- Home

- Domestic appliances

- Small kitchen appliances

- Barbecues & grills

- Champion

- Model 66 DRPW

- Owner's manual

Moyer Diebel | MD44 | MD66 | Owner's manual | Champion Model 66 DRPW Installation & Operation Manual

Add to my manuals

104 Pages

advertisement

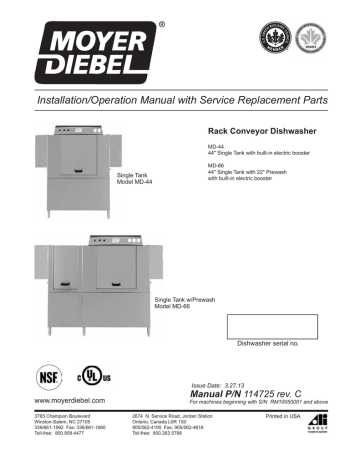

Installation/Operation Manual with Service Replacement Parts

Single Tank

Model MD-44

Rack Conveyor Dishwasher

MD-44

44" Single Tank with built-in electric booster

MD-66

44" Single Tank with 22" Prewash with built-in electric booster

Single Tank w/Prewash

Model MD-66

Dishwasher serial no.

www.moyerdiebel.com

3765 Champion Boulevard

Winston-Salem, NC 27105

336/661-1992 Fax: 336/661-1660

Toll-free: 800.858.4477

Issue Date: 3.27.13

Manual P/N 114725 rev. C

For machines beginning with S/N RM10050001 and above

Printed in USA 2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Champion Service Agent __________________________________ Tel:______________________

Champion Parts Distributor _________________________________ Tel:______________________

National Service Department

In the USA:

Toll-free: 800/ 858-4477

Tel: 336/ 661-1992

Fax: 336/ 661-1660 email: [email protected]

In Canada:

Toll-free: 800/ 263-5798

Tel:

Fax:

905/ 562-4195

905/ 562-4618 email: [email protected]

ATTENTION:

The dishwasher model number, serial number, voltage, hertz and phase are needed to identify your machine and to answer questions.

Please have this information on-hand if you call for service assistance.

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council and The Canadian Green

Building Council, respectively, and are used by permission. The logos signify only that Moyer Diebel is a USGBC member and a CaGBC member respectively. USGBC and CaGBC do not review, certify nor endorse the products or services offered by its members.

COPYRIGHT © 2013 All rights reserved Printed in the USA

PRODUCT REGISTRATION

ONLINE

MAKE SURE YOU ARE CONNECTED TO THE INTERNET

THEN ENTER

THE ADDRESS BELOW TO REGISTER YOUR PRODUCT ONLINE

In the U.S.A

http://www.moyerdiebel.com/register

In Canada http://www.championindustries.com/canada/register

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

Model

PRODUCT REGISTRATION CARD

Serial #

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

Contact:

(Street) Province Postal Code

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

Revision History

Revision History

A revision might be a part number change, new instructions, or information that was not available at print time. We reserve the right to make changes to this manual without notice and without incurring any liability by making the changes. Dishwasher owners may request a revised manual, at no charge, by calling (800) 263-5798 in Canada.

Description Revision

Date

Revised

Pages

Serial Number

Effectivity

9.30.10

12.2.10

7.16.12

3.27.13

93

35

41

All

2-9

58-61

82

60

61

67

RM10050001

RM10050001

RM10050001

RM10050001

RM1005001

RM1005001

RM1005001

RM1005001

RM1005001

RM1005001

69 RM1005001

Released First Edition

Added Direction Field Conversion Instructions

Revised P/N's for Pawl Bar Assemblies

Added jumper settings to instructions

Updated Schematic now 702260 rev. B

Item 4 ---, changed 111497 to 114797

Item 14, changed 0503479 to 0503749

Item 14, changed 201401 to 201041

Added assembly 414316 to list

Item 6, changed 206032 to 206302

Item 2, changed 114795 to 108002

Item 14, changed 107697 to 107967 i

Limited Warranty

LIMITED WARRANTY

Moyer Diebel, 3765 Champion Boulevard, Winston-Salem, North Carolina 27105, and P.O. Box 301,

2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts, as set out below.

Warranty of Machines: Moyer Diebel warrants all new machines of its manufacture bearing the name

"Moyer Diebel" and installed within the United States and Canada to be free from defects in material and workman ship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Moyer Diebel, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty registration card must be returned to Moyer Diebel within ten (10) days after installation. If warranty card is not returned to Moyer Diebel within such period, the warranty will expire after one year from the date of shipment.

Moyer Diebel will not assume any responsibility for extra costs for installation in any area where there are jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Moyer Diebel, at its election, will either repair or replace the defective machine or accept return of the machine for full credit; provided; however, as to glasswashers, Moyer Diebel's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Moyer Diebel elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular working hours by a Moyer Diebel authorized service technician. Defective parts become the property of Moyer Diebel.

Use of replacement parts not authorized by Moyer Diebel will relieve Moyer Diebel of all further liability in connection with its warranty. In no event will Moyer Diebel's warranty obligation exceed Moyer Diebel's charge for the machine.

The following are not covered by Moyer Diebel's warranty: a. Lighting of gas pilots or burners. b. Cleaning of gas lines. c. Replacement of fuses or resetting of overload breakers. d. Adjustment of thermostats. e. Adjustment of clutches. f. Opening or closing of utility supply valves or switching of electrical supply current. g. Cleaning of valves, strainers, screens, nozzles, or spray pipes. h. Performance of regular maintenance and cleaning as outlined in operator’s guide. i.

Damages resulting from water conditions, accidents, alterations, improper use, abuse, tampering, improper installation, or failure to follow maintenance and operation procedures. j.

Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such leaks caused by the installer, including those at machine table connections or by connection of chemical dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by labor dispute.

Warranty of Parts: Moyer Diebel warrants all new machine parts produced or authorized by Moyer Diebel to be free from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and workmanship is found to exist within the warranty period Moyer Diebel will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. MOYER DIEBEL'S WARRANTY IS ONLY TO THE

EXTENT REFLECTED ABOVE. MOYER DIEBEL MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUD-

ING, BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. MOYER DIEBEL

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN MOYER DIEBEL DISHWASHING MACHINES

AND MOYER DIEBEL PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR

INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Moyer Diebel does not authorize any other person, including persons who deal in Moyer Diebel dishwashing machines to change this warranty or create any other obligation in connection with Moyer Diebel Dishwashing Machines.

ii

Table of Contents

MD-44 and MD-66 Rack Conveyor Dishwashers

Revisions to this manual.............................................................................................. i

Limited Warranty ......................................................................................................... ii

Model Descriptions ...................................................................................................... iv

Installation ....................................................................................................... 1

Receiving ..............................................................................................................1

MD-44 Direction Field Conversion ........................................................................2

Plumbing Connections ..........................................................................................10

Drain Connections ................................................................................................11

Ventilation .............................................................................................................11

Electrical Connections ..........................................................................................12

Chemical Signal Connections ...............................................................................14

Vent Fan Signal Connection .................................................................................14

Running & Table Limit Switch Connections ..........................................................14

Curtain Locations ..................................................................................................15

Door Safety Switches ...........................................................................................16

Scrap Screens ......................................................................................................17

Installing Spray Arms ............................................................................................18

Installing the Pawl Bar ..........................................................................................22

Installing the Curtains ...........................................................................................23

Initial Start-Up Check List .....................................................................................24

Operation ......................................................................................................... 25

Operation ...........................................................................................................25

Cleaning and Maintenance ...................................................................................27

Troubleshooting ....................................................................................................30

Service Replacement Parts ............................................................................ 31

Solid State Control Module Operation and Troubleshooting ..................... 81

Electrical Schematics ..................................................................................... 93 iii

Model Descriptions

Model Descriptions

Model MD-44

Electric high temperature single tank rack conveyor dishwasher with a built-in electric booster in 40°F/22°C rise or optional 70°F/39°C rise.

This model's direction of operation is convertible in the field.

Model MD-66

Electric high temperature single tank with prewash tank rack conveyor dishwasher with a built-in electric booster in 40°F/22°C rise or optional 70°F/39°C rise.

