MHP TJK Installation guide

Add to my manuals

32 Pages

MHP TJK Below you will find brief product information to help you understand its capabilities and potential use cases.

Your MHP Gas Barbecue Grill is equipped with the following features:

- Stainless Steel Burner: Ensures durability and longevity.

- Porcelain Cooking Grids: Provides even heat distribution and easy cleaning.

- Porcelain Briquettes: Retains heat and distributes it evenly throughout the grill.

- Sta-Kool Handle: Remains cool to the touch for safe and comfortable handling.

- Grease Cup Holder: Conveniently collects excess grease for easy disposal.

Possible Use Cases:

advertisement

Warranty

—————————————————————

MODERN HOME

P R O D U C T S

—————————————————————–

LIMITED WARRANTY

Modern Home Products Corp. Offers to the original purchaser a Limited Warranty on all aluminum grill components except the 7 year “SearMagic” cooking system. These components will be free from defects in material and workmanship

(excluding paint) when subject to normal domestic use and service. The highest quality paint is used where applicable, but due to various atmosphere conditions, chemicals, fertilizers, care, cleaning and actual use, no extended warranty can be made on paint. Also, for these reasons the limited warranty does not cover rust or aluminum oxidation, unless there is a loss of structural integrity on the grill components.

The Stainless Steel Burner is covered for a period of 7 years, Porcelain Briquettes 5 years, all other grill components for 1 year.

Warranty coverage begins on the original date of purchase, confirmed by return registration card and bill of sale.

Proof of purchase is required to validate warranty.

Any component that proves defective within the warranty period will, if returned to the factory freight prepaid, be repaired or replaced free of charge. Warranties shall not apply, nor will M.H.P. assume responsibility for damages that might result from failure to follow M.H.P.’s instructions, local codes, or when the grill has been tampered with, or altered in any way. M.H.P. shall not be liable for any transportation charges, labor costs, or export duties.

Repair or replacement of a M.H.P. gas grill part does not extend the limited warranty beyond its original term from date of purchase, or begin a new limited warranty period.

This warranty does not include the cost of any inconvenience or property damage due to the failure of the product and does not cover damage due to misuse, abuse, accident, damage arising out of transportation of the product, or damage incurred through commercial use of the products. This express warranty is the sole warranty given by the manufacturer and is in lieu of all other warranties, expressed or implied, including implied warranty of merchantability or fitness for a particular purpose.

ALL WARANTIES are null & void if grills are put into commercial or community use such as by hotels, condominium associations, apartment committees, etc.

Date Warranty Registration Was Mailed___________

MODERN HOME PRODUCTS CORP.

150 S. RAM ROAD

Antioch, IL 60002

MODEL IDENTIFICATION

Your MHP Gas Barbecue Grill is identified by a model number and a serial number located on the left side of the control panel. Always use both the model and serial numbers when contacting Modern Home Products about your grill. For future reference, take the time now to record the model and serial numbers below:

MODEL NUMBER:______________________________

SERIAL NUMBER:______________________________

DATE PURCHASED:____________________________

How to contact us: phone: 1-888-647-4745, fax: 1-800-637-2918, or E-mail: [email protected],

or write: Customer Service

Modern Home Products

150 S. Ram Road

Antioch, IL 60002

To validate your warranty, you need to fill out and send in your warranty card within 10 days. You can either mail or Fax it to us. Or you can fill out the warranty card at our website: www.modernhomeproducts.com.

GENERAL INSTRUCTIONS

This installation guide provides you with easy to follow illustrations and instructions to assemble your

MHP Gas Barbecue Grill.

Before you start assembling and using your MHP

Gas Barbecue Grill we recommend that you read through all precautions, safe guards and instructions to avoid any personal injury or property damage.

Check Local Codes. Contact your local LP dealer or

Natural Gas company for recommended installation procedures and regulations. If there are no local codes, installation must conform to the latest National

Fuel Gas Code: ANSI Z 223.1. For Canada, installation must comply with local codes and/or Standard

CAN/CGA-B-149-1 for natural gas installation and

CAN/CGA- B-149-2 for propane installation.

For LP Gas Models the supplied Gaslow GS-801

Regulator must be used. Any replacement pressure regulator or hose assembly must meet or exceed the specifications of the Gaslow GS-801 Regulator.

For Natural Gas Models the grill is designed to operate at a pressure of 7” water column (W.C.) (1.75 kPa). Check your gas utility for local pressure. Pressures other than approximately 7” W.C. could affect the performance of your grill.

ASSEMBLY INSTRUCTIONS

There are 9 steps to assembling your MHP Gas Barbecue Grill: The mounting, LP tank mounting, control panel, gas supply connection, grill lid, lid handle, side shelves, and rock grate, cooking grid and warming rack.

The grill itself is partially assembled with the Burner,

Venturis, Ignitor Collector Box and the Gaslow Regulator installed.

