advertisement

Toll Free: 1 866 383-1657

3381 Cambie St., #211 Vancouver, BC Canada V5Z 4R3

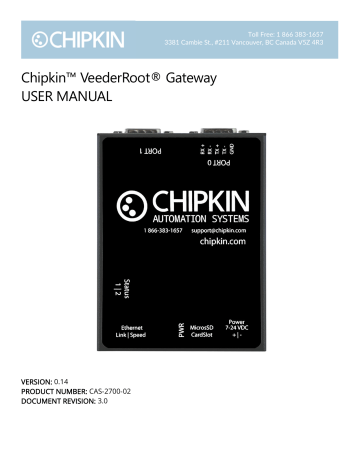

Chipkin™ VeederRoot® Gateway

USER MANUAL

VERSION: 0.14

PRODUCT NUMBER: CAS‐2700‐02

DOCUMENT REVISION: 3.0

TABLE OF CONTENTS

Chipkin™ VeederRoot® Gateway User Manual

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 2 of 67

Chipkin™ VeederRoot® Gateway User Manual

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 3 of 67

Chipkin™ VeederRoot® Gateway User Manual

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 4 of 67

Chipkin™ VeederRoot® Gateway User Manual

LIST OF FIGURES

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 5 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 5.3-4 - CAS BACnet Explorer - Discovered Objects .............................................................................49

LIST OF TABLES

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 6 of 67

COPYRIGHT & TRADEMARKS

Chipkin™ VeederRoot® Gateway User Manual

Copyright © 2017 Chipkin Automation Systems All rights reserved.

TM

(TM)

are trademarks of Chipkin Automation Systems

DISCLAIMER

Chipkin Automation Systems™ has limited its liability for damages incurred by the customer or its personnel in the contractual documents pursuant to which the product is provided to the customer.

The information and specifications contained throughout this user manual are up to date at the time of publication. Chipkin Automation Systems has used, and continues to use, its best efforts to maintain this user manual to reflect the most current configuration of the product. Chipkin Automation Systems reserves the right to change the contents of this user manual at any time without notice and assumes no liability for its accuracy. In the preparation of this user manual, Chipkin Automation Systems has incorporated, and/or compiled service information and maintenance procedures sourced from manufacturers and vendors of parts and components used in the manufacturing of this product.

Therefore, Chipkin Automation Systems shall not be liable for omissions or missing data. It is not the intension of this user manual to instruct service technicians in using common sense, basic skills and rules of service repair.

CONFIDENTIALITY

The information contained in this document is the intellectual property of Chipkin Automation

Systems and is Commercially Confidential. No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written permission of Chipkin Automation Systems.

DOCUMENT REVISION HISTORY

REVISION

1

2

3

DATE

2012-Feb-17

2013-Aug-24

2018-Feb-13

AUTHOR NOTE

ACF - Created document

ACF - Updated document adding additional support info

ACF - Updated style

- Added configuration info and section on how to decode setup reports

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 7 of 67

Chipkin™ VeederRoot® Gateway User Manual

1. PREFACE

WELCOME

As a new owner of Chipkin Automation Systems’™ (CAS) Gateway you have joined thousands of satisfied customers who use Chipkin’s protocol gateways, data clients and integration services to meet their building and industrial automation requirements. Our configuration expertise in this field combined with free BACnet and other tools ensure your success; and our customer support via phone, email and remote desktop tools means that we’re there when you need us. Thank you for choosing

Chipkin’s products.

CHIPKIN

Chipkin offers expert solutions for your building and industrial automation requirements. We develop, configure, install and support gateways (protocol converters), data loggers, and remote monitor and controlling applications. Founded in October 2000, Chipkin provides expert solutions for converting

BACnet®, Modbus®, and Lonworks®—to name just a few—and enabling interfaces for HVAC, fire, siren, intercom, lighting, transportation and fuel systems. The high-quality products we offer (including those from other vendors) interface with Simplex™, Notifier™, McQuay™, GE™ and many others—so you can rest assured that Chipkin will select the most appropriate solution for your application.

SAFETY WARNINGS

The CAS Gateway User Manual provides information on how to install and configure the gateway and is intended for engineers, project management consultants and building management services. Before you install the device, please observe the safety warnings described in in this manual.

PRODUCT SUMMARY

Chipkin’s™ VeederRoot® gateway is a protocol converter that can read data and alarms from a

VeederRoot® TLS Panel and serves the data as Modbus, BACnet or Web data. The gateway supports all these options simultaneously, use the data you want and ignore the other. The Gateway connects to the TLS Panel, reads data and stores it internally. When a remote system requests data, this data is served in a form that is appropriate to the protocol. If the connection to the TLS Panel is lost, or data cannot be read, the gateway can signal this to the remote data client.

CUSTOMER SUPPORT

Chipkin is a small responsive company, and we live or die by the quality of our service—and with offices in two time-zones—we can provide support when you need it. For information on sales, service, obtaining documentation or submitting a service request, please call us toll free at 1-866-383-

1657. Thanks for choosing Chipkin’s protocol gateways, data clients and integration services to meet your building and industrial automation requirements.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 8 of 67

SALES AND CUSTOMER SUPPORT

TOLL FREE: 1-866-383-1657

FAX: 1-416-915-4024

Email: [email protected]

GENERAL

TOLL FREE: 1-866-383-1657

FAX: 1-416-915-4024

EMAIL: [email protected]

SHIPPING ADDRESS

3381 Cambie St., #211

Vancouver, BC, Canada V5Z 4R3

Chipkin™ VeederRoot® Gateway User Manual

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 9 of 67

2. OVERVIEW

Chipkin™ VeederRoot® Gateway User Manual

SYSTEM OVERVIEW

The CAS 2700-02 VeederRoot® Gateway is a protocol converter that converts data from one protocol and makes it available to devices that support a different protocol. The gateway typically sends polling messages, extracts any data values, and stores the values in an internal database. The data is then made available via other protocol specific formats.

For this device, the gateway polls for data using the VeederRoot® TLS protocol over serial or TCP/IP.

The data is then served via Modbus (TCP or RTU), BACnet IP, or HTTP. All of these options are available simultaneously.

OPTIONAL EXPANSION MODULES

The CAS 2700-02 VeederRoot® Gateway does not have any optional expansion modules.

INSTALLATION AND CONFIGURATION SUMMARY

For more information on how to install and setup the CAS 2700-02 VeederRoot® Gateway please refer to the Getting Started with CAS Gateway.pdf document. For instructions on configuring this

device is completed primarily through a web interface.

DEVICE WIRING REQUIREMENTS

For more information on how to wire up the CAS 2700-02 VeederRoot® Gateway, please refer to the

of this document.

contains wiring pictures and diagrams as well as port pin-outs.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 10 of 67

3. CONNECTIONS

Chipkin™ VeederRoot® Gateway User Manual

NETWORK CONNECTIONS

This block diagram lists common network connections that can monitor from VeederRoot® devices using BACnet IP, Modbus (TCP or RTU), and HTTP protocols.

Figure 3.1-1 - Block Diagram

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 11 of 67

Chipkin™ VeederRoot® Gateway User Manual

WIRING CONNECTIONS

The following sections describe the wiring connections used by the various ports of the CAS 2700-02

VeederRoot® Gateway.

