advertisement

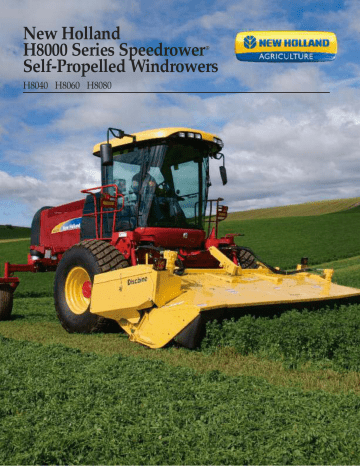

New Holland

H8000 Series Speedrower

®

Self-Propelled Windrowers

H8040 H8060 H8080

H

igh speed and high capacity

2

Model

H8040

H8060

H8080

Engine

126 hp, 4-cylinder

190 hp, 6-cylinder

226 hp, 6-cylinder

Cab

Deluxe

Deluxe

Deluxe

Disc Headers

NA

13 or 15.5 ft.

13, 15.5 or 18 ft.

A V A I L A B L E H E A D E R S

Sickle Headers HB Series Draper Headers

12, 14, 16, 18 ft.

21, 25, 30, 36 ft.

12, 14, 16, 18 ft.

12, 14, 16, 18 ft.

21, 25, 30, 36 ft.

21, 25, 30, 36 ft.

H8000 Series windrowers give you unsurpassed power, header capacity and control.

No matter what the crop—alfalfa, grass, small grains, canola, barley, lentils or peas—New Holland H8000

Series Speedrower ® windrowers deliver capacity that can’t be matched by other machines. H8000 models range from 126 hp to an industryleading 226 hp. And, the control achieved with the H8000 windrowers takes your productivity to a new level.

Turn the page to learn more about these best-in-class features. Then visit the haymaking specialists at your local New Holland dealer to learn more about the H8000 Series windrower model that’s right for you.

Superior disc, sickle or draper headers

New Holland Speedrower selfpropelled windrower power allows you to drive the widest variety of headers, including an industryleading 18-foot Discbine ® header.

New Holland offers a large selection of draper headers—from 21 to 36 feet wide. And, New Holland Haybine ® sickle headers, the recognized leader for quality hay, have a legendary history of top cutting and conditioning performance.

Industry-leading comfort and control

H8000 Series models feature a

Deluxe cab that spoils you with outstanding comfort, visibility and control. But that’s just a start. You get an unsurpassed smooth ride and superior header control with a long list of industry-leading features, including independent rear axle suspension, Comfort Ride™ cab with suspension, an independent hydraulic header flotation system and in-cab windrow shield adjustment.

3

4

I

nnovation: The New Holland legacy continues

H8000 Series windrowers offer a fresh approach to high performance.

Year after year, New Holland windrowers set the standard for highvolume, quality haymaking. The new

H8000 windrowers are no exception, offering improvements and innovations that lead to phenomenal capacity and in-field control.

Highest horsepower and the widest disc cutting

New engines deliver lower emissions and all the power you expect from a Speedrower windrower, including the highest horsepower windrower in the industry—the

H8080 at 226 hp. That’s the power you need to achieve high-speed disc cutting at its most extreme, with

New Holland’s 18-foot Discbine header. It gives you the all-out cutting capacity of 14 discs, to efficiently cut large acreages down to size.

flotation system on models H8060 and H8080 allows you to adjust the right and left side of the header separately, without leaving the cab. You can make on-the-fly flotation adjustments to compensate for variable cutting conditions, such as cutting on hillsides or on the top of irrigation borders.

Independent rear axle suspension

This patented axle suspension option improves your speed and efficiency on uneven terrain. Separate left- and right-hand axle members oscillate independently against adjustable, pressurized air suspension, providing an exceptional ride.

This improves your field speed and increases your productivity while still protecting the windrower tractor frame from harsh field terrain.

Comfort Ride cab suspension

Here’s another feature that takes the bumps out of your ride. The unique Comfort Ride cab suspension system cushions you from chassis motion. The four-point suspension includes iso-mounts on the front and coil springs over shocks at the rear.

This allows you to take full advantage of high-speed cutting without taking the abuse of rough ground conditions. The Comfort Ride suspension also allows you to work across pivot irrigation tracks without getting jostled in your seat.

MowMax™ cutterbar peace of mind

HD Discbine headers feature the new MowMax™ cutterbar. This is the latest true modular cutterbar innovation from New Holland, designed to reduce operating costs and downtime. The MowMax cutterbar, featuring the new ShockPRO™ cutterbar protection system, improves durability. See page 10 for more details.

The independent rear axle suspension option reduces operator fatigue and stress on the machine.

Standard Comfort Ride cab suspension offers best-in-class operator comfort.

In-cab windrow shield changes

Optional, electric windrow shield adjustment gives you constant control of windrow formation from the cab so you can quickly respond to field and crop conditions. Shield position is shown on the electronic display.

The swath gate maintains its independent manual control.

Control flotation from the cab

The independent hydraulic header

Dual switches in the H8060 and H8080 cab allow you to control the flotation of the left and right side of the header independently.