The JNR and WNK grills are specifically designed to fit the five mounting methods: Cart, In-Ground Post,

Deck/Patio Base, Optimum Console and Built-in. The

TJK Grill is supported by the Optimum Console mounting and Built-in.

You will need the following tools to assemble your grill:

•

A Phillips head screwdriver

•

A standard flat head screwdriver

•

Two 7/16” wrenches or sockets

General Instructions

STORAGE

Turn gas OFF at the LP cylinder (or at the shut OFF valve in the case of Natural Gas) when the MHP Gas

Barbecue Grill is not in use.

Do not store spare LP cylinders under the MHP Gas

Barbecue Grill.

Store disconnected LP cylinders outdoors in a wellventilated area, do not store in shed, building, garage or in any enclosed area.

OPERATING SAFEGUARDS

Do not install your MHP Gas Barbecue Grill in or on recreational vehicles and/or boats.

Never use your MHP Gas Barbecue Grill near combustible surfaces, including roof overhangs, roofs, vinyl siding and window shutters. Maintain at least a 6-foot clearance.

Use this barbecue outdoors in a wellventilated area.

Do not use your MHP Gas Barbecue Grill in a shed, garage, building, breezeway or any other confined area.

Do not use any kind of combustible material on or near the top, bottom, back or sides of the grill. Maintain at least a 2-foot clearance.

Leak test all gas supply line connections.

Do not let children operate a gas grill.

Keep the area around the grill clear of combustible vapors or liquids such as gasoline.

When operating the grill do not leave unattended. Keep children and pets away.

Keep fuel supply hose and electrical supply cord away from any heated surface.

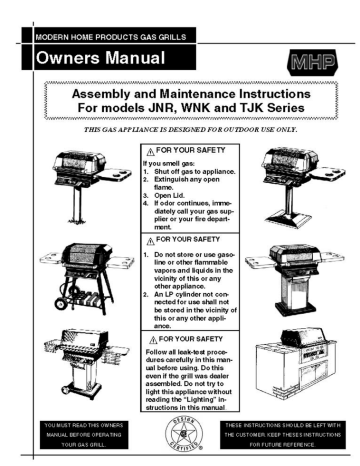

SAFETY

YOUR GRILL IS DESIGNED FOR OUTDOOR USE ONLY.

It should also not be used in an enclosed area such as a shed or garage because combustion uses available oxygen and discharges carbon monoxide.

The grill must be located no closer than 24" from any combustible surface behind or to the sides. Grill should not be located under overhead unprotected combustible surfaces.

Keep the area around the grill clear of combustible materials, flammable vapors or liquids such as gasoline.

Do not obstruct the flow of combustion and ventilation air.

Mountings

Step 2: Built-In Mounting Assembly

IMPORTANT: Since the mounting is attached directly to the grill, you must first partially assemble your grill by attaching the control panel to the grill head (refer to the appropriate grill section for assembly instructions).

Then the built-in mounting heat shield must be attached to the bottom of the grill head using four ¼-20 x

¾" bolts, see fig. 14 “Complete View” illustration.

Do not forget to remove the protective film from all stainless steel parts of your built-in mount.

To assemble the built-in frame (Fig. 17)

1. Align the holes of the right hand “L” bracket with the face panel (the face panel’s 12 vent slots should be on the top) and insert two 1/4 x ¾" Hex bolts and fasten with flat washer, lock washer and nut, do not tighten at this time. When properly connected the grill support tabs on the “L” bracket should be facing up and inward.

2. Repeat procedure to connect the left hand “L” bracket.

3. Attach the rear bracket to both the right and left “L” brackets using two ¼ - 20 x ¾" Hex bolts at each end. Secure bolts with a flat washer, lock washer and nut.

4. Attach the frame to the bottom grill head by aligning the frame support tabs with the grill head bottom holes. Insert the ¼ - 20 x 1 ¼" Hex bolt from inside the grill head and screw it into the threaded frame support tab.

Note: Be certain that the gas pressure is

between 6.5" and 7.5" water column. Excess gas pressure can cause warping and damage to grill head.

6. When finished connecting gas supply, slide grill all

the way into to opening so that the “L” bracket face

flanges fit snuggly to your enclosure face. Drill a

hole in the masonry to match up with the “L” bracket

face flange holes and fasten with lag bolts (not

supplied).

Do not build a shelf below the bottom of the grill. The grill requires an open area for proper ventilation and service access.

7. Install the pre-assembled door kit by securing with a suitable fastening method. (Anchors and/or screws not included.)

When you complete the mount assembly go to the appropriate Grill Assembly Section and fin-

ish assembling the grill head.

To connect the full assembly to the enclosure.

5.

Slide the grill head into the opening 3/4 of the way in. Connect the gas supply using an approved outdoor connector. Check for gas leaks. (See Gas

Leaks page 23.)

