advertisement

▼

Scroll to page 2

of 81

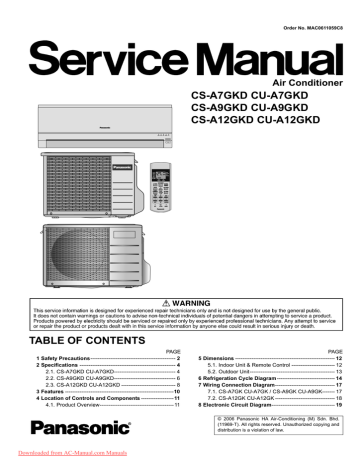

Order No. MAC0611059C8 Air Conditioner CS-A7GKD CU-A7GKD CS-A9GKD CU-A9GKD CS-A12GKD CU-A12GKD TABLE OF CONTENTS PAGE 1 Safety Precautions----------------------------------------------- 2 2 Specifications ----------------------------------------------------- 4 2.1. CS-A7GKD CU-A7GKD---------------------------------- 4 2.2. CS-A9GKD CU-A9GKD---------------------------------- 6 2.3. CS-A12GKD CU-A12GKD ------------------------------ 8 3 Features ------------------------------------------------------------10 4 Location of Controls and Components ------------------11 4.1. Product Overview----------------------------------------- 11 PAGE 5 Dimensions ------------------------------------------------------- 12 5.1. Indoor Unit & Remote Control ------------------------ 12 5.2. Outdoor Unit----------------------------------------------- 13 6 Refrigeration Cycle Diagram -------------------------------- 14 7 Wiring Connection Diagram--------------------------------- 17 7.1. CS-A7GK CU-A7GK / CS-A9GK CU-A9GK------- 17 7.2. CS-A12GK CU-A12GK --------------------------------- 18 8 Electronic Circuit Diagram----------------------------------- 19 © 2006 Panasonic HA Air-Conditioning (M) Sdn. Bhd. (11969-T). All rights reserved. Unauthorized copying and distribution is a violation of law. Downloaded from AC-Manual.com Manuals 11.13. Random Auto Restart Control -----------------------11.14. Remote Control Signal Receiving Sound---------11.15. Patrol Operation-----------------------------------------11.16. e-ion Operation------------------------------------------12 Servicing Mode-------------------------------------------------12.1. Auto OFF/ON Button ----------------------------------12.2. Select Remote Control Transmission Code------12.3. Remote Control Button --------------------------------13 Troubleshooting Guide --------------------------------------13.1. Refrigeration cycle system ---------------------------14 Disassembly and Assembly Instructions -------------14.1. Indoor Electronic Controllers and Control Board Removal Procedures -------------------------14.2. Indoor Fan Motor and Cross Flow Fan Removal Procedures ----------------------------------15 Technical Data --------------------------------------------------15.1. Thermostat Characteristics---------------------------15.2. Operation Characteristics ----------------------------16 Exploded View and Replacement Parts List----------16.1. Indoor Unit------------------------------------------------16.2. Outdoor Unit ---------------------------------------------- 9 Printed Circuit Board ------------------------------------------ 20 9.1. Indoor Unit (Main Printed Circuit Board) ----------- 20 9.2. Indoor Unit (Power Printed Circuit Board) --------- 22 9.3. Indicator ---------------------------------------------------- 23 10 Installation Instruction ---------------------------------------- 24 10.1. Select The Best Location ------------------------------ 24 10.2. Indoor Unit ------------------------------------------------- 25 10.3. Outdoor Unit ----------------------------------------------- 27 11 Operation and Control----------------------------------------- 30 11.1. Heating Operation---------------------------------------- 30 11.2. Cooling Operation---------------------------------------- 31 11.3. Soft Dry Operation --------------------------------------- 32 11.4. Automatic Operation------------------------------------- 33 11.5. Operation Control ---------------------------------------- 34 11.6. Indoor Fan Speed Control ----------------------------- 41 11.7. Outdoor Fan Speed Control --------------------------- 43 11.8. Vertical Airflow Direction Control --------------------- 43 11.9. Horizontal Airflow Direction Control ----------------- 44 11.10. Powerful Operation -------------------------------------- 44 11.11. Quiet Operation------------------------------------------- 46 11.12. Timer Control---------------------------------------------- 48 48 48 49 52 55 55 55 56 57 57 59 59 61 63 63 64 76 76 78 1 Safety Precautions • Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing. • Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. • The caution items stated here must be followed because these important contents are related to safety. The meaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instruction will cause harm or damage, and the seriousness is classified by the following indications. This indication shows the possibility of causing death or serious injury. This indication shows the possibility of causing injury or damage to properties. • The items to be followed are classified by the symbols: This symbol denotes item that is PROHIBITED from doing. • Carry out test running to confirm that no abnormality occurs after the servicing. Then, explain to user the operation, care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for future reference. 1. Engage dealer or specialist for installation and servicing. If installation or servicing done by the user is defective, it will cause water leakage, electrical shock or fire. 2. Install according to this installation instruction strictly. If installation is defective, it will cause water leakage, electrical shock or fire. 3. Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water leakage, fire or electrical shock. 4. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done, the set will drop and cause injury. 5. For electrical work, follow the local national wiring standard, regulation and the installation instruction. An independent circuit and single outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire. 6. Use the specified cable and connect tightly for indoor/outdoor connection. Connect tightly and clamp the cable so that no external force will be acted on the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the connection. 7. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will cause heat-up or fire at the connection point of terminal, fire or electrical shock. 2 Downloaded from AC-Manual.com Manuals 8. When connecting the piping, do not allow air or any substances other than the specified refrigerant to enter the refrigeration cycle. Otherwise, this may lower the capacity, cause abnormally high pressure in the refrigeration cycle, and possibly result in explosion and injury. 9. It is desirable that the amount of residual oil is less than 40 mg/10m. 10. Do not modify the length of the power supply cord or use of the extension cord, and do not share the single outlet with other electrical appliances. Otherwise, it will cause fire or electrical shock. 11. After completion of the installation servicing confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant contacts with fire. 12. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with fire. 1. The equipment must be earthed. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the furniture. 4. Pb free solder has a higher melting point than standard solder; typically the melting point is 50 - 70°F (30 - 40°C) higher. Please use a high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C). Pb free solder will tend to splash when heated too high (about 1100°F / 600°C). 5. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare may break and cause refrigerant gas leakage. 6. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury. ATTENTION 1. Selection of the installation location. Select an installation location which is rigid and strong enough to support or hold the unit, and select a location for easy maintenance. 2. Power supply connection to the conditioner. Connect the power supply cord of the air conditioner to the mains using one of the following methods. Power supply point shall be the place where there is ease for ease for access for the power disconnection in case of emergency. In some countries, permanent connection of this room air conditioner to the power supply is prohibited. 1. Power supply connection to the receptacle using a power plug. Use an approved power plug with earth pin for the connection to the socket. 2. Power supply connection to a circuit breaker for the permanent connection. Use an approved circuit breaker for the permanent connection. It must be a double pole switch with a minimum 3.5 mm contact gap. 3. Do not release refrigerant during piping work for installation, servicing, reinstallation and during repairing a refrigeration parts. Take care of the liquid refrigerant, it may cause frostbite. 4. Installation work. It may need two people to carry out the installation work. 5. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc. Downloaded from AC-Manual.com Manuals 3 2 Specifications 2.1. CS-A7GKD CU-A7GKD Item Performance Test Condition C Capacity O O L EER I N Noise Level G H Capacity E A T Cop I N Noise Level G Moisture Removal Air Volume kW BTU/h kcal/h W/W BTU/hW dB (A) Power level dB kW BTU/h kcal/h W/W BTU/hW dB (A) Power level dB l/h (pt/h) Heat Exchanger Air Filter Type High: 46 - 47 High: 61 - 62 2.10 - 2.10 7160 - 7160 1810 - 1810 4.20 - 4.00 14.3 - 13.6 High: 36 Low: 28 High: 49 High: 48 - 49 High: 64 - 65 1.3 2.7 cm3 — — Capillary Tube ATMOS M60 or m3/m (ft3/m) Hi m3/m (ft3/m) SHi kg (oz) mm (inch) mm (inch) mm (inch) kg (lbs) mm (inch) mm (inch) m (ft) m (ft) g/m (oz/ft) m (ft) mm mm W W W rpm rpm rpm rpm mm (inch) 4 Downloaded from AC-Manual.com Manuals High: 33 Low: 26 High: 46 m3/m (ft3/m) Me Motor Type Rated Output Type Material Motor Type Input power Output power Fan Speed Lo (Cool / Heat) Me (Cool / Heat) Hi (Cool / Heat) SHi (Cool / Heat) Fin material Fin Type Row × Stage × FPI Size (W × H × L) Material Style Outdoor unit JIS 2.00 - 2.00 6820 - 6820 1720 - 1720 3.28 - 3.17 11.2 - 10.8 Cooling; 29.5 (1040) - 30.0 (1060) — m3/m (ft3/m) Refrigerant (Charged) R22 Dimension Height Width Depth Net Weight Pipe Diameter Gas Liquid Height Difference Pipe Length Range Additional Gas Amount Refrigeration Charge Less Drain Hose Inner diameter Length Compressor Type Indoor unit Cooling; 5.9 (210) Heating; 6.4 (230) Cooling; 7.0 (250) Heating; 7.0 (250) Cooling; 7.8 (280) Heating; 9.0 (320) Cooling; 9.0 (320) Lo Refrigerant Control Device Refrigerant Oil (Charged) Fan Unit — — SUNISO 4GDID (290cm3) — 0.71 (25.0) 280 (11 - 1/32) 510 (20 - 3/32) 799 (31 - 15/32) 650 (25 - 19/32) 183 (7 - 7/32) 230 (9 - 1/16) 9 (20) 24 (53) 9.52 (3/8”) 6.35 (1/4”) 5 (16.4) 3 (9.8) ~ 10 (32.8) 20 (0.2) 7.5 (24.6) 16 — 650 — — Rotary (1 cylinder) rolling piston type — Induction (2-poles) — 550 Cross-flow Fan Propeller Fan ASG20K1 PP Resin Induction (4-poles) Induction (6-poles) 42 - 47 58 - 65 15 30 780 / 840 — 920 / 920 — 1030 / 1190 800 - 830 / — 1190 / — — Aluminium (Pre Coat) Aluminium (Blue Coat) Slit Fin Louver Fin 2 × 15 × 19 1 × 19 × 17 610 × 315 × 25.4 22 × 483 × 576 Polypropelene — One-touch — 1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.) 2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F D.B.), 6°C W.B. (42.8°F W.B.) Item Power Source (Phase, Voltage, Cycle) Unit ø V Hz Input power Cooling W Heating W Starting Current A Running Current Cooling A Heating A Power Factor Cooling % Heating % Power factor means total figure of compressor, indoor fan motor and outdoor fan motor. Power Cord Number of core Length m (ft) Thermostat Protection Device Single 220 50 610 500 12.4 2.9 2.4 96 95 Single 230 50 630 525 12.4 2.8 2.4 98 95 3 (1.5mm) 2 (6) — — — 2 Stage Overload Protector Note: • Specification are subjected to change without prior notice for further improvement. 5 Downloaded from AC-Manual.com Manuals 2.2. CS-A9GKD CU-A9GKD Item Performance Test Condition C Capacity O O L EER I N Noise Level G H Capacity E A T Cop I N Noise Level G Moisture Removal Air Volume kW BTU/h kcal/h W/W BTU/hW dB (A) Power level dB kW BTU/h kcal/h W/W BTU/hW dB (A) Power level dB l/h (pt/h) Heat Exchanger Air Filter Type High: 36 Low: 26 High: 49 High: 48 - 49 High: 63 - 64 2.80 - 2.85 9550 - 9720 2410 - 2450 4.00 - 3.85 13.6 - 13.1 High: 38 Low: 28 High: 51 High: 48 - 49 High: 64 - 65 1.6 3.4 m3/m (ft3/m) cm3 — — Capillary Tube ATMOS M60 or Me m3/m (ft3/m) Hi m3/m (ft3/m) SHi Motor Type Rated Output Type Material Motor Type Input power Output power Fan Speed Lo (Cool / Heat) Me (Cool / Heat) Hi (Cool / Heat) SHi (Cool / Heat) Fin material Fin Type Row × Stage × FPI Size (W × H × L) Material Style Outdoor unit JIS 2.65 - 2.65 9040 - 9040 2280 - 2280 3.19 - 3.08 10.9 - 10.5 Cooling; 29.5 (1040) - 30.0 (1060) — m3/m (ft3/m) Refrigerant (Charged) R22 Dimension Height Width Depth Net Weight Pipe Diameter Gas Liquid Height Difference Pipe Length Range Additional Gas Amount Refrigeration Charge Less Drain Hose Inner diameter Length Compressor Type Indoor unit Cooling; 6.4 (230) Heating; 6.9 (240) Cooling; 7.8 (270) Heating; 7.8 (270) Cooling; 9.4 (330) Heating; 9.8 (350) Cooling; 10.1 (360) Lo Refrigerant Control Device Refrigerant Oil (Charged) Fan Unit kg (oz) mm (inch) mm (inch) mm (inch) kg (lbs) mm (inch) mm (inch) m (ft) m (ft) g/m (oz/ft) m (ft) mm mm W W W rpm rpm rpm rpm mm (inch) — — SUNISO 4GDID (350cm3) 0.67 (23.7) 510 (20 - 3/32) 650 (25 - 19/32) 230 (9 - 1/16) 27 (60) 9.52 (3/8”) 6.35 (1/4”) 5 (16.4) 3 (9.8) ~ 10 (32.8) 20 (0.2) 7.5 (24.6) 16 — 650 — — Rotary (1 cylinder) rolling piston type — Induction (2-poles) — 750 Cross-flow Fan Propeller Fan ASG20K1 PP Resin Induction (4-poles) Induction (6-poles) 42 - 47 58 - 65 15 30 830 / 890 — 1000 / 1000 — 1210 / 1300 800 - 830 / — 1300 / — — Aluminium (Pre Coat) Aluminium (Blue Coat) Slit Fin Louver Fin 2 × 15 × 19 1 × 19 × 17 610 × 315 × 25.4 22 × 483 × 576 Polypropelene — One-touch — — 280 (11 - 1/32) 799 (31 - 15/32) 183 (7 - 7/32) 9 (20) 1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.) 2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F D.B.), 6°C W.B. (42.8°F W.B.) 6 Downloaded from AC-Manual.com Manuals Item Power Source (Phase, Voltage, Cycle) Unit ø V Hz Input power Cooling W Heating W Starting Current A Running Current Cooling A Heating A Power Factor Cooling % Heating % Power factor means total figure of compressor, indoor fan motor and outdoor fan motor. Power Cord Number of core Length m (ft) Thermostat Protection Device Single 220 50 830 700 18 3.9 3.3 97 96 Single 230 50 860 740 18 3.9 3.3 96 97 3 (1.5mm) 2 (6) — — — 2 Stage Overload Protector Note: • Specification are subjected to change without prior notice for further improvement. 7 Downloaded from AC-Manual.com Manuals 2.3. CS-A12GKD CU-A12GKD Item Performance Test Condition C Capacity O O L EER I N Noise Level G H Capacity E A T Cop I N Noise Level G Moisture Removal Air Volume kW BTU/h kcal/h W/W BTU/hW dB (A) Power level dB kW BTU/h kcal/h W/W BTU/hW dB (A) Power level dB l/h (pt/h) Heat Exchanger Air Filter Type High: 39 Low: 29 High: 52 High: 48 - 49 High: 63 - 64 4.00 - 4.05 13640 - 13810 3440 - 3480 3.67 - 3.62 12.5 - 12.3 High: 40 Low: 29 High: 53 High: 48 - 49 High: 64 - 65 2.0 4.2 m3/m (ft3/m) cm3 — — Capillary Tube ATMOS M60 or Me m3/m (ft3/m) Hi m3/m (ft3/m) SHi Motor Type Rated Output Type Material Motor Type Input power Output power Fan Speed Lo (Cool / Heat) Me (Cool / Heat) Hi (Cool / Heat) SHi (Cool / Heat) Fin material Fin Type Row × Stage × FPI Size (W × H × L) Material Style Outdoor unit JIS 3.52 - 3.54 12000 - 12100 3030 - 3040 3.26 - 3.16 11.1 - 10.8 Cooling; 32.5 (1150) - 33.0 (1160) — m3/m (ft3/m) Refrigerant (Charged) R22 Dimension Height Width Depth Net Weight Pipe Diameter Gas Liquid Height Difference Pipe Length Range Additional Gas Amount Refrigeration Charge Less Drain Hose Inner diameter Length Compressor Type Indoor unit Cooling; 6.1 (220) Heating; 6.5 (230) Cooling; 8.5 (300) Heating; 8.5 (300) Cooling; 9.9 (350) Heating; 10.0 (350) Cooling; 10.1 (360) Lo Refrigerant Control Device Refrigerant Oil (Charged) Fan Unit kg (oz) mm (inch) mm (inch) mm (inch) kg (lbs) mm (inch) mm (inch) m (ft) m (ft) g/m (oz/ft) m (ft) mm mm W W W rpm rpm rpm rpm mm (inch) — — SUNISO 4GDID (410cm3) 1.05 (37.1) 540 (21 - 1/4) 780 (30 - 23/32) 289 (11 - 3/8) 37 (82) 12.70 (1/2”) 6.35 (1/4”) 5 (16.4) 3 (9.8) ~ 15 (49.2) 20 (0.2) 7.5 (24.6) 16 — 650 — — Rotary (1 cylinder) rolling piston type — Induction (2-poles) — 950 Cross-flow Fan Propeller Fan ASG20K1 PP Resin Induction (4-poles) Induction (6-poles) 42 - 47 72 - 80 15 31 800 / 860 — 1120 / 1120 — 1300 / 1320 845 - 860 / — 1320 / — — Aluminium (Pre Coat) Aluminium Slit Fin Louver Fin 2 × 15 × 21 2 × 24 × 16 610 × 315 × 25.4 36.38 × 504 × 713:684 Polypropelene — One-touch — — 280 (11 - 1/32) 799 (31 - 15/32) 183 (7 - 7/32) 9 (20) 1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.) 2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F D.B.), 6°C W.B. (42.8°F W.B.) 8 Downloaded from AC-Manual.com Manuals Item Power Source (Phase, Voltage, Cycle) Unit ø V Hz Input power Cooling kW Heating kW Starting Current A Running Current Cooling A Heating A Power Factor Cooling % Heating % Power factor means total figure of compressor, indoor fan motor and outdoor fan motor. Power Cord Number of core Length m (ft) Thermostat Protection Device Single 220 50 1.08 1.09 27 5.1 5.2 96 95 Single 230 50 1.12 1.12 27 5.1 5.1 95 95 3 (1.5mm) 2 (6) — — — Inner Protector Note: • Specification are subjected to change without prior notice for further improvement. 