5

T

he power that puts the speed in Speedrower

Exceptional horsepower and easy maintenance keep you in the field instead of at the shop.

H8000 Series Speedrower windrowers offer abundant horsepower to run the header you select and deliver power on demand when conditions require. For the ultimate in power, choose the model that leads the industry in horsepower—the new

226-hp H8080.

Efficiency boost

Full-flow turbochargers and airto-air intercooler are standard on all

H8000 Series windrower engines, providing quick response and high fuel efficiency. The air-to-air intercooler cools air without adding heat to the engine cooling system to improve air density and combustion efficiency.

And, all H8000 Series engines are

Tier III–emissions certified to go easy on the environment.

6

• Two 12-volt, 650-CCA, maintenance-free batteries

• 120-gallon fuel tank

• 150-amp alternator

190-hp H8060 / 226-hp H8080

Six-cylinder turbocharged engines:

• 411 cubic-inch (6.7 liter) displacement engines

• Electronically controlled, highpressure, common-rail fuel injection system

• Four valves per cylinder

126 hp H8040

Four-cylinder turbocharged engines:

• 274 cubic-inch (4.5 liter) displacement engine

• Mechanically controlled fuelinjection system

• One 12-volt, 925-CCA, maintenance-free battery

• 120-gallon fuel tank

• 150-amp alternator

Easy service access

New Holland makes maintenance and refueling easy. You can reach the fuel fill point right from the ground— unlike other windrowers that require you to climb up steps. Reaching the engine and drive system is easy, too.

Simply lift up the side shields and you have complete access to routine maintenance points, including filters and fluid level check points.

Easy-lift side shields provide quick access to fluid reservoirs and fill points.

The rear screen opens easily for convenient servicing of the air-conditioning condenser, hydraulic oil cooler, radiator and intercooler.

The rotary screen precleaner reduces debris build-up on the rear screen by using the vacuum generated from the engine fan to continuously sweep the screen.

7

8

B

est-in-class comfort and control

Deluxe Comfort Ride cab features roomy dimensions and state-of-the-art controls.

H8000 Series windrowers reward you with a spacious, state-of-the-art work area offering comfort, convenience and high-performance features.

More space

The deluxe H8000 cab provides plenty of storage space, lots of legroom and the added comfort of built-in footrests. The spacious entry platform also features an outside, lockable storage box, easily accessed from ground level.

An extra-smooth ride

The Comfort Ride cab with suspension is standard equipment. Front iso-mount supports and coil springs over shocks with a lateral anti-sway bar at the rear support points give you the smoothest ride possible.

Better visibility

A tinted, curved-glass windshield enhances visibility to the header and provides an outstanding overall view.

The enhanced exterior lighting system includes six front lights, two stubble lights and two rear lights, allowing you to work productively even when darkness falls.

Floating operator console

The right-hand console “floats” with the seat whenever the seat is adjusted, so the controls always stay in the same position relative to your hand. The console is also independently fore-and-aft adjustable, providing the ability to perfectly match your personal comfort preferences.

Perfect comfort

The deluxe air-ride, fabric-covered operator seat offers three fore/aft adjustment ranges and includes a fore/aft isolator, lumbar adjustment and ride dampening. And, the threeway adjustable steering wheel can be telescoped and tilted at both floor and knee levels. The comfortable instructor’s seat is also standard equipment, and it folds out of the way when not needed. The high-capacity air-conditioning and heating system includes ten air vents for maximum air flow control. The dual cab air filtration system includes a fresh-air external filter and an in-cab recirculation filter.

Improved control

The Propulsion Control Lever is extremely comfortable to use and provides precise control of speed and direction. A dual-speed hydrostatic transmission provides expanded speed choices and infinitely variable speed control.

More conveniences

Both hydraulic header tilt and header power reverser are standard equipment. Add the optional electricadjust mirrors and you can make adjustments from inside the cab. You can view the crop while in the field and quickly change to view the road when traveling to another field.

More options

For the ultimate in convenience and comfort, the Deluxe cab upgrade includes these factory-installed features:

• Automatic Temperature Control

(ATC) with set-and-forget temperature control

• An “A” pillar information display with fuel level and coolant temperature bar graphs as well as six additional warning lights

• Front and rear sunscreens

• Four matched premium speakers instead of the two standard speakers

The floating operator console moves along with the seat to keep you comfortably in control at all times.

The deluxe performance monitor provides four lines of display space to keep you informed.

Get expanded information at a glance with this optional “A” pillar information panel (included in the Deluxe cab upgrade).

9

S

atisfy your need for speed

Discbine headers with MowMax™ cutterbar fly through acres of heavy crop.

You can knock down big hay acres in a hurry with the speed and high capacity of New Holland Discbine disc headers.