This includes pictures and diagrams of provided cables and the pin-outs of the ports for the protocols that are used.

CABLES

VeederRoot RS232 Serial Patch Cable

The photographs in the figure below show the cable that is shipped with the gateway. If you would like to replace the Ethernet patch cable with a longer segment, use the pin-out information to assemble your own.

Figure 3.2-1 - Veeder Quick Assembly Cable for RS232

Modbus RTU RS485 Terminal Block

The following picture shows the connector needed if using Modbus RTU on RS485. See the following section for a description of the Pin-out

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Figure 3.2-2 - Modbus RTU 485 Terminal Block

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 12 of 67

Chipkin™ VeederRoot® Gateway User Manual

PIN-OUT

The CAS 2700-02 VeederRoot® Gateway has two serial ports. This section describes the pin-out for using the port with a specific protocol.

Port 0 – RS485 – Modbus RTU

Pin-out for the DB9 Terminal Block for Modbus RTU communication – See Figure above (Figure 3.2-2) for a visual of what it should look like.

- Pin 1 jumped to Pin 3 => wire connected to Pin 1 connects to the positive terminal of the

Modbus Device.

- Pin 2 jumped to Pin 4 => wire connected to Pin 4 connects to the negative terminal of the

Modbus Device.

- Pin 5 connects to the ground or common terminal of the Modbus Device.

- Pin 6 jumped to Pin 9

- Pin 7 jumped to Pin 8.

Port 1 – RS232 – VeederRoot® Serial

The following shows the pin-out required for the VeederRoot serial communication.

Figure 3.2-3 - RS232 Pin-out for Port 1 to the VeederRoot panel

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 13 of 67

Chipkin™ VeederRoot® Gateway User Manual

4. CONFIGURATION AND SETTINGS

This section contains instructions and screenshots on how to configure this device. All configuration is handled via the web pages of the device.

The CAS 2700-02 VeederRoot® Gateway uses a meta-configurer. This means that during the configuration process, the end points (BACnet IP Objects and Modbus Registers) are automatically generated. There are two ways for configuring the unit, standard and advanced. The Standard configuration is useful if the VeederRoot® panel has 10 or less Tanks and 10 or less Sensors. If there are more than 10 Tanks or Sensors, then you must use the Advanced Configuration.

There are also two protocols to choose from for VeederRoot® communication, Serial or TCP/IP. The configuration process for both is very similar and any differences will be described in the following sections.

The next sections contain the steps on how to do both configurations and screenshots of the web pages.

VeederRoot® Standard Configuration

As mentioned above, the Standard Configuration has a limit of configuring up to 10 Tanks and 10

Sensors. If the VeederRoot® panel has more, then you must use the Advanced Configuration.

To access the Standard configuration webpage, open a web browser and type in the following:

- http://{ipAddress}/bin/veederrootserial/config/ for VeederRoot® Serial or

- http://{ipAddress}/bin/veederroottcp/config/ for VeederRoot® TCP/IP where {ipAddress} is the IP Address of the CAS 2700-02 device.

Note: To determine the IP Address of the device, please refer to section 6.2 Discover

The config web page contains a simple form to fill out to complete the configuration.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 14 of 67

Chipkin™ VeederRoot® Gateway User Manual

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Figure 4.1-1 - Standard Configuration

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 15 of 67

Chipkin™ VeederRoot® Gateway User Manual

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Figure 4.1-2 - Standard Configuration continued

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 16 of 67

Chipkin™ VeederRoot® Gateway User Manual

The images above are for the Standard VeederRoot® Serial configuration.

Here is a breakdown of each of the individual configuration sections:

BACnet Server Configuration

Figure 4.1-3 - BACnet Server configuration

This section is for specifying the settings for the BACnet IP server device.

- Port – This is the BACnet IP Port that the gateway will use as a BACnet IP Server device. The default is 47808.

- Device ID – This is the BACnet Device ID that will be assigned to the gateway. This must be unique throughout the entire BACnet network on site. The default is 389001.

Modbus Slave Configuration

Figure 4.1-4 - Modbus Slave configuration

This section is for configuring the settings for the Modbus slave device.

- RTU Baud Rate – The baud rate for the Modbus RTU RS485 serial connection. The default is

9600. The other serial connection parameters are pre-defined as 8 data bits, no parity, and 1 stop bit.

- Device ID – This is the Modbus Slave ID that will be assigned to the gateway.

- TCP Port – This is the Modbus TCP port that the gateway will use as a Modbus TCP Slave device. The default is 502.

Veeder Root Configuration

Depending on whether you are configuration for VeederRoot® serial or TCP, the fields in this section may differ.

For VeederRoot® serial

Figure 4.1-5 - VeederRoot serial configuration

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 17 of 67

Chipkin™ VeederRoot® Gateway User Manual

- Baud Rate – The baud rate for the VeederRoot® RS232 serial communication. The default is

9600.

- Data Bits – The data bits for the VeederRoot® RS232 serial communication. The default is 8.

- Parity – The parity for the VeederRoot® RS232 serial communication. The default is none.

- Stop Bits – The stop bits for the VeederRoot® RS232 serial communication. The default is 1.

Note: For newly installed VeederRoot® Serial communication cards whose communication settings have not been changed on the VeederRoot® panel, use 1200, 7, Odd, 1.

Or VeederRoot® TCP/IP

Figure 4.1-6 - VeederRoot TCP/IP configuration

- IP Address – The IP Address of the VeederRoot® TLS Panel.

- Port – The port for using the Veeder® TLS Protocol. It usually is 10001, and sometimes 3001 or 8001.

VeederRoot Settings

The following section contains settings used by the gateway when executing VeederRoot tasks to read data.

Figure 4.1-7 - VeederRoot Settings

- Default Value – Specifies the default value for all data points in the system. This is also used for when the gateway determines that the VeederRoot® panel has gone offline, all data in the database will be set to this value as a way of showing that the unit has been disconnected.

- Scan Interval – How many seconds to poll for data. The default is 10 seconds.

- Timeout Time – How many seconds to wait after a message has been sent to the panel before timing out. The default is 3 seconds.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 18 of 67

Chipkin™ VeederRoot® Gateway User Manual

- Number of Retries after a Timeout – How many times to attempt to retry sending the message.

The default is 3.

- Time between Retries – How many seconds to wait between retries. The default is 1 second.

- Disconnect Time – How many seconds after a timed-out message to determine if the

VeederRoot® panel is offline. The default is 120 seconds.

- Units – Specify either US or Metric.

The Disconnect Time and Default Value logic works as follows: once a message times out, the disconnect timer starts (by default 120 seconds). If the disconnect timer expires, then the system is flagged that the VeederRoot® panel has been disconnected and all values in the database are set to the Default Value.

Tank Configuration

Figure 4.1-8 - Standard Tank Configuration

In this part of the form, you can configure up to 10 tanks. As mentioned above, if the VeederRoot® panel contains more then you must use the Advanced Configuration.

- Name – The tank’s name, this field is only used internally in the gateway.

- Address – The tank’s address in the VeederRoot® panel. If the Tank has address 1-9, you must type 01 – 09 as addresses are 2 digits.

- Suffix – This is the name that gets appended to the BACnet data point. This usually is the same as the Name column entry.

Sensor Configuration

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 19 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.1-9 - Sensor Configuration

In this part of the form, you can configure up to 10 sensors. As mentioned above, if the VeederRoot® panel contains more then you must use the Advanced Configuration.