JNR & WNK Assembly Instructions

CARTON CONTENTS

Please check to be sure that all parts are included before proceeding with assembly. Contact your local dealer if any parts are missing.

Note: The grill is partially assembled. The Burner, Spider Guards, Venturis, Ignitor Collector

Box are installed. Also, for LP units the Gaslow Regulator and Hose are installed.

MODEL JNR GRILL

Parts Quantity

Top Casting (Grill Lid) 1

Bottom Casting (Grill Head) 1

Sta-Kool Handle 1

Handle End Caps 2

Warming Rack 1

Bottom Grate 1

Porcelain Cooking Grids 1 (SearMagic 2)

Control Panel Brackets 2

Heat Shield 1

Grease Cup Holder 1

Control Panel Assembly 1

Valve Control Knobs 2

Ignitor Knob 1

Side Shelf 1

Side Shelf Bracket 1

Venturi Tube Cleaning Brush 1

Bag of Briquettes (53 pieces) 1

Meat Probe 1

Forked Grid Cleaning Tool 1 (SearMagic Only)

Hardware Quantity

Connecting Wire for Ignitor 1

¼-20 x 1½" Rd. Hd. Sltd. Bolt 4

¼-20 x ½" Rd. Hd. Sltd. Bolt 2

¼-20 x ¾" Hex head Bolts 3

¼-20 x 1" Hex head Bolts 4

¼-20 x 1½" Hex Head Bolt 2

¼-20 KEP Nut 11

Keeper Washer 2

Graphite Washer 2

Flat Washer for Ignitor 1

1/8-27 Jam Connecting Nut 1

Lid Pivot Pin 2

Hitch Pin for Lid 2

MODEL WNK GRILL

Parts Quantity

Top Casting (Grill Lid) 1

Bottom Casting (Grill Head) 1

Sta-Kool Handle 1

Handle End Caps 2

Warming Rack 1

Bottom Grate 1

Stainless Steel Cooking Grids 2 (SearMagic 3)

Control Panel Brackets 2

Heat Shield 1

Grease Cup Holder 1

Control Panel Assembly 1

Valve Control Knobs 2

Ignitor Knob 2

Side Shelf 2

Side Shelf Bracket 2

Venturi Tube Cleaning Brush 1

Bag of Briquettes (63 Pieces) 1

Meat Probe 1

Forked Grid Cleaning Tool 1 (SearMagic Only)

Hardware Kit Quantity

Connecting Wire for Ignitor 1

¼-20 x 1½" Rd. Hd. Sltd. Bolt 6

¼-20 x ½" Rd. Hd. Sltd. Bolt 2

¼-20 x ¾" Hex head Bolts 3

¼-20 x 1" Hex head Bolts 8

¼-20 x 1½" Hex Head Bolt 2

¼-20 KEP Nut 13

Keeper Washer 2

Graphite Washer 2

Flat Washer for Ignitor 1

1/8-27 Jam Connecting Nut 1

Lid Pivot Pin 2

Hitch Pin for Lid 2

TJK Assembly Instructions

CARTON CONTENTS

Please check to be sure that all parts are included before proceeding with assembly. Contact your local dealer if any parts are missing.

Note: The grill is partially assembled. The Burner, Spider Guards, Venturis, Ignitor Collector

Box and the Stainless Steel Handle are installed. Also, for LP units the Gaslow Regulator and

Hose are installed.

MODEL TJK Grill

Parts Quantity

Top Lid Assembly 1

Bottom Casting (Grill Head) 1

Warming Rack 1

Bottom Grate 1

Stainless Steel Cooking Grids 2 (SearMagic 3)

Control Panel Brackets 2

Heat Shield 1

Grease Cup Holder 1

Control Panel Assembly 1

Valve Control Knobs 2

Ignitor Knob 2

Stainless Steel Side Shelf 2

Side Shelf Bracket 2

Condiment Holder 2

Venturi Tube Cleaning Brush 1

Bag of Briquettes (67 pieces) 1

Meat Probe 1

Forked Grid Cleaning Tool 1 (SearMagic Only)

Hardware Quantity

Connecting Wire for Ignitor 1

¼-20 x 1½” Rd. Hd. Sltd. Bolt 2

¼-20 x 1¼” Rd. Hd. Sltd. Bolt 4

10-24 x 1¼” Rd. Hd. Bolt 8

¼-20 x ¾” Hex Head Bolt 3

¼-20 x ½” Rd. Hd. Sltd. Bolt 2

10-24 KEP Nut 8

¼-20 KEP Nut 11

Keeper Washer 2

Flat Washer for Ignitor 1

1/8 – 27 Jam Connecting Nut 1

Lid Pivot Pin 2

Hitch Pin for Lid 2

TJK Assembly Instructions

Grill Head Assembly

Instructions

•

The grill head bottom must be attached to

the mount before starting.

•

It is easiest to work with the grill in the

upright position.

