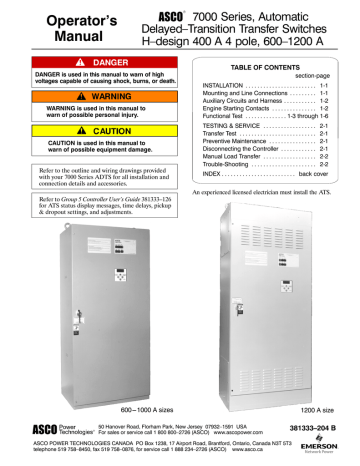

ASCO 7000 Series, Automatic Delayed–Transition Transfer Switches H–design 400 A 4 pole, 600–1200 A Operators Manual

Add to my manuals

11 Pages

advertisement

▼

Scroll to page 2

of 11

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

Download

PDF

advertisement