The installation of your dishwasher must be performed by qualified electricians, and plumbers and serviced by authorized service technicians trained in commercial dishwashers.

Defects and repairs caused by unauthorized installers will not be covered by the dishwasher warranty.

iv

Installation

Receiving

1. Inspect the outside of the dishwasher carton for signs of damage.

2. Remove the carton and inspect the dishwasher for damage.

3. Check for any options or accessories that may have shipped with your dishwasher.

4. Turn to the front of this manual and follow the instructions to register your product online or by fax.

NOTE:

The installation of your dishwasher must be performed by qualified service personnel.

Problems due to improper installation are not covered by the Warranty.

NOTE:

The installation of the dishwasher must comply with all local electrical, plumbing, health and safety codes or in the absence of local codes, installed in accordance with the applicable requirements in the National Electrical Code, NFPA 70, Canadian Electrical Code (CEC),

Part 1, CSA C22.1; and the Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations, NFPA 96.

!!ATTENTION!!

Use caution when moving or lifting the dishwasher to prevent damaging the dishwasher or the installation site. Check doorway and passageway clearance before moving the dishwasher.

Remove dishwasher front panels and check under the machine base for obstructions before moving.

1.

Inspect the dishwasher for shipping damage.

2.

Check the dishwasher interior for curtains, panels and other supplies.

3.

Lift the dishwasher off the shipping pallet and move the machine near its permanent location.

4.

Leave a minimum of 6" between walls and the rear of the dishwasher.

5.

Level the dishwasher side-to-side and front-to-back using a bubble level.

The dishwasher legs are adjusted by screwing them in or out.

6.

Do not remove tags attached to the utility connections.

7.

Remove the protective film from the dishwasher exterior.

8.

Remove any foreign material from the dishwasher interior.

Wall Clearances

6"

6"

1

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

ATTENTION

Conversion must be performed BEFORE the machine is permanently located and utilities connected. Access to the rear of the machine is required to perform the conversion.

Parts Needed for Conversion (Supplied by Others)

Qty. 1, Street Elbow, 3/4" NPT x 90°, Brass: For R-L to L-R Conversion

Qty. 1, Compression Fitting, 7/8" OD x 90° ELL, Brass: For L-R to R-L Conversion

80 inches, 3/4" Copper tubing Type K: For L-R to R-L Conversion

5A

Final

Rinse

Manifold

4 Upper

Rinse

Piping

3 Booster Piping

(From Vacuum Breaker to Booster)

2

Curtain

Baffle

6 Final Rinse

Diverter

7 Drain

Screen

4A Plug

5 Rear

Track

8 Rinse Drain

Piping

1 Pawl Bar

Right to Left Direction of Operation Shown

7A Seal

8A Cap

2

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

Refer to the illustration on the previous page and note that machine assemblies are numbered from 1-8A and labeled. To convert the machine, remove the assemblies in numerical order and reinstall them as described below.

Remove the front panel.

1. Remove the pawl bar assembly. Remove the crosshead from the end on the pawl bar.

Reattach the crosshead on the opposite end of the pawl bar. Install the pawl bar after the piping changes are complete.

1

2. Remove the curtain and curtain baffle from the unload end of the machine. The baffle is held by three 1/4-20 acorn nuts. Rotate the baffle 180° and install it on the studs provided at the opposite end of the machine. Install the curtain on the baffle.

3. Disconnect the L-shape copper tubing running between the booster tank outlet and the final rinse vacuum breaker. Set the tubing aside for modification and reuse later.

4. Remove the final rinse thermometer probe from the upper rinse piping assembly.

Unscrew the upper rinse piping assembly and set aside.

4A. Remove the black plug covering the hole on the top right rear of machine hood and

install it in the hole where the upper rinse piping assembly was removed in Step 4.

(continued on next page)

3

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

(continued)

5. Removing the final rinse manifold requires that the rear track be unfastened to provide clearance.

Refer to the illustration below. Remove six bolts holding the track supports that connect the front and rear tracks, then remove the four bolts holding the rear track at each end of the machine.

Pull the rear track away from the rear of the hood slightly. It is not necessary to pull the rear track out of the machine.

5

5A. Remove the 1/4-20 acorn nut holding the final rinse manifold to the rear of the machine

hood. Remove the 3/4" brass nut holding the final rinse manifold to the top of the hood.

Be careful not to lose the gasket on the end of the rinse manifold.

Pull the manifold down into the machine and turn the assembly so the lower rinse pipe points back toward the load end of the machine. Rotate the assembly toward the front and out of the machine.

Install the final rinse manifold at the opposite end of the machine then reinstall the rear track assembly and supports.

6. Remove the final rinse diverter. The diverter is held by four 1/4-20 acorn nuts.

Rotate the diverter 180° and install the it on the studs provided at the opposite end of the machine.

7. Remove the drain screen and install it on the opposite end of the machine after the drain piping assembly is repositioned and installed.

7A. Remove the drain hole seal assembly on the load end of the machine and set aside.

4

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

8. Remove the rinse drain piping from the unload end of the tank. To do this, remove three sections of black hose connecting the drain piping together (see the illustration below).

The easiest way to remove the drain piping is from the rear of the machine.

Remove the nipple in the 90° elbow then remove the elbow from the tank fitting.

8

= Hose

8A. Remove the 3/4" pipe cap from the fitting on the load end of the machine and install it on the tank fitting at the unload end of the machine where the drain piping was removed. Install the drain hole seal removed in 7A in the drain hole.

9. Reverse the direction of the drain trunk piping by loosening the drain valve union and rotating the piping 180°. Tighten the drain valve union (see illustration below).

9

(continued on next page)

5

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

(continued)

10. R-L to L-R Conversion ONLY

Rotate the drain piping assembly removed in Step 8 180° and install it on the opposite end of the machine. The easiest way to insert the piping is from the rear of the machine.

Install drain basket and the elbow. Screw the nipple into the elbow and connect the hoses to the drain piping and the drain trunk. See the illustration below.

10

10A

10B

10B

6

10A. Loosen the union directly above the cross fitting and rotate piping so it aligns with the booster outlet.

10B. Rotate the Street Elbow counterclockwise 90°. Screw a Street Elbow (supplied by others) into the existing elbow and install the existing compression fitting into the elbow.

11. Using the L-shaped 3/4" copper tubing saved in Step 3, cut a 46-1/2" piece of tubing and connect it between points 10A and 10B.

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

12. L-R to R-L Conversion ONLY

Rotate the drain piping assembly removed in Step 8 180° and install it on the opposite end of the machine. The easiest way to insert the piping is from the rear of the machine.

Install drain basket and the elbow. Screw the nipple into the elbow and connect the hoses to the drain piping and the drain trunk. See the illustration below.

12

12A

46-1/2"

12B

31-1/2"

12C

12A. Loosen the union directly above the cross fitting and rotate the upper rinse piping so it aligns with the back of the machine.

12B. Remove the upper street elbow and move the compression fitting to the lower street elbow then rotate the street elbow in the booster tank clockwise 90° so it points toward the unload end of the machine.

12C. Cut 2 pieces of Type K, 3/4" copper tubing (supplied by others) and connect them using a Brass 7/8" OD x 90° ELL Compression Fitting (supplied by others). Connect the piping to the fitting on the booster outlet described in 12B.

7

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

(continued)

Changing Wire Connections in the Lower Junction Box

The direction change requires that the rack switch and the final rinse switch connections must be reversed on the terminal bock located behind the front panel of the machine.

WARNING:

Electrocution or serious injury may result when working on an energized circuit.

Disconnect power at the main breaker or service disconnect switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being performed on the circuit.

13. Remove the junction box cover and identify the large terminal block located in the top left corner of the box. See the illustration below.

13

8

14. Refer to the illustration on the next page for the wiring diagram of the terminal block.

Located the wires marked 16 and 17 on the terminal block and reverse them.

Remove the existing wire labels and change wire 16 to 17 and 17 to 16.

Replace the junction box cover and the machine front panel.

15. The conversion is complete.

R - RED BL - BL

MD-44 Direction Field Conversion

MD-44 Direction Field Conversion

BSTR HEA

RINSE SWIT

MD44 JUNCTION BOX WIRING DIAGRAM B702285/0

9

Installation

Utilities

Hot Water Connections

NOTE:

Only qualified personnel should make dishwasher plumbing connections.