•

Leak test all gas connections before using.

•

Caution: Combustible material should never be within 24 inches of the top, bottom, back or sides of your MHP Gas Barbecue Grill.

Complete View of TJK Grill

IMPORTANT: Most of the TJK Model major component assembly is the same as the JNR/

WNK Models. Please refer to the JNR/WNK assembly instructions as indicated.

Step 1: Control Panel & Heat Shield

(See JNR/WNK instructions on page 15, Fig. 19 & 20)

Step 2: Connect The Gas Supply Line

(See JNR/WNK instructions, item D on page 17, Figs.

25-28)

Step 3: Attaching the TJK Side Shelf

( Fig. 37)

1. Fasten the Shelf Bracket to the Right side of grill head bottom with two ¼-20 x 1¼" Rd. Hd. Sltd bolts and ¼-20 Kep nuts.

2. Attach the Shelf and the Condiment Holder to the

Brackets. All four 10-24 x 1¼" bolts should be inserted into the bracket before tightening them with

10-24 Kep nuts..

(Note: Repeat steps 1 and 2 to attach the other

side shelf.)

Step 4: Attaching the Grill Lid

(See JNR/WNK instructions on page 18, Fig 30.)

Step 5: Grates, Briquettes and Cooking Grids

(See JNR/WNK instructions on page 18, Fig. 32)

Step 6: Warming Rack

(Fig. 38 & 39 )

1. The Warming Rack connects to the grill lid and the grill head bottom. First, insert the right Top and Bottom Rods into their respective mounting holes on right side of the grill lid and grill head bottom. Then slide the RACK to your left, positioning the left Top and Bottom Rods into their respective mounting holes simultaneously. The Lower Right Rod End can then be “popped” into place by flexing it inward.

2. The SearMagic Warming

Rack drops onto the top

edge of the grill head

bottom. The warming rack bracket is positioned be- tween the hinges of the grill head bottom inside back wall.

Before using your grill, leak test all gas line connections. And follow the lighting instructions. See page 23.

Gas & LP Tank Connections

GAS & LP CYLINDER

Check Local Codes

Consult your local LP dealer or Natural Gas Company for recommended installation procedures and regulations. In the absence of local codes, installation must conform to the National Fuel Gas Code, ANSI Z223.1 or CAN/CGA-B149.1 Natural Gas Installation Code or

CAN/CGA-B149.2, Propane Installation Code.

Natural Gas Models

The grill is designed to operate on Natural Gas at a pressure of 7” water column (W.C.) [1.75 kPa]. Check with your gas utility for local gas pressure. Use of your gas grill at pressures other than approximate 7” WC could affect the performance of your grill.

Natural Gas Hose & Inspection

A single hose of not more than 12 feet long (3.6 meters) is supplied with the cart-styled models.

•

Check the hose before each use at places where there could be extra bending, such as near the gas supply quick-disconnect coupling and at the grill valve connection. Look for cracking, cuts or heat damage. Check the entire length for cracking and excessive wear.

•

To replace the hose, turn off gas supply at valve.

Release the quick-disconnect coupling. Using a wrench, disconnect hose from grill valve connection under the control panel, and clean threads.

•

Replace only with an identical hose from the manufacturer or an authorized dealer. Do not use pipe joint compound on the flared fitting at the con-

trol panel grill valve connection.

LP Gas Models

The Grill using a Type ,, LP cylinder includes the

Gaslow Regulator that incorporates an industry exclusive Leak Detector and Fuel Supply Indicator. Any replacement pressure regulator or hose assembly must meet or exceed the specifications of the Gaslow

Regulator.

DO NOT CONNECT THE GRILL TO AN LP

GAS CYLINDER GREATER THAN 20 LB.

CAPACITY.

LP Gas Cylinder Requirements: (The LP-Gas Cylinder is not supplied with your MHP Grill.)

•

The LP cylinder should be equipped with an OPD

(Overflow Prevention Device) and a QCC! Or Type

1 (CGA810) cylinder connection. This cylinder connection is compatible with the grill connection. OPD is an internal mechanical device that limits the amount of liquid propane and prevents overfilling the LP cylinder. The correct filling methods for the filling of your cylinder are by weight or volume, as described in NFPA 58. Please make sure your LP dealer fills your LP cylinder by weight or volume.

Ask your LP dealer to read purging and filling instructions on the LP cylinder before attempting to fill.

•

All LP cylinders supply systems must include a collar to protect the cylinder valve.

•

The LP cylinder must be a 20-LB size (18 1/4 “ high, 12 ¼” in diameter).

•

The LP cylinder must be constructed and marked in accordance with the specifications for LP-gas cylinders of the U.S. Department of Transportation

(D.O.T.). In Canada, gas cylinders must meet Canadian LP Gas Tank Specification Code, National

Standard of Canada, CAN/CSA-B339, Spheres and Tubes for the Transportation of Dangerous

Goods and Commission.