Redefine high-volume haymaking

The new 770HD Discbine disc head uses the capacity of 14 high-speed discs to take down 18 feet at a time, making it the widest disc header on the market. Match it to the 226-hp

H8080 windrower and you’ll speed through the toughest, heaviest crops in less time. The 12-disc 750HD header matches with either the H8080 or

H8060 windrowers to slice through

15-1/2 feet at a clip. For haymakers working in moist climates that make drydown difficult, consider the

10-disc 720HD header that provides a narrower 13-foot cutting width.

Also compatible with either the

H8080 or H8060, the 720HD provides a narrower operating and transport width, making it easier to maneuver in smaller fields, through tight gates or narrow lanes.

True modular MowMax™ cutterbar design

These high-performance Discbine headers feature the new MowMax™ modular disc cutterbar design that’s durable and so easy to service. Each disc is driven by an individually sealed gearbox with a dedicated oil reservoir. There’s never an oil starvation issue, even with continuous cutting on an incline. Additional durability, including heavy cast rock guards, hardened alloy drive shafts, replaceable skid shoes, and superior lubrication is built into the design.

And, you gain extra peace of mind knowing that, if an internal driveline component does fail, damage will

10 remain isolated due to the

MowMax™ true modular design.

The ShockPRO™ difference

MowMax cutterbars are equipped with ShockPRO™ hubs that protect the internal cutterbar driveline from shock loads caused by impact with a foreign object. The ShockPRO hubs absorb the shock of an impact before damage to drive components can occur. If a ShockPRO hub fails, it can be easily replaced in under 10 minutes and at minimal cost.

The New Holland

ShockPRO™ hub heads off potential damage to gears and shafts. If a

ShockPRO hub fails, it can be replaced quickly with minimal cost, without requiring removal of the sealed hub. It saves you hassle, time and repair costs.

Cleaner MowMax cutting

The new MowMax cutterbar features thinner, lower-profile rock guards to allow closer cutting at a flatter cutting angle. The new cutterbar design also improves the straightness of the cutterbar, allowing it to run more lightly on the ground for

Disc Header Model 720HD

Matches

Windrower

750HD 770HD

H8060 or H8060 or H8080

H8080 H8080

Cutting width 13 ft.

Number of discs 10

15 ft., 5 in. 18 ft.

12 14 less wear, less damage and more consistent cut height. A broad, offering of cutting knives includes standard

14-degree twist knives, 7-degree twist knives, special-design rock knives, and 14-degree twist, serrated knives.

Rock knives are specifically designed for improved life when operating in extremely stony conditions. Serrated knives are ideally suited for sandy soils or abrasive operating conditions, providing long life in these harsh working environments. All knives are reversible for double the cutting life.

Smooth crop flow

From the discs, crop is delivered smoothly to the 20-inch diameter, floating auger (750HD and 770HD only). The feed auger stretches nearly the full width of the cutterbar, from the center of each outside disc, efficiently moving the crop away from the cutterbar and delivering it evenly to the conditioning rolls. Standard,

102-inch-length, chevron-design rolls gently and thoroughly condition crops. The 750HD and 770HD disc

The proven New Holland torsion-bar roll pressure system, featuring wide chevron rubber rolls, applies near-constant pressure for consistent conditioning, no matter how thick the crop, without plugging.

heads also provide additional conditioning alternatives. Either of these highly productive heads may be fitted with optional, high-contact chevron rolls, optional slatted steel rolls, or the conditioner module may be removed entirely, providing you with an outstanding range of available crop conditioning choices.

Fast adjustments

You can place crops as wide as a

96-inch swath or as narrow as a 38inch windrow—or any width in between. No tools are required to make width adjustments, and if you add the optional electric windrow shield adjustment feature, you can make changes without leaving the cab. New Holland makes adjusting roll pressure easy, too. A simple hand crank allows you to adjust conditioning aggressiveness. Likewise, roll gap adjustment is simple and precise.

One easy adjustment at each roll end completes the job in no time!

Hydraulic Header tilt

To make a cut-height adjustment, simply use the tilt switch on the multi-function handle. With a glance through the front windshield you can quickly observe the header tilt angle indicator located on the header top link on the H8040, or at the left side of the platform on the H8060 and

H8080 (also optional on H8040).

Power reverser

You can expel crop slugs without leaving the cab. At the touch of a button, the conditioning rolls, auger and discs reverse to remove plugs in seconds.

Multiple crops

If you cut crops that don’t require conditioning, you can easily remove

The new MowMax cutterbar is a truly modular design with independent sealed disc modules.

Durability is built into the design with heavy cast rock guards, hardened alloy drive shafts, replaceable skid shoes and superior lubrication.

the conditioning rolls on the 750HD and 770HD disc heads. You can also exchange the disc header with either the HS Series sickle header or HB Series draper header in about 30 minutes without tools, making New Holland windrowers perfect for custom operators and multi-crop growers.

New crop merger attachment

The new, rugged, dual-windrow merger attachment from New Holland allows you to place two windrows side by side, increasing forage crop volume for today’s high-capacity forage harvesters. In-cab adjustments for merger belt speed and the deflector position let you effortlessly place the windrows exactly the way the forage harvester operator wants, to optimize harvester productivity.

