advertisement

Bendix

®

MC-30

™

Trailer ABS Controller Assembly

LED Diagnostic

Display

30-Pin

Connector

ABS Modulator

Connector

(MOD1)

Control

Port

1/4" NPT

Delivery Ports

3/8" NPT (x4)

Supply Port

1/2" NPT

TABLE OF CONTENTS PAGE

Components . . . . . . . . . . . . . . . . . . . . . . .2

MC-30 ™ Controller Comparison to MC-12 ™ Modulator. .2

MC-30 ™ Controller Assemblies. . . . . . . . . . . . . .2

MC-30 ™ Controller with PLC . . . . . . . . . . . . . . .2

Wiring Harness (Pigtail) . . . . . . . . . . . . . . . . .3

Power and Ground . . . . . . . . . . . . . . . . . . . .5

ABS Indicator Lamp . . . . . . . . . . . . . . . . . . .5

Wheel Speed Sensors . . . . . . . . . . . . . . . . . .5

M-30T ™ ABS Modulator-Valves . . . . . . . . . . . . .6

J1708/J1587 Diagnostic Link . . . . . . . . . . . . . .6

Auxiliary I/O . . . . . . . . . . . . . . . . . . . . . . .6

MC-30 ™ Controller Power-up Sequence . . . . . . . . .7

ABS Operation . . . . . . . . . . . . . . . . . . . . . .7

Self-Confi guration/Control Toggle . . . . . . . . . . . .8

MC-30

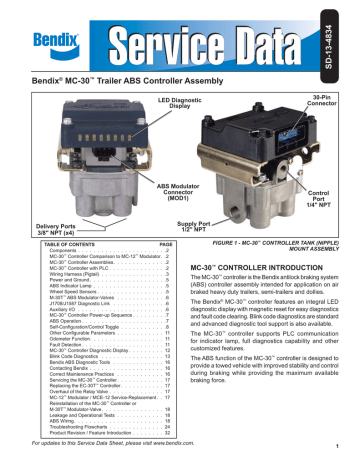

FIGURE 1 - MC-30 ™ CONTROLLER TANK (NIPPLE)

MOUNT ASSEMBLY

™

CONTROLLER INTRODUCTION

The MC-30 ™ controller is the Bendix antilock braking system

(ABS) controller assembly intended for application on air braked heavy duty trailers, semi-trailers and dollies.

The Bendix ® MC-30 ™ controller features an integral LED diagnostic display with magnetic reset for easy diagnostics and fault code clearing. Blink code diagnostics are standard and advanced diagnostic tool support is also available.

Odometer Function. . . . . . . . . . . . . . . . . . . 11

Fault Detection . . . . . . . . . . . . . . . . . . . . . 11

MC-30 ™ Controller Diagnostic Display . . . . . . . . . 12

Blink Code Diagnostics . . . . . . . . . . . . . . . . 13

Bendix ABS Diagnostic Tools . . . . . . . . . . . . . 16

Contacting Bendix . . . . . . . . . . . . . . . . . . . 16

Correct Maintenance Practices . . . . . . . . . . . . 16

Servicing the MC-30 ™

Replacing the EC-30T

Controller . . . . . . . . . . . . 17

™ Controller . . . . . . . . . . . 17

Overhaul of the Relay Valve . . . . . . . . . . . . . . 17

MC-12 ™ Modulator / MCE-12 Service-Replacement . . 17

Reinstallation of the MC-30 ™ Controller or

M-30T ™ Modulator-Valve . . . . . . . . . . . . . . . . 18

Leakage and Operational Tests . . . . . . . . . . . . 18

ABS Wiring . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting Flowcharts . . . . . . . . . . . . . . 24

Product Revision / Feature Introduction . . . . . . . . 32

The MC-30 ™ controller supports PLC communication for indicator lamp, full diagnostics capability and other customized features.

The ABS function of the MC-30 ™ controller is designed to provide a towed vehicle with improved stability and control during braking while providing the maximum available braking force.

For updates to this Service Data Sheet, please visit www.bendix.com.

1

MC-30

™

CONTROLLER COMPONENTS

The MC-30 ™ controller ABS installation consists of the following components:

- EC-30T ™ ABS Electronic Control Unit (ECU) (1)

- M-30T ™ ABS modulator-valve with relay function (1 or 2)

- WS-20 ™ wheel speed sensors (2 or 4)

- Sensors spring clips (2 or 4)

- Trailer mounted ABS indicator lamp

- Pigtail wiring harness

- PLC signal for dash mounted trailer ABS indicator lamp

(Towed vehicles manufactured after March 1, 2001)

MC-30

™

CONTROLLER COMPARISON TO

MC-12

™

MODULATOR

The MC-30 ™ controller has been designed to replace the

MC-12 ™ modulator as the standard Bendix trailer ABS controller assembly for OEM and aftermarket installations.

The EC-30T ™ controller has a black plastic enclosure similar to the Bendix ® EC-30 ™ tractor ABS controller, and is mounted to the modulator-valve with a bracket. The

MC-12 ™ modulator utilized a metal ECU enclosure and was directly bolted to the modulator body. The MC-30 ™ controller has a 30-pin electrical connector and the MC-12 ™ modulator has a 14-pin connector.

The M-30T ™ ABS modulator-valve utilizes a 3-pin external electrical connector, where the MC-12 ™ modulator used a

4-pin internal connector.

Physical

Feature

ECU Enclosure

ECU Mounting

ECU Electrical

Connector

ABS Modulator

Connector

MC-30 ™ MC-12 ™

Controller Modulator

Plastic ECU Metal ECU

Bracket Mounted to Directly Mounted to ABS

ABS Modulator Valve Modulator Valve Body

30-pin 14-pin

3-pin External

Connector

4-pin Internal

Connector

CHART 1 - MC-30 ™ CONTROLLER AND MC-12 ™

MODULATOR DIFFERENCES

FIGURE 2 - MC-30 ™ CONTROLLER BRACKET (FRAME)

MOUNT ASSEMBLY

MC-30

™

CONTROLLER ASSEMBLIES

Tank (Nipple) Mounted

The MC-30 ™ controller tank-mount assembly is mounted by using a schedule 80 (heavy gauge steel) 1/2" nipple directly between the trailer supply tank and the MC-30 ™ modulatorvalve supply port. A tank with a reinforced port must be used.

See Figure 1 for tank-mount MC-30 ™ modulator-valve.

CAUTION: The tank-mounted MC-30 ™ modulator-valve cannot be mounted on a frame or crossmember using the

ECU bracket holes.

Bracket (Chassis) Mounted

The MC-30 ™ controller bracket mount assembly is mounted directly to the trailer frame rail or crossmember. See Figure

2 for bracket mount MC-30 ™ controller. The bracket studs are secured using three 5/16-18 nuts and lock washers torqued to 180-220 in-lbs.

EC-30T

™

TRAILER ABS ECU

The EC-30T ™ is a plastic electronic controller with a single 30-pin electrical connector. The EC-30T ™ controller enclosure is fi lled with a hard epoxy-based potting that seals all internal components from the environment. A patented LED (light emitting diode) diagnostic display and magnetic reset switch are incorporated in the housing for simple, self-contained diagnostics. The design of the

EC-30T ™ controller’s electronics is robust against radio, electromagnetic and environmental interference.

The EC-30T ™ controller is typically mounted to the

M-30T ™ modulator-valve using four bolts and a bracket.

This assembly forms an MC-30 ™ ABS controller.

The EC-30T ™ controller can also be frame rail mounted, independent of the M-30T ™ modulator-valve.

MC-30

™

CONTROLLER WITH PLC

Effective March 1, 2001 all towed vehicles must transmit a signal to control an in-cab trailer ABS indicator lamp. Trailers built after this date will transmit the status of the trailer ABS unit over the ignition power wire (blue wire of the J560 connector) using Power Line Carrier (PLC) communications.

The PLC signal is usually broadcast by the trailer ABS ECU.

The application of PLC technology for the heavy vehicle industry is known as PLC4Trucks. MC-30 ™ controller models with PLC will support communication in accordance with SAE J2497.

Identifying MC-30

™

Controller units with PLC

Most MC-30 ™ controller units will contain PLC capability.

However, some MC-30 ™ controller units installed prior to

March 1, 2001 may not. An MC-30 ™ controller with PLC can be identifi ed by the individual part number label and pin stamp on the EC-30T ™ controller housing. On PLC units, the PLC function can be disabled with a diagnostic tool.

2

This will be the case when an MC-30 ™ controller is installed on a powered vehicle auxiliary axle.

Identifying / Measuring the PLC Signal

An MC-30 ™ controller with PLC will continuously broadcast

PLC messages that indicate trailer ABS status. At powerup or during a trailer ABS fault condition, the MC-30 ™ controller will signal the tractor ABS unit to illuminate the dash mounted trailer ABS indicator lamp.

Diagnostic tools are available that detect the presence of a PLC signal and perform further system diagnostics directly on the power line. For more information on these diagnostic tools, contact Bendix or refer to your local authorized Bendix dealer.