9 Downloaded from AC-Manual.com Manuals 3 Features • High Efficiency • Compact Design • Wider range of horizontal discharge air • Air Filter with function to reduce dust and smoke • Automatic air swing and manual adjusted by Remote Control for vertical airflow • Long Installation Piping - CS/CU-A7GK, CS/CU-A9GK, long piping up to 10 meter - CS/CU-A12GK, long piping up to 15 meter • e-ion Air Purifying System with Patrol Sensor - Discharged Active e-ions capture dust particles and bring it back with a boomerang-like mechanism • Quality Improvement - Random auto restart after power failure for safety restart operation - Gas leakage protection - Prevent compressor reverse cycle - Inner protector to protect Compressor - Noise prevention during soft dry operation - Blue Coated Condenser for high resistance to corrosion • Operation Improvement - Quiet mode to provide quiet operation - Powerful mode to reach the desired room temperature quickly - 24-hour timer setting • Serviceability Improvement - Removable and washable front panel 10 Downloaded from AC-Manual.com Manuals 4 Location of Controls and Components 4.1. Product Overview 4.1.1. Indoor Unit 4.1.2. Outdoor Unit 4.1.3. Remote Control 11 Downloaded from AC-Manual.com Manuals 5 Dimensions 5.1. 5.1.1. Indoor Unit & Remote Control CS-A7GK CS-A9GK CS-A12GK 12 Downloaded from AC-Manual.com Manuals 5.2. Outdoor Unit 5.2.1. CU-A7GK CU-A9GK 5.2.2. CU-A12GK 13 Downloaded from AC-Manual.com Manuals 6 Refrigeration Cycle Diagram 14 Downloaded from AC-Manual.com Manuals 7 Block Diagram 7.1. CS-A7GK CU-A7GK / CS-A9GK CU-A9GK 15 Downloaded from AC-Manual.com Manuals 7.2. CS-A12GK CU-A12GK 16 Downloaded from AC-Manual.com Manuals 8 Wiring Connection Diagram 8.1. CS-A7GK CU-A7GK / CS-A9GK CU-A9GK Resistance of Compressor Windings Resistance of Indoor Fan Motor Windings MODEL CONNECTION BLUE-YELLOW YELLOW-RED CS-A7GK CS-A9GK CWA921373 390.0 Ω 394.0 Ω MODEL CONNECTION C-R C-S CU-A7GK 2RS122D5BC02 5.193 Ω 5.557 Ω CU-A9GK 2PS156D3BB02 3.501 Ω 3.405 Ω Note: Resistance at 20°C of ambient temperature. Note: Resistance at 25°C of ambient temperature. Resistance of Outdoor Fan Motor Windings MODEL CONNECTION BLUE-YELLOW YELLOW-RED CU-A7GK CU-A9GK CWA951387J 287 Ω 238 Ω Note: Resistance at 25°C of ambient temperature. 17 Downloaded from AC-Manual.com Manuals 8.2. CS-A12GK CU-A12GK Resistance of Compressor Windings Resistance of Indoor Fan Motor Windings MODEL CONNECTION BLUE-YELLOW YELLOW-RED CS-A12GK CWA921373 390.0 Ω 394.0 Ω MODEL CONNECTION C-R C-S Note: Resistance at 20°C of ambient temperature. Note: Resistance at 25°C of ambient temperature. Resistance of Outdoor Fan Motor Windings MODEL CONNECTION BLUE-YELLOW YELLOW-RED CU-A12GK CWA951117J 230 Ω 255 Ω Note: Resistance at 25°C of ambient temperature. 18 Downloaded from AC-Manual.com Manuals CU-A12GK 2KS206D5AF04 2.234 Ω 2.630 Ω 9 Electronic Circuit Diagram 19 Downloaded from AC-Manual.com Manuals 10 Printed Circuit Board 10.1. Indoor Unit (Main Printed Circuit Board) TOP VIEW 20 Downloaded from AC-Manual.com Manuals BOTTOM VIEW 21 Downloaded from AC-Manual.com Manuals 10.2. Indoor Unit (Power Printed Circuit Board) TOP VIEW BOTTOM VIEW 22 Downloaded from AC-Manual.com Manuals 10.3. Indicator TOP VIEW BOTTOM VIEW 23 Downloaded from AC-Manual.com Manuals 11 Installation Instruction 11.1. Select The Best Location Indoor Unit Indoor/Outdoor Unit Installation Diagram • There should not be any heat source or steam near the unit. • There should not be any obstacles blocking the air circulation. • A place where air circulation in the room is good. • A place where drainage can be easily done. • A place where noise prevention is taken into consideration. • Do not install the unit near the door way. • Ensure the spaces indicated by arrows from the wall, ceiling, fence or other obstacles. • Recommended installation height for indoor unit shall be at least 2.5 m. Outdoor Unit • If an awning is built over the unit to prevent direct sunlight or rain, be careful that heat radiation from the condenser is not obstructed. • There should not be any animal or plant which could be affected by hot air discharged. • Keep the spaces indicated by arrows from wall, ceiling, fence or other obstacles. • Do not place any obstacles which may cause a short circuit of the discharged air. • If piping length is over the rated length, additional refrigerant should be added as shown in the table. Model C7GK/ C9GK A7GK/ A9GK C12GK A12GK Piping size Gas Liquid Additional Max. Max Rated Length Elevation Piping Refrigerant (g/m) Length (m) (m) (m) 7.5 5 10 10 3/8” 1/4” 3/8” 1/4” 7.5 5 10 20 1/2” 1/2” 1/4” 1/4” 7.5 7.5 5 5 15 15 10 20 • This illustration is for explanation purposes only. The indoor unit will actually face a different way. 24 Downloaded from AC-Manual.com Manuals 11.2. Indoor Unit 11.2.1. 11.2.2. How To Fix Installation Plate To Drill A Hole In The Wall And Install A Sleeve Of Piping 1. Insert the piping sleeve to the hole. 2. Fix the bushing to the sleeve. 3. Cut the sleeve until it extrudes about 15 mm from the wall. The mounting wall is strong and solid enough to prevent it from the vibration. Caution When the wall is hollow, please be sure to use the sleeve for tube ass’y to prevent dangers caused by mice biting the connecting cable. 4. Finish by sealing the sleeve with putty or caulking compound at the final stage. The centre of installation plate should be at more than 450 mm at right and left of the wall. The distance from installation plate edge to ceiling should more than 67 mm. From installation plate left edge to unit's left side is 74 mm. From installation plate right edge to unit's right is 94 mm. : For left side piping, piping connection for liquid should be about 15 mm from this line. : For left side piping, piping connection for gas should be about 45 mm from this line. : For left side piping, piping connection cable should be about 800 mm from this line. 11.2.3. Indoor Unit Installation For the right rear piping 1. Mount the installation plate on the wall with 5 screws or more. (If mounting the unit on the concrete wall, consider using anchor bolts.) • Always mount the installation plate horizontally by aligning the marking-off line with the thread and using a level gauge. 2. Drill the piping plate hole with ø70 mm hole-core drill. • Line according to the left and right side edge of the installation plate. The meeting point of the extended line is the centre of the hole. Another method is by putting measuring tape at position as shown in the diagram above. The hole centre is obtained by measuring the distance namely 150 mm and 125 mm for left and right hole respectively. • Drill the piping hole at either the right or the left and the For the right and right bottom piping hole should be slightly slanted to the outdoor side. 25 Downloaded from AC-Manual.com Manuals For the embedded piping Insert the connecting cable Install the Indoor unit Secure the Indoor Unit Pull out the piping and drain hose How to keep the cover (This can be used for left rear piping & left bottom piping also.) 26 Downloaded from AC-Manual.com Manuals • Secure the cable onto the control board with the holder (clamper). • How to pull the piping and drain hose out, in case of the embedded piping. • In case of left piping how to insert the connecting cable and drain hose. 11.3. Outdoor Unit 11.3.1. Install The Outdoor Unit • After selecting the best location, start installation according to Indoor/Outdoor Unit Installation Diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2. When installing at roof, please consider strong wind and earthquake. Please fasten the installation stand firmly with bolt or nails. 11.2.4. Connect The Cable To The Indoor Unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 (C7GK, C9GK, C12GK) or 5 (A7GK, A9GK, A12GK) × 1.5mm2 flexible cord, type designation 245 IEC 57 or heavier cord. • Ensure the colour of wires of outdoor unit and the terminal Nos. are the same to the indoor’s respectively. • Earth lead wire shall be longer than the other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage. Model C7GK, C9GK, A7GK, A9GK A12GK, C12GK 11.3.2. A 474 B 87 C 18.5 D 261 570 105 18.5 320 Connecting The Piping Connecting The Piping To Indoor Unit Please make flare after inserting flare nut (locate at joint portion of tube assembly) onto the copper pipe. (In case of using long piping) Connect the piping • Align the center of piping and sufficiently tighten the flare nut with fingers. • Further tighten the flare nut with torque wrench in specified torque as stated in the table. 27 Downloaded from AC-Manual.com Manuals CUTTING AND FLARING THE PIPING 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut onto the copper pipes. Model C7GK, C9GK, A7GK, A9GK C12GK, A12GK Piping size (Torque) Gas Liquid 3/8” [42 N•m] 1/4” [18 N•m] 1/2” [55 N•m] 1/4” [18 N•m] Connecting The Piping To Outdoor Unit Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the flare nut (locate at valve) onto the copper pipe. Align center of piping to valves and then tighten with torque wrench to the specified torque as stated in the table. 