Lowering and lifting the merger is also handled from the cab. When fully lowered, the merger rides only a few inches above the ground to catch all the crop. If a field obstruction is encountered, the robust design allows the merger to float up and over, then automatically return to its original operating position, without operator assistance. It’s also easy to switch between single windrows and merging windrows. When windrow merging is not required, the merger tucks up tight and out of the way under the windrower frame with industry-leading clearance, eliminating the chance of catching a windrow while crossing uneven terrain or other windrows on headlands. An endless merger belt takes the worry out of belt maintenance. A V-guide on the inside of the belt ensures the belt will track evenly no matter how heavily it’s loaded.

SP Windrow Merger Attachment Specifications

Header compatibility 2355, 2358, 750HD, 770HD Discbine headers with conditioning system

Conveyor belt speed range, mph (k/h) 7 to 13 (11.3 to 21)

Conveyor frame length, in (mm) 77.4 (1966.2)

Conveyor frame width, in (mm)

Conveyor belt width, in (mm)

Conveyor belt length, in (mm)

Belt roller diameter, in (mm)

Ground clearance, operating, in (mm)

89 (2260.5)

42 (1066.8)

84.6 (2150) center to center of rolls

4 (101.6)

Adjustable, 5 (127) recommended

Note: continuous ground contact is not intended

Ground clearance, transport, in (mm)

Weight, shipping, lb (kg)

Weight, operating, lb (kg)

28 (711)

1125 (510.3)

976 (443)

11

12

T

he H8040 Prairie Special

A customized Speedrower model for high-capacity grain swathing.

The H8040 Prairie Special cuts big acreage down to size fast.

New Holland has “custom-made” this swathing machine with the features most requested by prairie grain-swathing customers, including:

• Deluxe cab upgrade package

• Front windshield wiper/washer

• In-cab speed control for reel and canvas speeds

• Engine cold start

• Center-delivery draper package

• 18.4R-26 R1 drive tires

• Fixed-position crop shields

The H8040 Prairie Special gives you efficient cutting, smooth feeding and unmatched grain swathing control. Hydraulic knife, reel and draper belt drive mean smooth operation and maximum in-cab adjustment.

You get “on the go” control of header flotation, reel speed and knife angle, and a push-button return-to-cut feature after each pass.

You stay productive even when the sun goes down since you have plenty of illumination to see both the header and after-cut.

S

mooth swathing control

HB Series draper headers give you complete control of cutting, feeding and swath delivery.

Pair an HB Series draper header with any H8000 Series windrower and you get unmatched swathing control. HB headers are ideal for swathing small grains, canola, forage and specialty crops.

Interchangeable headers

Choose from four cutting widths—

21, 25, 30 or 36 feet. You can easily match any HB Series draper header to any New Holland H8000 Series

Speedrower windrower model.

Efficient cutting

Schumacher epicyclic, hydraulic drive, planetary-reduction sickle drives are used on all HB Series heads. Choose the cutterbar system you need to harvest the crops in which you work—the New Holland double-knife drive cutterbar or the

Schumacher cutterbar system which is available in single- or double-knife drive.

Reel options

You can tailor your HB Series draper header to match your needs.

Select from three reel options to match your crops and conditions:

• 5-bat pick-up with plastic fingers

• 6-bat pick-up with steel fingers

• 6-bat pick-up with plastic fingers

Smooth, even feeding

Strong 42-inch wide, heavy-duty draper belts with molded V-guide feed crop evenly to ensure consistent, uniform crop flow. You can choose either center delivery or double swath delivery to match your needs on the

25-, 30- and 36- foot models. Double swath heads feature shiftable decks that allow center- or end-windrow delivery for doubling of windrows.

Easy adjustments

It’s easy to adjust reel speed and draper speed to adapt to different crop conditions. In-cab hydraulic reel speed adjustment and draper speed adjustment are standard equipment.

You can change knife angle using the hydraulic tilt cylinder.

Return-to-cut feature

When cutting above ground level,

New Holland Speedrower windrowers equipped with draper head operating packages allow you to position cut height cylinders on each lift arm, making it a snap to return to your pre-set cutting height after each pass. A simple push of a button in the cab is all that’s required to reposition the cut height cylinders. You can also adjust the right- and left-hand cylinders separately to produce a stubble pattern that retains more windblown snow and its valuable moisture.

Model

21HB

25HB

30HB

36HB

Cutting Width ft. (m)

21 (6.4)

25 (7.6)

30 (9.1)

36 (11)

Weight lbs. (kg)

3,500 (1588)

3,900 (1769)

4,650 (2109)

5,085 (2306)

Material Delivery

Double Swath

Center or Double Swath

Center or Double Swath

Center or Double Swath

Fixed-position crop deflector shields protect the drives without restricting heavy or wide windrows.

Optional rear weight bracket and weights may be installed on any H8000 model to balance heavy or wide heads.

Adjustable cut height cylinders on each lift arm make it easy to return to the pre-set cutting height after each pass.

14

R

eliable, clean, cutting with

Haybine headers

HS Series sickle headers deliver time-proven mowing and conditioning performance.