An oscilloscope can also be used to verify the presence and strength of a PLC signal on the power line. The PLC signal is an amplitude and frequency modulated signal.

Depending on the load on the power line, the amplitude of the PLC signal can range from 5.0 mV p-p to 7.0 V p-p.

Suggested oscilloscope settings are (AC coupling, 1 volt/ div, 100 µsec/div). The signal should be measured on pin 7 of the J560 connector at the nose of the trailer. See

Figure 3 and Figure 4 for examples of PLC measurements using an oscilloscope.

FIGURE 3 - POWER LINE WITHOUT PLC SIGNAL

FIGURE 4 - POWER LINE WITH PLC SIGNAL

MC-30

™

CONTROLLER WIRING HARNESS

(PIGTAIL)

The EC-30T ™ controller utilizes a pigtail wire harness to interface with ABS and other trailer system components.

Various pigtail harness part numbers are available from

Bendix. The following connectors are optional and may not be present on all pigtail harnesses: Modulator 2, auxiliary, diagnostic, and rear axle wheel speed sensors.

All connector leads of the MC-30 ™ controller pigtail harness are weather sealed at the connector interface and are clearly labeled for proper installation.

Non over-molded versions of the MC-30 ™ controller pigtail, shown in Figure 5, are repairable. If repairs are needed, see chart 12 for connector and tool information.

Over-molded versions of the wiring harness must be replaced if corrosion or damage occurs.

ECU Connector

The 30-pin ECU connector of the pigtail is fastened to the

EC-30T ™ controller with a jackscrew tightened to 15-20 in. lbs. Improper tightening of the connector jackscrew can cause environmental contamination or damage to the

EC-30T ™ controller. The use of a inch-pound torque wrench is recommended.

Power / ABS Indicator Lamp Connector

The MC-30 ™ controller pigtail utilizes the TTMA RP 97-99

5-pin Packard Weather Pack connector for brake light power, constant power, ground and the trailer mounted ABS indicator lamp. The Power/ABS Indicator Lamp lead of the pigtail harness is available in various lengths to satisfy installation requirements such as slider axles.

Wheel Speed Sensor Connectors

Two or four wheel speed sensor connectors are provided.

These 2-pin connectors are labeled Right Front (RHT FRT),

Left Front (LFT FRT), Right Rear (RHT RER) and Left Rear

(LFT RER). Right Front and Left Front wheel speed sensor inputs must be used for two sensor installations, even if the wheel speed sensors are not physically located on the forward axle. Extension cables are available from Bendix that will provide longer wheel speed sensor lengths when required by the installation.

ABS Modulator Connectors

One or two modulator connectors are provided. These 3-pin connectors are labeled MOD 1 and MOD 2. Modulator 1 is always used for single modulator installations. For two modulator confi gurations, Modulator 1 is installed at the right or front position. Modulator 2 is installed at the left or rear position. An extension cable must be used for

Modulator 2. The remote modulator harness is available in various lengths to satisfy any installation requirement.

See Figure 6.

Diagnostic Connector

An optional 4-pin diagnostic connector provides a port for connecting a diagnostic tool. The connector provides ignition power, ground and data lines. Remote diagnostic cables are available from Bendix that will provide a standard J1708/J1587 diagnostic port at the side of the trailer. See Figure 7.

3

Auxiliary I/O Connector

An optional auxiliary connector provides a connection to the MC-30 ™ controller auxiliary feature I/O pins. The fi ve auxiliary ground-switch inputs and two auxiliary outputs can be activated and confi gured with a diagnostic tool.

POWER AND GROUND

Trailer electrical power is supplied to the MC-30 ™ controller from the ignition and brake light circuits. Note: The MC-30 ™ controller may not function properly when powered with a battery charger. See Chart 2.

ECU Connector Jackscrew

(Tighten to 15-20 in. lbs.)

30-Pin ECU

Connector

3-Pin Modulator 2

(MOD2)

3-Pin Modulator 1

(MOD 1)

8-Pin Auxiliary

(AUX)

5-Pin Power and

Indicator Lamp

(PWR/WL)

4-Pin Diagnostic

(DIAG)

Right Front

(RHT FRT)

Left Front

(LFT FRT)

Left Rear

(LFT RER)

Right Rear

(RHT RER)

2-Pin Wheel

Speed Sensors

FIGURE 5 - MC-30 ™ CONTROLLER PIGTAIL HARNESS (4S/2M WITH DIAGNOSTIC AND AUXILIARY CONNECTORS

SHOWN)

To

Pigtail

Modulator 2

(MOD2)

FIGURE 6 - REMOTE MODULATOR HARNESS (MOD2)

To

Pigtail

To Diagnostic

FIGURE 7 - REMOTE DIAGNOSTIC HARNESS

Tool

4

Circuit 7-Pin Trailer 5-Pin ABS 30-Pin ECU

Electrical Connector

Ignition Power (PLC) Pin 7 B Pin E1

Previous Bendix Wheel Speed Sensors

Brake Light Power Pin 4 A Pin E3

Ground Pin 1 E Pin D2

Indicator Lamp N/A D

Function Mode

Operating Range

ABS Active

(1 modulator)

ABS Active

(2 modulators)

Value

8.0 to 16.0 VDC

2.4 A @ 12 VDC

4.5 A @ 12 VDC

CHART 2 - POWER AND GROUND

Previous sensors are all replaced by the

Bendix WS-24 ™ wheel speed sensor shown below.

90° Speed

Sensors

ABS INDICATOR LAMP

Trailer Mounted Lamp

The MC-30 ™ controller controls an ABS indicator lamp to indicate the trailer ABS status. The MC-30 ™ controller directly controls the ABS indicator lamp by providing a

12.0 VDC signal to turn it on. The other side of the lamp is grounded. The MC-30 ™ controller must be powered in order to operate the trailer indicator lamp. Pin D3 of the

30-pin connector is the ABS indicator lamp output.

Straight Speed

Sensors

Dash Mounted Lamp (PLC Controlled)

MC-30 ™ controller models with PLC will transmit a signal to control a trailer ABS indicator lamp mounted on the dash of the tractor. MC-30 ™ controller will transmit the status of the trailer ABS unit over the ignition power pin E1 of the

30-pin connector. The ignition power wire (blue wire of the

J560 connector) will carry this signal to the towing vehicle.

MC-30 ™ controller models with PLC support communication in accordance with SAE J2497.

Previous clamping sleeves have

“BW” in a diamond

WS-24 sensors use clamping sleeves with

“BX” in a swoosh symbol

PREVIOUS AND NEW CLAMPING SLEEVES

FIGURE 8 - BENDIX WHEEL SPEED SENSORS

WHEEL SPEED SENSORS

Wheel speed data is provided to the MC-30 ™ controller from the Bendix wheel speed sensors. See Figure 8 for examples. Working with a tone (exciter) ring, the wheel speed sensors provide the MC-30 ™ controller with an AC signal, which varies in voltage and frequency in relation to the speed of the wheel. The MC-30 ™ controller is confi gured to receive wheel speed information from 100 tooth tone rings by default. Vehicle axle and ABS control confi gurations determine if two or four wheel speed sensors must be used. See the MC-30 ™ controller’s electrical system schematic for wheel speed sensor connector pin locations, Figure 16.

Wheel Speed Sensor Clips

The sensor spring clip is designed to fi rmly hold the wheel speed sensor in place while also allowing the sensor to adjust in position as the wheel and hub rotate. Wheel bearing play and heavily loaded axles will cause sensors to self-adjust. Proper sensor installation begins by fully inserting the spring clip into the block, with the retaining tabs toward the inside of the vehicle. See Figure 9.

FIGURE 9

CLIP AND SENSOR INSERTION

FIGURE 10

5

FIGURE 11 - M-30T ™ TANK (NIPPLE) MOUNT

MODULATOR-VALVE

Tank (Nipple) Mounted

The M-30T ™ modulator-valve tank-mount assembly is mounted by using a schedule 80 (heavy gauge steel) 1/2" nipple directly between the trailer supply tank and the

M-30T ™ modulator-valve supply port. A tank with a reinforced port must be used. See Figure 11.

Bracket (Chassis) Mounted

The M-30T ™ modulator-valve bracket mount assembly is mounted directly to the trailer frame rail or crossmember.

See Figure 12. The bracket studs are secured using three 5/16-18 nuts and lock washers torqued to 180-220 in-lbs.

J1708/J1587 DIAGNOSTIC LINK

The MC-30 ™ controller provides a J1708/J1587 diagnostic link with data and power to communicate with the vehicle and various diagnostic tools. Diagnostics, testing, confi guration, data transfer and other functions can be performed using this link. The MC-30 ™ controller is supported by diagnostic tools such as the MPSI Pro-Link ® and Bendix ® ABS Diagnostic Software. Ignition power must be provided to the MC-30 ™ controller for the diagnostic link to be active. See the MC-30 ™ controller electrical system schematic for J1708/J1587 diagnostic link pin locations,

Figure 16.