11.3.3. Evacuation Of The Equipment WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND PIPES in the following procedure. 1. Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way valve. • Be sure to connect the end of the charging hose with the push pin to the service port. 2. Connect the center hose of the charging set to a vacuum pump. 3. Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from 0 cmHg (0 MPa) to 76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes. 4. Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the gauge does not move after approximately five minutes. Note: BE SURE TO FOLLOW THIS PROCEDURE IN ORDER TO AVOID REFRIGERANT GAS LEAKAGE. 5. Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve. 6. Tighten the service port caps of the 3-way valve at torque of 18 N.m with a torque wrench. 7. Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “OPEN” using a hexagonal wrench (4 mm). 8. Mount valve caps onto the 2-way valve and the 3-way valve. • Be sure to check for gas leakage. 28 Downloaded from AC-Manual.com Manuals CAUTION • • • • If gauge needle does not move from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa), in step 3 above take the following measure: If the leak stops when the piping connections are tightened further, continue working from step 3. If the leak does not stop when the connections are retightened, repair the location of leak. Do not release refrigerant during piping work for installation and reinstallation. Take care of the liquid refrigerant, it may cause frostbite. 11.3.4. Connect The Cable To The Outdoor Unit 1. Remove the control board cover from the unit by loosening the screw. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 (C7GK, C9GK, C12GK) or 5 (A7GK, A9GK, A12GK) × 1.5 mm2 flexible cord, type designation 245 IEC 57 or heavier cord. 3. Secure the cable onto the control board with the holder (clamper). 4. Attach the control board cover back to the original position with the screw. 11.3.5. Pipe Insulation 1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation Diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by using POLY-E FOAM with thickness 6mm or above. 29 Downloaded from AC-Manual.com Manuals 12 Operation and Control 12.1. Heating Operation • Heating operation can be set using remote control. • This operation is applied to warm the room temperature reaches the setting temperature set on the remote control. • The remote control setting temperature, which takes the reading of intake air temperature sensor, can be adjusted from 16°C to 30°C. • During heating operation, the compressor will stop running and restart as shown in below figure. 12.1.1. Heating Operation Time Diagram 30 Downloaded from AC-Manual.com Manuals 12.2. Cooling Operation • Cooling operation can be set using remote control. • This operation is applied to cool down the room temperature reaches the setting temperature set on the remote control. • The remote control setting temperature, which takes the reading of intake air temperature sensor, can be adjusted from 16°C to 30°C. • During cooling operation, the compressor will stop running and restart as shown in below figure. 12.2.1. Cooling Operation Time Diagram 31 Downloaded from AC-Manual.com Manuals 12.3. Soft Dry Operation • • • • Soft Dry operation can be set using remote control. Soft Dry operation is applied to dehumidify and to perform a gentle cooling to the room. This operation starts when the intake air temperature sensor reaches the setting temperature on the remote control. When operation begins, Soft Dry will be switched “ON” for a maximum 10 minutes, then Soft Dry operation will be turned “OFF” for a minimum 6 minutes. After that, the Soft Dry operation will be “ON” and “OFF” based on the setting temperature as shown in below figure. • However after 3 minutes of compressor off, during Soft Dry “OFF” (within 6 minutes Soft Dry restart control), the indoor unit will start to operate at normal Cooling mode if the intake temperature is higher than Cooling “ON” point. 12.3.1. Soft Dry Operation Time Diagram 32 Downloaded from AC-Manual.com Manuals 12.4. Automatic Operation • Automatic operation can be set using remote control. • This operation starts to operate with indoor fan at SLo speed for 25 seconds to judge the intake air temperature. • After judged the temperature, the operation mode is determined by referring to the below standard. • Then, the unit start to operate at determined operation mode, until it is switched off using remote control, with the setting temperature as shown in below table. • Operation mode will be determine again for judgement after 1 hour of operation, if the room temperature reaches to set temperature and compressor off time is over 7 minutes 30 seconds continuously. The present operation mode will be continued, if the room temperature does not reach to set temperature (Compressor keeps running) eventhough after 1 hour from automatic operation mode started. Automatic Set Temperature Refer as below. 33 Downloaded from AC-Manual.com Manuals • Automatic Set Temperature For each operation, set temperature will automatically set as shown below. However it can be selected 2°C higher or 2°C lower from standard set temperature by pressing the “Room Temperature Setting button”. • The setting temperature for all the operations can be changed one level up or one level down from the standard temperature as shown in below table by pressing on the temperature up or temperature down button at remote control. • The operation mode judging temperature and standard setting temperature can be increased by 2°C permanently, by open the circuit of JX1 at indoor electronic controller. 12.5. Operation Control 12.5.1. Restart Control (Time Delay Safety Control) • When the thermo-off temperature (temperature which compressor stops to operate) is reached during:- Cooling/Heating operation - the compressor stops for 3 minutes (minimum) before resume operation. - Soft Dry operation - the compressor stops for 6 minutes (minimum) before resume operation. • If the operation is stopped by the remote control, the compressor will not turn on within 3 minutes from the moment operation stop, although the unit is turn on again within the period. • This phenomenon is to balance the pressure inside the refrigerant cycle. 12.5.2. Compressor Reverse Rotation Protection Control • If the compressor is operating continuously for 5 minutes or longer and the temperature difference between intake air and indoor heat exchanger is 2.5°C (cooling mode)/5°C (heating mode) or less for continuous 2 minutes, compressor will stop and restart automatically. • Time Delay Safety Control is activated before the compressor restart. T = Intake air temperature - Indoor heat exchanger temperature • This is to prevent compressor from rotate reversely when there is an instantaneous power failure. 34 Downloaded from AC-Manual.com Manuals 12.5.3. 7 Minutes Time Save Control • The compressor will start automatically if it has stopped for 7 minutes and the intake air temperature falls between the compressor ON temperature (A) and compressor OFF temperature (B) during the period. • This phenomenon is to reduce the built up humidity inside a room. 12.5.4. 60 Seconds Forced Operation • Once the air conditioner is turned on, the compressor will not stop within 60 seconds in a normal operation although the intake air temperature has reached the thermo-off temperature. However, force stop by pressing the OFF/ON operation button at the remote control is permitted. • The reason for the compressor to force operate at minimum 60 seconds is to allow the refrigerant oil run in a full cycle and return back to the outdoor unit. 12.5.5. Starting current Control • When the compressor, outdoor fan motor and indoor fan motor are simultaneously started, the indoor fan motor will start to operate at 1.6 second later. • The reason of the difference is to reduce the starting current flow. 12.5.6. Freeze Preventive Control • To protect indoor heat exchanger from freezing and to prevent higher volume of refrigerant in liquid form return to compressor. • This control will activate when the temperature of indoor heat exchanger falls below 2°C continuously for more than 4 minutes. • The current fan speed will change to freeze prevention speed after 70 seconds compressor on. When indoor pipe temperature reaches certain temperature for 5 sec. the speed will be increased as in below figure. • Compressor will turn off when indoor temperature falls below 2°C for more than 4 minutes. It will restart again when indoor heat exchanger temperature rises to 10°C. • Restart control (Time Delay Safety Control) will be applied in this control. 