For smooth, clean auger/sicklebar hay cutting, choose a 12-, 14-, 16- or

18-foot Haybine header to match your capacity needs.

38- to 96-inch windrows

No matter which width HS Series header you choose, you can lay down a swath as wide as 96 inches or a windrow as narrow as 38 inches to match crop and weather conditions.

There’s no need for tools to change from swath to windrow or back. Add the electric windrow shield adjustment option for control of windrow formation from the cab.

Fast, counter-stroking sickles

You get high-capacity cutting performance from the fast, 1810-spm sickle speed and a full, 3-inch stroke.

Dual counter-stroking sickles with reliable modular wobble drive assure smooth cutting with minimum vibration and maintenance. Bolt-on, over-serrated knife sections provide long cutting life and easy replacement, and adjustable knife holddown clips speed maintenance.

Consistent feeding

The fully adjustable five-bat reel sweeps crop smoothly to the exclusive floating auger. This 20-inch auger with 5-inch flighting floats up to

2 inches to handle heavy crops and delivers crop evenly to the conditioning rolls.

Proven conditioning action

New Holland chevron-design, intermeshing rubber rolls are known for their thorough conditioning and fast drydown. The proven torsion-bar roll-pressure system applies nearconstant pressure through the wide

102-inch rolls and allows the rolls to open automatically when needed to clear slugs of material without stopping. No tools are needed to adjust conditioning roll pressure. Highcontact chevron rolls are also available.

Heavy-duty wobble drives provide reliable, trouble-free operation.

A

Side shields flip up and lock in place for easy maintenance.

B

Use this handy crank (A) to adjust roll pressure— no tools needed. A roll pressure indicator (B) is also provided.

15

G

rass seed savers

New Holland Specialty Headers deliver fast cutting in delicate crops.

New Holland offers two header choices that have been specifically developed to bring legendary

Speedrower windrower performance and reliability to delicate crops that don’t require conditioning, including grass seed, mint and flower seed. Designed by New Holland engineers and built with genuine

New Holland parts, the 750HD disc and 14HS sickle Specialty headers are also backed by New Holland’s one-year factory warranty.

New 750HD Specialty disc header

The new 750HD Specialty head for the H8060 and H8080 windrowers provides the latest in specialty crop productivity, while handling delicate crops with kid gloves. This head features the MowMax™ cutterbar with a 15’5” cutting width, and is specifically designed to cut cleanly, make consistent, evenly formed windrows, minimize seed loss, and deliver significantly more throughput capacity than sickle heads. The curtain push bar allows the head to gently engage tall crops, minimizing seed loss. If not needed, the curtain can be quickly stored out of the way on the head without restricting operator visibility. The crop is cut with the adjustable disc speed, MowMax cutterbar, then gently, but positively moved to the center discharge opening by the specially designed, floating auger. The crop discharge opening can be set at

60 or 83 inches to tailor windrow width to your needs. For specific crop conditions, a special curtain can be installed above the cutterbar in seconds, and without tools, to keep the crop flowing smoothly.

14HS Specialty sickle header

Built-in features allow the 14HS to deliver clean cutting in damp, heavy or tangled conditions and gently windrow delicate seed crops for maximum seed retention. A fully adjustable 6-bat reel with standard hydraulic reel drive allows you to make “on the go” reel speed adjustments from the cab. Stub guards with quick-adjust hold downs allow for efficient cutting action in wet or dense undergrowth. Hydraulic-driven, dual, counter-stroking sickles are belt-timed for a swift 1828-spm knife speed for fast, clean cutting. Five-position adjustable skid shoes allow you to set the cutting height quickly, without tools. Auger speed is reduced to

196 rpm for gentle handling of valuable seed crops.

The wide opening in the header floor behind the cutterbar allows for gentle crop collection and windrow formation with the assistance of windrow forming rods.

Hydraulic-driven, dual, counter-stroking sickles are belt-timed for a swift 1828-spm knife speed for fast, clean cutting.

16

S

pecifications

H8000 Series Self-Propelled Windrowers

MODEL

Engine

Rated horsepower, hp (kW)*

Fuel injection pump

H8040

H8040 Prairie Special H8060 H8080

New Holland 4-cylinder

274 cu. in. (4.5 L)

Mechanical

New Holland 6-cylinder

411 cu. in. (6.7 L)

New Holland 6-cylinder

411 cu. in. (6.7 L)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Turbocharged with air-to-air intercooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

126 (94) @ 2300 rpm 190 (142) @ 2200 rpm 226 (168) @ 2200 rpm

Electronically controlled high-pressure common rail

Electronically controlled high pressure common rail

1, 12-volt 925 CCA / 150 amp

120 (454)

2, 12-volt 650 CCA / 150 amp

120 (454)

2, 12-volt 650 CCA / 150 amp

120 (454)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batteries / alternator

Fuel capacity, gal. (L)

Rotary radiator screen cleaner

Transmission

Final drive

Steering

Speed range, mph (kph)

Length, in. (mm) with header

less header and lift arms, in. (mm)