FIGURE 12 - M-30T ™ BRACKET (FRAME) MOUNT

MODULATOR-VALVE

Wheel Speed Sensor Adjustment

Speed sensors are properly adjusted by gently pushing

(not striking) the sensor into the clip until it makes contact with the face of the tone ring. The wheel speed sensor will automatically adjust as the wheel rotates. If rotating the wheel causes a gap of 0.020 in. or greater, check for excessive wheel bearing play or tone ring runout. Proper wheel speed sensor installation is critical to proper ABS operation. See Figure 10.

AUXILIARY I/O

Auxiliary Function Inputs

The MC-30 ™ controller offers fi ve auxiliary ground switch inputs. These inputs can be configured for various custom functions using a diagnostic tool. See the

MC-30 ™ controller’s system electrical schematic for auxiliary function input connector pin locations, Figure 16.

Auxiliary Function Outputs

The MC-30 ™ controller offers two auxiliary output drivers.

These outputs can be configured for various custom functions. Pin F1 of the 30-pin connector is the auxiliary low side output. Pin K2 of the 30-pin connector is the auxiliary high side output.

M-30T

™

ABS MODULATOR-VALVES

The M-30T ™ Bendix ® trailer ABS modulator-valve is controlled by the EC-30T ™ controller to modify driver applied air pressure to the service brakes during ABS activation. The

ABS modulator-valve is an electro-pneumatic control valve and is the last valve that air passes through on the way to the brake chambers. The hold and exhaust solenoids of the

M-30T ™ modulator-valve are activated to precisely modify the brake pressure on command. The EC-30T ™ controller is designed to control one or two modulator-valve assemblies.

See the MC-30 ™ controller’s electrical system schematic for ABS modulator connector pin locations, Figure 16.

The M-30T ™ modulator-valve is available in two mounting confi gurations.

6

MC-30

™

CONTROLLER POWER-UP

SEQUENCE

At power-up, the MC-30 ™ controller performs a series of self-checks that can assist a technician in determining the status and confi guration of the system.

Trailer ABS Indicator lamp

At power-up without detected faults, the trailer ABS indicator lamp will illuminate for 2.5 seconds as a bulb check and then turn off.

If a PLC tractor and PLC trailer are powered at the same time, the MC-30 ™ controller will also trigger a bulb check on the tractor dash using PLC.

Diagnostic LED Display of Confi guration

At power-up, the diagnostic LEDs all illuminate, then display the current confi guration for sensors, modulators and ABS control. See chart 3. After displaying the confi guration, only the green VLT LED will stay on. However, if a fault is detected, the faulted component will be displayed by the red diagnostic LEDs.

MC-30 ™ Controller – LED Power-Up Sequence

1st blink displays number of wheel speed sensors

SEN-FRT

SEN-RER-FRT

2nd blink displays modulator confi guration

1 Modulator (Dolly-Axle control)

1 Modulator (Axle control)

2 Modulators (Axle control)

2 Modulators (Side control)

Normal Operation

No Faults

MOD

MOD-FRT

MOD-RER-FRT

MOD-LFT-RHT

VLT (green) LED illuminated only

CHART 3 - LED POWER-UP SEQUENCE

Modulator Chuff Test at Power-Up

At power-up, the MC-30 ™ controller activates a modulator chuff test. This electrical and pneumatic ABS modulator test can assist the technician in verifying that the modulator wiring and installation are correct. With brake pressure applied, a properly installed modulator will cause fi ve rapid audible chuffs of air pressure. If two modulators are installed, the MC-30 ™ controller activates 5 chuffs at

Modulator 1 (MOD 1) then Modulator 2 (MOD2). The chuff sequence is then repeated.

If the modulator is wired incorrectly, the modulator will only produce one chuff, or no chuff at all. If an issue is detected during the modulator chuff test, compare the modulator wiring and plumbing to the MC-30 ™ controller’s electrical system schematic and make repairs. See Figures 16 and

17.

System

Sensors Modulators Available

2S/1M

CHART 4 - MC-30 ™ CONTROLLER ABS CONFIGURATIONS

ABS OPERATION

The MC-30 ™ controller uses wheel speed sensors, ABS modulator-valves and an ECU to control trailer wheels by axle or by side. By detecting excessive wheel slip during braking and adjusting the pressure to each brake chamber, the MC-30 ™ controller is able to optimize slip between the tire and the road surface. The EC-30T ™ controller controls the ABS modulator-valves, similar to a driver pumping the brakes. However, the MC-30 ™ controller is able to pump the brakes on the vehicle with greater speed and accuracy.

Axle Control

MC-30 ™ controller axle control will utilize a single ABS modulator-valve to control wheels from both sides of a given axle or axles. In the case of an unbalanced braking surface, axle control will control the high coeffi cient wheel just under the lock limit. Temporary periods of wheel lock are permitted on the low coeffi cient wheel. Axle control should not be used on 5th wheel dollies or steerable axles.

When braking on even surfaces, an axle-control system will perform similar to a side control, two modulator system.

Axle control is available in 2S/1M, 2S/2M and 4S/2M installations.

Dolly-Axle Control (Select Low)

MC-30 ™ controller dolly-axle control will utilize a single

ABS modulator-valve to control wheels from both sides of a given axle or axles. In the case of an unbalanced braking surface, dolly-axle control will control the low coeffi cient wheel just under the lock limit. Optimal vehicle stability is achieved by not allowing the high coeffi cient wheel to sustain wheel lock. When braking on even surfaces, a dolly axle control system will perform similar to side control or axle control system. Dolly axle control is only available in

2S/1M installations.

Steer Axle Option (MOD2 Select Low)

This option causes MOD2 to be Dolly-Axle controlled and is only active while confi gured for 4S/2M Axle control. This confi guration option should be set when MOD2 is installed on a forward or steer axle of a full trailer. Steer Axle option can be set using a diagnostic tool or by purchasing an

MC-30 ™ controller unit with this option pre-set.

Side Control

The MC-30 ™ controller will utilize a single ABS modulatorvalve to control one or more wheels on a given vehicle side.

In the case of an unbalanced braking surface, MC-30 ™ controller side control will individually control each side just under the lock limit. Side control is available in 2S/2M and

4S/2M installations.

Normal Braking

During normal braking, the MC-30 ™ controller functions as a standard relay valve. As brakes are applied or released by the driver, the control signal from the tractor foot valve causes the M-30T ™ modulator-valve to apply proportional pressure to the trailer brake chambers.

7

SELF-CONFIGURATION / CONTROL TOGGLE

When activated with a magnet or diagnostic tool, the self-confi guration feature allows for wheel speed sensor, modulator and ABS control settings to be altered. This is generally performed after replacement of an MC-30 ™ controller. See chart 5.

CAUTION: An incorrect ABS confi guration may cause a fault indication or degraded ABS performance. All

MC-30 ™ controller’s service replacement parts are initially defaulted to 4S/2M side control and may need to be reconfi gured upon installation. Before and after activating a self-configuration, always determine the current ABS configuration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics.

Wheel Speed Sensors

The MC-30 ™ controller will self-confi gure for either two or four wheel speed sensors. If either rear (RER) wheel speed sensors are detected, four wheel speed sensors will be selected. If neither rear wheel speed sensors are detected, the MC-30 ™ controller will confi gure for two wheel speed sensors. The MC-30 ™ controller will default to two

ABS modulators for any four sensor confi guration.

When confi gured for two wheel speed sensors, Right Front

(RHT FRT) and Left Front (LFT FRT) wheel speed sensor inputs must be used, even if the wheel speed sensors are not physically located on the front axle.

Modulators

The EC-30T ™ controller will self-confi gure for either one or two modulators. The EC-30T ™ controller will automatically confi gure for two ABS modulators if it detects Modulator 2

(MOD2) and/or either of the rear wheel speed sensors. If

MOD2 is not detected and no rear wheel speed sensors are detected, the EC-30T ™ controller will confi gure for a single ABS modulator.

When confi gured for a single modulator, Modulator 1 (MOD

1) must be used.

ABS Control Toggle

The MC-30 ™ ABS controller control setting can be toggled between Control Group A and Control Group B. When activated, the MC-30 ™ controller will toggle the ABS control between (axle control) and (dolly-axle control or side control). When a self-confi guration occurs without an ABS control toggle, the ABS control group does not change.

See chart 6 and chart 7.

Self-Confi guration Procedure

Verify that the ECU, wheel speed sensor and ABS modulator connectors are in place and then power the

MC-30 ™ controller.

Determine the current ABS confi guration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics.

Hold a magnet on the reset location of the diagnostic display. All of the LEDs will be on while the magnet is held in place.

After holding the magnet in place for 20 seconds, the

LEDs will begin to roll and the MC-30 ™ controller will selfconfi gure for the number of detected wheel speed sensors and modulators. If it is not desired to toggle the ABS

control, remove the magnet.

