25 Sailplane Section PROG MIX - Programmable Mixers (continued) the solid bar moves between the top and bottom line. If for example, the switch is set so that Pos0 percentages are in effect and the master channel is moved below the Offset, the solid bar will be on the lower line which means the lower percentage associated with Pos0 is in effect. When the master is moved above the Offset, the solid bar moves to the top line indicating that the upper percentage for Pos0 is in effect. The Direction Indicator works the same way when the Pos1 values are selected, indicating the upper or lower value of Pos1 as the Master is moved in both directions from the Offset. Direction - (Std. Prog Mixer) Each standard programmable mixer has two positions Pos0 and Pos1 and each position has 2 percentages (upper and lower) to accommodate mixing when the Master is moved in both directions. The direction indicator consists of a dotted and solid line next to the switch position on the top line of the display. The solid line indicates whether the upper or lower percentage is in effect for either Pos0 or Pos1, depending on which Position is currently selected. As the Master channel is moved above and below the Offset (where the mix turns on or changes direction), Master channel control in the other direction and set its value. Pos0 Settings - (Std. Prog Mixer) Each standard Programmable mixer can have two sets of mixing values - Pos0 and Pos1. Each set can have 2 percentages which control movement of the slave when the master is moved in both directions. A switch can be selected to switch between the Pos0 and Pos1 percentages. The Pos0 settings determine how far, and in which direction, the slave channel moves when the master is moved above and below the Offset (the Master moving in both directions) when the switch is in a position to select the Pos0 values. To enter Pos0 values, highlight and select Pos0, move the Master channel control (stick, lever or switch) in one direction and set the percentage and then move the Sailplane Section Pos1 Settings - (Std. Prog Mixer) The Pos1 settings are identical to the Pos0 settings and determine how far, and in which direction, the slave channel moves when the master is moved above and below the offset (the Master moving in both directions) when the switch is in a position to select the Pos1 values. To enter Pos1 values, highlight and select Pos1, move the Master channel control (stick, lever or switch) in one direction and set the percentage and then move the Master channel control in the other direction and set its value. 26 PROG MIX - Programmable Mixers (continued) percentages for Pos0 and the upper and lower percentages of Pos1. The amount of mix and actual direction that the slave moves is determined by the Pos0/Pos1 values. The Offset applies to both Pos0 and Pos1 settings. The Offset may be changed by highlighting and selecting Offset and adjusting either a positive (+) or negative (-) value. A positive percentage moves the offset in one direction from center while a negative percentage moves the Offset in the other direction from center. Offset - (Std. Prog Mixer) The Offset parameter defines the position of the Master where the mixer changes directions. The Offset automatically defaults to a channel’s center position or 0 (zero). For example, if the Rudder is the Master, the Offset will automatically default to the center stick position (no rudder input). Since the Offset is at the center, moving the rudder stick to the left of center causes a mix in one direction while moving the rudder stick to the right of center causes a mix in the other direction. Directions correspond to the upper and lower or Slave is highlighted Inhibits the entire mixer and it is no longer functional. Available Switches - (Std. Prog Mixer) There are 3 switches that can be always used to switch between the Pos0 and Pos1 settings (if the upper and lower settings for Pos0 or Pos1 are left at 0% the mixer can be turned on and off with the switch). They include the Butterfly switch, Motor switch and the Rudder D/R switch. In addition, if Flight Modes are activated in the Devic.SEL function, then 5 more switche positions may be selected: Cruise, Speed, Thermal, Launch and Land, which correspond to the various flight modes. To select a switch that will switch between the Pos0 and Pos1 values, highlight and select the switch name and it will toggle between pos0 and pos1. Set the desired switch(es) to pos1. LIST Button - (Std. Prog Mixer) Press the LIST button to return to the FUNCTION List, or rotate the rotary selector until LST appears next to LIST and select it to return to the SYSTEM Menu. ENT Button - (Std. Prog Mixer) Pressing the ENT button returns to the Main Display. TO INHIBIT A MIXER (TURN IT OFF ENTIRELY) Highlight either the Master or Slave and press the CLR button to completely disable a mixer. CLR Button - (Std. Prog Mixer) Pressing the CLR button while a modifiable parameter is selected will reset the parameter to its default value. NOTE: Pressing the CLR button when either the Master 27 Sailplane Section Timer The PCM9X II contains a Timer System that contains three timers. One is an integrated timer that keeps track of total TX-on time for the model and it is displayed on the Main display. The other timers can be configured as Countdown timers or as Stopwatches. These timers also appear on the Main display when active and can be started, stopped and reset from the Main display. 1. To Reset the Integrated Timer, highlight and select the time under INTEG-T and Push [CLR]=0:00 appears on the display. Press the CLR button to the left of the display to reset the integrated timer. 2. To configure a timer as a Countdown timer, highlight and select Timer in the FUNCTION LIST to obtain the Timer display. Highlight and select INH under TIMER1 or TIMER2 and then select DOWN-T. Use the Selector to set the countdown start time. The timers can be programmed to several different buttons or switches. Use the Selector to highlight the desired button or switch to operate the timer. Press the Selector to confirm the selection. 3. If TIM KEY has been selected to operate a timer, TIM will appear on the Main display in the lower left corner. Pressing the button next to TIM on the Main display starts and stops the timer while pressing the button next to CLR resets the timer to the programmed value 4. Pressing the button next to CLR resets the timer to the programmed value. Note that if both timers have been programmed, the CLR button cannot be used to reset the timers. It is necessary to clear them in the Timer menu by scrolling to each timer and pressing the Selector twice. Sailplane Section 28 Servo Monitor Sophisticated internal programming allows preset trim positions for the elevator, flaps and flaperons (and the aileron and rudder). The system can remain active in flight, allowing you to fine trim presets in each flight mode or can be locked in so they cannot be altered in flight. Flight mode presets are automatically selected via the flight mode switch and are adjusted with the digital elevator trim, the digital flap trim and the digital auxiliary trim (flaperon). While the presets are adjusted via the digital trims, their positions are recorded in the servo monitor. To access the servo monitor, in FUNC.LIST rotate the Selector until MONITOR is highlighted. Press the Selector to access the Monitor menu then press the Selector again to access the camber digital preset screen. To adjust the presets, move the flight mode switch to the launch mode (up) position. Adjust the preset positions via the flap trim, auxiliary trim and elevator trims on the transmitter. The values will be displayed in the screen and then will be memorized for that flight mode. If you wish to have these preset values be fixed (not active in flight), once the values are established return to the Trim Step screen in the system mode and reduce the value of the desired channel to 0. The preset values for all flight modes will be stored and no longer accessible with the digital trims. 29 Sailplane Section Sailplane Section 30 31 Sailplane Section Sailplane Section 32

advertisement

Key Features

- - Up to 5 flight modes with individually adjustable parameters

- - Programmable mixes for camber, elevator, rudder, and aileron

- - Active digital flight trims for in-flight adjustments

- - Adjustable trim step and wing type

- - Differential settings for aileron and flaps

- - Flight mode delay adjust and break-off delay

- - Flaperon mix and aileron-to-rudder mix

- - Butterfly mix for landing flaps

- - Flap rate adjustment

- - Programmable spoiler-to-elevator curve mix

Related manuals

Frequently Answers and Questions

How many flight modes can be programmed in the JR PCM9X II?

Can the JR PCM9X II adjust trim settings during flight?

Does the JR PCM9X II provide differential settings for ailerons and flaps?

Is it possible to program a spoiler-to-elevator curve mix using the JR PCM9X II?

Can the JR PCM9X II assign timers to switches or buttons?

advertisement