- Name – The sensor’s name, this field is only used internally in the gateway.

- Address – The sensor’s address in the VeederRoot® panel. If the Sensor has address 1-9, you must type 01 – 09 as addresses are 2 digits.

- Suffix – This is the name that gets appended to the BACnet data point. This usually is the same as the Name column entry.

- Type – The type of sensor. The default is Liquid Sensor

Vacuum Sensor Configuration

Figure 4.1-10 - Vacuum Sensor configuration

In this part of the form, you can configure up to 2 vacuum sensors. As mentioned above, if the

VeederRoot® panel contains more then you must use the Advanced Configuration.

- Name – The sensor’s name, this field is only used internally in the gateway.

- Address – The sensor’s address in the VeederRoot® panel. Addresses are 2 digits as above.

- Suffix – This is the name that gets appended to the BACnet data point. This usually is the same as the Name column entry.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 20 of 67

Relay Configuration

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.1-11 - Relay configuration

In this part of the form, you can configure up to 10 relays. As mentioned above, if the VeederRoot® panel contains more then you must use the Advanced Configuration.

- Name – The relay’s name.

- Address – The relay’s address in the VeederRoot® panel. Addresses are 2 digits as above.

Other Options

Figure 4.1-12 - Other Options

Finally, there are two other options.

- Tank Deliveries – enables all tank delivery data points for the tanks. The gateway polls and stores the 3 most recent tank deliveries.

- System Alarms – enables VeederRoot® panel system alarm and errors data points.

Saving the Configuration

Click on the “Save Configuration” Button once you have filled out the form.

If successful, you will see the following message:

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 21 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.1-13 - Save Configuration Success

Please refer to Section 4.3 Rebooting the Gateway for next steps.

VeederRoot® Advanced Configuration

To access the Advanced configuration webpage, open a web browser and type in the following:

- http://{ipAddress}/bin/veederrootserial/config/advanced for VeederRoot® Serial or

- http://{ipAddress}/bin/veederroottcp/config/advanced for VeederRoot® TCP/IP where {ipAddress} is the IP Address of the CAS 2700-02 device.

Note: To determine the IP Address of the device, please refer to section 6.2 Discover

Example of the Advanced Configuration form:

Figure 4.2-1 - Advanced Configuration

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 22 of 67

Chipkin™ VeederRoot® Gateway User Manual

BACnet, Modbus, and VeederRoot® Configuration

As can be seen in Figure4.2-1 the BACnet Server, Modbus Slave, Veeder Root Configuration and

VeederRoot Settings options are the same as the Standard Configuration. For more information on those sections, please review:

-

4.1.1 – BACnet Server Configuration

-

4.1.2 – Modbus Slave Configuration

-

4.1.3 – Veeder Root Configuration

-

Tank Configuration

To configure a Tank, first click on the “Insert” link as seen below:

Figure 4.2-2 - Insert Advanced Configuration

Then in the “Choose a device type”, select Tank. You will see the following form:

Figure 4.2-3 - Tank Advanced Configuration

Fill out the form with the Tank Name, Tank Address, and check which data points to poll for.

Finally Click the “insert” button to add the tank to the configuration.

If the tank was added successfully, you will see the following:

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 23 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.2-4 - Tank added successfully

Repeat this process to add additional tanks.

Sensor Configuration

To add a sensor, click the “Insert” link and select Sensor in the “Choose a device type” and you will see the following form:

Figure 4.2-5 - Sensor Advanced Configuration

Fill out the Sensor Name and Sensor Address and select the type of sensor, then click the “insert” button.

Vacuum Sensor Configuration

To add a vacuum sensor, click the “Insert” link and select Vacuum in the “Choose a device type” and you will see the following form:

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 24 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.2-6 - Vacuum Sensor Advanced Configuration

Fill out the Vacuum Name and Vacuum Address and click the “insert” button.

Relay Configuration

To add a relay, click the “Insert” link and select Relay in the “Choose a device type” and you will see the following form:

Figure 4.2-7 - Relay Advanced Configuration

Interpreting the Setup Report

Typically to complete a VeederRoot configuration, a setup report needs to be printed from the

VeederRoot panel. To print the setup report, follow the instructions found here: Printing Setup

Report .

The setup report contains the communication port settings and the list of tanks, sensors, and relays that are installed on the panel. The following images are examples of setup reports and how to interpret them to configure the gateway.

System Units

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 25 of 67

Chipkin™ VeederRoot® Gateway User Manual

One of the first sections is the System Setup. In this section of the report, we can determine the units.

Figure 4.3-1 - Setup Report – TLS 300/350 – System Units

The units are configured as part of the VeederRoot Settings .

Communications Setup

The Communications Setup contains information about the comm ports installed on the VeederRoot panel. For VeederRoot serial, look for a RS232 COMM Board. For VeederRoot TCP/IP, look for a

Ethernet COMM Board.

Figure 4.3-2 - Setup Report – TLS 300/350 – Communication Setup

The communication settings are configured in the Veeder Root Configuration section.

In-Tank Setup

The In-Tank Setup section of the report contains all the information we need to configure the tanks.

See image below for an example:

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 26 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.3-3 - Setup Report – TLS 300/350 – Tank Setup

The highlighted section read T1: Diesel. The T1 is the Tank Number. When we configure the tank

either using the Tank Standard Configuration

or Tank Advanced Configuration , we would specify the

Tank address as 01. Diesel is the name of the tank, so we could configure it to have a name of

Tank01_Diesel in our system. Continue this for each tank listed in the report.

Sensor Setup

There may be multiple Sensor Setup sections in the report if the VeederRoot panel contains multiple sensor types. The most common is Liquid Sensor. Here is an example of a Liquid Sensor Setup:

Figure 4.3-4 - Setup Report – TLS 300/350 – Liquid Sensor Setup

Like the Tank Setup, each sensor has a letter and number specification. In the example above, L1:

Tank 1 Interstitial. When configuring the sensor using the Sensor Standard Configuration

Advanced Configuration , we would specify the address as 01, the type as Liquid Sensor, and the name

/ suffix as L01_Tank1_Interstitial.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 27 of 67

Chipkin™ VeederRoot® Gateway User Manual

Other sensor types will have separate sections in the setup report. Here are some examples of letter specifications for other sensors:

- L – Liquid Sensor

- V – Vapor Sensor

- G – Ground-water Sensor

- C – Type-A Sensor

- H – Type-B Sensor

Relay Setup

Finally, there is a Relay Setup section in the report. Here is an example of the Relay Setup:

Figure 4.3-5 - Setup Report – TLS 300/350 – Relay Setup

Like the Tank Setup, each relay has a letter and number specification. In the example above, R1: Low

Level Tank 1. When configuring the relay using the Relay Standard Configuration

Configuration , we would specify the address as 01 and the name as R01_Low_Level_Tank_1.

Completing the Configuration

Once the configuration process has finished, either using the Standard or Advanced configuration, you will need to reboot the system for the new configuration to take effect.

First, return to the main system page by typing in the follow URL into a web browser:

- http://{ipAddress}/bin/system/ where {ipAddress} is the IP Address of the gateway.

From this page, under the System actions, first click the “Save Database” link to save all changes.