The MC-30 ™ controller will then automatically go through the power-up sequence and display the new confi guration on the diagnostic LEDs. Verify the new ABS confi guration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics.

If an erroneous sensor or modulator combination is detected during the self-confi guration, fault codes are activated when the MC-30 ™ controller returns to normal operating mode.

ABS Control Toggle Procedure

To also toggle the ABS control, continue to hold the magnet in place while the LEDs are rolling, for an additional 20 seconds (total of 40 seconds). After holding the magnet in place for 40 seconds, the LEDs will begin to rapidly fl ash.

At this point the MC-30 ™ controller will toggle the ABS control confi guration. Remove the magnet.

The MC-30 ™ controller will then automatically go through the power-up sequence and display the new confi guration on the diagnostic LEDs. Verify the new ABS confi guration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics.

ABS

Confi guration

Control Group A Control Group B

2S/1M

2S/2M

4S/2M

Axle

Axle

Axle

Toggle

Toggle

Toggle

Dolly-Axle

Side

Side

CHART 6 - ABS CONFIGURATION AND CONTROL TOGGLE

CHART 5 - SELF-CONFIGURATION AND ABS CONTROL TOGGLE ACTIVATION

8

4S/2M Side to 2S/1M Axle

Your trailer has two wheel speed sensors and one ABS modulator that is plumbed for axle control.

The MC-30 ™ controller you have installed is currently confi gured for

4S/2M side control.

Provide power to the MC-30 ™ controller and verify the current configuration using the LEDs or blink codes.

2S/1M Axle to

2S/1M Dolly-Axle

Your dolly or steer axle has two wheel speed sensors and one ABS modulator that is plumbed for axle control.

The MC-30 ™ controller you have installed is currently confi gured for

2S/1M axle control.

Provide power to the MC-30 ™ controller and verify the current configuration using the LEDs or blink codes.

4S/2M Side

2S/1M Axle

H o l d m a g n e t i n p l a c e f o r 2 0 seconds.

The LEDs will begin to roll as the installed sensors and modulators are detected.

H o l d m a g n e t i n p l a c e f o r 2 0 seconds.

The LEDs will begin to roll as the installed sensors and modulators are detected.

2S/1M Dolly-Axle

2S/1M Axle

With the LEDs rolling, continue to hold the magnet in place for an additional

20 seconds. (Total of 40 seconds)

The LEDs begin to fl ash as the ABS control toggle activation occurs.

Remove magnet.

With the LEDs rolling, continue to hold the magnet in place for an additional

20 seconds. (Total of 40 seconds)

The LEDs begin to fl ash as the ABS control toggle activation occurs.

Remove magnet.

2S/1M Axle

2S/1M Dolly-Axle

Verify the new confi guration using the LEDs or blink codes.

Verify the new confi guration using the LEDs or blink codes.

CHART 7 - EXAMPLES OF SELF-CONFIGURATION AND ABS CONTROL TOGGLE (1 of 2)

9

4S/2M Axle to 2S/2M Axle

Your trailer has two wheel speed sensors and two ABS modulators that are plumbed for axle control.

The MC-30 ™ controller you have installed is currently confi gured for

4S/2M axle control.

Provide power to the MC-30 ™ controller and verify the current confi guration using the LEDs or blink codes.

4S/2M Axle

H o l d m a g n e t i n p l a c e f o r 2 0 seconds.

The LEDs will begin to roll as the installed sensors and modulators are detected.

Remove the magnet.

2S/2M Axle

Stop! You do not need to perform an

ABS control toggle in this case.

Verify the new confi guration using the LEDs or blink codes.

4S/2M Side to

2S/1M Dolly-Axle

Your trailer has two wheel speed sensors and two ABS modulators that are plumbed for side control.

The MC-30 ™ controller you have installed is currently confi gured for

4S/2M side control.

Provide power to the MC-30 ™ controller and verify the current configuration using the LEDs or blink codes.

4S/2M Side

H o l d m a g n e t i n p l a c e f o r 2 0 seconds.

The LEDs will begin to roll as the installed sensors and modulators are detected.

Remove the magnet.

2S/1M Dolly-Axle

Stop! You do not need to perform an

ABS control toggle in this case.

Verify the new confi guration using the LEDs or blink codes.

CHART 7 - EXAMPLES OF SELF-CONFIGURATION AND ABS CONTROL TOGGLE (2 of 2)

10

OTHER CONFIGURABLE PARAMETERS

The MC-30 ™ controller has various confi gurable function parameters that can be enabled to provide the user with additional customized features. The default settings for these parameters are chosen by the vehicle OEM. The configurable features include serial communications message broadcasts, alternative lamp control, various I/O recognition, ABS control settings and others. To ensure that the replacement unit has the correct default settings, reference the original part number. These settings can be altered using a diagnostic tool. For further information, contact Bendix or refer to your local authorized Bendix dealer.

ODOMETER FUNCTION

The MC-30 ™ controller’s odometer function stores the accumulated mileage of the vehicle. The mileage will be calculated using wheel speed sensor information. Every

1.0 mile accumulated during powered operation will be recorded.

Mileage will only be recorded while the MC-30 ™ controller is powered. If stop light power is the only power source to the MC-30 ™ controller, correct accumulated mileage will not be recorded.

The odometer will store vehicle mileage up to 9,999,999 miles. When the odometer mileage counter function is full, it will latch and not record or calculate any additional mileage.

The odometer mileage can be read using a diagnostic tool or blink code diagnostics. Refer to the Blink Code

Diagnostics section for further information.

The odometer mileage can be cleared or reset using a diagnostic tool. This function is password protected.

It is necessary to properly confi gure wheel rolling radius and tone ring tooth count for accurate odometer mileage to be accumulated.

Calibration of Non-Standard Wheel Sizes

The MC-30 ™ controller allows for tire rolling radius and tone ring tooth count parameters to be set for each axle using a diagnostic tool. These adjustments may be necessary for the MC-30 ™ controller to accurately calculate the vehicle velocity and odometer mileage. Wheels of the same axle must be set to the same rolling radius and tone ring tooth count.

In most cases, these parameters are set by the trailer OEM and do not need to be adjusted. In the case of a service replacement unit, these parameters will need to be adjusted if the default settings do not match the vehicle.

Parameter Default Settings Available Settings

Rolling

Radius

500 revs/mile 300 to 700 revs/mile

Tooth Count

CHART 8 - WHEEL SIZE CALIBRATION FACTORS

The tire rolling radius is defaulted to 500 revs/mile and can be adjusted from 300 to 700 revolutions per mile. Refer to the manufacturer’s tire specifi cation for correct settings.

Tone ring tooth count is defaulted to 100 teeth and can be set to 80, 86, 100 or 120 teeth.

FAULT DETECTION

The MC-30 ™ controller contains self testing diagnostic circuitry that continuously checks for proper operation of the ABS components and wiring. The MC-30 ™ controller controls a trailer mounted indicator lamp to advise the driver of the status of the system. The MC-30 ™ controller may also send the system status to the towing vehicle using

PLC communications.

When the MC-30 ™ controller senses an erroneous system condition, it stores the fault code in memory, activates the indicator lamp and disables all or part of the affected ABS functions. The faulted component is also identifi ed on the

MC-30 ™ controller diagnostic display.

In some instances, the MC-30 ™ controller will automatically reset (self-heal) the active fault code when the fault is corrected. However, repeated occurrences of a given fault will cause the fault code to latch. Once the fault code is latched, a manual reset is required. Latching of faults assists the technician in troubleshooting intermittent faults.

The fault code is stored in the MC-30 ™ controller’s memory, even when power is removed.

After repair, latched fault codes can be reset by briefl y holding a magnet on the reset location of the MC-30 ™ controller’s diagnostic display. Fault codes can also be reset with blink code diagnostics or with a diagnostic tool.

When a fault self-heals or is manually reset, the fault code remains in fault history. Fault history can be retrieved with blink code diagnostics or with a diagnostic tool.

MC-30

™

Controller ABS Partial Shutdown

Depending which fault is detected, the ABS function may be completely or partially disabled. Even with the ABS indicator lamp on, dual modulator confi gurations may still provide some level of ABS function on wheels that are not affected by the fault. Single modulator confi gurations are completely disabled for any single fault.

ECU Fault

All functions are completely disabled. The system reverts to normal braking.

Voltage Fault

While voltage is out of range, ABS function is disabled. The system reverts to normal braking. When the correct voltage level is restored, full ABS function is available. Operating voltage range is 8.0 to 16.0 VDC.

11

MC-30

™

CONTROLLER DIAGNOSTIC DISPLAY

The MC-30 ™ controller diagnostic display consists of seven red fault LEDs, one green power LED and an internal magnetic reset switch. See Figure 13 for illustration.

No diagnostic tools are needed to read the MC-30 ™ controller’s diagnostic display. A fault displayed on the

LEDs will always cause the ABS indicator lamp to be on.