Height, in. (mm)

Wheelbase, in. (mm)

Front tread width, in (mm)

Rear tread width

(adjustable), in. (mm)

Rear axle suspension

Tractor weight, lbs. (kg)

Rear axle tires

Rear axle ground clearance

Header drive

Header flotation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dual range hydrostatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Double reduction planetary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydrostatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0–10.6 (0–17) working** 0–12.5 (0–20) working*** 0–12.5 (0–20) working***

0–15.8 (0–25.4) road** 0–18 (0–29) road*** 0–18 (0–29) road***

283.1 (7192) with HS Series

205.2 (5213)

134.1 (3415)**

138 (3494)

127 (3225)**

269.5 (6847) with 2355

205.2 (5213)

136.1 (3456)***

138 (3494)

130.2 (3308)***

269.5 (6847) with 2358

205.2 (521)

136.1 (3456)***

138 (3494)

130.2 (3308)***

90–105–120 (2286–2667–3048) 90–105–120 (2286–2667–3048) 90–105–120 (2286–2667–3048)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10,745 (4874)**

14L x 16.1 8PR

11,365 (5155)***

14L x 16.1 8PR

11,365 (5155)***

14L x 16.1 8PR

35.7 (908) with 18.4 x 26 front tires

35.7 (908) with 18.4 x 26 front tires

38.8 (986) with 23.1 x 26 front tires

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic (in-cab adjustable) . . . . . . . . . . . . . . . . . . . .Independent hydraulic flotation . . . . . . . . . . . . . .

(flotation weight at each end of header independently controlled from cab)

Header Tilt

Hydraulic

Header power reverser

Adjustable windrow shields

In-cab windrow-width adjustment

Single lever header transport lock system

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cab

Cab suspension

Cab air filtration

Seat

Instructor seat

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Deluxe, curved tinted glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . Dual: 1 external air filter and 1 in-cab recirculation filter . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . Deluxe air suspension seat with fore / aft lumbar adjuster, ride dampening . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*Manufacturer's rating per ECE R120 / ISO 14396 **with 18.4 x 26 tires ***with 23.1 x 26 tires

HEADER COMPATIBILITY

HEADERS

H8040

H8060

H8080

•

•

•

Sickle Hay Headers

12HS* 14HS 16HS 18HS

12 ft., 3 in.

14 ft., 3 in.

16 ft., 3 in. 18 ft., 3 in.

•

•

• •

•

•

•

•

•

*12-foot header requires 16.9 x 28 drive tires **not compatible with 23.1 x 26 drive tires

Disc Hay Header

•

720HD** 750HD

13 ft.

770HD

15 ft., 5 in. 18 ft.

•

NA

•

•

NA

•

NA

NA

Draper Headers

•

•

•

21HB** 25HB

21 ft.

25 ft.

•

•

•

•

•

•

30HB 36HB

30 ft.

36 ft.

•

•

•

17

S

pecifications

Sickle Headers

MODEL

Cutting width, ft. in. (m)

Overall width, ft. in. (m)

Weight, lb. (kg) – rubber rolls

Cutterbar

Type

Knives

Guards

Angle range, degrees

Skid shoes

Cutting height, in. (mm)

Sickle drive

Type

Speed, spm

Stroke, in. (mm)

Reel

Type

Adjustments

Speed

Mechanical drive, rpm

Hydraulic drive (optional), rpm

Speed adjustment

Diameter, in. (mm)

Drive

12HS

12' 3" (3.73)

14' 3" (4.34)

3630 (1647)

14HS

14' 3" (4.34)

16' 3" (4.95)

3900 (1770)

14HS Specialty

14' 3" (4.34)

16' 3" (4.95)

3180 (1442)

16HS

16' 3" (4.95)

18' 3" (5.56)

4120 (1869)

18HS

18' 3" (5.56)

20' 3" (6.17)

4370 (1983)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Timed, dual, counterstroking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Overserrated, bolted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-tine, double-hardened

2-tine, double-hardened

2-tine stub, double-hardened independent adjustable hold-down

2-tine, double-hardened

2-tine, double-hardened

-6 to -12

2

-6 to -12

4

-6 to -12

4

-6 to -12

4

-6 to -12

4

1.2–6.2 (30.5–157.5) 1.2–6.2 (30.5–157.5) 1.2–6.2 (30.5–157.5) 1.2–6.2 (30.5–157.5) 1.2–6.2 (30.5–157.5)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Open, dual, wobble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1810 1810 1828 1810 1810

3 (76) 3 (76) 3 (76) 3 (76) 3 (76)

5-bat 5-bat 6-bat 5-bat 5-bat

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fore/aft & vertical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52–83

0–76

Variable sheave

42 (1067)

Belt & chain

52–83

0–76

Variable sheave

42 (1067)

Belt & chain

NA

Standard 0–76

In cab

42 (1067)

Hydraulic Motor and Chain

52–83

0–76

Variable sheave

42 (1067)

Belt & chain

52–83

0–76

Variable sheave

42 (1067)

Belt & chain

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Segmented . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .1.25 (31.75) bearing w/collar at cam end & bushings at all other locations . . . . . . . . . . . . . . . . . . . . . .