Figure 4.4-1 - Save Database Link

Click “Ok” when prompted and you will see the following XML, check that the response status is OK.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 28 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.4-2 - Save Database Successful

Click the back button in your web browser and then click the “Reboot System” link:

Figure 4.4-3 - Reboot System Link

Click “Ok” when prompted and you will see the following screen with a timer counting up:

Figure 4.4-4 - Reboot System Count

The system page will refresh once the device has been properly rebooted.

Resetting the Gateway or Deleting the Configuration

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 29 of 67

Chipkin™ VeederRoot® Gateway User Manual

Sometimes you want to delete the entire configuration and begin again. To do this, return to the

system page as described in the Completing the Configuration section above. Then click on the

“Delete Database” Link:

Figure 4.5-1 - Delete Database Link

Click “Ok” when prompted and verify that the result XML has a response status of OK:

Figure 4.5-2 - Delete Database Successful

Click the back button in the web browser and then follow the instructions in the Completing the

Exporting the Configuration

To save a copy of the configuration, return to the system page as described in the Completing the

Configuration section above. Then click on the “Generate Configuration File” Link:

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 30 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.6-1 - Generate Configuration File Link

After a while, a link to “Export Configuration” will appear. Click on the link to download the config.csv file which is the configuration of the gateway.

Figure 4.6-2 - Export Configuration

Importing the Configuration

Sometimes Chipkin will send you a configuration file to load onto the Gateway, or you would like to load an older configuration file that you may have saved. To do this, return to the system page as

described in the Completing the Configuration section above.

Then find the section titled “Import Configuration”:

Figure 4.7-1 - Import Configuration

Click the “Choose File” button to open a file browser. Browse to the csv configuration file you wish to import and Click “Open”.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 31 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.7-2 - Import File Browser

The file should now be displayed next to the “Choose File” button.

Figure 4.7-3 - Configuration File Ready for Import

Finally, click the “Import” Button. The file will be parse and the output will be displayed. Here is an example of the output:

Figure 4.7-4 - Importing the Configuration File

Scroll to the bottom of the page to see the if the Import was successful. You should see the following:

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 32 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 4.7-5 - Import Successful

After this, return to the system page and follow the instruction in the Completing the Configuration

section to finish and apply the new configuration.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 33 of 67

Chipkin™ VeederRoot® Gateway User Manual

5. READING DATA AND TEST PROCEDURE

This section contains information on how to view the VeederRoot data.

Important Note: These next sections display sample data using a default configuration. The

Modbus Map and BACnet objects are generated during the configuration process, so they will change and will be different than what is described here.

READING DATA USING HTML / WEB Browser

To view the data on the device’s webpage, enter the following URL into a web browser: http://{ipaddress}/bin/veederrootserial/reports where {ipAddress} is the IP Address of the gateway.

The link will open a web page containing a table of the stored values as well as the Modbus Register and BACnet IP object and units associated with that data point.

See the image below for an example of the data.

Figure 5.1-1 - Example Reports Page

READING MODBUS DATA

You can access Modbus register data from the gateway by using a Modbus RTU or TCP client. To find out what registers exist on the device, please refer to the Modbus Register Map . For some guides on

Modbus, please refer to the following links:

• Modbus For Field Technicians

• Modbus FAQ

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 34 of 67

•

What is Modbus?

•

Testing Modbus Communication

Chipkin™ VeederRoot® Gateway User Manual

Interpreting Modbus Data

Modbus does not have a mechanism for reporting the validity of data. If the gateway loses its connection to the Veeder-Root device (or a data point cannot be read), it will disregard previous data as unreliable.

Unreliable data will be tagged with the value 65535 (‐1, configurable) in the registers.

Some values have been encoded as IEEE754 format floating point numbers. These values use 2x16-bit registers and are clearly identified in the Modbus map. Since Modbus does not support floating point numbers, all values are served as whole numbers.

Modbus Functions Supported (RTU and TCP)

This device supports the following functions:

• 01 (0x01) Read Coils

• 02 (0x02) Read Discrete Inputs

• 03 (0x03) Read Holding Registers

• 04 (0x04) Read Input Registers

Most masters should be configured to use function 3, read holding registers.

Modbus Register Map

The sections contain an example of the Modbus Register Map for this gateway.

Important Note: As mentioned above, this map is based on sample data using a default configuration. The Modbus Map is generated during the configuration process, so it will change and will be different than what is described here. You can view the current Modbus