Reading a Fault

When a fault is detected, the MC-30 ™ controller identifi es the faulted component with the diagnostic LEDs. A wheel speed sensor or modulator LED (SEN or MOD) may be accompanied by wheel location LEDs. An example is

FRT-RHT-SEN. When these three LEDs are on, this is an indication of a fault on the front axle (FRT), right side

(RHT), wheel speed sensor (SEN).

For complete explanation and troubleshooting of faults displayed by the LEDs, go to section E, Troubleshooting.

The red diagnostic LEDs only indicate active system faults.

When a fault self-heals or is manually reset, the LEDs are cleared but the fault code remains in fault history. Fault history can be retrieved with blink code diagnostics or with a diagnostic tool.

If faults occur on multiple components, the diagnostic

LEDs will display one fault at a time. When the fi rst fault is repaired and the MC-30 ™ controller is reset, the next fault will be displayed on the LEDs.

Fault Reset

After the fault is corrected, the active fault code and LEDs can be reset by briefl y holding a magnet in place at the

RESET location of the diagnostic display. See Figure

13. All of the LEDs will be on while the magnet is held in place. If one or more of the LEDs do not go on when the magnet is in place, replace the EC-30T ™ controller. When the magnet is removed from the reset location, only the green VLT diagnostic LED should be on. However, if any red LEDs are still on, active faults are still present in the system.

Note: A self-confi guration will occur if the magnet is held at the reset location for greater than 20 seconds. Do not hold the magnet at the reset location for longer than 10 seconds unless a self-confi guration is desired.

FIGURE 14 - MC-30 ™ CONTROLLER LED DIAGNOSTIC

DISPLAY

BLINK CODE DIAGNOSTICS

The MC-30 ™ controller provides diagnostic and confi guration functions through blink code diagnostics. Blink code diagnostics are activated by providing constant power to the ignition circuit and toggling the brake light power input to the MC-30 ™ controller.

When blink code mode is activated, the MC-30 ™ controller will blink the trailer mounted ABS indicator lamp to display active fault codes, fault code history, ABS confi gurations and odometer mileage. Blink code diagnostics can also be used to reset active fault codes. See chart 9 for all blink code functions.

Following a single display of all available messages, the

ABS indicator lamp will remain on for fi ve seconds and then return to normal operating mode.

FIGURE 13 - MC-30 ™ CONTROLLER LED DIAGNOSTIC DISPLAY

12

It may be necessary to wait until after the modulator chuff test before activating brake light power. If wheel speeds are detected during blink code diagnostics mode, the MC-30 ™ controller will exit blink code diagnostics and return to normal operating mode. Blink code diagnostics can only be activated following a power-up, where wheel speeds have not been detected. Blink code diagnostics must be activated within 15 seconds of ignition power being applied.

If brake light power is continuously applied for greater than fi ve seconds, blink code diagnostics will be disabled until ignition power is cycled.

With Ignition Power Applied, Code

Cycle Brake Light Power Action

3 times Display Active Fault Codes

4 times Display Fault Code History

5 times

6 times

Reset Active Fault Codes

Display EC-30T Confi guration

7 times Display of Odometer Mileage

(x1000)

CHART 9 - BLINK CODE ACTIVATION

Display MC-30

™

Controller Confi guration

To check the ECU confi guration, apply ignition power.

Apply and release the brake pedal six times. Following activation, there will be a 5 second delay followed by a blink code display of the MC-30 ™ ABS controller confi guration.

See chart 10.

Sensor

3

2nd Digit

1

2

3

4

Modulators

1 Modulator (Dolly-Axle control)

1 Modulator (Axle control)

2 Modulators (Axle control)

2 Modulators (Side control)

CHART 10 - BLINK CODES FOR MC-30 ™ CONTROLLER

CONFIGURATION

Display Active Fault Codes

To display active fault codes, apply ignition power. Apply and release the brake pedal three times. Following activation, there will be a 5 second delay followed by a blink code display of all active fault codes. See chart 11.

Display Fault Code History

To display history fault codes, apply ignition power.

Apply and release the brake pedal four times. Following activation, there will be a 5 second delay followed by a blink code display of all history fault codes. See chart 11.

Reset Active Fault Codes

To reset active fault codes, apply ignition power. Apply and release the brake pedal fi ve times. Following activation, there will be a 5 second delay followed by a blink code message of:

1-1, (System Fully Operational - No Faults Detected)

or

A blink code display of all remaining active fault codes.

See chart 11.

The ABS indicator lamp will stay on if active faults are still present.

Resetting active fault codes with blink code diagnostics does not clear information from fault history. Fault history can be retrieved by using blink code diagnostics or a diagnostic tool.

Display Odometer Mileage

To display the trailer odometer mileage, apply ignition power. Apply and release the brake pedal seven times.

Following activation, there will be a 5 second delay followed by a blink code display of the odometer information

(x1000).

Example: 152,431 miles will be displayed as:

152 (x1000) or

1 blink (pause), 5 blinks (pause), 2 blinks.

Zeros will be displayed by a strobing ABS indicator lamp twice.

Odometer mileage can not be altered with blink code diagnostics. Complete odometer information can be retrieved using a diagnostic tool.

BENDIX ABS DIAGNOSTIC SOFTWARE

Bendix ABS Diagnostic Software is an RP-1210 compliant

PC-based program that provides technicians with the highest level of diagnostic and control information for the MC-30 ™ controller. It can also be used to diagnose the EC-15 ™ ,

EC-16 ™ , EC-17 ™ and EC-30 ™ tractor ABS controller units.

With Bendix ABS Diagnostic Software, the technician can perform full ABS diagnostics, confi guration, testing and more.

An RP-1210 compliant communication link is needed when connecting a PC to the trailer’s diagnostic connector

(J1708/J1587).

For more information on the Bendix ABS Diagnostic

Software program, or RP-1210 compliant tools, contact

Bendix or refer to your local authorized Bendix dealer.

13

CHART 11 - MC-30 ™ CONTROLLER BLINK CODE DEFINITIONS (1 of 2)

14

CHART 11 - MC-30 ™ CONTROLLER BLINK CODE DEFINITIONS (2 of 2)

15

READ/WRITE (SCRATCHPAD) FUNCTION

Using the Bendix ABS diagnostic software, OEM and fl eet service records can be permanently stored in the EC-30 ™ controller. Data contained in the OEM scratchpad area is protected by a special password and can not be revised in the fi eld. Technician and date information must be entered prior to the fl eet scratchpad being updated. Some earlier revisions of the EC-30 ™ controller do not support the read/write function.

For more information on the Bendix ABS Diagnostic

Software program, or RP-1210 compliant tools, contact

Bendix or refer to your local authorized Bendix parts outlet.

NEXIQ (MPSI) BENDIX CARTRIDGE

MPSI provides a Bendix cartridge for use with the Pro-Link ® tool. It can also be used to diagnose the EC-15 ™ , EC-16 ™ ,

EC-17 ™ and EC-30 ™ tractor ABS controller units. For more information on the Bendix diagnostic cartridge from

MPSI, contact Bendix or refer to your local authorized

Bendix dealer.

PLC DIAGNOSTIC TOOL

Diagnostic tools are available that detect the presence of a PLC signal and perform further system diagnostics directly on the power line. For more information on these diagnostic tools, contact Bendix or refer to your local authorized Bendix dealer.

CONTACTING BENDIX - www.Bendix.com

The Bendix on-line troubleshooting guide for the MC-30 ™ controller will help you determine the cause of any conditions that may be preventing 100% performance of your braking system. For additional troubleshooting information on the MC-30 ™ controller, please refer to our literature request section.

The Bendix on-line contacts guide will make it easy for you to fi nd the Bendix contacts you need. From this page, you can navigate to technical support contacts, service engineers, Bendix account managers, international contacts and more. Bendix.com is your complete Bendix resource.

Bendix Technical Assistance Team:

For direct personal technical support, call the Bendix technical assistance team at 1-800-AIR-BRAKE (1-800-247-2725),

Monday through Friday, 8:00 A.M. to 6:00 P.M. EST, and follow the instructions in the recorded message.

Or, you may e-mail the Bendix technical assistance team at: [email protected].

To better serve you, please record the following information before calling the Bendix Tech Team:

Bendix product model number, part number and confi guration; vehicle make and model; Vehicle confi guration. (Number of axles, tire size, etc.); System performance symptoms.

When do they occur?; What faults have been identifi ed using LEDs, blink codes or diagnostic tools?; What troubleshooting / measurements have been performed?;

What Bendix service data literature do you have or need?;

Do you have access to the internet or email?

Lap Top

Computer

J1708/J1587 or J1939

Parallel or

Serial Cable

PDM (RP-1210)

FIGURE 15 - BENDIX ABS DIAGNOSTIC SOFTWARE

CORRECT MAINTENANCE PRACTICES

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when working under or around the vehicle. When working in the engine compartment, the engine should be shut off and the ignition key should be removed. Where circumstances require that the engine be in operation, EXTREME CAUTION should be used to prevent personal injury resulting from contact with moving, rotating, leaking, heated or electrically charged components.