35 Downloaded from AC-Manual.com Manuals 12.5.7. Dew Prevention control • To prevent dew formation at indoor unit discharge area. • This control will be activated if:- Cooling mode or Quiet mode. - Remote Control setting temperature is less than 25°C. - Fan speed is at CLo or QLo. - Room temperature is constant (±1°C) for 30 minutes. - Compressor is continuously running. • Fan speed and angle of horizontal louver (vertical airflow angle) will be adjusted accordingly in this control. - Fan speed will be increased slowly if the unit is in quiet mode but no change in normal cooling mode. - The angle of horizontal louver will be changed as below figure. Operation mode Cooling, Soft Dry A B Airflow direction auto-control 12° ~ 32° 20° ~ 30° Airflow direction manual control 12°, 15°, 20°, 26°, 32° 22°, 24°, 26°, 28°, 30° Note: A = Normal operation angle of rotation B = Dew prevention angle of rotation Horizontal Louver Angle During Anti-Dew condensation prevention, the horizontal louver angle in Auto-control are as below figure. During Anti-Dew condensation prevention, the horizontal louver angle in Manual control are as below figure. 36 Downloaded from AC-Manual.com Manuals 12.5.8. 30 Minutes Time Save Control • The compressor will start automatically if it has stopped for 30 minutes and the intake air temperature falls between the compressor OFF temperature (A) and compressor ON temperature (B) during the period. • This is to maintain the room temperature as set. Despite of this, it is to prevent a wrong judgement of intake air temperature due to poor installation near the sensor area. 12.5.9. Compressor Overload Protection Control Outdoor Fan Control • If the temperature of the indoor heat exchanger rises to 51°C, outdoor fan stops. The outdoor fan restarts when the indoor heat exchanger temperature falls to 49°C. Compressor high pressure protection • If the indoor heat exchanger becomes 65°C or more, the compressor will stop and restart automatically. (Time Delay Safety Control - 4 minutes waiting). • This is to reduce the pressure, as to reduce the indoor heat exchanger temp. Nevertheless, is to protect the compressor from overload of too high temperature. 12.5.10. 4-Way Valve Control • 4-way valve always on during Heating operation. (except deicing operation) • When the unit is switched off by remote control during Heating operation, the 4-way valve stay at Heating position for 5 minutes. • This is to prevent the refrigerant flow process sound for being occur. 12.5.11. Outdoor Fan Motor Control • When compressor stops (reaches room temperature), outdoor fan will operate for 30 seconds (forced operation). • This is to release the heat and to obtain the lowest pressure as fast as possible. 12.5.12. Hot Start Control • Hot Start Control is to prevent cool air discharge into the room when heating operation start. • When Heating operation starts, Indoor fan will not start until the indoor heat exchanger reaches 30°C as diagram shown. • Hot start is completed when indoor heat exchanger rises to 39°C or operation over 4 minutes. 37 Downloaded from AC-Manual.com Manuals 12.5.13. Anti Cold Draft Control • This operation is to prevent the Cold Draft during Heating mode operation. • The operation will start when compressor OFF (Thermo OFF) during Heating operation. • For the first 30 sec. from compressor OFF (Thermo OFF), Indoor fan speed will operate accordingly to the Indoor heat exchanger temperature as shown below: • After 30 sec. from compressor OFF (thermo OFF), Indoor fan will run at SSLo speed only. • Anti Cold Draft Control will stop when: - Intake temperature < set temperature. (Time Delay Safety Control 4 minutes waiting is valid) - 30 Minutes Time Save Control activates. 38 Downloaded from AC-Manual.com Manuals 12.5.14. Deicing Control Deice starts to prevent frosting at outdoor heat exchanger. • Normal Deicing Deice operations detection commences after 30 minutes of Heating operation starts or 60 minutes after previous deice operation. If the TRS (Thermal Reed Switch) senses the outdoor piping temperature drops to -3°C (TRS CLOSE) or less for 50 sec. continuously during compressor is in operation, deice will start. (There is no detection during Outdoor Fan stops.) • Overload Deicing During heating operation, if the outdoor Fan OFF duration (due to overload control) is accumulated up to 60 minutes and after compressor starts for 1 minutes, deicing starts. • Deicing ends when 1. 12 minutes after deicing operation starts; 2. TRS senses the outdoor piping temperature rises to 4°C (TRS OPEN). Deicing will not end immediately as time delay (Td) is valid as shown below: • Once deicing operation starts, it will not end for 60 seconds. • After deicing operation, compressor stops for 30 seconds and 4-way valve stays at cooling position for 10 seconds. 39 Downloaded from AC-Manual.com Manuals Normal Deicing Time Diagram Overload Deicing Time Diagram 40 Downloaded from AC-Manual.com Manuals 12.6. Indoor Fan Speed Control • Indoor Fan Speed can be set using remote control. 12.6.1. Fan Speed Rotation Chart Fan Speed (rpm) S Hi Hi Me H Lo C Lo LoS Lo SS Lo Q S Hi Q Hi Q Me Q H Lo Q Lo CS-A7GKD 1190 1030 920 840 780 750 700 300 1090 930 820 770 680 CS-A9GKD 1300 1210 1000 890 830 780 750 300 1200 1110 900 790 730 CS-A12GKD 1320 1300 1120 860 800 750 700 300 1220 1200 1020 810 700 12.6.2. Automatic Fan Speed Control • When set to Auto Fan Speed, the fan speed is adjusted between maximum and minimum setting as shown in the table. - Fan speed rotates in the range of Hi, Me and Lo-. - Deodorizing Control will be activated. 41 Downloaded from AC-Manual.com Manuals • Auto Fan Speed during cooling operation: 1. Indoor fan will rotate alternately between off and on as shown in below diagram. 2. At the beginning of each compressor start operation, indoor fan will increase fan speed gradually for deodorizing purpose. 3. For the first time the compressor operate, indoor fan will be switched to Hi fan speed from Lo- after 70 seconds from the start of compressor. This cause the room temperature to achieve the setting temperature quickly. 4. During compressor stop, indoor fan will operate at Lo- for the beginning 3 minutes to prevent higher volume of refrigerant in liquid form returning to the compressor. 5. For the resume of compressor operation, indoor fan will operate at Me fan speed to provide comfort and lesser noise environment, after 70 seconds from the restart of compressor. • Auto Fan Speed during Soft Dry operation: 1. Indoor fan will rotate alternately between off and Lo-. 2. At the beginning of each compressor start operation, indoor fan will increase fan speed gradually for deodorizing purpose. 3. When compressor at turn off condition for 6 minutes, indoor fan will start fan speed at Lo- to circulate the air in the room. This is to obtain the actual reading of intake air temperature. 42 Downloaded from AC-Manual.com Manuals • Auto Fan Speed during Heating operation. 1. Indoor fan will rotate in the range of SLo → Me according to the heat exchanger temperature. 12.6.3. Manual Fan Speed Control • Manual fan speed adjustment can be carried out by using the Fan Speed selection button at the remote control. • There are 3 types of fan speed settings: Lo, Me, Hi. 12.7. Outdoor Fan Speed Control • There is only one speed for outdoor fan motor. • When the air conditioner is turned on, the compressor and the outdoor fan will operate simultaneously. • Likewise, both compressor and outdoor fan will stop at the same time if the unit is turned off. 12.8. Vertical Airflow Direction Control 12.8.1. Auto Control • When the vertical airflow direction is set to Auto using the remote control, the louver swings up and down as shown in the diagram. • When stop operation using the remote control, the discharge vent is reset, and stop at the closing position. • During Cooling operation or Soft Dry operation, indoor fan motor may stop to rotate at certain periods. At that condition, the louver will stop swinging and rest at the upper limit. 43 Downloaded from AC-Manual.com Manuals Heating Operation (Heating Operation condition) • When the piping air temperature reaches 38°C, the louver is changed from upper to lower limit. When the piping air temperature falls to 35°C, the louver is changed from lower to upper limit. 