Map by reviewing the Reports page. Follow the instructions found in Section 5.1

VeederRoot Modbus

# of

Registers

Units

1 no_units Tank01_tank_product_code

Tank01_tank_tank_status

Tank01_tank_volume

Tank01_tank_tc_volume

40001

40002

40003

40004

1 no_units

1 us_gallons

1 us_gallons

Tank01_tank_ullage

Tank01_tank_height

Tank01_tank_water

Tank01_tank_temperature

40005

40006

40007

40008

1 us_gallons

1 inches

1 inches

1 degrees_Fahrenheit

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 35 of 67

Tank01_tank_water_volume

Tank02_tank_product_code

Tank02_tank_tank_status

Tank02_tank_volume

Tank02_tank_tc_volume

Tank02_tank_ullage

Tank02_tank_height

Tank02_tank_water

Tank02_tank_temperature

Tank02_tank_water_volume

Tank03_tank_product_code

Tank03_tank_tank_status

Tank03_tank_volume

Tank03_tank_tc_volume

Tank03_tank_ullage

Tank03_tank_height

Tank03_tank_water

Tank03_tank_temperature

Tank03_tank_water_volume

Tank04_tank_product_code

Tank04_tank_tank_status

Tank04_tank_volume

Tank04_tank_tc_volume

Tank04_tank_ullage

Tank04_tank_height

Tank04_tank_water

Tank04_tank_temperature

Tank04_tank_water_volume

Tank01_tank_common_alarm

Tank01_tank_setup_data_warning

Tank01_tank_leak_alarm

Tank01_tank_high_water_alarm

Tank01_tank_overfill_alarm

Tank01_tank_low_product_alarm

Tank01_tank_sudden_loss_alarm

Tank01_tank_high_product_alarm

Tank01_tank_invalid_fuel_level_alarm

Tank01_tank_probe_out_alarm

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

Chipkin™ VeederRoot® Gateway User Manual

40009 1 us_gallons

40101 1 no_units

40308

40309

40010

40011

40012

40013

40014

40208

40209

40301

40302

40303

40304

40305

40306

40307

40015

40016

40017

40018

40019

40201

40202

40203

40204

40205

40206

40207

40102

40103

40104

40105

40106

40107

40108

40109

1 no_units

1 us_gallons

1 us_gallons

1 us_gallons

1 inches

1 inches

1 degrees_Fahrenheit

1 us_gallons

1 no_units

1 no_units

1 us_gallons

1 us_gallons

1 us_gallons

1 inches

1 inches

1 degrees_Fahrenheit

1 us_gallons

1 no_units

1 no_units

1 us_gallons

1 us_gallons

1 us_gallons

1 inches

1 inches

1 degrees_Fahrenheit

1 us_gallons

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

© 2018 Chipkin Automation Systems

All rights reserved

Page 36 of 67

Tank01_tank_high_water_warning

Tank01_tank_delivery_needed_warning

Tank01_tank_maximum_product_alarm

Tank01_tank_gross_leak_test_fail_alarm

Tank01_tank_periodic_leak_test_fail_alarm

Tank01_tank_annual_leak_test_fail_alarm

Tank01_tank_periodic_test_needed_warning

Tank01_tank_annual_test_needed_warning

Tank01_tank_periodic_test_needed_alarm

Tank01_tank_annual_test_needed_alarm

Tank01_tank_leak_test_active

Tank01_tank_no_csld_idle_time_warning

Tank01_tank_siphon_break_active_warning

Tank01_tank_csld_rate_increase_warning

Tank01_tank_accuchart_calibration_warning

Tank01_tank_hrm_reconciliation_warning

Tank01_tank_hrm_reconciliation_alarm

Tank01_tank_cold_temperature_warning

Tank01_tank_missing_delivery_ticket_warning

Tank01_tank/line_gross_leak_alarm

Tank01_delivery_density_warning

Tank01_tank_unknown_alarm

Tank02_tank_common_alarm

Tank02_tank_setup_data_warning

Tank02_tank_leak_alarm

Tank02_tank_high_water_alarm

Tank02_tank_overfill_alarm

Tank02_tank_low_product_alarm

Tank02_tank_sudden_loss_alarm

Tank02_tank_high_product_alarm

Tank02_tank_invalid_fuel_level_alarm

Tank02_tank_probe_out_alarm

Tank02_tank_high_water_warning

Tank02_tank_delivery_needed_warning

Tank02_tank_maximum_product_alarm

Tank02_tank_gross_leak_test_fail_alarm

Tank02_tank_periodic_leak_test_fail_alarm

Tank02_tank_annual_leak_test_fail_alarm

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

Chipkin™ VeederRoot® Gateway User Manual

40020 1 0 = Normal, 1 = Alarm

40021 1 0 = Normal, 1 = Alarm

40114

40115

40116

40117

40118

40119

40120

40037

40038

40039

40040

40041

40110

40111

40112

40113

40121

40122

40123

40124

40125

40030

40031

40032

40033

40034

40035

40036

40022

40023

40024

40025

40026

40027

40028

40029

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

© 2018 Chipkin Automation Systems

All rights reserved

Page 37 of 67

Tank02_tank_periodic_test_needed_warning

Tank02_tank_annual_test_needed_warning

Tank02_tank_periodic_test_needed_alarm

Tank02_tank_annual_test_needed_alarm

Tank02_tank_leak_test_active

Tank02_tank_no_csld_idle_time_warning

Tank02_tank_siphon_break_active_warning

Tank02_tank_csld_rate_increase_warning

Tank02_tank_accuchart_calibration_warning

Tank02_tank_hrm_reconciliation_warning

Tank02_tank_hrm_reconciliation_alarm

Tank02_tank_cold_temperature_warning

Tank02_tank_missing_delivery_ticket_warning

Tank02_tank/line_gross_leak_alarm

Tank02_delivery_density_warning

Tank02_tank_unknown_alarm

Tank03_tank_common_alarm

Tank03_tank_setup_data_warning

Tank03_tank_leak_alarm

Tank03_tank_high_water_alarm

Tank03_tank_overfill_alarm

Tank03_tank_low_product_alarm

Tank03_tank_sudden_loss_alarm

Tank03_tank_high_product_alarm

Tank03_tank_invalid_fuel_level_alarm

Tank03_tank_probe_out_alarm

Tank03_tank_high_water_warning

Tank03_tank_delivery_needed_warning

Tank03_tank_maximum_product_alarm

Tank03_tank_gross_leak_test_fail_alarm

Tank03_tank_periodic_leak_test_fail_alarm

Tank03_tank_annual_leak_test_fail_alarm

Tank03_tank_periodic_test_needed_warning

Tank03_tank_annual_test_needed_warning

Tank03_tank_periodic_test_needed_alarm

Tank03_tank_annual_test_needed_alarm

Tank03_tank_leak_test_active

Tank03_tank_no_csld_idle_time_warning

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

Chipkin™ VeederRoot® Gateway User Manual

40126 1 0 = Normal, 1 = Alarm

40127 1 0 = Normal, 1 = Alarm

40220

40221

40222

40223

40224

40225

40226

40211

40212

40213

40214

40215

40216

40217

40218

40219

40227

40228

40229

40230

40231

40136

40137

40138

40139

40140

40141

40210

40128

40129

40130

40131

40132

40133

40134

40135

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

© 2018 Chipkin Automation Systems

All rights reserved

Page 38 of 67

Tank03_tank_siphon_break_active_warning

Tank03_tank_csld_rate_increase_warning

Tank03_tank_accuchart_calibration_warning

Tank03_tank_hrm_reconciliation_warning

Tank03_tank_hrm_reconciliation_alarm

Tank03_tank_cold_temperature_warning

Tank03_tank_missing_delivery_ticket_warning

Tank03_tank/line_gross_leak_alarm

Tank03_delivery_density_warning

Tank03_tank_unknown_alarm

Tank04_tank_common_alarm

Tank04_tank_setup_data_warning

Tank04_tank_leak_alarm

Tank04_tank_high_water_alarm

Tank04_tank_overfill_alarm

Tank04_tank_low_product_alarm

Tank04_tank_sudden_loss_alarm

Tank04_tank_high_product_alarm

Tank04_tank_invalid_fuel_level_alarm

Tank04_tank_probe_out_alarm

Tank04_tank_high_water_warning

Tank04_tank_delivery_needed_warning

Tank04_tank_maximum_product_alarm

Tank04_tank_gross_leak_test_fail_alarm

Tank04_tank_periodic_leak_test_fail_alarm

Tank04_tank_annual_leak_test_fail_alarm

Tank04_tank_periodic_test_needed_warning

Tank04_tank_annual_test_needed_warning

Tank04_tank_periodic_test_needed_alarm

Tank04_tank_annual_test_needed_alarm

Tank04_tank_leak_test_active

Tank04_tank_no_csld_idle_time_warning

Tank04_tank_siphon_break_active_warning

Tank04_tank_csld_rate_increase_warning

Tank04_tank_accuchart_calibration_warning

Tank04_tank_hrm_reconciliation_warning

Tank04_tank_hrm_reconciliation_alarm

Tank04_tank_cold_temperature_warning

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

Chipkin™ VeederRoot® Gateway User Manual

40232 1 0 = Normal, 1 = Alarm

40233 1 0 = Normal, 1 = Alarm

40326

40327

40328

40329

40330

40331

40332

40317

40318

40319

40320

40321

40322

40323

40324

40325

40333

40334

40335

40336

40337

40310

40311

40312

40313

40314

40315

40316

40234

40235

40236

40237

40238

40239

40240

40241

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

© 2018 Chipkin Automation Systems

All rights reserved

Page 39 of 67

Tank04_tank_missing_delivery_ticket_warning

Tank04_tank/line_gross_leak_alarm

Tank04_delivery_density_warning

Tank04_tank_unknown_alarm

Chipkin™ VeederRoot® Gateway User Manual

40338 1 0 = Normal, 1 = Alarm

40339 1 0 = Normal, 1 = Alarm

40340

40341

1 0 = Normal, 1 = Alarm

1 0 = Normal, 1 = Alarm

Table 5.2-1 - Example Modbus Map

Test Procedure Using the CAS Modbus Scanner

You can test the Modbus TCP data using the free test software provided by Chipkin Automation

Software. The software can be downloaded at http://www.chipkin.com/cas‐modbus‐scanner .