3. Do not attempt to install, remove, disassemble or assemble a component until you have read and thoroughly understand the recommended procedures. Use only the proper tools and observe all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air brake system, or any auxiliary pressurized air systems, make certain to drain the air pressure from all reservoirs before beginning ANY work on the vehicle. If the vehicle is equipped with an

AD-IS ® air dryer system or a dryer reservoir module, be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended procedures, deactivate the electrical system in a manner that safely removes all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a component or plug unless you are certain all system pressure has been depleted.

8. Use only genuine Bendix ® replacement parts, components and kits. Replacement hardware,

16

tubing, hose, fi ttings, etc. must be of equivalent size, type and strength as original equipment and be designed specifi cally for such applications and systems.

9. Components with stripped threads or damaged parts should be replaced rather than repaired. Do not attempt repairs requiring machining or welding unless specifi cally stated and approved by the vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make certain all components and systems are restored to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC), the ATC function must be disabled (ATC indicator lamp should be ON) prior to performing any vehicle maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

SERVICING THE MC-30

™

CONTROLLER

CAUTION! All MC-30 ™ and EC-30T ™ controller service replacement parts are initially defaulted to 4S/2M side control and may need to be reconfi gured upon installation. An incorrect ABS configuration may cause fault indication or degraded ABS performance.

Before and after activating a self-confi guration, always determine the current ABS confi guration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics.

Prior to performing service to the MC-30 ™ controller, always perform the following steps:

1. Turn power off.

2. Drain the air pressure from all reservoirs.

3. Remove as much contamination as possible prior to disconnecting electrical connections and air lines.

4. Note the MC-30 ™ controller assembly mounting position on the vehicle.

REMOVING THE MC-30

™

CONTROLLER OR

M-30T

™

MODULATOR-VALVE

1. Disconnect the 30-pin ECU connector and the 3-pin modulator connector from the MC-30 ™ controller.

2. Remove all air lines connected to the unit.

3. Remove the MC-30 ™ controller assembly from the vehicle by removing the mounting bracket nuts or by rotating the entire assembly counterclockwise from the tank mount.

REPLACING THE EC-30T

™

CONTROLLER

In some cases, only the EC-30T ™ controller will need to be replaced. See Figure 18. If suffi cient clearance is available, the EC-30T ™ controller can be removed while the MC-30 ™ controller assembly is still mounted to the frame or tank. If the MC-30 ™ controller is removed from the vehicle, it may be lightly clamped in a bench vise during disassembly. However, over-clamping will result in damage, leakage, and/or malfunction. If a vise is to be used, position the MC-30 ™ controller so the jaws bear on the fl at area of the ECU bracket.

1. Disconnect the 30-pin ECU connector and the 3-pin modulator connector from the MC-30 ™ controller.

2. Remove the MC-30 ™ controller from the vehicle if necessary.

3. Note the EC-30T ™ controller position on the MC-30 ™ controller assembly and remove the four ECU mounting bolts. The original bolts can be reused for installation if they are in good condition. If replacement bolts are needed, grade 5 bolts or stronger are required.

4. Reinstall the new EC-30T ™ controller in the original mounting orientation. Torque the mounting bolts to

98 in. Ibs. Over-tightening the ECU bolts can cause damage to the EC-30T ™ controller.

5. The new EC-30T ™ controller may need to be reconfi gured for proper operation. Leakage and Operational Tests must be performed before returning the vehicle to service.

OVERHAUL OF THE RELAY VALVE

Several maintenance kits are available when a relay valve overhaul is necessary due to excessive leakage or contamination of the valve. See Figure 18. Instructions for the overhaul are provided in the replacement service kit. For more information on Bendix valve maintenance kits, contact Bendix or refer to your local authorized Bendix dealer.

CAUTION: There are no serviceable parts in the solenoid assembly portion of the modulator-valve and it should never be disassembled. If troubleshooting indicates failures in the solenoid function, replace the entire M-30T ™ modulatorvalve.

MC-12

™

MODULATOR / MCE-12 SERVICE

REPLACEMENT

The MC-30 ™ controller is designed to be the service replacement part for the MC-12 ™ modulator product.

When EC-12, M-12 ™ antilock modulator or ME-12 service replacement parts are required, the entire MC-12 ™ modulator assembly and pigtail harness must be replaced by an

MC-30 ™ controller assembly and pigtail harness. When replacing an MCE-12, the integral emergency function

(EV-2) must be replaced by a DC-4 and TR-3 ™ valve combination. See Figure 19 for plumbing details.

MC-30 ™ controller kits are available to replace all

MC-12 ™ modulator assemblies and harnesses. For more information, contact Bendix or refer to your local authorized

Bendix dealer.

CAUTION: The tank-mount MC-30 ™ controller must not be mounted on a frame or crossmember using the ECU bracket holes.

1. Disconnect the power connector and wheel speed sensors from the MC-12 ™ modulator pigtail harness.

2. Remove all air lines connected to the unit.

3. Remove the MC-12 ™ modulator assembly and pigtail from the vehicle by removing the mounting bracket nuts or by rotating the entire assembly counterclockwise from the tank nipple mount.

4. Install the new pigtail, starting at the power connector and properly securing the harness every 18 inches to the ECU location.

5. Next, refer to the Reinstallation of the MC-30 ™ controller or M-30T ™ modulator-valve section.

17

REINSTALLATION OF THE MC-30

™

CONTROLLER OR M-30T

™

MODULATOR-VALVE

CAUTION! All MC-30 ™ controller service replacement parts are initially defaulted to 4S/2M side control and may need to be reconfi gured upon installation. An incorrect ABS confi guration may cause fault indication or degraded ABS performance. Before and after activating a self-configuration, always determine the current ABS configuration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics.

The original mounting hardware can be reused for installation if it is in good condition. If replacement hardware is needed, use grade-5 5/16-18 nuts and lock washers for the bracket mount unit or a schedule 80 (heavy gauge steel) 1/2" nipple for the tank mount unit.

1. Position and secure the unit in the original mounting orientation: (The exhaust port must point straight down.)

Tank (nipple) mount unit - Install the nipple fi tting into the modulator-valve supply port. Then rotate the entire assembly into the tank port until secure. Over-torquing of the tank nipple could cause damage to the valve body.

Frame (bracket) mount unit - Torque the mounting nuts to 180-220 in-lbs.

2. Reconnect all air lines and plugs to the modulatorvalve assembly. Make certain that no thread sealing material enters the valve. All air lines and fi ttings should be checked for leaks prior to returning the vehicle to service.

3. Reconnect the ECU, modulator and sensor electrical connectors to the unit. Apply a moderate amount of non-conductive electrical grease to each connector pin before reconnecting. Torque the 30-pin ECU connector jack-screw to 15-20 in. lbs. Overtightening the jack-screw can cause damage to the

EC-30T ™ controller.

4. The new MC-30 ™ controller may need to be reconfi gured for proper operation. Leakage and Operational Tests must be performed before returning the vehicle to service.

LEAKAGE AND OPERATIONAL TESTS

1. Before performing leak tests, block the wheels.

2. Fully charge the air brake system and verify proper brake adjustment.

3. Make several trailer brake applications and check for prompt application and release at each wheel.

4. Check the modulator-valve body and all air line fi ttings for leakage by spraying each area with a soap solution:

- Check the ABS solenoid body with the trailer service brakes fully applied. If leakage is excessive, replace the entire M-30T ™ modulator-valve.

- Check the relay exhaust port and the area around the retaining ring with the trailer service brakes released.

A single 1" bubble within 3 seconds is permitted.

- Check the relay exhaust port and the area around the retaining ring with the trailer service brakes fully applied.

A single 1" bubble within 3 seconds is permitted.

If excessive leakage is detected at the relay exhaust port, perform the following test before replacing the

M-30T ™ modulator-valve:

Apply the trailer spring brakes. Recheck for leakage around the relay exhaust port. If the exhaust port stops leaking, this indicates a leak between the emergency and service sides of the spring brake chamber.

However, if the relay exhaust port continues to leak, replace the entire M-30T ™ modulator-valve.

5. Apply power and monitor the MC-30 ™ controller powerup sequence to verify proper system operation. Refer to the MC-30 ™ Controller Power-Up Sequence section.

6. Determine the current ABS confi guration by monitoring the diagnostic LEDs at power-up or by activating blink code diagnostics. If necessary, reconfi gure the

MC-30 ™ controller using self-configuration or a diagnostic tool. Refer to the Self-Confi guration / Control

Toggle section.

7. Calibrate and set odometer parameters if necessary using a diagnostic tool. Refer to the Odometer Function section.

8. When necessary, it is possible to road test the ABS function by making an abrupt stop from a vehicle speed of about 20 MPH to check for proper function. The wheels should not enter a prolonged lock condition and

ABS function should be audible. It is the responsibility of the technician to perform this test in a safe location.