•

Be sure your LP cylinder has a D.O.T. certification and has been tested within five years. This information is usually marked on the protective collar.

WARNING: If you use an LP tank exchange service, be sure that the exchanged tank is equipped with an OPD. If there is not an LP tank available for exchange equipped with an OPD, we recommend that you have your

LP tank filled by an authorized LP dealer.

DANGER

Do not use an open flame to check for gas leaks. Be sure there are no sparks or open flames in the immediate area while you check for leaks. Sparks or flames will result in a fire or explosion which can cause serious bodily injury or death, and damage to property.

Gas& LP Tank Connections

CONNECTING THE LP CYLINDER (Fig. 40)

1. Slip the LP cylinder into the grill LP Tank Mounting.

Position the LP cylinder so that the tank valve receives the regulator without kinking or creating sharp bends in the hose. Secure the tank to the grill base. For cart base models fasten the mounting thumbscrew to secure the tank in place. The Optimum Console base models has the LP Tank Locking Bar to hold the LP Cylinder in place (refer to mounting section for detail).

2. The Gaslow Regulator has a large plastic nut -

QCC-1 fitting - for hand tightening (no tools required) and a RIGHT HAND THREAD (turn clockwise). Connect the regulator to the cylinder by inserting the regulator nipple into the tank valve.

Tighten the large plastic nut CLOCKWISE by

hand until secure.

LP-GAS CYLINDER FILLING & HANDLING

(Continued)

•

Air must be removed from a new LP cylinder before the initial filling. Your LP dealer is equipped to do this.

•

The cylinder supply system must be arranged for vapor withdrawal

•

Always keep and store cylinders in an upright, secure position.

•

Use this grill outdoors in a well-ventilated area. Do not use in a garage, building, or any other enclosed area.

•

Storage of an outdoor cooking gas appliance indoors is permissible only the cylinder is disconnected and removed from the outdoor cooking gas appliance.

•

If the outdoor cooking appliance is not in use, the gas must be turned off at the supply cylinder.

•

Cylinders must be stored outdoors out of reach of children and must not be stored in a building, garage or any other enclosed area.

REMOVAL OF THE LP CYLINDER (Fig. 38)

1. Close the LP tank valve.

2. Unscrew the QCC-1 plastic nut BY HAND COUN-

TERCLOCKWISE (to the left).

3. Loosen the LP cylinder from the Tank Mounting

4. Lift cylinder off.

WARNING: If you exchange your LP cylinder, make sure you get a similar tank in return.

Your exchanged LP cylinder must be equipped with a QCC-1 or type-1 valve and an OPD

(Overflowing Prevention Device). Other LP cylinders may not be compatible with your grill connection.

LP-GAS CYLINDER FILLING & HANDLING

A qualified attendant, who fills the cylinder by weight, should fill your LP cylinder at an authorized LP gas dealer. Improper filling is dangerous.

•

When transporting the LP cylinder be sure the plastic dust cover is in place over the valve. This keeps the valve threads free of dirt.

•

Do not handle the cylinder roughly.

•

Do not apply heat directly to the cylinder.

LP GAS CYLINDERS SAFE HANDLING TIPS

•

Liquid propane (LP) gas is a petroleum product as are gasoline and natural gas. LP gas is a gas at regular temperatures and pressures. Under moderate pressure, inside a cylinder, LP gas is a liquid. As the pressure is released, the liquid readily vaporizes and becomes gas.

•

LP gas has an odor similar to natural gas. Be aware of this odor.

•

LP gas is heavier than air. Leaking gas collects in low areas and prevents dispersion.

•

To fill, take the LP cylinder to your local authorized LP dealer, or look up “gas-propane” in the yellow pages to find authorized dealers.

•

A new LP cylinder must be purged before the first filling. Your LP dealer is equipped to do this.

•

An LP cylinder must be transported, installed and stored in an upright position.

•

LP cylinders should not be handled roughly.

•

Never store or transport an LP cylinder where the temperatures can reach 125 degrees. Never leave an

LP cylinder in a car on a hot day.

•

Always close the LP cylinder valve before disconnecting the tank or any other gas fitting.

•

Always close the LP Cylinder valve after using grill.

•

Do not use a damaged LP cylinder. Dented, rusty or a damaged LP cylinder valve may be hazardous and should be replaced with a new one immediately.

• Never fill the LP cylinder beyond 80% full.

• Do not store a spare LP gas cylinder under or near the grill.

If this information is not followed exactly, a fire causing death or serious injury may occur.

Leak Testing & Lighting Grill

Leak Testing Lighting Your Grill

LEAK TEST ALL GAS CONNECTIONS BE-

FORE USING YOUR GRILL.

DO NOT SMOKE WHILE LEAK TESTING.

DO NOT LEAK TEST WITH A MATCH OR

OPEN FLAME.