To Configure the CAS Modbus Scanner:

1. Add a connection (specify the IP address of the gateway)

2. Add a device to the connection (specify the configured slave ID)

3. Add a request to the device (read holding register offset=1 Length=100)

4. Click the Poll button

5. Use the values found in the int16 column and the data map table to review the data.

Figure 5.2-1 - Configuring the CAS Modbus Scanner

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 40 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 5.2-2 - Reviewing Data with the CAS Modbus Scanner

READING BACNET DATA

You can access BACnet report data from the Veeder-Root device by using discover to detect gateway objects and their properties. Although each BACnet device (including the gateway) needs to have a unique instance number, discovery does not require the number to be known in advance. Discovery will not occur if the device or application reading the data is on another subnet. This can be resolved by changing the gateway’s IP address to match the subnet or by installing BBMD. It’s the responsibility of the company installing the BAS system to provide BBMD. For more information about reading

BACnet data or installing BBMD, please refer to these guides:

• http://www.chipkin.com/bacnet‐solutions

• http://www.chipkin.com/articles/bacnet‐bbmd

You can discover the device and poll for values using the CAS BACnet Explorer. For more information about the CAS BACnet Explorer, please visit: http://store.chipkin.com/products/tools/cas-bacnetexplorer

Interpreting BACnet Data

BACnet has a mechanism for reporting the validity of data. If the gateway loses its connection to the

Veeder-Root device (or a data point cannot be read), the data object’s out of service property is set to

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 41 of 67

Chipkin™ VeederRoot® Gateway User Manual true and it will disregard previous data as unreliable. The value of the present value property is not changed, so the last good value will be shown.

BACnet Object List

The sections contain an example of the BACnet Object List for this gateway.

Important Note: As mentioned above, this list is based on sample data using a default configuration. The BACnet Object List is generated during the configuration process, so it will change and will be different than what is described here. You can view the current BACnet

Object List by reviewing the Reports page. Follow the instructions found in Section 5.1

VeederRoot

Tank01_tank_product_code

BACnet IP Units

analog_input (1) no_units

Tank01_tank_tank_status

Tank01_tank_volume

Tank01_tank_tc_volume

Tank01_tank_ullage

Tank01_tank_height analog_input (2) analog_input (3) analog_input (4) analog_input (5) analog_input (6) no_units us_gallons us_gallons us_gallons inches

Tank01_tank_water

Tank01_tank_temperature

Tank01_tank_water_volume

Tank02_tank_product_code

Tank02_tank_tank_status

Tank02_tank_volume

Tank02_tank_tc_volume

Tank02_tank_ullage

Tank02_tank_height

Tank02_tank_water

Tank02_tank_temperature

Tank02_tank_water_volume

Tank03_tank_product_code

Tank03_tank_tank_status

Tank03_tank_volume

Tank03_tank_tc_volume

Tank03_tank_ullage

Tank03_tank_height

Tank03_tank_water

Tank03_tank_temperature analog_input (7) analog_input (8) analog_input (9) analog_input (101) analog_input (102) analog_input (103) analog_input (104) analog_input (105) analog_input (106) analog_input (107) analog_input (108) analog_input (109) analog_input (201) analog_input (202) analog_input (203) analog_input (204) analog_input (205) analog_input (206) analog_input (207) analog_input (208) inches degrees_Fahrenheit us_gallons no_units no_units us_gallons us_gallons us_gallons inches inches degrees_Fahrenheit us_gallons no_units no_units us_gallons us_gallons us_gallons inches inches degrees_Fahrenheit

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 42 of 67

Tank03_tank_water_volume

Tank04_tank_product_code

Tank04_tank_tank_status

Tank04_tank_volume

Tank04_tank_tc_volume

Tank04_tank_ullage

Tank04_tank_height

Tank04_tank_water

Tank04_tank_temperature

Tank04_tank_water_volume

Tank01_tank_common_alarm

Tank01_tank_setup_data_warning

Tank01_tank_leak_alarm

Tank01_tank_high_water_alarm

Tank01_tank_overfill_alarm

Tank01_tank_low_product_alarm

Tank01_tank_sudden_loss_alarm

Tank01_tank_high_product_alarm

Tank01_tank_invalid_fuel_level_alarm

Tank01_tank_probe_out_alarm

Tank01_tank_high_water_warning

Tank01_tank_delivery_needed_warning

Tank01_tank_maximum_product_alarm

Tank01_tank_gross_leak_test_fail_alarm

Tank01_tank_periodic_leak_test_fail_alarm

Tank01_tank_annual_leak_test_fail_alarm

Tank01_tank_periodic_test_needed_warning

Tank01_tank_annual_test_needed_warning

Tank01_tank_periodic_test_needed_alarm

Tank01_tank_annual_test_needed_alarm

Tank01_tank_leak_test_active

Tank01_tank_no_csld_idle_time_warning

Tank01_tank_siphon_break_active_warning

Tank01_tank_csld_rate_increase_warning

Tank01_tank_accuchart_calibration_warning

Tank01_tank_hrm_reconciliation_warning

Tank01_tank_hrm_reconciliation_alarm

Tank01_tank_cold_temperature_warning

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Chipkin™ VeederRoot® Gateway User Manual analog_input (209) us_gallons analog_input (301) no_units analog_input (302) analog_input (303) analog_input (304) analog_input (305) analog_input (306) analog_input (307) analog_input (308) analog_input (309) binary_input (10) binary_input (11) binary_input (12) binary_input (13) binary_input (14) binary_input (15) binary_input (16) binary_input (17) binary_input (18) binary_input (19) binary_input (20) binary_input (21) binary_input (22) binary_input (23) binary_input (24) binary_input (25) binary_input (26) binary_input (27) binary_input (28) binary_input (29) binary_input (30) binary_input (31) binary_input (32) binary_input (33) binary_input (34) binary_input (35) binary_input (36) binary_input (37) no_units us_gallons us_gallons us_gallons inches inches degrees_Fahrenheit us_gallons

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 43 of 67

Tank01_tank_missing_delivery_ticket_warning

Tank01_tank/line_gross_leak_alarm

Tank01_delivery_density_warning

Tank01_tank_unknown_alarm

Tank02_tank_common_alarm

Tank02_tank_setup_data_warning

Tank02_tank_leak_alarm

Tank02_tank_high_water_alarm

Tank02_tank_overfill_alarm

Tank02_tank_low_product_alarm

Tank02_tank_sudden_loss_alarm

Tank02_tank_high_product_alarm

Tank02_tank_invalid_fuel_level_alarm

Tank02_tank_probe_out_alarm

Tank02_tank_high_water_warning

Tank02_tank_delivery_needed_warning

Tank02_tank_maximum_product_alarm

Tank02_tank_gross_leak_test_fail_alarm

Tank02_tank_periodic_leak_test_fail_alarm

Tank02_tank_annual_leak_test_fail_alarm

Tank02_tank_periodic_test_needed_warning

Tank02_tank_annual_test_needed_warning

Tank02_tank_periodic_test_needed_alarm

Tank02_tank_annual_test_needed_alarm

Tank02_tank_leak_test_active

Tank02_tank_no_csld_idle_time_warning

Tank02_tank_siphon_break_active_warning

Tank02_tank_csld_rate_increase_warning

Tank02_tank_accuchart_calibration_warning

Tank02_tank_hrm_reconciliation_warning

Tank02_tank_hrm_reconciliation_alarm

Tank02_tank_cold_temperature_warning

Tank02_tank_missing_delivery_ticket_warning

Tank02_tank/line_gross_leak_alarm

Tank02_delivery_density_warning

Tank02_tank_unknown_alarm

Tank03_tank_common_alarm

Tank03_tank_setup_data_warning

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Chipkin™ VeederRoot® Gateway User Manual binary_input (38) 0 = Normal, 1 = Alarm binary_input (39) 0 = Normal, 1 = Alarm binary_input (40) binary_input (41) binary_input (110) binary_input (111) binary_input (112) binary_input (113) binary_input (114) binary_input (115) binary_input (116) binary_input (117) binary_input (118) binary_input (119) binary_input (120) binary_input (121) binary_input (122) binary_input (123) binary_input (124) binary_input (125) binary_input (126) binary_input (127) binary_input (128) binary_input (129) binary_input (130) binary_input (131) binary_input (132) binary_input (133) binary_input (134) binary_input (135) binary_input (136) binary_input (137) binary_input (138) binary_input (139) binary_input (140) binary_input (141) binary_input (210) binary_input (211)

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 44 of 67

Tank03_tank_leak_alarm

Tank03_tank_high_water_alarm

Tank03_tank_overfill_alarm

Tank03_tank_low_product_alarm

Tank03_tank_sudden_loss_alarm

Tank03_tank_high_product_alarm

Tank03_tank_invalid_fuel_level_alarm

Tank03_tank_probe_out_alarm

Tank03_tank_high_water_warning

Tank03_tank_delivery_needed_warning

Tank03_tank_maximum_product_alarm

Tank03_tank_gross_leak_test_fail_alarm

Tank03_tank_periodic_leak_test_fail_alarm

Tank03_tank_annual_leak_test_fail_alarm

Tank03_tank_periodic_test_needed_warning

Tank03_tank_annual_test_needed_warning

Tank03_tank_periodic_test_needed_alarm

Tank03_tank_annual_test_needed_alarm

Tank03_tank_leak_test_active

Tank03_tank_no_csld_idle_time_warning

Tank03_tank_siphon_break_active_warning

Tank03_tank_csld_rate_increase_warning

Tank03_tank_accuchart_calibration_warning

Tank03_tank_hrm_reconciliation_warning

Tank03_tank_hrm_reconciliation_alarm

Tank03_tank_cold_temperature_warning

Tank03_tank_missing_delivery_ticket_warning

Tank03_tank/line_gross_leak_alarm

Tank03_delivery_density_warning

Tank03_tank_unknown_alarm

Tank04_tank_common_alarm

Tank04_tank_setup_data_warning

Tank04_tank_leak_alarm

Tank04_tank_high_water_alarm

Tank04_tank_overfill_alarm

Tank04_tank_low_product_alarm

Tank04_tank_sudden_loss_alarm

Tank04_tank_high_product_alarm

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Chipkin™ VeederRoot® Gateway User Manual binary_input (212) 0 = Normal, 1 = Alarm binary_input (213) 0 = Normal, 1 = Alarm binary_input (214) binary_input (215) binary_input (216) binary_input (217) binary_input (218) binary_input (219) binary_input (220) binary_input (221) binary_input (222) binary_input (223) binary_input (224) binary_input (225) binary_input (226) binary_input (227) binary_input (228) binary_input (229) binary_input (230) binary_input (231) binary_input (232) binary_input (233) binary_input (234) binary_input (235) binary_input (236) binary_input (237) binary_input (238) binary_input (239) binary_input (240) binary_input (241) binary_input (310) binary_input (311) binary_input (312) binary_input (313) binary_input (314) binary_input (315) binary_input (316) binary_input (317)

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 45 of 67

Tank04_tank_invalid_fuel_level_alarm

Tank04_tank_probe_out_alarm

Tank04_tank_high_water_warning

Tank04_tank_delivery_needed_warning

Tank04_tank_maximum_product_alarm

Tank04_tank_gross_leak_test_fail_alarm

Tank04_tank_periodic_leak_test_fail_alarm

Tank04_tank_annual_leak_test_fail_alarm

Tank04_tank_periodic_test_needed_warning

Tank04_tank_annual_test_needed_warning

Tank04_tank_periodic_test_needed_alarm

Tank04_tank_annual_test_needed_alarm

Tank04_tank_leak_test_active

Tank04_tank_no_csld_idle_time_warning

Tank04_tank_siphon_break_active_warning

Tank04_tank_csld_rate_increase_warning

Tank04_tank_accuchart_calibration_warning

Tank04_tank_hrm_reconciliation_warning

Tank04_tank_hrm_reconciliation_alarm

Tank04_tank_cold_temperature_warning

Tank04_tank_missing_delivery_ticket_warning

Tank04_tank/line_gross_leak_alarm

Tank04_delivery_density_warning

Tank04_tank_unknown_alarm

Chipkin™ VeederRoot® Gateway User Manual binary_input (318) 0 = Normal, 1 = Alarm binary_input (319) 0 = Normal, 1 = Alarm binary_input (320) binary_input (321) binary_input (322) binary_input (323) binary_input (324) binary_input (325) binary_input (326) binary_input (327) binary_input (328) binary_input (329) binary_input (330) binary_input (331) binary_input (332) binary_input (333) binary_input (334) binary_input (335) binary_input (336) binary_input (337) binary_input (338) binary_input (339) binary_input (340) binary_input (341)

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

0 = Normal, 1 = Alarm

BACnet Test Procedure

CAS BACnet Explorer is a software application that can discover, test and document objects and properties on a network system. You can download the software at http://www.chipkin.com/files/resources/Installer_CAS%20BACnet%20Explorer.exe

and use the USB key to activate the application. If you don’t have a key, the software can also be activated through an internet connection.

Perform the set-up procedure below, or refer to the video and these articles for more information:

• http://store.chipkin.com/articles/cas-bacnet-explorer-software-activation

• http://store.chipkin.com/articles/bacnet-how-to-overcome-cas-bacnet-explorer-usbsoftwareactivation-problems

• http://store.chipkin.com/products/tools/cas-bacnet-explorer/license-agreement

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657

Table 5.3-1 - Example BACnet Object List

Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 46 of 67

To Set-up BACnet Explorer:

1. Start the application

2. Click Settings

3. Check IP and uncheck MSTP and Ethernet

4. Click on the network card you will use

5. Click OK

6. Click Discover

7. Click Send

Chipkin™ VeederRoot® Gateway User Manual

Figure 5.3-1 - CAS BACnet Explorer - Devices were discovered.

8. Click on the ‘+’ icon to see the list of discovered devices.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 47 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 5.3-2 - CAS BACnet Explorer – Device Selection

9. Select the device you wish to further discover and click the Discover button.

Figure 5.3-3 - CAS BACnet Explorer - Discover Dialogue

10. Check the Discover device’s properties, Discover object, and Discover object’s properties check boxes and click the Send button.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 48 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 5.3-5 - CAS BACnet Explorer - Single Object

Figure 5.3-4 - CAS BACnet Explorer -

Discovered Objects

11. Read the BACnet object properties Present-Value is the current value of the data point.

Here is a list of some the important properties:

• Present Value: The current value of the object

• Reliability: On the CAS Gateway or Data Client, represents the validity of the data

• Status Flags: Various flags that show the state of the object.

• Units: If the object has units, this will show the unit type.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 49 of 67

Chipkin™ VeederRoot® Gateway User Manual

6. COMMISIONING, DIAGNOSTICS, AND TROUBLE-

SHOOTING

WHAT TO TAKE TO SITE FOR COMMISSIONING

Below is a list of software and hardware tools that should be taken to site for the install installation.

Some of these tools are depend on the type of installation and drivers on the gateway. Most of the software tools can be found on the included USB drive.

Software

• IP Setup Tool - Used to update the IP address of the CAS Gateway. Free http://www.chipkin.com/cas-gateway-ip-address-tool

• Auto Update Tool - Used to update the firmware on the CAS Gateway. Free http://www.chipkin.com/cas-gateway-firmware-download-tool/

• Wirehark - Used to capture and log network traffic. Free https://www.wireshark.org/

• CAS BACnet Explorer – Used to test BACnet IP configurations. Trial http://www.chipkin.com/products/software/bacnet-software/cas-bacnet-explorer/

• CAS Modbus Scanner – Used to test Modbus TCP and Modbus RTU configurations. Free http://store.chipkin.com/articles/modbus-scanner-what-is-the-cas-modbus-scanner

Hardware

• A laptop –Used to configure and diagnose the gateway. The laptop should include a ethernet port.

• RS232 to USB converter – Used when communicating with drivers that use RS232 such as

VeederRoot serial.

• RS485 to USB converter – Used when communicating with drivers that use RS485 such as

Modbus RTU or BACnet MSTP.

• Ethernet patch cable – Useful for connecting the gateway to your laptop or into a local switch.

Included in the accessory kit.

• Micro screw driver set – Useful for securing wires into screw terminals. Included in the accessory kit.

• Ethernet hub - Use a hub (and not a switch) as a last resort for troubleshooting problems with

Modbus TCP or BACnet IP. A hub is not a switch, that most switches are not supervised and that only a supervised switch can be used as an alternative. For more information about hubs and switches, please refer to this article: http://www.chipkin.com/articles/hubs‐vs‐switches‐ using‐wireshark‐to‐sniff‐networkpackets

• Db9 gender changer - Connector make-up kits are always useful but not required if you have tested your cable prior to attending the site.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 50 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 6.1-1 - DB9 Gender Changers

• Serial RS232 mini-tester – Useful for testing to ensure that a serial cable has the correct pinout.

Figure 6.1-2 - RS232 Mini-Tester

• Serial cable – A Null modem or crossover serial cable can be useful when communicating with drives that use serial connections such as Modbus RTU and VeederRoot serial

DISCOVER GATEWAY’S IP ADDRESS

By default, the gateway is shipped with an IP address of 192.168.1.113. The IP address may have been changed since being installed on site. The following techniques can be used to discover the new gateways IP address.

Setup reference card

By default, the gateways are shipped with a setup reference card attached to the bottom of the gateway. This setup reference card will show the configured IP address as well as the job reference number.

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 51 of 67

Chipkin™ VeederRoot® Gateway User Manual

Figure 6.2-1 - Setup reference card

Using the IP Setup tool

1. Download the IP Setup tool from chipkin’s website http://www.chipkin.com/cas-gateway-ipaddress-tool

2. Run the IP Setup Tool application and you will see the following window

Figure 6.2-2 - IP Setup tool

3. The IP address of the CAS Gateway will be shown on the right-hand side.

DEFAULT USERNAME AND PASSWORD

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 52 of 67

Chipkin™ VeederRoot® Gateway User Manual

To view or change the settings on the gateway, a username and password will need to be entered. By default, the username and passwords are

Username: admin

Password: admin

The default password can be changed on the system page. http://<IPAddress>/bin/system

DEBUG LOG OR WIRESHARK LOG

If a problem is discovered on site, you may be asked to take a debug log, or a Wireshark log.

Debug logging

By default, the gateway has a debug logging level of 10 (important messages only) and logs messages to the syslog port (514). These settings can be changed on the system page. http://<IPAddress>/bin/system

Settings

• Log to file - Logs the system and driver messages to a log file on the SD card of the gateway.

This log file can be viewed and downloaded by going to “log messages” page http://<IPAddress>/bin/system/log . The log file will automatically be disabled if the free space on the SD card is less than 10% of the total. Default: Disabled.

• Log to Syslog – Sends syslog (UDP 514) message for each system and driver log message. These log messages can be viewed by taking a Wireshark log. Default: Enabled.

• Logging level – The logging level that messages will be created. The higher the number the more messages that will be created. Logging levels higher than NORMAL (50) may impact the performance of the gateway. Default: IMPORTANT (10)

Wireshark log

Wireshark is a free utility used for capturing and logging network traffic. This tool can be instrumental in resolving local network issues. Wireshark can be downloaded for free from https://www.wireshark.org/

CHANGE THE GATEWAY IP ADDRESS

By default, the gateway is shipped with a static IP address of 192.168.1.113. The default IP address can be changed using the IP setup tool.

4. Download the IP Setup tool from chipkin’s website http://www.chipkin.com/cas-gateway-ipaddress-tool

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 53 of 67

Chipkin™ VeederRoot® Gateway User Manual

5. Run the IP Setup Tool application and you will see the following window

Figure 6.5-1 - IP Setup tool

6. Select the Gateway from the list on the left.

7. Change the “NDK Settings” as required.

Note: Please do NOT change the Baudrate value.

8. Click the “Set -->” button to apply the new changes to the CAS Gateway. The gateway will automatically reboot with the new assigned IP address.

UPDATE FIRMWARE

This document assumes that you have successfully connected to the gateway and can see the gateway in the IP Setup Tool.

Note: Usually, the firmware is already loaded on the CAS Gateway when it is shipped.

However, if there was a specific requirement that was developed or a bug fix, you may have to download an updated firmware which you will receive from Chipkin Automation Systems

(CAS). All updated firmware files should come from CAS.

Do Not upload any other firmware files with this tool unless CAS specifically advices to do so.

To download the firmware to the gateway, follow the steps below:

1. Download the CAS Gateway AutoUpdate tool from the following link: http://www.chipkin.com/cas-gateway-firmware-download-tool/

3381 Cambie Street, #211

Vancouver, BC, Canada, V5Z 4R3

1-866-383-1657 Chipkin.com

© 2018 Chipkin Automation Systems

All rights reserved

Page 54 of 67

Chipkin™ VeederRoot® Gateway User Manual

2. Running the AutoUpdate application will display the following window:

Figure 6.6-1 - AutoUpdate tool window

The IP Address of the gateway should be filled out in the “IP address” section. If not, or if the IP address is wrong, then click the “Find” button and it will display the IP addresses of gateways on the network. Select the IP address of the gateway to download the firmware.

3. Click the “Browse…” button. This will open a file explorer. Navigate to the firmware file and click the “Open” button. The file path will be inserted into the “FileName” field.

Figure 6.6-2 - AutoUpdate tool window

Image 2 – AutoUpdate tool with firmware file name

4. Verify that “Reboot when complete” is checked, as shown above.