12.8.2. Manual Control • When the vertical airflow direction is set to Manual using the remote control, the automatic airflow is released and the airflow direction louver move up and down in the range shown in the diagram. • The louver can be adjusted by pressing the button to the desired louver position. • When stop operation using the remote control, the discharge vent is reset, and stop at the closing position. • During Anti-dew condensation prevention, Airflow Direction Manual control angle change from 10°, 15°, 20°, 26°, 32° to 22°, 24°, 26°, 28°, 30° under Cooling and Soft Dry operation mode. Cooling and Soft Dry Operation Heating Operation 12.9. Horizontal Airflow Direction Control • The horizontal airflow direction louvers can be adjusted manually by hand. 12.10. Powerful Operation • The Powerful operation is to achieve the setting temperature quickly. (Cooling and Soft Dry Operation condition) • When Powerful operation is set, the setting temperature will be automatically decreased 3°C internally against the present setting temperature (Lower temperature limit: 16°C). • This operation automatically will be running under SHi fan Speed (Cooling). • Vertical Airflow Direction:- In “Manual” setting, the vane will automatically shift down 10° lower than previous setting. - In “Auto” setting, the vane will automatically swing up and down. However the lower limit will be shifted 10° downward. (Heating Operation condition) • When Powerful operation is set, the setting temperature will be automatically increased 3°C against the present setting temperature (Higher temperature: 30°C). 44 Downloaded from AC-Manual.com Manuals • The Fan Speed will shift as shown below: • Vertical Airflow Direction:- In “Manual” setting, the vane will automatically shift down 5° lower than previous setting. - In “Auto” setting, the vane will automatically shift between upper and lower limit depending on the intake air temperature as Heating Mode, Airflow Direction Auto-Control. However the upper and lower limit will be shifted 5° downward. • Powerful operation stops when:- Powerful operation has operate for 15 minutes. - Powerful button is pressed again. - Quiet button is pressed. - Stopped by OFF/ON operation button. - Timer OFF activates. - Operation mode is changed. 45 Downloaded from AC-Manual.com Manuals 12.11. Quiet Operation (For Cooling Operation or cooling region of Soft Dry Operation) • To provide quiet cooling operation condition compare to normal operation. • Once the Quiet Mode is set at the remote control, the Quiet Mode LED illuminated. The sound level will reduce around 2 dB(A) for Lo fan speed or 3 dB(A) for Hi/Me fan speed against the present operation sound level. • Dew formation become severe at Quiet Lo cool, therefore Quiet Lo cool is operated only 1hr 30 min (1hr QLo, 30 min QLo + 50 rpm). After that, it goes back to Lo cool (However Quiet LED remains on). • Manual Airflow Direction:- RPM control during Lo cool - RPM control during Hi & Me cool • Auto Fan Speed:- • Quiet operation stops when:- Quiet button is pressed again. - Stopped by OFF/ON operation button. - Timer OFF activates. - Operation mode button is changed. 46 Downloaded from AC-Manual.com Manuals (Heating Operation condition) • When the Quiet Mode is set at the remote control, Quiet Mode LED illuminates. The sound level will reduce either around 2 dB (Lo) or 3 dB (Hi, Me), against the present sound level operation. • Quiet setting of fan speed rpm refer to Indoor Fan Speed Control. • Manual Fan Speed:- Rpm control during Lo, Me & Hi Cool • Auto Fan Speed:- Rpm control depends on the piping air temperature sensor of Indoor heat exchanger • Quiet operation stops when:- Quiet button is pressed again. - Powerful button is pressed. - Stopped by OFF/ON operation button. - Timer OFF activates. 47 Downloaded from AC-Manual.com Manuals 12.12. Timer Control 12.12.1. ON Timer • • • • When the ON Timer is set by using the remote control, the unit will start to operate slightly before the set time, so that the room will reach nearly to the set temperature by the set time. For Cooling and Soft Dry operation, the operation will start 15 minutes before the set time. For Automatic operation, the indoor fan will operate at SLo speed for 20 seconds, 30 minutes before the set time to detect the intake air temperature to determine the operation mode. The operation indication lamp will blink at this time. 12.12.2. OFF Timer • When the OFF Timer is set by using the remote control, the unit will stop operate according to the desired setting. Notes: 1. By pressing ON/OFF operation button, the ON Timer or OFF Timer setting will not be cancelled. 2. To cancel the previous timer setting, press CANCEL button. 3. To activate the previous timer setting, press SET button. 4. If main power supply is switched off, the Timer setting will be cancelled. 12.13. Random Auto Restart Control • If there is a power failure during operation, the air conditioner will automatically restart after 3 to 4 minutes when the power is resumed. • It will start with previous operation mode and airflow direction. • If there are more than one air conditioner unit in operation and power failure occur, restart time for each unit to operate will be decided randomly using 4 parameters:- intake air temperature, setting temperature, fan speed and air swing louver position. • This Random Auto Restart Control is not available when Timer is set. 12.14. Remote Control Signal Receiving Sound • Short beep sound will be heard when:- enable initial Patrol Operation. • Long beep sound will be heard for others setting. 48 Downloaded from AC-Manual.com Manuals 12.15. Patrol Operation 1. Purpose To monitor air dirtiness level by using gas sensor and activates e-ion operation whenever air is dirty. 2. Control Condition a. Patrol operation start condition • When the unit operation is started with “OFF/ON” button. • When the unit stops, “Patrol” button is pressed, Patrol individual operation will start. • During cooling only operation, “Patrol” button is pressed. b. Patrol operation stop condition When any of the following condition is fulfilled: • When “OFF/ON” button is pressed. • During any operation with Patrol, "Patrol" button is pressed again. • When “e-ion” button is pressed. • When OFF Timer activates. c. Patrol operation disable • To disable the Patrol Operation during unit start (default) with “OFF/ON” button, press “Patrol” button and hold for 5 seconds, then release. • To disable the Patrol Operation, press “Patrol” button and hold for 15 seconds, then release. 49 Downloaded from AC-Manual.com Manuals 3. Control Content a. Gas Sensor Control • First 2 minutes from Patrol function activates is stabilization time, during stabilization time, no air dirtiness level is monitored. The Air Dirtiness level is set to level 2. • After that, gas sensor starts to record the resistance value at fixed interval. Higher resistance value indicates cleaner air. • The air dirtiness level is monitored by comparing the current resistance value with maximum resistance value from time to time to get the Air Dirtiness Value. • There are 3 air dirtiness level, based on the Air Dirtiness Value: - Air Dirtiness level 0: Clean - Air Dirtiness level 1: Moderate - Air Dirtiness level 2: Contaminated - Dirtiness level sensitivity adjustment. It is possible to change the gas sensor sensitivity, where the Threshold value (G1 ~ G4) will be shifted accordingly: a. Press and release “SET” button. b. Press “Timer increment” / “Timer decrement” button to select sensitivity. (Low <–> Standard (Default) <–> High) c. Confirm setting by pressing “Timer Set” button. LCD returned to original display after 2 seconds. d. LCD returned to original display if remote control does not operate for 30 seconds. b. e-ion Control • When dirtiness level is 1 or 2, e-ion operation starts. • If dirtiness level improves from level 2 to level 1, the unit carries out level change after 60 seconds. • When dirtiness level returns to level 0 continuously for 10 minutes or more, e-ion operation stops. Dirtiness Level Shift • For Auto Fan Speed, the fan speed increased based on dirtiness level: 50 Downloaded from AC-Manual.com Manuals c. Indoor Fan Control • During any operation mode combines with Patrol operation, fan speed follows respective operation mode. • During Patrol individual operation if e-ion starts, only Auto Fan Speed and no Powerful operation is allowed. Even if “Fan Speed” button is pressed, no signal is sent to air conditioner, and no change on LCD display. • During Patrol individual operation if e-ion stops, Indoor Fan stop operation. d. Airflow direction (Horizontal, Vertical) Control • During any operation mode combines with Patrol operation, air flow direction follows respective operation mode. • During Patrol individual operation if e-ion starts, only Auto Air Swing is allowed. Even if “Air Swing” button is pressed, no signal is sent to air conditioner, and no change on LCD display. • During Patrol individual operation if e-ion stops, Airflow direction louver closed. e. Indicator • When Patrol operation starts, Patrol Sensor indicator ON. • When e-ion operation starts based on dirtiness level, e-ion indicator ON. f. Remote Control Receiving Sound • • • • Normal Operation Patrol Mode Patrol Mode Stop → → → → Patrol Mode Stop Normal Operation Patrol : Beep : Long Beep : Beep : Beep g. Timer Control • When ON timer activates when unit stops, previous operation resumes without Patrol operation. • When ON timer activates during any operation, no change and carry on current operation. • When OFF timer activates during any operation, all operation stops. h. Power failure • During Patrol individual operation, if power failure occurs, after power resumes, Patrol individual operation resumes immediately. • During combination operation, if power failure occurs, after power resumes combination operation resume immediately. 