Tine Bars

Bushings / bearings, in. (mm)

Conditioner

Type

Roll length (crush area), in. (mm)

Roll diameter, in. (mm)

Roll drive

Speed, rpm

Roll pressure

Roll gap

Windrow width, in. (mm)

Chevron-design Chevron-design NA intermeshing rubber intermeshing rubber NA

102 (2591)

10.375 (263.5)

102 (2591)

10.375 (263.5)

NA

NA

Spur gearbox & PTOs Spur gearbox & PTOs NA

717 717 NA

Hand crank Hand crank

Adjustable stop-bolt Adjustable stop-bolt

38–96 (910–2438) 38–96 (910–2438)

NA

NA

60 (1324) or 83 (2108)

Chevron-design Chevron-design intermeshing rubber intermeshing rubber

102 (2591)

10.375 (263.5)

102 (2591)

10.375 (263.5)

Spur gearbox & PTOs Spur gearbox & PTOs

717 717

Hand crank Hand crank

Adjustable stop-bolt Adjustable stop-bolt

38–96 (910–2438) 38–96 (910–2438)

Auger

Type

Diameter, in. (mm)

Floating range, in. (mm)

Flighting depth, in. (mm)

Speed, rpm

Options (field-installed)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single, floating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 (508) 20 (508) 20 (508) 20 (508) 20 (508)

2 (50.8)

5 (178)

287

2 (50.8)

5 (178)

287

2 (50.8)

5 (178)

215

2 (50.8)

5 (178)

287

2 (50.8)

5 (178)

287

• Crop dividers

• High-contact chevron conditioning rolls

• Hydraulic reel drive (requires windrower drive kits)

• Reel truss kit

• Push bar extension kit (for tall crops)

• Slatted steel conditioner rolls (for cane crops)

• Stub guard conversion kit (standard headers)

• Right- and left-hand conditioner throat opening wear plates (recommended for abrasive soil conditions)

• Stainless steel replacement floor inserts (for abrasive soil conditions)

• Gauge wheels

18

HB Series Draper Headers

MODEL

Versions Available:

Single-knife drive, standard deck

Single-knife drive, double swath

Double-knife drive, standard deck

Double-knife drive, double swath

Header

Cutting width, ft. (m)

Approximate weight (includes reel), lbs. (kg)

Cutting height (minimum), in. (mm)

Castering gauge wheels

Standard deck center windrow width opening, in. (m)

Double swath center windrow width opening, in. (m)

Slow speed header transport kit

Transport height, in. (m)

Cutterbar

Cutting system

Knife drive

Sickles

Sickle speed, spm

Sickle stroke, in. (mm)

Hay guard

Reels

Type

Speed range

Drive

Hydraulic reel fore / aft adjustment

Draper Belts

Belt width and construction

Speed range, ft. (m)

In cab canvas-speed control

Angle

Double swath shift means

* with 18.4 x 26 drive tires

21HB

x

25HB

x x x x

30HB

x x x x

36HB

x x

21 (6.4)

3880 (1760)

1.0 (25)*

25 (7.6)

4135 (1875)

1.0 (25)*

30 (9.1)

5021 (2278)

1.0 (25)

36 (11)

5434 (2465)

1.0 (25)*

NA

NA

Optional

80 (2.03)

Standard

80 (2.03)

Standard

80 (2.03)

50 (1.27) 56 (1.42) 56 (1.42) 56 (1.42)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 40 (1.02) from tip of guards to ground)* . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . Choice of New Holland dual-knife system or Schumacher single- or dual-knife system . . . . . . . .

. . . . . . . . . . . . . . . . . Schumacher hydraulically-driven, planetary-reduction sickle drive . . . . . . . . . . . . . . . .

2 1 or 2 1 or 2 2

1400

3.31 (84)

1400

3.31 (84)

1400

3.31 (84)

1400

3.31 (84)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steel . . . . .Pick-up with steel or plastic fingers . . . . .

Plastic fingers

20–48 rpm 20–48 rpm 20–48 rpm 20–48 rpm

. . . . . . . . . . . . . . . . . . . . . . . Direct hydraulic drive w/45 cu. in. (.74 L) motor . . . . . . . . . . . . . . . . . . . . . .