Connections must meet local plumbing and sanitary codes.

Improper installation is not covered be the dishwasher warranty.

Hot Water Requirements:

1. Connect a 3/4" NPT hot water supply line to the line strainer located at the top rear of the dishwasher. A water hardness of 3 grains/gal (US) [51.3 mg/L] or less is recommended.

2. For a dishwasher without a booster heater, the hot water connection must supply a minimum of 180°F/82°C measured at the dishwasher.

3. For a 40°F/22°C rise booster heater, the hot water connection must supply a minimum of

140°F/60°C measured at the dishwasher.

4. For a 70°F/39°C rise booster heater, the hot water connection must supply a minimum of

110°F/43°C measured at the dishwasher.

5. Install a pressure regulating valve (PRV) before the dishwasher supply connection to maintain a flowing pressure of 20-25 PSI/137.8-172.4 kPa.

6. Install a service shut-off valve in the supply line, as close to the dishwasher as possible.

The size of the valve must be the same size or larger as the supply line.

Cold Water Connections

Cold Water Requirements:

1. Connect a 1/2" NPT cold water supply line for a dishwasher equipped with a prewash cold water tempering option. Connection is located at the top of rear of the dishwasher load end.

A water hardness of 3 grains/gal (US) [51.3 mg/L] or less is recommended.

2. Connect a 1/2" NPT cold water supply line for dishwashers required to have a drain water temperature tempering option. A water hardness of 3 grains/gal (US) [51.3 mg/L] or less is recommended. Request a P/N 452891 for a drain tempering water kit.

10

Installation

Drain Connections

1. The 1-1/2" drain line was removed and packed inside the dishwasher prior to shipping.

Install the drain line once the dishwasher has been placed in its final location.

2. Connect the 1-1/2" NPT drain line to above a drain sink or to a 1-1/2" or larger drain line connection.

3. Observe all local plumbing and sanitary codes when installing.

Ventilation Connections

1.

DO NOT VENT THE DISHWASHER INTO WALLS,

CEILINGS OR ENCLOSED PLACES.

2.

Vent stacks with adjustable dampers are supplied with the dishwasher to connect house vent.

3.

Connect stainless steel water-tight duct inside the 4" x 16"/ 106mm x 407mm vent stacks supplied with the dishwasher.

4.

A minimum of 6 air changes per hour of kitchen is recommended

Ventilation Guidelines:

Dishwasher without a prewash tank option:

Load end- 200 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

Dishwasher with a Prewash tank option:

Load end- 150 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

11

Installation

Electrical Connections

WARNING:

Electrocution or serious injury may result when working on an energized circuit.

Disconnect power at the main breaker or service disconnect switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being performed on the circuit.

ATTENTION

A qualified electrician must connect the main incoming power to the dishwasher in accordance with all local codes and regulations or in the absence of local codes in accordance with the National Electrical

Code.

!!ATTENTION!!

Electrical and grounding connections must comply with the National Electrical Code or in the absence of a National Code then all Local Electrical Codes.

A qualified electrician MUST compare the electrical power supply with the machine electrical specifications stamped on the

MACHINE ELECTRICAL

CONNECTION PLATE located inside the control cabinet before connecting the main power to the dishwasher.

MACHINE ELECTRICAL CONNECTION

1. The main incoming power to the dishwasher is made at the top of machine in the control cabinet.

2. The electrician must connect the incoming power based on the information that is stamped on the Machine Electrical Connection Plate.

3. Any change to the Machine Electrical Connection Plate must be approved by the factory in advance.

4. The dishwasher main power terminal block is located inside the top-mounted control cabinet.

5. A knock-out plug is provided at the rear of the control cabinet for electrical service connections.

6. Electric blower-dryers have a separate main power connection.

12

Installation

Electrical Connections

(continued)

Motor Rotation

1. Motor rotation was set at the factory.

2. The conveyor drive motor rotation is indicated by a red arrow located on the side of the motor.

3. Check if all motors are running in the wrong direction.

4. Reverse the L1 and L2 wires on the output side of the dishwasher Main Terminal

Block (MTB) located inside the top-mounted control cabinet.

5. The photograph below shows the conveyor drive motor with its direction arrow.

6. A wash pump/motor assembly can be seen in the background of the photo.

WARNING:

Moving Conveyor Parts may cause INJURY OR DEATH.

Keep hands and clothing clear of the conveyor when the conveyor is moving.

USE EXTREME CAUTION WHEN THE CONVEYOR

IS MOVING.

THREE PHASE

POWER CONNECTION

LINE IN

L1 L2 L3

GRD

Main Terminal Block Inside the Top-mounted Control

Cabinet.

Motor Direction Rotation Label on Motor Frame.

13

Installation

Chemical Signal Connections

1. Use a qualified detergent/chemical supplier for detergent/chemical and dispensing equipment needs.

2. Labeled detergent control circuit connection terminals are provided in the control cabinet for detergent and rinse agent/sanitizer dispensing equipment (supplied by others).

3. The illustration at right, shows the terminal board for the machine.

4. The signal connection points include:

• Detergent signal 120VAC, 1A max load.

• Rinse aid/Sanitizer signal 120VAC, 1A load.

5. A removable black plug is provided in the load end side of the wash tank for installation of the detergent conductivity cell.

SIGNAL ONLY

VENT FAN

120V

COMMON

RINSE AID

120V

COMMON

DETERGENT

120V

Vent Fan Signal Connection

NOTE:

The Vent Fan Signal Connection supplies 120VAC to a control relay (supplied by others) when the dishwasher is ON and O VAC when the dishwasher is OFF. Power to operate the vent fan (supplied by others) must be supplied separately.

6. The Vent Fan signal connection point is located on the same terminal board as the chemical connections (see illustration above). The connection is:

• Vent Fan 120VAC, 1Amp max amp load

Running Signal and

Table Limit Switch Connections

7. Connections are provided for systems that require a signal to indicate the dishwasher is running.

8. A signal connection is provided to indicate that the dishwasher has stopped due to a conveyor jam or when the clean dish table is full of racks and additional racks cannot exit the machine.

9. The table limit switch option installation is recommended for all dishwashers and can be ordered from the factory by P/N 407400.

SIGNAL ONLY

MACHINE

RUNNING

TABLE

LIMIT

SWITCH

14

Installation

Curtain Locations

1. Refer to the illustrations below and hang the curtains as shown.

J-hooks are located in the corners of each section to accept the curtain rods.

• Standard long curtains

• Standard medium curtains

• Standard short curtain

24" x 20-1/4"

24" x 13-/14"

24" x 6-1/4"

2. Make sure the that the short flaps of the curtains face the load end of the dishwasher.

Medium Curtain

Long Curtain

Short Curtain

Long Curtain

Medium Curtain

Wash

NOTE:

Misplacing a curtain or failing to install a curtain will adversely affect the proper operation of the machine.

Medium Curtain

Long Curtain

Short Curtain

Long Curtain

Long Curtain

Medium Curtain

Wash Prewash

15

Installation

Door Safety Switches

Dishwasher access doors are equipped with a door safety switch that automatically stops the dishwasher pumps and conveyor drive if a door is raised while the dishwasher is running. In addition, the dishwasher will not start if a door is left open.

1. If the dishwasher is running and a door is raised, then lighted GREEN START pushbutton goes out and the pumps and conveyor drive stop.

2. Check the interior of the dishwasher for any dish racks still in the machine.

These dish racks must be washed again to ensure they are washed and sanitized completely.

3. To restart the dishwasher, make sure all doors are closed, then push the GREEN

START pushbutton.

Pump Intake Screen and Dual Float Switch

Refer to the illustration below and note the location of the pump intake screen and dual float switch.

1. Make sure the pump intake screen is installed by sliding it on the bracket located in front of the wash pump intake.

2. Make sure the float balls on the dual float switch move freely on the float stem.

3. Check the interior of the tank for any foreign objects and make sure the drain screen is clean.

Pump Intake

Screen

Drain

Screen

Dual Float

Switch

Make sure tank is clean, the pump intake screen is installed and the dual float switch moves freely.