ABS WIRING

The Bendix pigtail wiring harness and connectors are weather resistant and sealed at the connector interface.

See chart 12 for connector details and repair tools. 16 gauge GXL cable is typical. When troubleshooting ABS wiring, some general rules should be followed where applicable.

1. Check all wiring and connectors to ensure they are secure and free from visible damage. Check for evidence of wire chafi ng due to poor routing or poor securing of wires. Check connectors for proper insertion and locking. Verify that the connector leads are properly greased with a non-conductive electrical grease compound. Connector terminals must not show signs of corrosion or exposure to the environment.

2. During wiring repair, a splice must be properly soldered or mechanically crimped and made water proof.

3. Never pierce wire insulation when checking for continuity.

4. Do not deform individual pins or sockets during probing with a volt/ohm meter.

5. Only use the specifi ed crimping tools when replacing wire terminals and connectors.

6. Properly secure all wiring harness and sensor leads when repairs are made. (every 18 inches)

7. Apply a moderate amount of non-conductive electrical grease to each connector pin before reconnecting.

18

ABS Component Connector

12048455

MC-30

™

Controller

Harness

30-pin Packard

Metri-Pack

150 Series (Gray)

ABS Modulator

Connector

3-Pin Packard

Metri-Pack

280 Series

12040977

15300003

MOD 2

(Pigtail Side)

3-Pin Packard

Metri-Pack

280 Series

Power Connector

(Pigtail Side)

5-Pin Packard

Weather-Pack

15324197

Power Connector

(Vehicle Side)

5-Pin Packard

Weather-Pack

12065158

Wire

12103881

(18-16 GA)

12077411

(18-16 GA)

12048159

(18-16 GA)

12124580

(14-16 GA)

12124582

(14-16 GA)

Wire Seal/ Terminal

Plug

12065266

12015323

(18-16 GA)

Plug

12010300

N/A

12034145

N/A

Wheel Speed

Sensor

2-Pin

Diagnostic Port

4-Pin

DTM06-4S

(Pigtail Side)

DTM04-4P

(Remote Side / Cap)

Auxiliary

Port

8-Pin

DTM04-#P

DTM04-2P

(Pigtail Side)

DTM06-2S-E007

(Sensor Side)

DTM06-8S

(Pigtail Side)

DTM04-8P

(Remote Side)

DTM06-#S

Deutsch

DTM Series

462-201-20141

(S-Side of

Connector)

460-202-20141

(P-Side of

Connector)

N/A

WM-#P

WM-2P

(Pigtail Side)

WM-2S

(Sensor Side)

WM-4S

(Pigtail Side)

WM-4P

(Remote Side)

WM-8S

(Pigtail Side)

WM-2P

(Remote Side)

WM-#S

Terminal

12094429 for Metri-

Pack Terminals

12014012 for Weather

Pack Terminals

15300015

12155975 for Metri-

Pack Terminals

12014254 for Weather

Pack Terminals

HDT-48-00

CHART 12 - MC-30 ™ CONTROLLER WIRING AND COMPONENT CONNECTORS

19

FIGURE 16 - MC-30 ™ CONTROLLER ELECTRICAL SYSTEM SCHEMATIC

20

2S/1M - AXLE CONTROL

Ignition

Power

Ground

7-Pin

Connector

Brake Light

Power

A Brake Light Power

B Ignition Power

C NC

D Warning Lamp

E Ground

A

D

B

C

E

5-Pin

Connector

Trailer Chassis Harness

NOTE:

Front wheel speed sensor inputs must be used for two sensor installation even if sensors are not physically located at the forward axle.

Pigtail Harness

MC-30

MOD1

AntiLock

Right Front

WS Sensor

Dual Axle Trailer

ABS

ABS Light

Left Front

WS Sensor

2S/2M - SIDE CONTROL

Ignition

Power

Ground

7-Pin

Connector

Brake Light

Power

A Brake Light Power

B

Ignition Power

C NC

D Warning Lamp

E Ground

A

D

B

C

E

5-Pin

Connector

Trailer Chassis Harness

NOTE:

Front wheel speed sensor inputs must be used for two sensor installation even if sensors are not physically located at the forward axle.

For side control, MOD1 must control the right side.

Pigtail Harness

Dual Axle Trailer

ABS Light

ABS

MC-30

MOD1

AntiLock

MOD2

Right Front

WS Sensor

Left Front

WS Sensor

FIGURE 17 - MC-30 ™ CONTROLLER SYSTEM APPLICATIONS (1 OF 2)

21

4S/2M - SIDE CONTROL

Ignition

Power

Ground

7-Pin

Connector

A Brake Light Power

B Ignition Power

C NC

D Warning Lamp

E Ground

A

D

B

C

E

5-Pin

Connector

Trailer Chassis Harness

Brake Light

Power NOTE:

For side control, MOD1 must control the right side.

Pigtail Harness

Right Front

WS Sensor

Right Rear

WS Sensor

MC-30

MOD1

AntiLock

MOD2

Dual Axle Trailer

ABS Light

ABS

4S/2M - AXLE CONTROL

Ignition

Power

Ground

7-Pin

Connector

Right Front

WS Sensor

A Brake Light Power

B Ignition Power

C NC

D Warning Lamp

E Ground

A

D

B

C

E

5-Pin

Connector

Pigtail Harness

Trailer Chassis Harness

Brake Light

Power

NOTE:

For axle control, MOD1 must control the front axle.

MC-30

MOD1

AntiLock

Left Front

WS Sensor

Left Rear

WS Sensor

Right Rear

WS Sensor

MOD2

Dual Spread Axle Trailer

ABS

ABS Light

FIGURE 17 - MC-30 ™ CONTROLLER SYSTEM APPLICATIONS (2 OF 2)

22

Left Front

WS Sensor

Left Rear

WS Sensor

FIGURE 18 - MC-30 ™ CONTROLLER DISASSEMBLY

DOLLY / TOWING-TRAILER WITH EMERGENCY FUNCTION

+

Coupling - Control

Control

Supply

Dolly

R-12P

SC-3

SV-4

PR-3

Coupling - Supply

FIGURE 19 - EMERGENCY FUNCTION VALVE SCHEMATIC

AntiLock

MC-30

DC-4

Emergency

Function

TR-3

This is a piping schematic only, not a construction drawing.

Components and configuration are designed to enable compliance with

FMVSS 121

23

TROUBLESHOOTING

Fault information can be retrieved from the MC-30 ™ controller by using the diagnostic LED display, blink code diagnostics, or a diagnostic tool. However, the technician must also confi rm whether the fault resides in the component, wiring or connectors. The following troubleshooting fl ow charts will assist the technician in isolating the cause of the fault.

Troubleshooting should always begin by observing the ABS indicator lamp during the MC-30 ™ controller powerup sequence.

If it is necessary to make electrical measurements, always begin by taking voltage and resistance measurements at the

30-pin pigtail harness connector.

Once the circuit fault is found, isolate the area needing repair by repeating the measurements at all connections in the affected circuit towards the modulator, wheel speed sensor, etc.

No voltage or resistance measurements are to be made on the bulkhead connector pins of the EC-30T ™ controller.

When repairs are made, reconnect the electrical connector to the MC-30 ™ controller. Torque the connector retaining jack-screw to 15-20 in. lbs. Over-tightening the ECU connector jack-screw can cause damage to the EC-30T ™ controller.

Troubleshooting Flowcharts

Section A - (Power-Up) Trailer Mounted ABS Indicator Lamp

Section B - (Power-Up) Dash Mounted ABS Indicator Lamp

Section C - Trailer Mounted ABS Indicator Lamp

Section D - Dash Mounted Trailer ABS Indicator Lamp

Section E - Diagnostic LED Quick Reference

Section F - Power to the MC-30 ™ Controller

Section G - Wheel Speed Sensors

Section H - ABS Modulators

SECTION A - POWER-UP SEQUENCE -

TRAILER MOUNTED ABS INDICATOR LAMP

ABS Indicator Lamp at Power-Up

Apply ignition or brake light power and observe the ABS indicator lamp.

ABS indicator lamp does not come on.

Go to Section C.

The ABS indicator lamp stays on.

Go to Section E.

NO

The ABS indicator lamp should immediately illuminate when power is applied to the trailer.

YES

NO

Verify that the ABS indicator lamp stays on for 2.5 seconds and then turns off.

YES

The MC-30 ™ controller is functioning normally.

No service to ABS unit is needed.

24

SECTION B - POWER-UP SEQUENCE -

DASH MOUNTED TRAILER ABS INDICATOR LAMP

Dash Mounted Trailer ABS

Indicator Lamp at Power-Up

Verify that a PLC trailer is connected to the tractor via the 7-pin connector. Turn ignition on and observe the trailer ABS indicator lamp on the dash.

Trailer ABS indicator lamp does not come on.

Note: Only towing vehicles built after

March 1, 2001 will be required to have

a trailer ABS indicator lamp. The trailer

ABS indicator lamp, located on the vehicle dash, is only activated by a PLC signal from a trailer or diagnostic tool. The towing vehicle must be equipped with an

ABS unit with PLC.