51 Downloaded from AC-Manual.com Manuals 12.16. e-ion Operation 1. Purpose This operation provides clean air by producing negative ions to attract dust captured at the positively charged e-ion filters. 2. Control Condition a. e-ion operation start condition • During unit running at any operation mode, if “e-ion” button is pressed, combination operation (operation mode + e-ion operation) starts. • During unit is OFF, if “e-ion” button is pressed, e-ion individual operation starts. b. e-ion operation stop condition • When “OFF/ON” button is pressed to stop the operation. • When “e-ion” button is pressed again. • When “Patrol” button is pressed. • When OFF Timer activates. c. e-ion operation pause condition • When indoor fan stop (during deice, odor cut control, thermostat off, etc.). e-ion operation resume after indoor fan restarts. • When indoor intake temperature 40°C. e-ion operation resume after indoor intake temperature < 40°C continuously for 30 minutes. 52 Downloaded from AC-Manual.com Manuals 3. Control Content a. Indoor fan control • During any operation mode combines with e-ion operation, fan speed follows respective operation mode. • During e-ion individual operation - only Auto Fan Speed and no Powerful operation is allowed. Even if Fan Speed button is pressed, no signal is sent to air conditioner, and no change on LCD display. Auto Fan Speed for e-ion operation switches between HLo and CLo at pattern below: b. Airflow direction control • During any operation mode combines with e-ion operation, air flow direction follows respective operation mode. • During e-ion individual operation, only Auto Air Swing is allowed. Even if Air Swing button is pressed, no signal is sent to air conditioner, and no change on LCD display. c. Timer control • When ON timer activates when unit stops, previous operation resumes without e-ion operation. • When ON timer activates during any operation, no change and carry on current operation. • When OFF timer activates during any operation, all operation stops. d. Indicator • When e-ion operation starts, e-ion indicator ON. e. e-ion Check Mode • To check if e-ion is malfunctioning, during e-ion operation press “e-ion” button for 15 seconds and release to enter e-ion Check Mode and supplies power to the e-ion AIR PURIFYING SYSTEM. • If abnormal discharge is detected at filter (short-circuited) due to water or dust adhesion, etc., the e-ion indicator blinks immediately. f. Power failure • During e-ion individual operation, if power failure occurs, after power resumes, e-ion individual operation resumes immediately. • During combination operation, if power failure occurs, after power resumes, combination operation resume immediately. 53 Downloaded from AC-Manual.com Manuals g. Error Detection Control When e-ion indicator blink, it indicates error listed below: a. e-ion AIR PURIFYING SYSTEM main connector to PCB is open: Judgment Method • During e-ion operation (include during Patrol operation), e-ion AIR PURIFYING SYSTEM main connector to PCB is opened. Troubleshooting Methods • Connect the connector or stop operation (include during Patrol operation) to cancel the blinking. b. Abnormal Discharge Judgment Method • During e-ion operation, when feedback voltage is-Lo (at micro controller) is detected, it is judged abnormal discharge and stops power supplies to the e-ion AIR PURIFYING SYSTEM. • The unit retries after 30 minutes and repeat for 24 times. (not applicable for e-ion Check Mode) Troubleshooting Method • Press “e-ion” button or “OFF/ON” button to stop the operation and check the e-ion AIR PURIFYING SYSTEM main connector to PCB. • After that, press “e-ion” button again to confirm the e-ion indicator not blinking. • The 24 times counter will be clear after 10 minutes of normal operation or when operation stops. • • • • • Error Reset Method Press “OFF/ON” button to OFF the operation. Press AUTO OFF/ON button at indoor unit to OFF the operation. OFF Timer activates. Press “e-ion” button during e-ion individual mode. Power supply reset. c. e-ion breakdown Judgment Method • When hi-feedback voltage (at micro controller) supplied to filter during e-ion stop, due to PCB or filter's high voltage power supply damage. • Operations except e-ion continue. Both Timer indicator and e-ion indicator blinks. Troubleshooting Method • Press “e-ion” button or “OFF/ON” button to stop the operation. • Change main circuit board or filter's high voltage power supply. • When lo-feedback voltage supplied to e-ion AIR PURIFYING SYSTEM during e-ion operation, e-ion indicator and Timer indicator stop blinking. 54 Downloaded from AC-Manual.com Manuals 13 Servicing Mode 13.1. Auto OFF/ON Button 1. AUTO OPERATION MODE The Auto operation will be activated immediately once the Auto OFF/ON button is pressed. This operation can be use to operate air conditioner with limited function if remote control is misplaced or malfunction. 2. TEST RUN OPERATION (FOR PUMP DOWN/SERVICING PURPOSE) The Test Run operation will be activated if the Auto OFF/ON button is pressed continuously for more than 5 seconds. A “beep” sound will occur at the fifth seconds, in order to identify the starting of Test Run operation. 3. REMOTE CONTROL RECEIVING SOUND OFF/ON MODE The Remote Control Receiving Sound OFF/ON operation will be activated if (within 20 seconds of Test Run Operation) the Auto OFF/ON button is pressed for more than 5 seconds. 2 “beep” sound will occur at to identify the starting of Remote Control Receiving Sound Off/On Mode. Press “Auto OFF/ON button” to toggle remote control receiving sound. - Short “beep”: Turn ON remote control receiving sound. - Long “beep”: Turn OFF remote control receiving sound. After Auto OFF/ON Button is pressed, the 20 seconds counter for Remote Control Receiving Sound OFF/ON Mode is restarted. 13.2. Select Remote Control Transmission Code • There are 4 type of remote control transmission code could be selected and stored in EEPROM of indoor unit. The indoor unit will only operate when received signal with same transmission code from remote control. This could prevent signal interference when there are 2 or more indoor unit installed nearby together. • To change remote control transmission code, short or open jumpers at the remote control printed circuit board. • During Remote Control Receiving Sound OFF/ON Mode, press any button at remote control to transmit and store the desired transmission code to the EEPROM. 55 Downloaded from AC-Manual.com Manuals 13.3. Remote Control Button 13.3.1. SET BUTTON • To check current remote control transmission code. - Press for more than 10 seconds. • To change the air quality sensor sensitivity: - Press and release with pointer. - Press the Timer Decrement button to select sensitivity: 1. Low Sensitivity 2. Standard (Default) 3. Hi Sensitivity - Confirm setting by pressing Timer Set button, a “Beep” sound will be heard. LCD returns to original display after 2 seconds. - LCD returns to original display if remote control does not operate for 30 seconds. 13.3.2. CLOCK BUTTON • To change the remote control’s time format. - Press for more than 5 seconds. 13.3.3. RESET (RC) • To clear and restore the remote control setting to factory default. - Press once to clear the memory. 13.3.4. TIMER • To change indoor unit indicator’s LED intensity. - Press continuously for 5 seconds. 13.3.5. TIMER • To change remote control display from Degree Celsius to Degree Fahrenheit. - Press continuously for 10 seconds. 56 Downloaded from AC-Manual.com Manuals 14 Troubleshooting Guide 14.1. Refrigeration cycle system In order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a fan. The normal outlet air temperature and pressure of the refrigeration cycle depends on various conditions, the standard values for them are shown in the table to the right. 