16

Installation

Scrap Screens

1.

The model MD-44 and the

MD-66 have scrap screens in the top of the wash tank.

Install four scrap screens in the wash tank making sure they fit securely without large gaps between them.

Model MD-44 and MD-66 have four scrap screens in the wash tank.

2.

The model MD-66 has a prewash tank containing a single large scrap screen which extends from front to back in the prewash tank.

The prewash screen also holds a refuse basket to facillitate cleaning when the machine is off.

Install the large scrap screen making sure the screen fits securely in the front and back of the tank then install the refuse basket as shown in the illustration to the right.

Never remove the prewash scrap screen while the dishwasher is running.

Model MD-66 has a scrap screen and refuse basket located in the prewash tank.

17

Installation

Installing the Lower Spray arm Assembly

Spray Arm O-ring Lower Spray Arm Latch

1.

The lower spray arm assembly is connected to the rear wall of the wash tank and locked into place by the spray arm latch.

2.

The spray arm o-ring makes a water-tight seal when the latch locks the spray arm.

Spray Arm Guide

3.

Slide the lower arm into place and push the latch down to lock the arm in place.

4.

The spray pipes are supported on each side by the spray arm guides.

18

Installation

Installing the Upper Spray Arm Assembly

The upper wash arm assembly is suspended from the top of the dishwasher hood interior by front and rear supports. Follow the instructions and illustrations below to install the upper wash arm assembly.

Wash Arm Connection

Flange Pin

Rear Support

Front Support

Connection

Flange

Upper Wash Arm Assembly

Upper wash arm assembly shown installed.

(Note that the Wash Arm Connection Flange Pin is seated in the Connection Flange.)

Upper Wash Arm

Rear Support

1

Connection

Flange

2

O-ring

3

Make sure the upper spray arm o-ring is in good condition and fits securely in the connection flange before installing the upper wash arm assembly.

Components

1. Upper Wash Arm Rear Support

The rear support holds the wash arm and serves as a guide when the upper wash arm is pushed to the toward the connection flange at the rear of the dishwasher.

2. Connection Flange

The connection flange holds the wash arm securely in place when the upper wash arm is placed in position. In addition, the connection flange holds the wash arm o-ring in position.

3.

O-ring

The wash arm o-ring rests in the center of the connection flange and forms a water-tight seal when the upper wash arm is in place.

19

Installation

Installing the Upper Spray Arm Assembly (continued)

1. Upper Wash Arm

Rear Guide Pin

The rear guide pin is attached to the rear of the upper wash arm. It mates with the upper wash arm rear support.

4

Upper Wash Arm

Rear Guide Pin

Rear Support

2. Connection Flange Pins

The connection flange pins are welded to the sides of the upper wash arm. These pins mate with two slots in the connection flange to hold the wash arm in place when installed.

Connection

Flange Pin

5

Upper Wash Arm

Connection

Flange Pin

5

The upper wash arm is shown with the rear guide pin placed on the rear support before sliding the upper wash arm into position.

3. Upper Wash Arm

Front Guide Pin

The front guide pin is attached to the front of the upper wash arm.

It mates with the front supports.

4. Front Supports

There are two fronts supports which hold the front of the upper wash arm in place when the wash arm is installed.

6

Upper Wash Arm Front

Guide Pin

Upper Wash Arm

Front Supports

7

The upper wash arm is shown with the front guide pin resting in the front supports.

20

Installation

2

Upper Wash Arm

Rear Support

Connection Flange

1

Installing the Upper Spray Arm Assembly

Upper Wash Arm

Front Supports

Upper Wash Arm Assembly

Installation

1. Open the dishwasher access doors and check the location and condition of the connection flange o-ring. Replace the o-ring if it is worn or damaged.

Place the upper wash arm rear guide pin in the rear support so the wash arm hangs in the support.

The upper wash arm assembly is shown resting on the upper wash arm rear support as it slides toward the connection flange.

2. Slide the upper wash arm toward the rear of the dishwasher making sure the rear guide pin is centered in the rear supports.

3

4

5

The upper wash arm assembly is shown resting on the upper wash arm rear support as it slides toward the connection flange.

3. Raise the front of the wash arm so the connection flange pin mates with the connection flange pin slots.

4. Swing the front of the wash arm up toward the front of the dishwasher.

The wash arm front guide pin should be positioned close to the door opening and before the front wash arm supports.

5. Slide the upper wash arm forward as far as it will go making sure that the front guide pin is above the front support notched cut-out.

Lower the upper wash arm so the front guide pin seats securely in the front support notch. Installation is complete.

21

Installation

Installing the Pawl Bar

Pawl Bar

Crosshead

Brass Crosshead

Roller

Guide Roller

The pawl bar assembly is installed in the center of the dishwasher and moves the dish racks through the machine. To install the pawl bar:

1.

Position the pawl bar on the guide rollers located at each end of the machine.

2.

Lower the pawl bar so the crosshead fits on top of the brass crosshead roller.

3.

The crosshead roller must fit inside the crosshead without binding.

4.

Check the alignment of the pawl bar making sure that it rests evenly within the guide rollers.

22

Short Curtain

Installation

Installing the Curtains

J-hook

Long

Curtain

Medium

Curtain

Curtain Installation Shown at the Final Rinse End of the Dishwasher

1.

Curtain are equipped with curtain rods. The rods are hung on J-hooks located in the top of the dishwasher.

2.

Make sure that the short flaps on the curtains face the load end of the dishwasher.

3. Refer to page 15, Curtain Locations, for additional information on curtain placement.

23

Initial Start-Up

Check list

1. Remove white protective film from the dishwasher exterior.

2. Install lower panels to the dishwasher.

3. Remove any foreign material from inside of the machine.

4. Check dishwasher drain/overflows are closed and in securely seated.

5. Install scrap screens, spray arms and pawl bar.

6. Turn main utilities to the dishwasher ON. (Power, water).

7. Make sure doors are closed.

8. Turn dishwasher power switch ON.

9. Check tank water temperatures reach proper levels.

10. Check for leaks.

11. Drain the dishwasher and check that floor drains handle the water volume leaving the dishwasher.

12. Push the Start button.

13. Open each dishwasher door to make sure the safety switch stops the conveyor.

14. Restart the dishwasher.

15. Insert an empty dish rack into the load end of the dishwasher.

The pumps and conveyor will run.

16. Allow the dish rack to travel to the unload end of the dishwasher. The final rinse will run.

17. Allow the rack to exit the dishwasher. The dishwasher pumps should run an additional 90-seconds and stop.

18. Push the Stop button when the machine is running and the dishwasher should stop.

19. Push the dishwasher Power Switch OFF. The dishwasher should shut down.

24

Operation

Control Panel Operation

The final rinse pressure gauge is located behind the control panel. The top-mounted control panel contains the Power ON/OFF switch, start push button, stop push button, and the water temperature gauges for the wash tank and the final rinse. The function of these controls are:

A Final Rinse Pressure Gauge - Indicates the flowing water pressure during the final rinse.

Proper reading is 20-22 PSI.

B Power Switch - Turns power on and off to the dishwasher. The machine wills automatically when the power is turned on.

Indicates when the dishwasher is ready for automatic operation.

C Cycle Light -

D Start Push button - Pushing the Start push button sets the machine for automatic operation. The conveyor and pumps start when a dish rack is inserted into the machine.

Pushing the Stop push button stops the conveyor and pumps.

E Stop Push button -

F Temperature Gauges - Temperature gauges indicate the water temperature in the wash tank and the final rinse water temperature during the final rinse.

A 20-22 PSI

30

20

40

PSI

10

0

CHAMPION INDUSTRIES, INC.

WINSTON-SALEM,NC

60

50

Final Rinse

Pressure

B

POWER

ON

OFF

C

D

START

E

STOP

160°F/71°C

40

60

80

20

100

40

120

60

140

80

160

0 100

180

200

20

220

Wash

Temperature

F

40

60

80

180-195°F

82-91°C

100

120

140

40

60

20

80

160

180

0 100

200

20

220

Final Rinse

Temperature

Model MD-44 Shown

25

Operation

Operation

1. Check that the spray pipes, curtains, and scrap screens are in place and clean.

2. Check that the overflow drains are closed.

3. Check the chemical supplies. Turn on the detergent dispenser switches.

4. Turn on the exhaust vent system (if applicable), and make sure it is operating.

5. Close the door(s). Push the power switch ON, light will illuminate.

Machine will begin to fill via the fill valve and the final rinse piping.