Verify that a PLC signal is present on the trailer ignition power lines. (Refer to the

MC-30 ™ controller with PLC section of this document).

If a PLC signal is present and the trailer

ABS lamp does not come on at power-up, troubleshoot the dash mounted trailer lamp circuit on the tractor.

If the tractor is equipped with an Bendix

EC-30 ™ controller, Go to Section D.

The dash mounted trailer ABS indicator lamp stays on. This is an indication that the trailer ABS unit has a fault.

Go to Section A

If the trailer ABS lamp stays on with no trailer connected,

Go to Section D.

NO

Verify that the dash mounted trailer

ABS indicator lamp illuminates within 2 seconds of ignition power being applied to the vehicle.

YES

NO

Verify that the dash mounted trailer

ABS indicator lamp stays on for 2.5 seconds and then turns off.

YES

T h e A B S u n i t i s functioning normally.

No service to ABS components is needed.

25

26

SECTION C - TROUBLESHOOTING THE

TRAILER MOUNTED ABS INDICATOR LAMP

ABS Indicator Lamp did not illuminate during the MC-30 ™ controller powerup sequence.

ABS Indicator Lamp stays on with no red LEDs on.

With ignition or brake light power applied to the trailer, verify that the green VLT LED is on.

NO

YES

Turn off power to the MC-30 ™ controller.

Inspect the condition of the ABS indicator lamp, connector and ground.

Using a volt/ohm meter, verify continuity across the bulb. Verify continuity from trailer chassis ground to the ABS indicator lamp ground pin.

If repair is made, rerun the power up sequence.

Go to Section A.

Continue if the indicator lamp and ground wire check out OK.

Turn off the power and disconnect the 30-pin connector from the

MC-30 ™ controller.

With a volt/ohm meter, check the

ABS indicator lamp wiring. Refer to

(fi gure 16). When repair is made, reconnect the 30-pin connector to the MC-30 ™ and rerun the power up sequence. Go to Section A.

If the condition still exists, replace the EC-30T ™ controller.

Troubleshoot the power supply to the

MC-30 ™ controller. Go to Section F.

With power off to the MC-30 ™ controller, disconnect the 30-pin connector. Verify continuity from pin D3 of the 30-pin connector and the ABS indicator lamp connector. Refer to (fi gure 16). When repair is made, rerun the power up sequence.

Go to Section A.

If condition still exists, replace the

EC-30T ™ controller.

30-Pin Connector

K J H G F E D C B A

D3

1

2

3

SECTION D - TROUBLESHOOTING THE DASH MOUNTED TRAILER

ABS INDICATOR LAMP WITH EC-30

™

CONTROLLER

The dash mounted trailer ABS indicator lamp did not illuminate at vehicle power-up.

Trailer ABS indicator lamp stays on with no trailer connected to towing vehicle.

See note this page

With ignition off, remove the 30-pin connector from EC-30 ™ controller.

With ignition off, remove the 30-pin connector from EC-30 ™ controller.

See note this page

Turn ignition on and measure voltage between pin E2 and ground (pins A1,

A2 or A3). Verify a measurement equal to battery voltage. (About 12.0

VDC)

NO

YES

With a volt/ohm meter, verify no continuity from trailer ABS indicator lamp connector pin to ground.

Check for corrosion or damage on the 30-pin connector and wiring. If no issues are found, replace the

EC-30 ™ controller.

Only towing vehicles built after

March 1, 2001 will be required to have a trailer ABS indicator

lamp. The trailer ABS indicator lamp, located on the vehicle dash, is only activated by a PLC signal from a trailer or diagnostic tool. The towing vehicle must be equipped with an EC-30 ™ controller with

PLC. Refer to the part number and confi guration to ensure that the

EC-30 ™ controller supports PLC communications.

Check for corrosion or damage on the 30-pin connector and wiring. If none is found, replace the EC-30 ™ controller.

EC-30 ™ Controller

30-Pin Connector

K J H G F E D C B A

E2

A1,A2,A3 Ground

1

2

3

With a volt/ohm meter, check wiring, trailer ABS indicator lamp and fuse.

When repair is made, reconnect the 30-pin connector to the EC-30 ™ controller and rerun the power up sequence. Go to Section A.

Note: If there is no wire in pin

E2 of the 30-pin connector, the

EC-30 ™ controller is commanding the trailer ABS indicator lamp, using the J1939 or J1587 serial communications link.

In this confi guration, the actual trailer

ABS indicator lamp is driven by a vehicle dash controller. Obtain the vehicle manual and verify the wiring and function of the trailer ABS indicator lamp.

To verify proper EC-30 ™ controller communication, refer to the EC-30 ™

ABS / ATC Controller service data sheet, SD-13-4815.

27

SECTION E - DIAGNOSTIC LED QUICK REFERENCE

Comparing your MC-30

™

controller to the following images, identify the fault indicated by the diagnostic

LEDs and follow the instructions in the related troubleshooting section.

Power

System OK - A solid green VLT LED indicates proper voltage is reaching the MC-30 ™ controller. If no red

LEDs are on, then no faults are detected.

If the ABS indicator lamp is on with no red LEDs, Go to Section C.

Voltage Out of Range - A fl ashing green VLT LED indicates ECU voltage below 8.0 VDC or above 16.0

VDC. The VLT LED will fl ash until power is brought into normal range. Go to Section F.

No Voltage - When the VLT LED is off, the MC-30 ™ controller is receiving very low or no voltage. The ECU

LED may be on in this case. Go to Section F.

Wheel Speed Sensor Fault

The red SEN LED is on to indicate a fault condition with a wheel speed sensor. The example shown is a front right sensor fault. Troubleshooting and repair are the same for a fault on any wheel speed sensor.

The indicated sensor fault may a static or dynamic fault.

Static faults are related to wiring or component failures such as open or short circuits.

Dynamic faults are related to abnormal wheel speed signals or behaviors.

Go to Section G.

28

ABS Modulator Fault

The red MOD LED is on to indicate a fault condition with an ABS modulator. The example shown is a right modulator fault. Troubleshooting and repair are the same for a fault on either ABS modulator.

The indicated modulator fault may a static or dynamic fault.

Static faults are related to wiring or component failures such as open or short circuits.

Dynamic modulator faults are related to abnormal wheel speed behaviors during ABS.

Go to Section H.

ECU Fault

The red ECU LED is on to indicate a fault condition internal to the EC-30T ™ controller. Reset the MC-30 ™ controller with a magnet. If the fault returns, replace the EC-30T ™ controller.

If the red ECU LED is on and the green VLT LED is off, the MC-30 ™ controller may have very low voltage.

In this case, Go to Section F.

Faulty Power Supply - the MC-30 ™ controller may not function properly when powered with a battery charger or other similar device. Power the MC-30 ™ controller using a battery or clean power supply. Go to Section A.

Magnetic Fault Reset - All LEDs will be on while a magnet is held in place at the RESET location. If one or more LEDs do not come on, replace the EC-30T ™ controller. Do not reset fault codes until troubleshooting of the indicated component is complete.

SECTION F - TROUBLESHOOTING POWER TO THE MC-30

™

CONTROLLER

T h e g r e e n V LT L E D i s o f f o r fl ashing.

The MC-30 ™ controller may not function properly when powered with a battery charger or other similar device. Power the MC-30 ™ controller using a battery or clean power supply.

D u e t o c o r r o s i o n , d a m a g e o r poor termination, the wiring and/ or connectors may be limiting the electrical current fl ow to the MC-30 ™ controller. This means that when the

MC-30 ™ controller needs more current, the voltage level may be dropping. In order to measure the voltage under load, place a load such as a type 1157 brake light bulb between pin E1 and ground pin D2 at the 30-pin connector.

Supply ignition power to the trailer and measure the voltage across the pins while the lamp is in place. Repeat the loaded measurements using brake light power and pins E3 and D2 at the 30-pin connector.

The operating range of the MC-30 ™ controller is 8.0-16.0 VDC. Verify a measurement equal to battery voltage.

(About 12.0 VDC) The loaded voltage should drop no more than 1.0 VDC from the measured unloaded voltage.

Turn off power to the MC-30 ™ controller and disconnect the 30-pin connector.

Supply ignition power to the trailer and measure voltage between pin E1 and ground pin D2 at the 30-pin connector.

YES

Supply brake light power to the trailer and measure voltage between pin

E3 and ground pin D2 at the 30-pin connector.

The operating range of the MC-30 ™ controller is 8.0 -16.0 VDC. Verify a measurement equal to vehicle voltage at both power inputs. (About 12.0 VDC)

NO

With a volt/ohm meter, check the power and ground wiring. Look for corroded or damaged wires or connectors. When repair is made, reconnect the 30-pin connector to the MC-30 ™ controller and rerun the power up sequence.

Go to Section A.

Measure the loaded voltage across a type