57 Downloaded from AC-Manual.com Manuals 14.1.1. Relationship Between The Condition of The Air Conditioner and Pressure and Electric Current Cooling Mode Condition of the air conditioner Low Pressure High Pressure Heating Mode Electric current during operation Low Pressure High Pressure Electric current during operation Insufficient refrigerant (gas leakage) Clogged capillary tube or Strainer Short circuit in the indoor unit Heat radiation deficiency of the outdoor unit Inefficient compression • Carry out the measurements of pressure, electric current, and temperature fifteen minutes after an operation is started. 14.1.2. Diagnosis Methods Of A Malfunction Of A Compressor And 4-way Valve Nature of fault Symptom • Electric current during operation becomes approximately 20% lower than the normal value. Insufficient compressing of a compressor • The discharge tube of the compressor becomes abnormally hot (normally 70 to 90°C). • The difference between high pressure and low pressure becomes almost zero. • Electric current reaches a high level abnormally, and the value exceeds the limit of an ammeter. In some cases, a breaker turns off. Locked compressor • The compressor has a humming sound. • Electric current during operation becomes approximately 80% lower than the normal value. Insufficient switches of the 4-way valve • The temperature different between from the discharge tube to the 4-way valve and from suction • tube to the 4-way valve becomes almost zero. 58 Downloaded from AC-Manual.com Manuals 15 Disassembly and Assembly Instructions WARNING • Cautions! When handling electronic controller, be careful of electrostatic discharge. • Be sure to return the wiring to its original position. • There are many high voltage components within the heat sink cover so never touch the interior during operation. Wait at least two minutes after power has been turned off. 15.1. Indoor Electronic Controllers and Control Board Removal Procedures 59 Downloaded from AC-Manual.com Manuals 60 Downloaded from AC-Manual.com Manuals 15.2. Indoor Fan Motor and Cross Flow Fan Removal Procedures 61 Downloaded from AC-Manual.com Manuals 62 Downloaded from AC-Manual.com Manuals 16 Technical Data 16.1. Thermostat Characteristics Cooling Soft Dry Heating 63 Downloaded from AC-Manual.com Manuals 16.2. Operation Characteristics 16.2.1. CS-A7GK CU-A7GK 64 Downloaded from AC-Manual.com Manuals 65 Downloaded from AC-Manual.com Manuals 66 Downloaded from AC-Manual.com Manuals 67 Downloaded from AC-Manual.com Manuals 16.2.2. CS-A9GK CU-A9GK 68 Downloaded from AC-Manual.com Manuals 69 Downloaded from AC-Manual.com Manuals 70 Downloaded from AC-Manual.com Manuals 71 Downloaded from AC-Manual.com Manuals 16.2.3. CS-A12GK CU-A12GK 72 Downloaded from AC-Manual.com Manuals 73 Downloaded from AC-Manual.com Manuals 74 Downloaded from AC-Manual.com Manuals 75 Downloaded from AC-Manual.com Manuals 17 Exploded View and Replacement Parts List 17.1. Indoor Unit Note: The above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 76 Downloaded from AC-Manual.com Manuals REF. NO. 1 2 3 4 5 AI 6 7 8 A2 9 10 11 12 13 14 15 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 PART NAME & DESCRIPTION CHASSY COMPLETE FAN MOTOR, AC 15W SINGLE CROSS FLOW FAN COMPLETE BEARING ASS’Y SCREW - CROSS FLOW FAN ION GENERATOR EVAPORATOR CO. FLARE NUT (1/4) FLARE NUT (3/8) (1/2) E-ION AIR PURIFYING SYSTEM CLIP FOR SENSOR DISCHARGE GRILLE COMPLETE VERTICAL VANE CONNECTING BAR CONNECTING BAR CONNECTING BAR A.S.MOTOR, DC SINGLE 12V300 OHM CAP - DRAIN TRAY HORIZONTAL VANE COMPLETE BACK COVER CHASSIS CONTROL BOARD CASING TERMINAL BOARD COMPLETE P.S.CORD W/OUT PLUG ELECTRONIC CONTROLLER - MAIN ELECTRONIC CONTROLLER - POWER SENSOR COMPLETE CONTROL BOARD FRONT COVER INDICATOR COMPLETE INDICATOR HOLDER INDICATOR HOLDER CONTROL BOARD TOP COVER REMOTE CONTROL COMPLETE FRONT GRILLE COMPLETE INTAKE GRILLE COMPLETE GRILLE DOOR COMPLETE E-ION FILTER SCREW - FRONT GRILLE CAP - FRONT GRILLE DRAIN HOSE INSTALLATION PLATE BAG COMPLETE - INSTALLATION SCREW FULCRUM QTY. 1 1 1 1 1 1 1 1 1 1 1 1 12 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 1 1 1 1 (Note) • All parts are supplied from PHAAM, Malaysia (Vendor Code: 061). 77 Downloaded from AC-Manual.com Manuals CS-A7GKD CWD50C1513 CWA921373 CWH02C1045 CWH64K007 CWH551146 CWH94C0014 CWB30C1844 CWT251026 CWT251027 CWH14C5332 CWH32143 CWE20C2627 CWE241157 CWE261092 CWE261071 CWE261091 CWA981091 CWH521096 CWE24C1183 CWD932454 CWH102321 CWA28C2162 CWA20C2589 CWA73C2467 CWA744529 CWA50C2122 CWH131207 CWE39C1168 CWD932744 CWD932745 CWH13C1171 CWA75C3002 CWE11C3638 CWE22C1329 CWE14C1010 CWD00K1001 XTT4+16CFJ CWH521109 CWH851063 CWH361067 CWH82C067 CWH621049 CS-A9GKD ← ← ← ← ← ← CWB30C2141 ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← CWA73C2621 ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← CS-A12GKD ← ← ← ← ← ← CWB30C2138 ← CWT251035 ← ← ← ← ← ← ← ← ← ← ← ← CWA28C2163 ← CWA73C2620 ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← 17.2. Outdoor Unit 17.2.1. CU-A7GK CU-A9GK Note: The above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 78 Downloaded from AC-Manual.com Manuals REF. NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 24 25 26 27 28 29 30 31 32 34 35 36 37 38 39 41 42 45 46 47 48 49 PART NAME & DESCRIPTION CHASSY ASS’Y SOUND PROOF MATERIAL FAN MOTOR BRACKET SCREW - FAN MOTOR BRACKET FAN MOTOR (AC 30W SINGLE) SCREW - FAN MOTOR MOUNT PROPELLER FAN ASS’Y NUT - PROPELLER FAN COMPRESSOR ANTI - VIBRATION BUSHING NUT - COMPRESSOR MOUNT CONDENSER 4-WAY VALVE STRAINER HOLDER COUPLING 2-WAY VALVE (LIQUID) 3-WAY VALVE (GAS) OVERLOAD PROTECTOR HOLDER - O.L.P. TERMINAL COVER NUT - TERMINAL COVER SOUND PROOF BOARD TERMINAL BOARD ASS’Y CAPACITOR - COM. HOLDER CAPACITOR CAPACITOR - F.M CABINET SIDE PLATE (L) CABINET SIDE PLATE COMP. CABINET FRONT PLATE ASS’Y WIRE NET CABINET TOP PLATE CONTROL BOARD COVER BAG COMPLETE TUBE ASS’Y (CHK VALVE, CAPILLARY) CAPILLARY TUBE ASS’Y ELECTRO MAGNETIC SWITCH ELCTROLYTIC CAPACITOR TEMPERATURE RELAY V-COIL COMPLETE OPERATION INSTRUCTIONS INSTALLATION INSTRUCTIONS OPERATION INSTRUCTIONS INSTALLATION INSTRUCTIONS INSTALLATION INSTRUCTIONS QTY. 1 1 1 2 1 3 1 1 1 3 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 (Note) • All parts are supplied from PHAAM, Malaysia (Vendor Code: 061). 79 Downloaded from AC-Manual.com Manuals CU-A7GKD CWD50K2112 CWG302255 CWD541075 CWH551198 CWA951387J CWH55406J CWH03K1020 CWH56053J 2RS122D5BC02 CWH50077 CWH56000J CWB32C1979 CWB001024J CWB11025 CWH351047 CWB021218 CWB011258 CWA121050J CWH7041200 CWH171011 CWH7080300J CWH151074 CWA28K1021J DS371206CPNA CWH301038 DS441205NPQA CWE041110A CWE04C1042 CWE06K1048 CWD041057A CWE031041A CWH13C1099 CWG87C900 CWT01C3976 — CWA00059 CWA32C1003 CWA14C1009 CWA43C2187 CWF565377 CWF613059 CWF565456 CWF613060 CWF613061 CU-A9GKD ← ← ← ← ← ← ← ← 2PS156D3BB02 ← ← CWB32C1493 ← ← ← CWB021217 CWB011257 CWA121210J ← ← ← ← ← DS371306CPND CWH301035 ← ← ← ← ← ← ← ← — CWB15K1166 ← ← ← ← ← ← ← ← ← 17.2.2. CU-A12GK Note: The above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 80 Downloaded from AC-Manual.com Manuals REF. NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 20 21 22 24 25 26 27 28 29 30 31 32 33 34 35 36 38 39 40 41 42 44 45 46 47 48 49 PART NAME & DESCRIPTION CHASSY ASS’Y SOUND PROOF MATERIAL FAN MOTOR BRACKET SCREW - FAN MOTOR BRACKET FAN MOTOR (AC 30W SINGLE) SCREW - FAN MOTOR MOUNT PROPELLER FAN ASS’Y NUT - PROPELLER FAN COMPRESSOR ANTI - VIBRATION BUSHING NUT - COMPRESSOR MOUNT CONDENSER 4-WAY VALVE STRAINER HOLDER COUPLING 2-WAY VALVE (LIQUID) 3-WAY VALVE (GAS) TERMINAL COVER NUT - TERMINAL COVER SOUND PROOF BOARD TERMINAL BOARD ASS’Y CAPACITOR - COMP. HOLDER CAPACITOR CAPACITOR - F.M CABINET SIDE PLATE (L) CABINET SIDE PLATE COMP. CABINET FRONT PLATE ASS’Y WIRE NET CABINET TOP PLATE PLATE - C.B.COVER CONTROL BOARD COVER BAG COMPLETE TUBE ASS’Y (CHK VALVE, CAPILLARY) ELECTRO MAGNETIC SWITCH ELCTROLYTIC CAPACITOR - COMPLETE MAGNET RELAYS TEMPERATURE RELAYS V-COIL COMPLETE HANDLE OPERATION INSTRUCTIONS INSTALLATION INSTRUCTIONS OPERATION INSTRUCTIONS INSTALLATION INSTRUCTIONS INSTALLATION INSTRUCTIONS QTY. 1 1 1 2 1 3 1 1 1 3 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 CU-A12GKD CWD50K2074 CWG302410 CWD541030 CWH551198 CWA951117J CWH55406J CWH03K1006 CWH56053J 2KS206D5AF04 CWH50055 CWH561049 CWB32C1266 CWB001026J CWB11025 CWH351023 CWB021117 CWB011482 CWH171012 CWH7080300J CWH151023 CWA28K1034J DS371356CPNC CWH30060 DS441205NPQA CWE041248A CWE04C1118 CWE06K1034 CWD041111A CWE031014A CWH13C1064 CWH131295 CWG87C900 CWT01C3650 CWA00059 CWA32C067 K6A2C7A00002 CWA14C1009 CWA43C2273 CWE161010 CWF565377 CWF613059 CWF565456 CWF613060 CWF613061 (Note) • All parts are supplied from PHAAM, Malaysia (Vendor Code: 061). • “O” marked parts are recommended to be kept in stock. [PHAAM] Printed in Malaysia SSYW0612-00 81 Downloaded from AC-Manual.com Manuals

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project