6. When the tanks are full, wait until the wash tank has reached the proper temperature.

Check the wash tank temperature gauges located on the control cabinet. Minimum wash temperatures are:

•

•

•

•

MD-44 160°F/71°C to 175°F/79°C

MD-66 160-175°F/71-79°C

Final Rinse for all models is a minimum of 180-195°F/82-91°C.

Prewash for MD-66 model has no temperature rating.

7. Push the Green start button. The cycle light illuminates indicating the dishwasher is ready for automatic operation.

8. Pre-scrap wares to remove large food particles and load wares into the dish racks.

DO NOT OVERLOAD RACKS.

9. Pegged racks are for plates and/or trays. Flat racks are for bowls and/or silverware.

Spread silverware evenly in a single layer in a flat rack or upright (loosely packed) in a cutlery rack/cylinder.

10. Push a dish rack into the load-end of the dishwasher until it contacts the idle pump switch lever, the conveyor and pumps will start.

11. The dishwasher will run for 90 seconds to wash, rinse and move the dish rack out of the unload-end of the dishwasher.

12. Inserting another dish rack into the machine before the first rack exits will keep the dishwasher running until the last dish rack exits the machine.

13. Check the final rinse pressure and temperature as the racks pass through the final rinse. This final rinse pressure MUST be 20-22 psi [137.8-145 kPa] and the final rinse temperature MUST be a minimum of 180-195°F/82-91°C .

14. The pumps and the conveyor drive will automatically stop after the last rack exits the machine.

15. The machine may be stopped at any time during the cycle by pressing the red STOP pushbutton. The green light or LED will go out.

16. Check the interior of the dishwasher for any dish racks still in the machine.

These dish racks must be washed again to ensure they are washed and sanitized completely.

17. To restart, push the green START pushbutton and push another dish rack into the dishwasher load-end until the pumps and conveyor start again.

18. Repeat steps 7-10 until all wares are washed.

26

Cleaning your dishwasher is the best maintenance you can do.

The cleaning intervals below are the minimum requirements for most dishwashers.

You may need to clean your dishwasher more often when washing heavily soiled wares or during long hours of continuous operation.

Cleaning

Cleaning

O-ring

Remove the wash arm end caps and flush the spray arm pipes with fresh water to clean the spray arm assemblies.

Daily or every 2 hours of operation

1. Turn power switch to OFF.

2. Pull drain lever(s) to drain water. Remove scrap screens and scrap baskets.

Clean inside of the tanks and flush with clean water.

Back flush the scrap screens until clean.

DO NOT STRIKE SCREENS OR BASKETS AGAINST SOLID OBJECTS

3. Remove the spray arm assemblies. Remove the end cap from each spray arm.

4. Flush the spray arms and nozzles to remove any debris.

5. Replace the end caps. Check the condition of the manifold O-ring.

6. Reinstall the spray arms.

7. Remove and clean the curtains. Allow them to dry at the end of the day.

8. Leave the doors open between operations, allowing the machine to dry.

9. Make sure that the final rinse nozzles are clear of mineral deposits.

10. Straighten a metal paper clip to clean the nozzles.

11. Check the temperature and pressure gauge readings during operation.

12. Inspect the machine for signs of water leaks.

13. Check the chemical supplies and refill as necessary.

27

Cleaning

Cleaning

(continued)

At the End of the Day

1. Perform Steps 1-10 on the previous page.

2.

Remove the upper and lower rinse and wash spray arms and end plugs and flush with fresh water.

3.

Clean the final rinse arm nozzles using a small paper clip.

4. Remove the curtains and clean with fresh water.

DO NOT USE STEEL WOOL TO CLEAN THE INTERIOR OF THE MACHINE.

Wipe the interior and exterior of the machine with a soft cloth and a mild detergent.

DO NOT HOSE THE EXTERIOR OF THE MACHINE WITH WATER.

5. Reassemble the dishwasher and leave the door open to allow overnight drying

6. Contact the chemical supplier for de-liming if required.

De-liming

Lime (scale) deposits are the result of minerals contained in the water feeding the dishwasher and appear as a white haze on the surface of the dishwasher. Severe scaling can appear as a granular deposit.

These deposits are a result of the mineral content in the geographic area of the machine's location.

WARNING:

Death or injury can result from toxic fume when de-liming agents come in contact with Chlorine Bleach, or other chemicals that contain iodine, bromine, or fluorine.

USE EXTREME CAUTION WHEN HANDLING ANY DE-LIMING AGENT

CAUTION:

De-liming agents can cause chemical burns.

Wear rubber gloves, eye protection and any other protective clothing as instructed by a qualified chemical supplier and follow the instructions provided by the chemical supplier.

28

Maintenance

Maintenance

Weekly

1. Inspect all water lines for leaks and tighten at joints if required.

2. Clean any detergent residue from the exterior of the machine.

3. Check that the drain/overflow pipes seat tightly in their drains.

4. Clean any accumulated scale from the heating element.

5. Inspect the spray arms for any damage or missing parts.

6. Inspect the final rinse arms for missing parts.

7. Inspect the pawl bar and drive assembly for damage or missing parts.

8. Check that float switches move freely.

9. Check the idle pump actuator and the final rinse actuator for freedom of travel.

Monthly

1. Inspect interior of machine for lime deposits and clean.

2. Check o-rings on spray arm piping connections.

3. Check that the drain/overflow o-rings

4. Clean any accumulated scale from the heating element.

5. Inspect the spray arms o-rings and ensure all plugs are installed.

6. Inspect the final rinse arms for missing parts and are clean.

7. Inspect the pawl bar and drive assembly for damage or missing parts.

8. Check that float switches move freely.

9. Check the idle pump actuator and the final rinse actuator for freedom of travel.

10. Check the drive clutch and adjust as necessary.

11. Check the pump rotation and direction of rotation.

12. Check the operation of temperature gauges or displays.

13. Perform complete operation check.

Yearly

1. Contact authorized service agent to perform complete maintenance review of machine.

2. Correct any abnormal situations as recommended.

29

Troubleshooting

Before calling for service check the following conditions.

1. Dishwasher main power and water supply is on.

2. Machine has been assembled correctly.

3. Conveyor is clear of any obstructions.

4. Drains are closed.

5. Screens and pump intake screens are clear.

6. Doors are closed and secure.

Condition

Dishwasher will not run.

Low or no water.

Poor wash results.

Dishwasher stays in wash cycle.

Dishwasher conveyor will not run.

Cause

Door not closed.

Main power OFF.

Dishwasher OFF.

Dish rack inserted wrong

Solution

Close door completely.

Check breaker on panel.

Turn dishwasher ON.

Check dish rack loading.

Main water supply off.

PRV setting incorrect

Solenoid strainer clogged.

Solenoid valve defective.

Detergent not added to tank

Open supply valve.

Adjust the PRV setting

Clean strainer.

Contact Service Agent.

Check detergent suppy.

Wares incorrectly loaded. in dishrack.

Reposition wares or reduce amount of wares.

Clogged screens .

Clogged spray arms.

Thermostat defective.

Clean screens..

Clean spray arms.

Contact Service Agent.

End plugs missing.

Water temperature low.

Check spray arms.

90-second timer defective

Conveyor jammed or table limit switch has stopped conveyor.

Check incoming water temperature.

Contact Service Agent

Check conveyor for jams

Remove racks from load end of table.