DO NOT USE A GRILL THAT IS LEAKING GAS.

YOU SHOULD TEST FOR GAS LEAKS EVERY

TIME YOU DISCONNECT AND RECONNECT A

GAS FITTING.

PERFORM A LEAK TEST EVEN IF YOUR

GRILL WAS DEALER OR STORE ASSEM-

BLED.

DO NOT IGNITE BURNERS WHEN LEAK

TESTING.

LEAK TESTING

1. For LP models, leak test with a full propane cylinder.

2. For systems other than self-contained LP cylinders:

A. The grill and its individual shut-off valve must be disconnected from the gas supply piping systems during any pressure testing of that system at test pressures in excess of 1/2 psi

(3.5 kPa).

B. The grill must be isolated from the gas supply piping system by closing its own manual shut off valve during any pressure testing of the gas supply piping system at pressures equal to or less than 1/2 psig (3.5 kPa).

1. Grill burner control valves should be turned off and the gas turned on at source.

2. Apply soap solution to all gas connections.

To make soap solution, mix together equal

amounts of liquid detergent and water.

3. Soap bubbles will appear if there is a leak.

4. Tighten the connection to make proper seal. And recheck for soap bubbles.

If you cannot stop a gas leak by tightening, turn gas supply off. Take leaking joint apart, clean it, reconnect and test again. If leak persists, contact the dealer or gas utility.

A gas system MUST be tested yearly, or whenever the LP cylinder or any other gas system part is replaced.

ALWAYS OPEN GRILL BEFORE LIGHTING THE

BURNER.

DO NOT LEAN OVER AN OPEN GRILL. KEEP

YOUR HEAD AND BODY AT LEAST ONE FOOT

AWAY WHEN LIGHTING THE GRILL.

IF BURNER DOES NOT LIGHT, IMMEDIATELY

TURN BURNER CONTROL KNOBS TO OFF.

WAIT FIVE MINUTES TO LET GAS CLEAR BE-

FORE YOU TRY LIGHTING AGAIN.

LIGHTING

1. Open Lid. Examine the interior to be sure it appears normal.

2. Turn burner control knobs to OFF position.

3. Turn gas ON at LP tank or supply. Wait 5 seconds for regulator to set itself.

4. Turn either burner control knob to HIGH and rotate the ignitor knob CLOCKWISE several times. One half of the burner should light. Turn the other burner control knob to HIGH and the other half of the burner will light automatically.

5. Check that the burner is lit by looking through the match light hole on the lower right hand side. The burner flame should be a hard blue cone with a minimum amount of yellow flame, although some yellow dust flicks may occur.

6. Close the grill lid and pre-heat the grill for five to ten minutes before cooking.

WARNING: If burner fails to light, turn control knobs

OFF and wait five minutes for gas to clear and try lighting procedure again.

To light burner manually, use a paper book match or other hand held ignitor. Insert match through lower right side match hole. Turn on the RIGHT burner control knob to the high setting. Light burner.

To Extinguish your grill: Turn each burner control knob to OFF position. Turn gas supply OFF at the source.

Maintenance

Annual Maintenance

After a period of nonuse or to keep your grill in top operating condition, you should perform the following maintenance procedures to keep the grill ready for instant use and for your safety.

•

Do not obstruct the flow of combustion and ventilation air.

•

Clean inside the grill head. Remove the burner/ venturi assembly and cover the valve orifices with a piece of aluminum foil to keep out dirt. Brush inside bottom and sides with a stiff wire brush to remove built-up grease and debris. Be careful not to dam-

age the Ignitor or Collector Box.

•

Test the Ignitor for a good spark. (See Rotary

Spark Ignitor System in the General Maintenance section.)

•

The stainless steel burner may be brushed lightly with a stiff laundry brush. Any clogged flame holes may be opened using a thin wire. Use the supplied venturi cleaning brush or a bottle brush, pipe cleaner to clean out the venturis. (See Flashback in

General Maintenance.)

•

Clean the Control Panel, Side Shelf Supports, Lid

Handle Spacers, Lower Cart Frame, Posts with a mild detergent soap and warm water solution. For the Optimum Console use a mild detergent soap and water, Windex or a quality stainless steel cleaner such as MHP’s Stainless Steel Cleaner

(Part #SSC) to clean the column and grill lid facing.

Do Not Use cleaning agents such as bleach, powdered cleansers, steel wool pads or caustic solutions like oven cleaners because they will damage the surfaces.

•

Porcelain cooking grids should be cleaned by first pre-heating the grill on high for ten minutes, lid closed. Then with a brass bristled grill brush clean off the debris. Do Not wash the porcelain grates in a sink or dishwasher. It may ultimately cause the porcelain to chip.

•

Occasional white oxidation on the exterior of your grill head and lid may be washed off with mild soap and warm water.