Standard Optional Optional Standard

42 in. (1.07 m) rubberized polyester belt with fiberglass reinforcement, tie bar end connection and molded V-Guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 705 (215) / minute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 20 degrees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Hydraulic Hydraulic Hydraulic

Options (factory-installed)

: Poly cutterbar skid plates • End-gauge wheels • Castering gauge wheels for 25HB • Cross auger kit

Disc Headers

MODEL

Windrower Model

Header drive

Cutting width, ft. in. (m)

Overall width, ft. in. (m)

Weight, lbs. (kg)

720HD

H8060/H8080

750HD

H8060/H8080

750HD Specialty

H8060/H8080

770HD

H8080

. . . . . . . . . . . . . . . . . . . . . . . . .Hydrostatically driven header with dual hydraulic header drive motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13' (3.96) 15' 4" (4.7) 15' 4" (4.7) 17' 11" (5.45)

13' 3" (4.04) 15' 6" (4.75) 15' 6" (4.75) 18' 1" (5.51)

3010 (1365) 4680 (2123) 3305 (1499) 4890 (2218)

Modular Disc Cutterbar

Number of discs

Maximum disc speed, rpm

10

3000

Number of reversible, swing-away knives 20 (2 per disc)

Knife tip speed, mph (kph)

Flotation

Cutting angle and height

12

3000

24 (2 per disc)

12

3000

24 (2 per disc)

14

3000

28 (2 per disc)

187 (301) 187 (301) 187 (301) 187 (301)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic adjustment from windrower cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .Standard hydraulic control, from 2 to 12 degrees (minimum: 0.6 in. [15 mm]) . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .with standard skid shoes* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transport height— bottom of skid shoes, in. (mm)

Hood liner

24.5 (622) 29.6 (754) 29.6 (754) 29.6 (754)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . High density, impact-resistant polyethylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditioner

Type

Length, in. (m)

Roll speed, rpm

Roll pressure

Roll gap

Windrow/swath width, in. (mm)

Chevron-design, intermeshing molded rubber rolls

102 (2.6)

920

Chevron-design, intermeshing molded rubber rolls

102 (2.6)

923

NA

NA

NA

Torsion-bar roll pressure system Torsion-bar roll pressure system NA adjusts with a single crank, rolls adjusts with a single crank, rolls separate automatically “on the go” separate automatically “on the go” to allow thick material to pass to allow thick material to pass

Adjustable stop-bolt

38–96 (965–2438)

Adjustable stop-bolt

38–96 (965–2438)

NA

60 (1524), 83 (2108) or 100 (2540)

Chevron-design, intermeshing molded rubber rolls

102 (2.6)

923

Torsion-bar roll pressure system adjusts with a single crank, rolls separate automatically “on the go” to allow thick material to pass

Adjustable stop-bolt

38–96 (965–2438)

Auger

Type

Maximum diameter, in. (mm)

Flighting depth, in. (mm)

NA

NA

NA

*with 18.4 x 26 tires **with 23.1 x 26 tires

Floating

20 (508)

5 (127)

Floating

20 (508)

Tapered, 7 (178) to 1 (25)

Floating

20 (508)

7 (178)

Options (field-installed):

Crop dividers • High-contact chevron conditioning rolls • High stubble kit • Corner marker kit • Slatted-steel conditioning bundle • Gauge wheels • Push bar • Closure kit

19

V

alue, Service and Solutions

When you place your confidence in

New Holland agricultural equipment, you also get the finest support. Your local New Holland dealer stands behind you at every step with the equipment, parts, service, and financial services you and your operation need.

Become part of the family.

You’ll find the perfect combination of equipment at your New Holland dealer, including a full line of tractors, hay and forage equipment, harvesting, crop production and material handling equipment. We’re one big productive family. Ask your New Holland dealer about becoming part of the family and receive special FAMILY VALUE$ discounts.

NEW HOLLAND TOP SERVICE

MAKES YOUR NEEDS A TOP PRIORITY

Top Service is managed in close partnership

TOP AVAILABILITY

24/7, year-round support and information — just by calling one toll-free number.

TOP SPEED

New Holland is redefining “fast” — with express parts delivery when and where you need it.

TOP PRIORITY

Fast-track solutions maximize your productivity — because your harvest can’t wait.

Quality parts and service.

Turn to your New Holland dealer after the sale for expert, factory-trained service and genuine New Holland-branded parts to keep you working productively season after season.

Financing solutions.

Your New Holland dealer can tell you about smart ways to turn your financial challenges into opportunities with a portfolio of innovative financial services available through

CNH Capital, including customized financing, leasing, insurance, and the purchasing convenience of a Commercial

Revolving Account.

TOP SATISFACTION

We drive and track the solution you need, keeping you informed — until you are satisfied.

866-NEW-HLND

8 6 6 - 6 3 9 - 4 5 6 3

For reliable equipment, parts and service – or just honest advice on farming and finance – turn to New Holland and your trusted New Holland dealer.

We are proud to support the FFA.

Visit our Web site at www.newholland.com/na

Design, materials and/or specifications are subject to change without notice and without liability therefor.

Specifications are applicable to units sold in Canada, the

United States, its territories and possessions, and may vary outside these areas.

© 2008 CNH America LLC. All rights reser ved. New Holland and CNH Capital are registered trademarks of CNH America

LLC. Any trademarks referred to herein, in association with goods and/or services of companies other than CNH America

LLC, are the proper ty of those respective companies.

Safety begins with a thorough understanding of the equipment.

Always make sure you and your operators read the Operator’s Manual before using the equipment. Pay close attention to all safety and operating decals and never operate machinery without all shields, protective devices and structures in place.

NH7030802 • 070830 • MG • PRINTED IN U.S.A.

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project