30

Service Replacement Parts

Illustrations Page

Control Panel ................................................................................................................................................ 32

Control Cabinet............................................................................................................................................. 34

Extended Vent Cowls ................................................................................................................................... 36

Wash Tank Door, Panels and Curtains ......................................................................................................... 38

Wash Tank Heat, Float Switch and Scrap Screens ...................................................................................... 40

Wash Tank Junction Box Terminal Block ...................................................................................................... 42

MD-66 Prewash Tank, Door and Curtains .................................................................................................... 44

Fill Piping ...................................................................................................................................................... 46

Final Rinse Piping......................................................................................................................................... 48

MD-66 Prewash Spray Arms ........................................................................................................................ 50

MD-44, MD-66 Wash Spray Arms ................................................................................................................ 52

MD-44 Track Assembly................................................................................................................................. 54

MD-66 Track Assembly................................................................................................................................. 56

MD-44 Pawl Bar Assembly ........................................................................................................................... 58

MD-66 Pawl Bar Assembly ........................................................................................................................... 60

Drive Motor Assembly................................................................................................................................... 62

Conveyor Drive Assembly ............................................................................................................................ 64

Pump/Motor Assembly.................................................................................................................................. 66

MD-44 Pump Installation .............................................................................................................................. 68

MD-66 Pump Installation .............................................................................................................................. 70

Electric Booster Assembly 40°F and 70°F Rise ........................................................................................... 72

MD-44 Drain Assembly ................................................................................................................................. 74

MD-66 Drain Assembly ................................................................................................................................. 76

Dish racks ..................................................................................................................................................... 78

31

Control Panel

11

12

10

8

9 7

8

9

5

5

6

3

4

1

2

1

32

Control Panel

Item

No. Part No.

4

5

6

7

1

2

3

8

9

10

11

12

100097

333533

114768

114767

107440

113622

114758

0512217

0512216

0512218

114506

0512922

Description

SCREW, TRUSS HD., 10-32 X 1/2" SST

COVER, CONTROL CABINET

DECAL 36" CONTROL CABINET 3-HOLE, PW-W-R

DECAL 36" CONTROL CABINET 2-HOLE, W-R (not shown)

THERMOMETER, 8FT. FLANGE (Qty. 1 MD44) (Qty. 3 MD66)

THERMOMETER, 4FT. GAS FILLED (Qty. 1 MD44 Only)

PUSHBUTTON, RED SQUARE

HOUSING, SWITCH

CONTACT BLOCK, N.O.

PUSHBUTTON, GREEN SQUARE

LIGHT, GREEN LED 24V

SWITCH, ON/OFF

Qty.

1

A/R

1

1

3

1

1

1

1

2

2

1

33

Control Cabinet

34

Control Cabinet

Item

No. Part No.

---

---

23

---

20

21

---

22

16

17

18

19

13

---

14

15

24

25

26

27

---

---

---

---

9

10

11

12

7

---

8

---

---

5

6

---

1

2

3

4

180171

108424

0503749

111068

100294

114760

109064

114756

114759

111633

111671

180175

180174

180243

180176

180175

113936

107171

111153

112482

114797

108122

111624

111623

111629

111627

111629

111627

103310

111833

111827

180171

180243

108448

180059

180173

114771

114769

114770

114772

Description

LABEL, TABLE LIMIT SWITCH/ MACHINE RUN

TERMINAL BLOCK, 4-POLE

FUSE BLOCK, 600V 30A

FUSE, 3.5A, LPCC 200-220-230-240/60/3

FUSE, 2.0A, LPCC 460-480/60/3

CONTACTOR, MTR. 12A (Qty. 2 for MD44, Qty. 3 for MD66)

OVERLOAD, MTR. 200-220-230-240/60/3 (.63-1.0A) Drive

OVERLOAD, MTR. 460-480/60/3 (.4-.63A) Drive

OVERLOAD, MTR. 200-220-230-240/60/3 (6-10A) Prewash MD66

OVERLOAD, MTR. 460-480/60/3 (2.5-4.0A) Prewash MD66

OVERLOAD, MTR. 200-220-230-240/60/3 (6-10A) Wash

OVERLOAD, MTR. 460-480/60/3 (2.5-4.0A) Wash

LUG, GROUND

BLOCK, TERMINAL 175A

CONTACTOR, HEAT 60A (Qty. 2 for 40°Rise, Qty. 3 for 70°)

FUSE BLOCK, 600V/60A 200-220-230-240-460-480V WASH

FUSE BLOCK 600V/60A 3P J-TYPE FOR 40°RISE BOOSTER

FUSE BLOCK 600V/100A 3P T-TYPE FOR 70° RISE BOOSTER

TERMINAL BLOCK, 11-POLE

RELAY, 2 POLE 120V

TERMINAL BLOCK, 6-POLE

LABEL, DETERGENT/RINSE AID/VENT FAN

TRANSFORMER, 250VA 200-220-230-240-460-480:120V

RACK CONTROL MODULE

SUPPPORT, PCB

BUS SYSTEM (2-UNIT) FOR MD44

BUS SYSTEM (3-UNIT) FOR MD66

FUSE, 600V/50A J-TYPE 200-220V/60/3

FUSE, 600V/45A J-TYPE 230-240/60/3

FUSE, 600V/25A J-TYPE 460-480/60/3

FUSE, 600V/60A J-TYPE 200-220V/60/3 40°Rise Booster

FUSE, 600V/50A J-TYPE 230-240V/60/3 40°Rise Booster

FUSE, 600V/25A J-TYPE 460-480V/60/3 40°Rise Booster

FUSE, 600V/90A T-TYPE 200-220V/60/3 70°Rise Booster

FUSE, 600V/80A T-TYPE 230-240V/60/3 70°Rise Booster

FUSE, 600V/40A J-TYPE 460-480V/60/3 70°Rise Booster

WIRE HARNESS, MOLEX 8-PIN INPUT

WIRE HARNESS, MOLEX 6-PIN INPUT

WIRE HARNESS, MOLEX 6-PIN OUTPUT

WIRE HARNESS, MOLEX 6-PIN OUTPUT HEAT

Qty.

3

3

3

3

1

3

4

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

3

3

1

1

A/R

1

1

1

1

1

2

A/R

1

1

2

2

1

1

35

Extended Vent Cowls

6

4

3

2

1

8

5

7

9

36

Extended Vent Cowls

Item

No.

4

5

6

7

1

2

3

8

9

Part No.

100073

106026

106482

106014

333092

201589

113828

114622

401487

Description

SCREW, 1/4-20 X 1/2" TRUSS HD., SST

WASHER, 1/4" FLAT

WASHER, LOCK 1/4" SPLIT

NUT, ACORN 1/4-20

SPLASH SHIELD, VENT 8" EXTENDED (MD44, MD66)

DAMPER REGULATOR ASSY.

ROD, CURTAIN 5/16" X 21-1/2" SST

CURTAIN, 21-3/4" X 13-1/4"

VENT STACK 4" X 16"

Qty.

1

1

6

1

1

1

6

6

6

37

12

1

Wash Tank Door, Panels and Curtains

16

4

25

18

20

19

13

18

4

21

14

22

17

7

18

10

15

8

17

9

23

2

6

5

20

19

3

11

1

22

24

(L-R Direction Shown)

38

Wash Tank Door, Panels and Curtains

Item

No.

12

13

14

15

8

9

10

11

4

5

6

7

1

2

3

20

21

22

23

24

25

16

17

18

19

Part No.

100212

108250

109723

113691

113720

113828

308133

317345

328023

331981

333163

333539

333267

329985

113937

113486

100141

100734

106482

106026

106382

108954

106014

113719

114798

Description

SCREW, 10-32 X 3/4" TRUSS HD.

ROD, CURTAIN

CURTAIN, 24" X 6-1/4" (RINSE CURTAIN)

GUIDE, U-CHANNEL, DOOR

CURTAIN, 24" X 20-1/4"

ROD, CURTAIN, 5/16" DIA. X 21-1/2" LG.

BRACKET, DOOR HOOK

BRACKET, DOOR CATCH

BAFFLE, CURTAIN WELDMENT

BRACKET, DOOR STOP

PANEL, FRONT 44" MT-RACK

PANEL, END, FULL MT-RACK

DOOR, 26"

BRACKET, WATER DIVERTER

MAGNET, DOOR

SCREW, 8-32 X 5/8" FLAT HD., SST

NUT, GRIP 1/4-20 SST

BOLT, 1/4-20 X 1/2" SST

WASHER, LOCK 1/4" SPLIT

WASHER, 1/4" FLAT

SCREW, 6-32 X 3/8" TRUSS HD., SST

GRIP NUT, 6-32 W/NYLON INSERT, SST

NUT, ACORN 1/4-20

SWITCH, REED ALEPH

HANDLE, DOOR

Qty.

1

1

1

1

1

1

2

1

2

1

2

2

4

1

1

8

3

1

5

6

1

12

4

6

5

39

Wash Tank Heat, Float Switch, and Scrap Screens

25

26 27

22

21

28

20

28

21

(L-R Direction Shown)

40

16

19

18

17

14 2

12

See Next Page

7

8

C

11

10

5

2

H

23

14 29

H

24

15

C 1

H = High-Limit Thermostat

C = Control Thermostat

6

4

9

4

3

13

Wash Tank Heat, Float Switch, and Scrap Screens

Item

No. Part No.

17

18

19

20

21

---

14

15

16

26

27

28

29

22

23

24

25

4

5

6

7

1

2

3

100154

100547

100740

102376

104882

106013

107089

8

9

107589

108345

10 109069

11 110561

12 113291

--- 111151

13 113516

--- 113517

113518

201041

323430

107440

108418

108417

109034

305163

333078

305164

100097

107966

106014

106482

106026

100141

333088

Description

HEX PLAIN NUT, 5/16-18 SST

LOCKNUT, 1/2" NPT SST

BOLT, HEX HD., 5/16-18 X 1" SST

WASHER, FLAT 5/16", SST

WASHER, FLAT SST

WASHER, LOCK 5/16" SPLIT

HEX PLAIN JAM NUT, 1/2-13 SST

WASHER, LOCK 1/2" SPLIT SST

GASKET, HEATER

THERMOSTAT, CONTROL WITH CAPILLARY

THERMOSTAT, HIGH LIMIT WITH CAPILLARY

FLOAT SWITCH

C-CLIP

HEATER, 15/18.1kW 200-220/3

HEATER, 15/16.3kW 230-240/3

HEATER, 15/16.3kW 460-480/3

WASHER, SPACER

BRACKET, THERMOSTAT

THERMOMETER, 8 FT. FLANGED

PLUG, 1/2" NPT PLASTIC

NUT, 1/2" NPT PLASTIC

GASKET, 1/2" PLUG

SCREEN SUPPORT WELDMENT

FILLER, SCREEN

SCREEN, SCRAP WELDMENT

SCREW, 10-32 X 1/2" TRUSS HD.

NUT, GRIP 10-32 W/NYLON INSERT

NUT, ACORN 1/4-20

WASHER, LOCK 1/4" SPLIT

WASHER, FLAT 1/4"

NUT, GRIP 1/4-20 SST

ENCLOSURE WELDMENT, 3.25" X 12" X 16"

Qty.

1

1

2

1

1

1

1

1

3

6

6

2

1

2

6

4

2

1

4

1

1

2

2

1

1

4

1

8

1

4

3

4

41

Wash Tank Junction Box Terminal Block

6

1

5

4

3

2

1

7

42

Wash Tank Junction Box Terminal Block

Item

No.

4

5

6

7

1

2

3

Part No.

114519

114514

114517

114512

114513

114516

114518

Description

END BLOCK, E/NS 35N

TERMINAL, SINGLE, ST 2.5 WH (WHITE)

TERMINAL, DOUBLE STTB 2.5

TERMINAL, SINGLE ST 2.5 (GRAY)

TERMINAL, SINGLE, ST 2.5 BU (BLUE)

END COVER, SINGLE TERMINAL D-ST 2.5

END COVER, DOUBLE TERMINAL D-STTB 2.5

Qty.

1

1

2

6

2

1

4

43

MD-66 Prewash Tank, Door and Curtains

16

13

12

15 17

18

22

20

19

10

9

8

19

1

11

6

7

3

14

L-R Direction Shown

21

14

12

26

23

22

24

23

25

28

27

29

30

5

4

2

31

44

MD-66 Prewash Tank, Door and Curtains

Item

No. Part No.

16 113486

17 100141

18 317345

19 331981

20 308133

21 333656

22 100734

23 108954

24 329985

25 113937

26 113719

27 114798

28 106382

29 333709

30 333792

31 333088

4

5

6

7

1

2

100547

102376

12 108250

3 104882

106013

106014

107089

107589

8

9

108417

108418

10 109034

11 110854

12 113720

13 113828

14 333645

15 113691

Description

LOCKNUT, 1/2" NPT SST

WASHER, FLAT 5/16"

ROD, CURTAIN

WASHER, FLAT .531" X 1.06" X .062"

WASHER, LOCK 5/16" SPLIT SST

HEX ACORN PLAIN NUT, 1/4-20 SST

HEX PLAIN JAM NUT, 1/2-13 SST

WASHER, LOCK, 1/2" SPLIT SST

LOCKNUT, 1/2" NPT PLASTIC

LOCKNUT, 1/4: PLASTIC

GASKET (1/2" PLLUG)

FLOAT SWITCH, RACK MACHINE

CURTAIN, 24" X 20-1/4"

ROD, CURTAIN, .31"D X 21-1/2" LG.

SCREEN WELDMENT, PREWASH MD66

GUIDE, U-CHANNEL, DOOR

SCREW, 8-32 X 5/8" FLAT HD., SST

NUT, GRIP 1/4-20 SST

BRACKET, DOOR CATCH

BRACKET, DOOR STOP

BRACKET, DOOR HOOK

DOOR, 15" PREWASH

BOLT, 1/4-20 X 1/2" SST

GRIP NUT, 6-32 W/NYLON INSERT, SST

BRACKET, WATER DIVERTER

MAGNET, DOOR

SWITCH, REED ALEPH

HANDLE, DOOR

SCREW, 6-32 X 1/2" TRUSS HD., SST

REFUSE BASKET WELDMENT, MD66

SCREEN FILLER, FRT PW MD66

PANEL, FRONT MD66

Qty.

1

1

6

1

1

1

1

1

6

8

1

1

12

4

2

1

1

2

2

1

1

1

1

1

1

1

3

3

1

1

1

3

45

Fill Piping

24

8

3

10

13

21

19

7

1

20

MD-44

Fill

23

3

2

26

17

26

28

15

4

6

MD-66

Prewash Fill

Only

12

33

29

5

18

16

11

30

9

14 5

22

29

21

6

15

4

16

5

3

11

9

30

Main Water

Connection

3

7

3

25

27

17

18

32

12 From Booster

Outlet

To Booster

Inlet

31

26

(R-L Direction Shown)

46

Fill Piping

Item

No. Part No.

30

31

32

33

---

29

---

---

5

6

---

7

1

2

3

4

100135

100171

100184

100206

100209

100500

900836

100571

8

9

100599

100709

10 101259

11 101397

12 207082

--- 207036

13 102388

14 102392

15 102435

16 102438

17 102442

18 102444

19 102470

20 102505

21 102525

22 102549

23 104429

--- 900837

24 105976

25 107550

26 109879

27 110768

28 111437

--- 109903

111472

109886

109902

108516

201029

206383

333654

114384

Description

GAUGE, PRESSURE 0-60 PSI

BUSHING, RED. FACE 3/4" X 1/2" BRASS

NIPPLE, 3/4" NPT X CLOSE BRASS

NIPPLE, 1/2" NPT X 2-1/2" LG. BRASS

NIPPLE, 1/2" NPT X CLOSE BRASS

VACUUM BREAKER, 1/2" NPT BRONZE

KIT, REPAIR 1/2" VACUUM BREAKER

UNION, 3/4" NPT BRASS

CROSS, 3/4" NPT BRASS

LOCKNUT, 1/2" NPT BRASS

PLUG, 1/8" NPT SQ. HEAD BRASS

NIPPLE, RTOE, 1/2" NPT X 7" LG. BRASS

TUBE, BOOSTER OUTLET, 45" (L-R DIRECTION)

TUBE, BOOSTER OUTLET, FORMED (R-L DIRECTION)

BUSHING, REDUCING 1/2" NPT X 1/4" NPT BRASS

BUSHING, REDUCING, 3/4" NPT X 1/2" NPT BRASS

ELBOW, 1/2" NPT X 90° BRASS

ELBOW, STREET, 1/2" NPT X 90° BRASS

ELBOW, 3/4" NPT X 90° BRASS

ELBOW, STREET, 3/4" NPT X 90° BRASS

NIPPLE, 3/4" NPT 3" LG. BRASS

PLUG, 3/4" NPT, SQ. HEAD BRASS

TEE, RED, 3/4" X 1/2" X 3/4" NPT BRASS

UNION, 1/2" NPT BRASS

VACUUM BREAKER, 3/4" BRASS

KIT, REPAIR VACUUM BREAKER 3/4"

BUSH, RED, 3/4" X 1/2" BRASS

VALVE, PRESSURE REGULATING 3/4" NPT BRONZE

FITTING, COMP 7/8" OD X 3/4" MPT BRASS

STRAINER, LINE 3/4" NPT BRONZE FEMALE

VALVE, SOLENOID 3/4" NPT HW

KIT, REPAIR 3/4" SOLENOID VALVE

COIL, SOLENOID 3/4" 120VAC

VALVE, SOLENOID 1/2" NPT HW

KIT, REPAIR 1/2" SOLENOID VALVE

COIL, SOLENOID 1/2" 120VAC

LOCKNUT, 1/2" NPT NP

TUBE, BOOSTER INLET, FORMED (R-L & L-R DIRECTION)

BRACKET, FILL PIPING SUPPORT

FITTING, COMP 7/8" OD X 1/2" MPT BRASS

Qty.

1

A/R

1

1

3

1

1

A/R

1

1

1

1

2

3

2

2

1

1

2

1

A/R

2

A/R

A/R

1

1

1

1

1

2

2

2

2

2

A/R

2

8

2

1

1

47

Final Rinse Piping

1

6

2

7

4

5

3

4

5

48

Item

No. Part No.

4

5

6

7

1

2

3

100156

108620

111203

113716

113795

114842

0507451

Description

LOCKNUT, 3/4" NPT, BRASS

GASKET, RINSE MANIFOLD, 3/4" PIPING

NOZZLE, VEE-JET #8003

WASH ARM ORING

PLUG, E FINAL RINSE MANIFOLD

MANIFOLD, WELDMENT FINAL RINSE MD-RACK

NOZZLE, RINSE SS H-1/8-W-SS 8006

Final Rinse Piping

Qty.

1

3

2

2

1

1

4

49

MD-66 Prewash Spray Arms

10

6

13

1

5 3

8

8

14

9

11

Rear of Hood

12

4

7

2

50

MD-66 Prewash Spray Arms

Item

No. Part No.

4

5

6

7

1

2

3

100154

100734

102376

106026

106013

106014

106482

8

9

108345

111532

10 333105

11 333460

12 333566

13 333589

14 333712

Description

HEX PLAIN NUT, 5/16-18 SST

BOLT, HEX HEAD, 1/4-20 SST

WASHER, FLAT 5/16" SST

WASHER, FLAT 1/4" SST

WASHER, LOCK 5/16" SST

HEX ACORN PLAIN NUT, 1/4-20 SST

WASHER, LOCK 1/4" SPLIT SST

GASKET, HEATER/STANDPIPE

O-RING

UPPER WASH SUPPORT ROD WELDMENT, MT-RACK

FLANGE WELDMENT, WASH SYS. CONN. MT-RACK

BRACKET, UPPER WASH ADJUSTMENT MT-RACK

MANIFOLD TAPER ASSY. UPPER WASH

STANDPIPE WELDMENT, 1-1/4" OD MD66

Qty.

2

1

1

2

1

2

1

4

4

4

4

4

4

4

51

MD-44, MD-66 Wash Spray Arms

2

4

10

12

20

19

14

7

16

4

6

20

17

7

Rear of Hood

10

8

19

4

20

2

18

15

9

11

1

8

6

3

17

8

13

52

MD-44, MD-66 Wash Spray Arms

Item

No. Part No.

100154

100734

102376

106026

106013

106014

108345

109009

111532

113555

113692

113716

333096

333101

333102

333105

333460

333463

333566

106482

12

13

14

15

8

9

10

11

16

17

18

19

20

4

5

6

7

1

2

3

Description

HEX PLAIN NUT, 5/16-18 SST

BOLT, HEX HEAD, 1/4-20 X 1/2" SST

WASHER, FLAT 5/16" SST

WASHER, FLAT 1/4" SST

WASHER, LOCK 5/16" SPLIT SST

HEX ACORN PLAIN NUT, 1/4-20 SST

GASKET, HEATER/STANDPIPE

HEX GRIP NUT, 5/16-18 SST W/NYLON

O-RING

THREADED PLUG, WASH ARM

SCREW, 3/8" X 3/4" X 5/16-18 SHOULDER

WASH-ARMS O-RING

STANDPIPE WELDMENT 44" MT-RACK

MANIFOLD TAPER ASSEMBLY, UPPER

MANIFOLD TAPER ASSEMBLY, LOWER

UPPER WASH SUPPORT ROD WELDMENT, MT-RACK

FLANGE WELDMENT, WASH SYS. CONN. MT-RACK

LATCH WASH SYS, LOWER MT-RACK

BRACKET, UPPER WASH ADJUSTMENT MT-RACK

WASHER, LOCK 1/4" SPLIT SST

Qty.

16

1

1

1

8

1

16

2

2

2

1

2

4

4

2

8

8

4

4

8

53

MD-44 Track Assembly

16

1

7

2 5

7 6

15

(L-R Direction Shown)

13

54

9

11

14

10

7

3

4

8

12

11

8

Item

No. Part No.

4

5

6

7

1

2

3

100734

100735

100736

100764

106026

106014

106482

8

9

108954

113937

10 327833

11 113719

12 333082

13 333083

14 333094

15 333459

16 333568

Description

BOLT, HEX HD., 1/4-20 X 1/2" SST

BOLT, HEX HD., 1/4-20 X 5/8" SST

BOLT, HEX HD., 1/4-20 X 3/4" SST

SCREW, ROUND HEAD 6-32 X 1/2" SST

WASHER, FLAT 1/4" SST

HEX ACORN PLAIN NUT, 1/4-20 SST

WASHER, LOCK 1/4" SPLIT SST

HEX GRIP NUT, 6-32 SST W/NYLON

MAGNET, REED SWITCH

PIN, IDLE PUMP SWITCH

SWITCH, REED ALEPH

TRACK WELDMENT, FRONT 44" MT-RACK

TRACK WELDMENT, REAR 44" MT-RACK

SWITCH WELDMENT, IDLE PUMP MT-RACK

TRACK LOWER WASH SUPPORT MT-RACK

PLATE, TRACK ADJUSTMENT MD-RACK

MD-44 Track Assembly

Qty.

2

2

1

1

4

2

2

4

2

4

16

8

20

8

8

4

55

MD-66 Track Assembly

17

18

6

7

5

16

1 7

15

5

3

12

(L-R Direction Shown)

11

9

13

14

10

7

1

6

7

5

2

4

8

56

Item

No. Part No.

5

6

7

8

1

2

3

4

100734

100735

100736

100764

106026

106014

106482

108954

9 113937

10 327833

11 333080

12 333082

13 113719

14 333094

15 333459

16 333568

17 333574

18 333575

Description

BOLT, HEX HD., 1/4-20 X 1/2" SST

BOLT, HEX HD., 1/4-20 X 5/8" SST

BOLT, HEX HD., 1/4-20 X 3/4" SST

SCREW, ROUND HEAD 6-32 X 1/2" SST

WASHER, FLAT 1/4" SST

HEX ACORN PLAIN NUT, 1/4-20 SST

WASHER, LOCK 1/4" SPLIT SST

HEX GRIP NUT, 6-32 SST W/NYLON

MAGNET, REED SWITCH

PIN, IDLE PUMP SWITCH

TRACK DEVP. 44" MT-RACK

TRACK WELDMENT, FRONT 44" MT-RACK

SWITCH, REED ALEPH

SWITCH WELDMENT, IDLE PUMP MT-RACK

TRACK LOWER WASH SUPPORT MT-RACK

PLATE, TRACK ADJUSTMENT MD-RACK

TRACK DEVP. PREWASH MD66

TRACK WELDMENT REAR PREWASH MD66