•

Severe weathering of the grill head and lid can be remedied by lightly sanding or rubbing with steel wool. Then it can be recoated with a high quality heat resistant paint similar to MHP’s BF-1 Paint, available in spray cans from your dealer.

•

Inspect the hose and gas fittings. Remember to leak check every time you disconnect and reconnect a gas fitting.

•

Keep the ventilation openings of the LP cylinder enclosure free and clear from debris.

Warning: Check the hose before each use of the grill for nicks, cracking, abrasions or cuts. If the hose is found to be damaged in any way, do not use the grill. Replace using only MHP authorized replacement hose.

General Maintenance

Flashback

In some areas of the country, spiders and other insects build nests, lay eggs and spin webs in the grill’s venturi tube or valve orifice. This obstructs the full flow of gas to the burner. Some gas backs up resulting in a

“Flashback” - a fire in the venturi behind the control panel which could cause serious bodily injury or damage to your grill.

To remove spider webs and/or other obstructions, you must clean out the venturis. This should be done routinely if the grill has sat idle for extended periods. Also, if you live in an area where spiders are plentiful, you should clean the venturis often, especially in the fall when there is an increase in egg

sack production.

To clean, be sure the grill is cold. Open lid and remove the cooking grids, the briquettes and the briquette grate.

1.

Remove the burner clip holding the burner in place. (See Fig. 42)

2.

Lift burner and venturi assembly out. With supplied cleaning brush, a pipe cleaner or a flexible wire, clean out the venturi tube.

3.

Remove hex head orifice with a 3/8" wrench.

Clean Orifice hole and inner part of the valve with a toothpick. Be careful not to enlarge the orifice hole.

4.

Check orifice receptacle in valve body.

When finished cleaning reassemble the complete unit.

Troubleshooting

Problem Cause Check

Yellow or orange flame and the smell of gas.

Burner does not light or flame is low in

HIGH position.

1.

2.

3.

Blockage in the venturi tube or orifice.

Orifice not seated properly in the venturi Tube.

Bent or kinked hose.

1.

Clean venturi (See section “Annual

Maintenance”.)

2.

Orifice must fit into venturi tube at least ¼” to ½”

3.

Check gas supply line. Also, check all connections.

1.

Could be a kink in the gas supply line.

2.

LP tank could be low or empty.

3.

LP regulator excess flow feature has been activated.

1. Straighten

2.

Refill LP cylinder

3.

Turn grill control knobs off, close LP tank valve and reopen valve slowly.

Wait 5-seconds before turning on grill valves

Erratic flame pattern from burner or flame is low when burner control knob set at

HIGH or flames do not run the whole length of burner.

Dirty burner

Constant flare-ups

Clean burner holes with a small pin. Be careful not to enlarge holes

1.

Grill too cold before start of cooking.

2.

Cooking grate or briquettes may be heavily coated with burned-on grease.

3.

Fatty foods.

4.

Heat setting too high.

5.

Briquettes laid out improperly allowing grease to hit flame.

1. You should always pre-heat grill

for 5 to 10 minutes before cooking.

2. Clean cooking grate. Clean and turn over briquettes.

3.

Trim excessive fat from fatty meats.

4.

Lower heat setting.

5.

Layout briquettes according to instructions on page 18.

Briquettes have turned black.

Food sticks to cooking grid.

Flame blows out.

Dripping grease has Burned-onto briquettes.

1.

Cooking grid is probably too hot.

2.

Food being turned before sear lines are produced.

During periods of high wind and sometimes while cooking on a low setting, flame may be extinguished.

Turn briquettes over. Over time black side of briquettes will self clean.

1. Lower heat setting. Grids, especially

SearMagic transfer heat quickly.

You’ll need to experiment with heat setting to get the best results. Or use a non-stick cooking spray.

2. Time food to turn over only once.

1.

On cart, simply turn away from wind.

2.

Increase the heat setting.

Oxidation Graying of grill head.

Grill does not get hot.

Due to extreme cooking temperatures and severe weather conditions the grill body may bleed through the paint and cause white spotting (Oxidation).

Use a wire brush, sandpaper and wash with mild soap to remove flaking paint and grease. Repaint with high quality heat resistant paint similar to MHP’s BF-1

Paint .

1.

See low flame above.

2.

On natural gas, inadequate pressure at grill.

3.

Incorrect orifice.

1. See low flame above.

2. Check pressure. Should be at or near 7" water column.

3. Check orifice size.

CAUTION: If problems can not be corrected using these methods, contact your local MHP dealer for assistance.

Parts Information

Parts are divided below into lists associated with the three different grill configurations . When ordering a part please provide the grill Identification, part number, quantity and product description. To order contact your local

MHP dealer or MHP’s customer service: phone: 1-888-647-4745, fax: 1-800-637-2918, or E-mail: mhp@voyager.

net for the dealer nearest you.

Item Qty. WNK Part # JNR Part # TJK Part # Description

1 1 GG-TC HH-TC ** Top Casting

2 1 GG-LG GG-LG GG-TLG Logo

3 1 GG-SH HH-SH ** Sta-Kool Handle

4 2 GG-SHC HH-SHC ** Sta-Kool Handle End Caps

5 3 GG-M8 GG-M8 GG-M8 1/4-20 x ¾" Hex Head Bolt

6 2 GG-M30 GG-M30 ** ¼ x 20 x 1½ " Hex Head Bolt

7 2 GGM-4 GGM-4 (10)GG-M13 10-24 Kep Nut

8 1 GG-TS HH-TS GG-TS All Purpose Rack

9 1 GG-BC HH-BC GG-TBC Bottom Casting

10 1 GG-DLB HH-DSB GG-DLB Burner with DV-13 Venturi

11 2 GG-M15 GG-M15 GG-M15 8-32 x 1½" Rd. Hd. Sltd. Screw

12 1 GG-IB GG-IB GG-lB Collector Box & Electrode

13 1 GG-M17 GG-M17 GG-M17 Flat Washer for Ignitor

14 1 GG-JN GG-JN GG-JN 1/8-27 Jam Nut

15 1 GG-Grate-P HH-Grate-P GG-Grate-P Bottom Grate

16 2 GG-SS-Grid (1)HH-Grid GG-SS-Grid Cooking Grids

17 1 GG-BQ3 HH-BQ3 GG-BQ3 Bag of Briquettes (67 pcs.& 53 pcs.)

18 1 GG-GCH GG-GCH GG-GCH Grease Cup Holder

19 1 GG-CP HH-CP GG-CP Control Panel

20 1 GG-VLV32 ** GG-VLV32 Valve #50 Orifice-Nat. Gas

1 ** HH-VLV32 ** Valve #52 Orifice-Nat . Gas

21 1 GG-VLV28 ** GG-VLV28 Valve #55 Orifice-L.P.

1 ** HH-VLV28 ** Valve #57 Orifice-L.P.

22 1 GG-RI GG-RI GG-RI Rotary Spark Generator

23 1 GG-RIW GG-RIW GG-RIW Connecting Wire for Ignitor

24 2 GG-K1O GG-K1O GG-K1O Valve Control Knobs

25 1 GG-K9 GG-K9 GG-K9 Ignitor (Rotor) Knob

26 1 GG-M16 GG-M16 GG-M16 1/4-20 x ½" Hex Head Bolt

27 13 GG-M4 (11)GG-M4 (8)GG-M4 1/4-20 Kep Nut

28 2 GG-SSB (1)GG-SSB GG-SSB Upper Shelf Bracket

29 4 GG-M5 (2)GG-M5 GG-M5 1/4-20 x1½" Rd.Hd.Sltd.Screw

30 4 GG-M4 (2)GG-M4 GG-M4 1/4-20 Kep Nut

31 2 GG-SS

II

(1 )GG-SS

II

GG-SST Side Shelf

32 4 GGM62 (2)GGM62 ** ¼ x 20 x 1¼" Phillips Head Bolt

33 4 SW1 (2)SW1 ** ¼ x 20 Lock Washer

34 1 GG-M31 GG-M31 ** Graphite Gasket

36 4 GG-M26 (2)GG-M26 (8)GG-M26 10-24 x 1¼" Rd. Hd. Screw

66 1 GS-801 GS-801 GS-801 Gaslow Regulator, L.P. Hose Assy.

68 1 GG-M25 GG-M25 GG-M25 Label (L.P,-Nat.) A.G.A.

70 2 GG-LPP GG-LPP GG-LPP Lid Pivot Pin

71 4 GG-LPP-1 GG-LLP-1 GG-LPP-1 Hitch Pin for Lid & Burner

76 1 BR-VTC BR-VTC BR-VTC Venturi Tube Cleaning Brush

77 2 BR-SG BR-SG BR-SG Spider Guards

81 1 GG-DEF HH-DEF GG-DEF Heat Shield

82 1 BR-MPI BR-MPI BR-MPI Meat Probe

83 2 GG-CPB GG-CPB GG-CPB Control Panel Brackets

84 2 GG-M61 GG-M61 GG-M61 ¼ - 20 x ½" Phillips Head Bolt

85 2 GG-M62 GG-M62 GG-M62 ¼ - 20 x 1¼" Phillips Head Bolt

TJK Lid and Upper Side Shelves Parts Not listed above (See Inset Illustrations)

T1 2 GG-TEC Aluminum End Cap

T2 1 GG-TLG Optimum Logo

T3 1 GG-TSH Stainless Steel Handle

T4 12 GG-M60 ¼ x 10 x ¾" Phillips Truss Screw

T7 10 GG-M13 10 x 24 Kep Nut

T32 1 GG-TSl Stainless Steel Lid

T33 2 BR-CH Condiment Holder

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement