advertisement

I

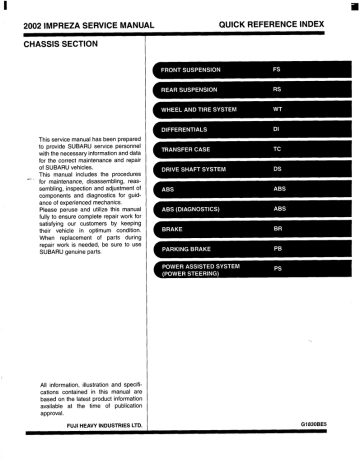

2002

IMPREZA SERVICE MANUAL

~~

CHASSIS SECTION

QUICK REFERENCE INDEX

a

This service manual has been prepared to provide SUBARU service personnel with the necessary information and data for the correct maintenance and repair of SUBARU vehicles.

This manual includes the procedures for maintenance, disassembling, reas- sembling, inspection and adjustment of components and diagnostics for guid- ance of experienced mechanics.

Please peruse and utilize this manual fully to ensure complete repair work for satisfying our customers by keeping their vehicle in optimum condition.

When replacement of parts during repair work is needed, be sure to use

SUBARU genuine parts.

All information, illustration and specifi- cations contained in this manual are based on the latest product information available at the time of publication approval.

FUJI HEAVY INDUSTRIES LTD.

G18306E5

FRONT SUSPENSION

F S r

1

.

2

.

3

.

4

.

5

.

6

.

7

.

9

.

General Description

Wheel Alignment

Sub Frame

....................................................................................

.........................................................................................

2

8

................................................................................................

16

Front Transverse Link

...............................................................................

17

Front Ball Joint

..........................................................................................

19

Front Strut

.................................................................................................

20

Front Stabilizer

..........................................................................................

24

Front Crossmember

..................................................................................

25

General Diagnostic Table

..........................................................................

26

I

FRONT SUSPENSION

1. General Description

A: SPECIFICATIONS

1.

STABILIZER

GENERAL DESCRIPTION

Model

ALL MODEL

2.

WHEEL ALIGNMENT

Bar diameter.

20 mm (0.79 in)

Sedan Wagon

Model

Caster (common difference: f0'45')

Toe-in

I

Kingpin angle (tolerance: +0"45')

Wheel arch height

[tolerance: f 1 2 mm

(f0.47 in)]

3'35'

I

I

3'25'

I

3'35'

I

3'25'

I

I

I

I

0+3 mm (Of0.12 in)

Each toe anale: kO"O7'30

(Total toe anale: fO"15')

I

14"35'

I

14"20'

I

13"45'

I

13"30'

I

3'25'

13'20'

396 mm 406 mm 387 mm 397 mm

(15.59 in) (15.98 in) (15.24 in) (15.63 in)

AOTE:

Front and rear toe-ins and front camber can be adjusted. If the toe-in or camber tolerance exceeds specifications, adjust toe-in and camber to the mid- dle value of specification.

The other items indicated in the specification ta- ble cannot be adjusted. If the other items exceeds specifications, check suspension parts and con- nections for deformities; replace with new ones as required.

402 mm

5.83 in)

B4M2250B

(1) Front

A

-

B

=

Positive: Toe-in, Negative: Toe-out

a

Each toe angle

FS-2

I

GENERAL DESCRIPTION

FRONT

SUSPENSION

FS-3

FRONT SUSPENSION

B: COMPONENT

GENERAL DESCRIPTION

FS-4

GENERAL DESCRIPTION

FRONT SUSPENSION

Front crossmember

Bolt ASSY

Housing

Washer

Stopper rubber (Rear)

Rear bushing

Stopper rubber (Front)

Ball joint

Transverse link

Cotter pin

Front bushing

Stabilizer link (Except sedan turbo model)

Clamp

Bushing

Stabilizer

Jack-up plate

Dust seal

Strut mount

Spacer

Tightening torque: N.m (kgf-m, ft-lb)

T I : ZO(2.0, 14.5)

T2: 25 (2.5, 18.1)

(20)

Upper spring seat

(21)

Rubber seat

(22)

Dust cover

(23)

Helper

(24)

Coil spring

(25)

Damper strut

(26)

Adjusting bolt

(27)

Castle nut

(28)

Self-locking nut

(29)

Sub frame

(30)

(31

1

Cover

Clip

(32)

T3: 30 (3.1,22)

T4: 34 (3.5,25)

T5: 40 (4.1, 30)

T6: 45 (4.6, 33)

T7: 50 (5.1, 37)

T8: 55 (5.6, 41)

T9: 71 (7.2, 52)

T10: 100 (10.2, 74)

T11: <Ref. to FS-17, INSPECTION,

Sub Frame.>

T12: 175 (17.8, 129)

T13: 190(19.4, 140)

Stabilizer link (Sedan turbo model) T14: 250 (25.5, 184)

1

.-

FS-5

I

GENERAL DESCRIPTION

FRONT SUSPENSION

C: CAUTION

Wear working clothing, including a cap, protec- tive goggles, and protective shoes during opera- tion.

Remove contamination including dirt and corro- sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro- tect them from dust or dirt.

Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary re- moval, installation, disassembly, and replacement.

Use SUBARU genuine grease etc. or the equiv- alent. Do not mix grease etc. with that of another grade or from other manufacturers.

Be sure to tighten fasteners including bolts and nuts to the specified torque.

Place shop jacks or safety stands at the specified points.

Apply grease onto sliding or revolution surfaces before installation.

Before installing O-rings or snap rings, apply suf- ficient amount of grease to avoid damage and de- formation.

Before securing a part on a vice, place cushion- ing material such as wood blocks, aluminum plate, or shop cloth between the part and the vice.

FS-6

GENERAL DESCRIPTION

D:

PREPARATION TOOL

1.

SPECIAL TOOLS

ILLUSTRATION

TOOL NUMBER

927380002

FRONT SUSPENSION

REMARKS sed as an adapter for camber & caster gauge

,hen measuring camber and caster.

I

) 281 99AC000 PLATE

2) 281 99AC010 BOLT

927680000

~

NSTALLER &

3EMOVER SET

Jsed for replacing transverse link bushing.

84M2385

927760000

STRUT MOUNT

SOCKET

Used for disassembling and assembling strut and shock mount.

2.

GENERAL PURPOSE

TOOLS

TOOL NAME

Alignment gauge

Turning radius gauge

Toe-in gauge

Dial gauge

REMARKS

Used for wheel alignment measurement.

Used for wheel alignment measurement.

Used for toe-in measurement.

Used for damper strut measurement.

FS-7

WHEEL ALIGNMENT

FRONT

SUSPENSION

2.

Wheel Alignment

A:

INSPECTION

Check, adjust and/or measure wheel alignment in accordance with procedures indicated in figure:

WHEEL ARCH HEIGHT (FRONT AND REAR)

1

CAMBER (FRONT AND REAR)

I

FRONT TOE-IN

REAR TOE-IN

THRUST ANGLE (REAR)

WHEEL STEERING ANGLE

B4M1 OBBA

FS-8

I

WHEEL ALIGNMENT

FRONT SUSPENSION

1. WHEEL ARCH HEIGHT

1) Adjust the tire pressure to specifications.

2) Set the vehicle under “curb weight” conditions. (Empty luggage compartment, install spare tire, jack, ser- vice tools, and top up fuel tank.)

3)

Set the steering wheel in a wheel-forward position.

4)

Suspend a thread from wheel arch (point “ A in figure below) to determine the point directly above center of spindle.

5 )

Measure the distance between measuring point “ A and center of spindle.

I

c

a,

.c

c

3

7

~

Sedan

Wagon

I

OUTBACK

Model

Front

Rear

Front

Rear

Front

Rear

I

t

.-

a,

c

2

m a, a,

c

5

L m a, a

E

.-

c

.c

2

-

f

End

of

spindle;,y//,/

Specified wheel arch height

Turbo mm

(1

~~

376k12

mm

(1

in) mm (1

5.24k0.47

376+12

mm

(1

in)

-

-

Non-turbo mm

(1

mm

(15.0k0.47

mm

(1 5.63k0.47

mm

(1

386k12

(1 suo009

FS-9

I

WHEEL ALIGNMENT

FRONT SUSPENSION

2. CAMBER

Inspection

1) Place the front wheel on turning radius gauge.

Make sure the ground contacting surfaces of front and rear wheels are set at the same height.

2) Set the ST into the center of the wheel, and then install the wheel alignment gauge.

ST 927380002 ADAPTER

2) Turn the camber adjusting bolt so that the cam- ber is set at the specification.

NOTE:

Moving the adjusting bolt by one scale graduation changes the camber by approximately 0’10’.

(1) Alignment gauge

(2) Turning radius gauge

NOTE:

Refer to the ‘SPECIFICATIONS” for the camber va I u es.

Front: <Ref. to FS-2, SPECIFICATIONS, General

Description.>

Rear: <Ref. to RS-2, SPECIFICATIONS, General

Description.>

Front camber adjustment

1) Loosen the two self-locking nuts located at the lower front portion of strut.

CAUTION:

When the adjusting bolt needs to be loos- ened or tightened, hold its head with a wrench and turn the self-locking nut.

Discard the loosened self-locking nut and re- place with a new one.

(1) Strut

(2) Adjusting bolt

(3) Housing

(4)

Outer

( 5 )

Inner

(6) Camber is increased.

(7) Camber is decreased.

J

FS-10

I

WHEEL ALIGNMENT

FRONT SUSPENSION

Camber is increased.

Left side

J

@)

;hte counterclock-

Right side

~

@

Rotate clockwise.

Camber is decreased. u

04M0190

@

Rotate clockwise.

B4M0350

3 )

Tighten the two self-locking nuts.

--

Tightening torque:

175 N.m (1 7.8 kgf-m, 129 ft-lb)

3. CASTER

Inspection

1)

Place the front wheel on turning radius gauge.

Make sure the ground contacting surfaces of front and rear wheels are set at the same height.

2) Set the ST into the center of the wheel, and then install the wheel alignment gauge.

ST 927380002 ADAPTER

B4M03Gn

‘

I

@

;?:e counterclock-

W

B4M0190

4.

FRONT WHEEL TOE-IN

Inspection

1) Using a toe gauge, measure the front wheel toe- in.

Toe-in:

Of3 mm

(OdU.

12 in)

2) Mark the rear sides of left and right tires at height corresponding to the center of spindles and mea- sure distance

“ A

3) Move the vehicle forward so that the marks line up with front sides at height corresponding to the center of spindles.

4)

Measure the distance right marks. Toe-in can then be obtained by the fol- lowing equation:

A

- B =

Toe-in

I

B

A

i i

(1) Alignment gauge

(2) Turning radius gauge

NOTE:

Refer to the ‘SPECIFICATIONS’ for the caster val- ues. <Ref. to FS-2, SPECIFICATIONS, General

Description.>

Adjustment

1) Loosen the left and right side steering tie-rods lock nuts.

FS-11

I

WHEEL ALIGNMENT

FRONT SUSPENSION

2) Turn the left and right tie rods equal amounts un- til the toe-in is at the specification.

Both the left and right tie-rods are right-hand threaded. To increase toe-in, turn both tie-rods clockwise equal amounts (as viewed from the in- side of the vehicle).

4)

Measure the distance “B” between left and right marks. Toe-in can then be obtained by the follow- ing equation:

A

-

B

=

Toe-in

I

-

S4M0348A

(1) Lock nut

3) Tighten the tie-rod lock nut.

Tightening torque:

N-m (8.5 61.5 ff-lb)

CAUTION:

Correct the tie-rod boot, if it is twisted.

NOTE:

Check that the left and right wheel steering angle is within specifications.

5.

REAR WHEEL

TOE-IN

Inspection

1) Using a toe-in gauge, measure the rear wheel toe-in.

Toe-in:

-132 mm

(-0.039fo.079 in)

2)

Mark the rear sides of left and right tires at height corresponding to the center of spindles and mea- sure distance

“A”

between marks.

3) Move the vehicle forward so the that marks line up with front sides at height corresponding to the center of spindles.

Adjustment

1) Loosen the self-locking nut on inner side of link rear.

CAUTION:

When loosening or tightening the adjusting bolt, hold the bolt head and turn self-locking nut.

Discard the loosened self-locking nut and re- place with a new one.

(1)

Adjusting

bolt

(2) Link rear

2) Turn the adjusting bolt head until toe-in is at the specification.

FS-12

WHEEL

ALIGNMENT

FRONT

SUSPENSION

NOTE:

When the left and right wheels are adjusted for toe-in at the same time, the movement

of

one scale gradu- ation changes toe-in by approximately 1.5 mm (0.1 2 in).

Left

side Right side

~~

I

Toe-in is increased.

B4M0192

Rotate clockwise.

B4M0352

Rotate counterclock- wise.

~~

c

Toe-in is decreased.

Rotate clockwise.

Rotate counterclock- wise.

B4M0352

1)

Tighten the self-locking nut.

Tightening torque:

100 N-m (10.2 kgf-m,

74 ft-lb)

6.

STEERING ANGLE

Inspection

1) Place the vehicle on a turning radius gauge.

2) While depressing the brake pedal, turn the steer- ing wheel fully to the left and right. With the steer- ing wheel held at each fully turned position, measure both the inner and outer wheel steering angle.

Steering angle:

Model

Turbo, sedan and

OUTBACK

Others

Outerwheel

I

29"35"f1.5"

~~ I

31 "35Y1.5"

84M0192

Adjus ment

Turn the tie-rod to adjust the steering angle of both inner and outer wheels.

CAUTION:

Check the toe-in.

Correct the boot if it is twisted.

-

S4M0348A

(1) Locknut

FS-13

I

WHEEL ALIGNMENT

FRONT SUSPENSION

7.

THRUST ANGLE

Inspection

1) Position the vehicle on a level surface.

2) Move the vehicle 3 to 4 meters directly forward.

3) Determine the locus of both front and rear axles.

4) Measure the distance “L” between center line of loci of the axles.

Thrust angle:

Less than 20‘ when “L” is equal to or less than 15 mm (59 in).

3)

When the left and right adjusting bolts are turned incrementally by one graduation in the same direc- tion, the thrust angle will change approximately 16’

Thrust angle:

O ” f 2 0 ’

T

S4M0350B

(1) Center line of loci (front axle)

(2)

Center line of loci (rear axle)

Adjustment

1) Make the thrust angle adjustments by turning toe-in adjusting bolts of rear suspension equally in the same direction.

2) When one rear wheel is adjusted in a toe-in di- rection, adjust the other rear wheel equally in toe- out direction, in order to make the thrust angle ad- justment.

M

S4M0350B

(1)

Center line of loci (front axle)

(2) Center line of loci (rear axle)

NOTE:

Thrust angle refers to a mean value of left and right rear wheel toe angles in relation to the vehicle body center line. Vehicle is driven straight in the thrust angle direction while swinging in the oblique direction depending on the degree of the mean thrust angle.

( 1

1

t

FS-14

(1) Front

(2) Thrust angle

(3) Body center line

I

WHEEL ALIGNMENT

Thrust angle: r

= (a

a:

Right rear wheel toe-in angle p:

Left rear wheel toe-in angle

NOTE:

Here, use only positive toe-in values from each wheel to substitute for

a

and p in the equation.

FRONT SUSPENSION

I

(1) Front

(2)

Body center line

B4M01948

FS-15

FRONT SUSPENSION

3.

Sub Frame

A: REMOVAL

1) Lift-up the vehicle.

2) Remove the under cover.

3) Remove the bolt cover.

SUB FRAME

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Replace the M12 bolt with a new one.

Tightening torque:

T1: 34 N.m (3.5 kgf-m, 25 ff-lb)

T2: 55 N-m (5.6 kgf-m, 41 ff-lb)

T3: 71 N.m (7.2 kgf-m, 52 ff-lb)

T4: 105 N-m (10.7 kgf-m, 77 ff-lb)

4)

Remove the clip.

(1) M8 bolt

(2) M12 bolt (with max)

(3)

M12 bolt (with oil)

(4)

M10 bolt

5)

Remove the sub frame.

NOTE:

Loosen bolt (1) and leave a few threads caught, then remove the bolts in the order of

(2), (4),

(6).

FS-16

SUB FRAME

C: INSPECTION

1)

Check that there is no damage and distortion at the sub frame.

2)

Check that the bolts are tightened with the spec- ified torque. If there is looseness, tighten to the specified torque.

NOTE:

The tightening torque differs by the color for bolt

(3).

Always verify the bolt color before checking tightening torque.

Tightening torque:

T I : 34 N-m (3.5 kgf-m, 25 ff-lb)

T2: 55 N.m (5.6 kgf-m, 41 ff-lb)

T3: 71 N-m (7.2 kgf-m, 52 ff-lb)

T4: Dark green bolt

T4: Except dark green bolt

55 N-m (5.6 kgf-m, 41 ff-lb)

FRONT SUSPENSION

FS-17

FRONT

SUSPENSION

3.

Sub Frame

A: REMOVAL

1) Lift-up the vehicle.

2) Remove the under cover.

3) Remove the bolt cover.

SUB FRAME

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Replace the M12 bolt with a new one.

Tightening torque:

T1: 34 N-m (3.5 kgf-my 25 ft-16)

T2: 55 N-m (5.6 kgf-my 41 ft-16)

T3: 71 N-m (7.2 kgf-my

52 ft-16)

4)

Remove the clip.

5 )

Remove the sub frame.

NOTE:

Loosen bolt (1) and leave a few threads caught, then remove the bolts in the order of

(2), (4),

and

(6).

(1) M8 bolt

(2)

M12 bolt

(3) MlO bolt

C: INSPECTION

Check that there is no damage and distortion at the sub frame.

FS-16

4.

FRONT TRANSVERSE LINK

Front Transverse Link

A: REMOVAL

1) Set the vehicle on the lift.

2) Disconnect the ground terminal from battery.

3) Lift-up the vehicle and remove the wheel.

4)

Remove the sub frame. <Ref. to FS-16, RE-

MOVAL, Sub Frame.>

5)

Disconnect the stabilizer link from transverse link.

6) Remove the bolt securing the ball joint of trans- verse link to housing.

FRONT SUSPENSION

B: INSTALLATION

1) Temporarily tighten the two bolts used to secure the rear bushing of the transverse link to body.

NOTE:

These bolts should be tightened to such an extent that they can still move back and forth in the oblong shaped hole in the bracket (which holds the bush- ing).

2) Install the bolts used to connect the transverse link to crossmember and temporarily tighten with nut.

CAUTION:

Discard the loosened self-locking nut and re- place with a new one.

3)

Insert the ball joint into housing.

4)

Connect the stabilizer link to transverse link, and temporarily tighten bolts.

CAUTION:

Discard the loosened self-locking nut and re- place with a new one.

S4MOO9(

7)

Remove the nut (do not remove bolt.) securing the transverse link to crossmember.

8)

Remove the two bolts securing the bushing bracket of transverse link to vehicle body at rear bushing location.

I

9) Extract the ball joint from housing.

10) Remove the bolt securing the transverse link to crossmember and extract the transverse link from crossmember.

5) Tighten the following points in the order shown below when the wheels are in full contact with the ground and vehicle is curb weight.

(1) Transverse link and stabilizer

Tightening torque:

Sedan Turbo model:

45 N.m (4.6 kgf-m, 33 ft-lb)

Except sedan Turbo model:

30 N m (3.1 kgf-m,

22 ft-lb)

(2)

Transverse link and crossmember

Tigh tening torque:

100 N-m (10.2 kgf-m, 74 ft-lb)

( 3 )

Transverse link rear bushing and body

Tightening torque:

250 N-m (25.5 kgf-m, 184 ff-16)

FS-17

I

FRONT TRANSVERSE LINK

FRONT SUSPENSION

NOTE:

Move the rear bushing back and forth until trans- verse link-to-rear bushing clearance is established

(as indicated in figure.) before tightening.

Unit: mm (in)

.059)

D: ASSEMBLY

1. FRONT BUSHING

To reassemble, reverse disassembly procedures.

CAUTION:

Install the front bushing in correct direction, as shown in the figure.

(1) Rear bushing

6) Install the sub frame. <Ref. to FS-16, INSTALLA-

TION, Sub Frame.>

7) Inspect the wheel alignment and adjust if neces- sary. <Ref. to FS-8, Wheel Alignment.>

C: DISASSEMBLY

1. FRONT BUSHING

Using ST, press the front bushing out of place.

ST 927680000 INSTALLER & REMOVER

SET

G4M0494

2. REAR

BUSHING

1) Scribe an aligning mark on the transverse link and rear bushing.

2)

Loosen the nut and remove the rear bushing.

S4M0351A

(1) Face bushing toward center of ball joint

(2) Ball joint

2. REAR

BUSHING

1) Install the rear bushing to transverse link and align the aligning marks scribed on the two.

2) Tighten the self-locking nut.

CAUTION:

Discard the loosened self-locking nut and re- place with a new one.

While holding the rear bushing so as not to change position of aligning marks, tighten the self-locking nut.

Tightening torque:

190 N-m (19.4 kgf-m, 140 ff-lb)

E: INSPECTION

1) Check the transverse link for wear, damage and cracks, and correct or replace if defective.

2) Check the bushings for cracks, fatigue or dam- age.

3)

Check the rear bushing for oil leaks.

G4M0495

I

FS-18

5.

Front Ball Joint

FRONT BALL JOINT

A:

REMOVAL

1) Remove the front wheel.

2) Pull out the cotter pin from the ball stud, remove the castle nut, and extract the ball stud from the transverse link.

3) Remove the bolt securing the ball joint to the housing.

FRONT SUSPENSION

C: INSPECTION

1) Measure the play of ball joint by the following procedures. Replace with a new one when the play exceeds the specified value.

(1) With 686 N (70 kgf, 154 Ib) loaded in the di- rection shown in the figure, measure dimension

e

1 .

\

G4M0499

--

4)-€xtract the ball joint from the housing.

B: INSTALLATION

1) Install the ball joint onto the housing.

Torque (Bolt):

50 N-m

(5- kgf-m, 37 ft-lb)

CAUTION:

Do not apply grease to the tapered portion of ball stud.

2) Connect the ball joint to transverse link.

Torque (Castle nut):

Sedan turbo model:

30 N-m (3.7 kgf-m, 22ft-lb)

Except sedan turbo model:

45 N.m (4.6 kgf-m, 33ft-lb)

3) Retighten the castle nut further within 60" until a slot in castle nut is aligned with the hole in ball stud end, then insert the new cotter pin and bend it around castle nut.

4) Install the front wheel.

I

-

G4M0500

(2)

With 686 N (70 kgf, 154 Ib) loaded in the op- posite direction shown in the figure, measure di- mension e,.

4

G4M0501

(3) Calculate plays from the following formula.

S =

Q 2

- 0 1

(4) When plays are larger than the following val- ue, replace with a new one.

FRONT BALL JOINT

Specified play for replacement: S

Less than 0.3 mm (0.012 in)

2)

When the play is smaller than the specified val- ue, visually inspect the dust cover.

3)

The ball joint and cover that have been removed must be checked for wear, damage or cracks, and any defective part must be replaced.

4) If the dust cover is damaged, replace with a new ball joint.

I

FS-19

I

FRONT STRUT

FRONT SUSPENSION

6. Front Strut

A: REMOVAL

1) Remove the front wheel.

2) Remove the bolt securing brake hose from strut.

6) Remove the three nuts securing strut mount to body.

R4Mi78A

3)

Scribe an alignment mark on the camber adjust- ing bolt which secures strut to housing.

4)

Remove the bolt securing the ABS sensor har- ness. suo01

1

5 )

Remove the two bolts securing housing to strut.

CAUTION:

While holding the head of adjusting bolt, loosen self-locking nut.

FS-20

I

B: INSTALLATION

FRONT STRUT

1) Install the strut mount at upper side of strut to body and tighten with nuts.

Tightening torque:

20 N-m (2.0 kgf-m, 74.5 ft-lb)

2) Position the aligning mark on camber adjustment bolt with aligning mark on lower side of strut.

CAUTION:

While holding the head of adjusting bolt, tighten self-locking nut.

Be sure to use a new self-locking nut.

Tightening torque:

775 N-m (77.8 kgf-m, 729 ft-lb)

3 )

Install the ABS sensor harness to strut.

Tightening torque:

33 N.m (3.4 kgf-m, 24.3 ft-lb)

4)

Install bolts which secure the brake hose to strut.

FRONT SUSPENSION

C: DISASSEMBLY

1)

Using a coil spring compressor, compress the coil spring.

S4M0095

2) Using the ST, remove the self-locking nut.

ST 927760000 STRUT MOUNT SOCKET

33 N-m (3.4 kgf-m, 24.3 ft-lb)

5 )

Install the front wheels.

NOTE:

Check wheel alignment and adjust if necessary.

3) Remove the strut mount, upper spring seat and rubber seat from strut.

4)

Gradually decreasing the compression force, and remove the coil spring.

5 )

Remove the dust cover and helper spring.

I

FS-21

I

FRONT STRUT

FRONT SUSPENSION

D:

ASSEMBLY

1) Before installing the coil spring, strut mount, etc., on the strut, check for the presence of air in the dampening force generating mechanism of the strut since air prevents proper dampening force from being produced.

2)

Checking for the presence of air:

(1)

Place the strut vertically with the piston rod facing up.

(2)

Move the piston rod to the center of its entire stroke.

(3) While holding the piston rod end with finger- tips, move the rod up and down.

(4) If the piston rod moves at least 10 mm (0.39 in) in the former step, purge air from the strut.

3) Air purging procedure:

(1)

Place the strut vertically with the piston rod facing up.

(2) Fully extend the piston rod.

(3) With the piston rod fully extended, place the

--

-piston rod side down. The strut must stand ver- tically.

(4)

Fully contract the piston rod.

(5)

Repeat 3 or 4 times from the first step.

NOTE:

After completely purging air from the strut, be sure to place the strut with the piston rod facing up. If it is laid down, check for entry of air in the strut as outlined under “Checking for the presence of air”.

4)

Using a coil spring compressor, compress the coil spring.

NOTE:

Make sure that the vertical installing direction of coil spring is as shown in the figure.

( 2

5)

Set the coil spring correctly so that its end face fits well into the spring seat as shown.

I

4

( 1 )

S4M0353A

6)

Install the helper and dust cover to the piston rod.

7) Pull the piston rod fully upward, and install the rubber seat and spring seat.

NOTE:

Ensure the upper spring seat is positioned as shown in the figure.

S4M0097B

(1)

Outside of body

8)

Install the strut mount to the piston rod, and tight- en the self-locking nut temporarily.

CAUTION:

Be sure to use a new self-locking nut.

9) Using a hexagon wrench to prevent strut rod from turning, tighten self-locking nut with ST.

ST 927760000 STRUT MOUNT SOCKET

Tightening torque:

55

N.m (5.6 kgf-m, 41 ft-lb)

I

B4M0568B

I

(1) Fiat (top side)

(2) identification paint

(3) inclined (bottom side)

FS-22

10)

Loosen the coil spring carefully.

E:

INSPECTION

Check the disassembled parts for cracks, damage and wear, and replace with new parts if defective.

1. DAMPER STRUT

1) Check for oil leakage.

2) Move the piston rod up and down to check that it operates smoothly without any binding.

3) Play of piston rod

Measure the play as follows:

Fix the outer shell and fully extend the rod. Set a dial gauge at the end of the rod: L [ l o mm (0.39 in)], then apply a force of W [20 N (2 kgf, 4 Ib)] to threaded portion. With the force of 20 N (2 kgf, 4 Ib) applied, read the dial gauge indication: PI. Apply a force of 20 N (2 kgf, 4 Ib) in the opposite direction of “W”, then read the dial gauge indication: P,.

FRONT STRUT

FRONT SUSPENSION

5.

HELPER

Replace it with a new one if cracked or damaged.

F: DISPOSAL

CAUTION:

On struts which have “GAS FILLED” marked on the outer housing under spring seat, com- pletely discharge the gas before disposing, fol- lowing the methods below.

Do not disassemble the strut damper or place into a fire.

Drill holes before disposing of gas filled struts.

Before handling gas filled struts, be sure to wear goggles to protect eyes from gas, oil and/ or filings.

GAS FILLED

DO NOT

OPEN

DO NOT HEAT

I

B4M1201

1)

Place the gas filled strut on a flat and level sur- face with piston rod fully extended.

2) Using a 2 to 3 mm (0.08 to 0.12 in) dia. drill, make holes in areas shown in the figure.

The free play is determined by the following equa- tion:

Play

=

PI, P2

Limit of play:

Less than 0.8 mm (0.031 in)

If the play is greater, replace the strut.

2.

STRUT MOUNT

Check the rubber part for creep, cracks and deteri- oration, and replace it with a new one if defective.

3. DUSTCOVER

If any cracks or damage are found, replace it with a new one.

4.

COIL SPRING

One having permanent strain should be replaced with a new one. When the vehicle posture is un- even, although there are no considerable reasons like tire puncture, uneven loading, etc., check the coil spring for its free length referring to specifica- tions, cracks, etc., and replace it with a new one if defective.

I

piston rod

M

(1.57 in)

,-Strut

B4M1202P

I

FS-23

I

FRONT STABILIZER

FRONT SUSPENSION

7. Front Stabilizer

A: REMOVAL

Jack-up the front part

Of the and it with safety stands (rigid racks).

2,

Remove the j a c k w plate from lower

Of crossmember.

3)

Remove the sub frame. <Ref. to

LbVAL, Sub Frame.>

4)

Remove the bolt and nut which secure the stabi- lizer to crossmember.

B: INSTALLATION

1) Install in the reverse order of removal.

NOTE:

Install the bushing (on front crossmember side) while aligning it with paint mark on stabilizer.

Ensure the bushing and stabilizer have the Same identification colors when installing.

5 )

Remove the bolts which Secure the stabilizer link to front transverse link.

(1)

Mark stamped on stabilizer

(2)

Bushing identification color

' ' suo012 wheels are in full contact with the ground and ve- hicle is curb weight.

Tightening torque (Sedan turbo model):

Jack-up plate to crossmember:

Stabilizer link to front transverse link:

45 N-m (4.6 kgf-m, 33 ft-lb)

Stabilizer to crossmember:

25 N.m (2.5 kgf-m, 18.1 ft-lb)

Tightening torque (Except sedan turbo model):

Jack-up plate to crossmember:

20 N.m (2.0 kgf-m, 14.5 ft-lb)

Stabilizer link to front transverse link:

30 N.m

(3.

kgf-m, 22 ft-lb)

Stabilizer to crossmember:

25 N-m (2.5 kgf-m, 18.1 ft-lb)

3)

Install the sub frame. <Ref. to FS-16, INSTALLA-

TION, Sub Frame.>

C: INSPECTION

1)

Check the bushing for cracks, fatigue or dam- age.

2) Check the stabilizer link for deformities, cracks or damage, and bushing for protrusions from the hole of stabilizer link.

FS-24

8.

Front Crossmember

FRONT CROSSMEMBER

A: REMOVAL

1) Disconnect the ground terminal from battery.

2) Lift-up the vehicle and remove the front tires and wheels.

3) Remove the sub frame. <Ref. to FS-16, RE-

MOVAL, Sub Frame.>

4) Remove both stabilizer and jack-up plate.

c.

(1) Front stabilizer

(2)

Front crossmember

5) Disconnect the tie-rod end from housing.

6) Remove the front exhaust pipe. (Non-turbo mod- el) <Ref. to. EX(S0HC)-5, REMOVAL, Front Ex- haust Pipe.>

7 ) Remove the front transverse link from front crossmember and body.

FRONT SUSPENSION

12) Support the crossmember with a jack, remove the nuts securing crossmember to body and lower crossmember gradually along with the steering gearbox.

CAUTION:

When removing the crossmember downward, be careful that the tie-rod end does not inter- fere with SFJ boot.

13) Remove the steering gearbox from crossmem- ber.

B: INSTALLATION

1) Install in the reverse order of removal.

CAUTION:

Always tighten the rubber bushing when wheels are in full contact with the ground and vehicle is curb weight.

Tightening torque:

Transverse link bushing to crossmember:

100

N.m (10.2 kgf-m, 74 ft-lb)

Stabilizer to bushing:

25 N.m (2.5 kgf-m, 18.1 ft-lb)

Tie-rod end to housing:

27.0 N-m (2.75 kgf-m, 19.9 ft-lb)

Front cushion rubber to crossmember:

85 N.m (8.7 kgf-m, 62.7 ft-lb)

Universal joint to pinion shaft:

24 N-m (2.4 kgf-m, 17.4 ff-16)

Crossmember to body:

100 N-m (10.2 kgf-m, 74 ft-lb)

2) Purge air from the power steering system.

NOTE:

Check the wheel alignment and adjust if necessary.

C: INSPECTION

Check the crossmember for wear, damage and cracks, and correct or replace if defective.

8) Remove the nuts attaching engine mount cush- ion rubber to crossmember.

9) Remove the steering universal joint. <Ref. to PS-

26, REMOVAL, Steering Gearbox.>

10) Disconnect the power steering pipe from steer- ing gear box.

11) Lift the engine by approx. 10 mm (0.39 in) by using a chain block.

FS-25

GENERAL DIAGNOSTIC TABLE

FRONT SUSPENSION

9.

General Diagnostic Table

A:

INSPECTION

1. IMPROPER VEHICLE POSTURE OR IMPROPER WHEEL ARCH HEIGHT

Possible causes Countermeasures

(2)

Unsmooth operation of damper strut and/or shock absorber

(3)

Installation of wrong strut and/or shock absorber

(4)

Installation of wrong coil spring

Replace.

Replace with proper parts.

Replace with proper parts.

1)

Large rebound shock ning over bump and/or hump.

3)

Large shock in bumping

(1)

Breakage of coil spring

(2) Overinflation pressure of tire

I

(3) Improper wheel arch height

(4)

Fault in operation of damper strut and/or shock absorber

I

Replace.

I

Adjust.

I

Adjust or replace coil springs with new ones.

I

Replace.

*(5) Damage or deformation of strut mount and/or shock absorber mount

Replace.

(6) Unsuitability of maximum and/or minimum length of damper strut and/or shock absorber

I

( 7 )

Deformation or loss of bushing

(8) Deformation or damage of helper

in

strut assembly and/or shock absorber

Replace with proper parts.

I

Replace.

Replace.

(9) Oil leakaae of damDer strut and/or shock absorber Replace.

I

I

Possible causes Countermeasures

(1 ) Wear or damage of damper strut and/or shock absorber component parts

(2) Loosenina of suspension link installing bolt

(3) Deformation or loss of bushing

(4)

Unsuitability of maximum and/or minimum length of damper strut and/or shock absorber

Replace.

I

Retighten to the specified torque.

1

Replace.

Replace with proper parts.

(5) Breakaae of coil sprina

I

(6)

Wear or damaae of ball ioint

I

(7)

Deformation of stabilizer clamp

Replace.

I

Replace.

I

Replace.

I

I

I

I

I

FS-26

REAR SUSPENSION

1

.

2

.

3

.

4

.

5

.

6

.

7

.

RS

.

a

Page

General Description

....................................................................................

2

Wheel Alignment

.........................................................................................

9

Rear Stabilizer

...........................................................................................

10

Rear Trailing Link

......................................................................................

11

Rear Strut

..................................................................................................

15

Lateral link

.................................................................................................

16

Rear Crossmember

...................................................................................

19

General Diagnostic Table

..........................................................................

20

I

REAR SUSPENSION

1.

General Description

A: SPECIFICATIONS

GENERAL DESCRIPTION

I

Camber (tolerance:

Toe-in

Wheel arch height

Item fO"45')

[tolerance: k12 mm (k0.47 in)l

I

Thrust angle

Diameter of stabilizer

I

Turbo

Sedan

Wagon

I

Non-turbo

1

Turbo

1

Non-turbo

I

-1"30'

I

-1"25'

I

-1'20'

I

-1'15'

I

- I f 2 mm (-0.039k0.079 in)

OUTBACK

-1"10'

Each toe-in angle: fO"07'30 (Total toe-in angle 0"+1 5')

376

m m

381 mm 376

m m

381

m m

(14.80 in) (15.0 in) (14.80 in) (15.0 in)

386

m m

(15.20 in)

20 mm

(0.79 in)

1 3 mm

(0.51 in)

O"f20'

17 mm

(0.67 in)

13mm

(0.51 in)

NOTE:

Front and rear toe-ins and front camber can be adjusted. If the toe-in or camber tolerance exceeds specifications, adjust the toe-in and camber to the middle value of specification.

The other items indicated in the specification ta-

%le cannot be adjusted. If the other items exceeds specifications, check the suspension parts and connections for deformities; replace with new ones as required.

I

I

B4M2250C

(1) Front

A

-

=

Positive: Toe-in, Negative: Toe-out

a l , a2: Each toe-in angle

RS-2

GENERAL DESCRIPTION

REAR SUSPENSION

3

RS-3

I

REAR SUSPENSION

B: COMPONENT

GENERAL DESCRIPTION

I

P

I

SI

RS-4

c.

Stabilizer

Stabilizer bracket

Stabilizer bushing

Clamp

Floating bushing

Stopper

Stabilizer link

Rear lateral link

Bushing (C)

Bushing (A)

Front lateral link

Bushing (B)

Trailing link rear bushing

Trailing link

Trailing link front bushing

GENERAL DESCRIPTION

Trailing link bracket

Cap (Protection)

Washer

Rear crossmember

Strut mount cap

Strut mount

Rubber seat upper

Dust cover

Coil spring

Helper

Rubber seat lower

Damper strut

Self-locking nut

Rear differential member rear

REAR SUSPENSION

Tightening torque: N-m (kgf-m, ft-lb)

T1: 20(2.0, 14.5)

T2: 25 (2.5, 18.1)

T3: 45 (4.6, 33.2)

T5: 70 (7.1, 52)

T6: 90 (9.2, 66)

T7: 100 (10.2, 74)

T8: 115(11.7, 85)

T9: 130 (13.3, 96)

TlO: 135(13.8, 100)

T11: 220(22.4, 162)

RS-5

I

GENERAL DESCRIPTION

REAR SUSPENSION

C: CAUTION

Wear working clothing, including a cap, protec- tive goggles, and protective shoes during opera- tion.

Remove contamination including dirt and corro- sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro- tect them from dust or dirt.

Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary re- moval, installation, disassembly, and replacement.

Use SUBARU genuine grease etc. or the equiv- alent. Do not mix grease etc. with that of another grade or from other manufacturers.

Be sure to tighten fasteners including bolts and nuts to the specified torque.

Place shop jacks or safety stands at the specified points.

Apply grease onto sliding or revolution surfaces before installation.

-0

Before installing O-rings or snap rings, apply suf- ficient amount of grease to avoid damage and de- formation.

Before securing a part on a vice, place cushion- ing material such as wood blocks, aluminum plate, or shop cloth between the part and the vice.

Before disposing shock absorbers, be sure to bleed gas completely. Also, do not throw away in fire.

RS-6

GENERAL DESCRIPTION

I

D: PREPARATION TOOL

1. SPECIAL TOOLS

ILLUSTRATION

TOOL NUMBER

927380002 rDAPTER

REAR

SUSPENSION

REMARKS

Jsed as an adapter for camber & caster gauge vhen measuring camber and caster.

1) 28199ACOOO PLATE

2) 281 99AC010 BOLT

I

Jsed for replacing front bushing.

I suo01

4

927730000

NSTALLER &

3EMOVER

Used for replacing rear bushing.

I

SUOOI!

28099PA100 REMOVER

Used for removing DOJ.

RS-7

REAR SUSPENSION

ILLUSTRATION

GENERAL DESCRIPTION

TOOL NUMBER

92770000

DESCRIPTION

INSTALLER &

REMOVER

REMARKS

Used for replacing lateral link bushing.

I

SUO015

927690000 HELPER SOCKET

WRENCH

Used for replacing lateral link bushing.

SUO015

2.

GENERAL PURPOSE TOOLS

Alignment gauge

Turnina radius aauae

I

Transmission iack

I

Bearing puller

TOOL NAME

REMARKS

Used for wheel alignment measurement.

Used for wheel alianment measurement.

I

Used for toe-in measurement.

I

Used for suspension assembly/disassembly.

I

Used for removing bushings.

I

I

RS-8

WHEEL ALIGNMENT

2.

Wheel Alignment

A: INSPECTION

NOTE:

The front and rear wheel alignment must be mea- sured and/or adjusted at once to obtain accuracy.

Measure and/or adjust the rear wheel alignment to- gether with the front. Follow the procedure in "FS" section "Wheel Alignment" for measurement and/or adjustment of wheel alignment. <Ref. to FS-8, IN-

SPECTION, Wheel Alignment.>

REAR SUSPENSION

I

RS-9

I

REAR STABILIZER

REAR SUSPENSION

3. Rear Stabilizer

A: REMOVAL

1)

Jack-up the rear part of the vehicle, support it with safety stands (rigid racks).

2)

Remove the bolts which secure stabilizer link to rear lateral link.

B: INSTALLATION

1)

Install in the reverse order of removal.

NOTE:

Install the bushing while aligning it with paint mark on stabilizer.

Ensure that the bushing and stabilizer have the same identification colors when installing.

3) Remove the bolt which secures stabilizer to sta- bilizer bracket.

(1)

Mark stamped on stabilizer

(2) Bushing identification color

2) Always tighten the rubber bushing location when wheels are in full contact with the ground and vehi- cle is curb weight.

Tightening torque:

Stabilizer link to rear lateral link

45 N-m (4.6 kgf-m, 33.2 ft-lb)

Stabilizer to stabilizer bracket

25 N.m (2.5 kgf-m, 18.1 ft-lb)

C: INSPECTION

1) Check the bushing for cracks, fatigue or dam- age.

2)

Check the stabilizer links for deformities, cracks, or damage, and bushing for protrusions from the hole of stabilizer link.

RS-10

4. Rear Trailing Link

A: REMOVAL

1)

Loosen the rear wheel nuts.

REAR TRAILING LINK

(rigid racks) and remove the rear wheels.

3) Remove both rear parking brake clamp and

ABS

sensor harness. (Models equipped with

ABS)

4)

R~~~~~ the bolt which Secures trailing link to trailing link bracket.

REAR SUSPENSION

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

Always tighten the .rubber bushing location when wheels are in full contact with the ground and vehicle is at curb weight condition.

NOTE:

Check the wheel alignment and adjust if necessary.

1

(1)

Trailing

link

5 )

Remove the bolt which secures trailing link to rear housing.

RS-11

REAR TRAILING LINK

REAR SUSPENSION

C:

DISASSEMBLY

1. FRONT BUSHING

Using ST, press the front bushing out of place.

ST 927720000 INSTALLER & REMOVER

SET

2. REAR

BUSHING

1)

Remove the housing. <Ref. to DS-23, REMOV-

AL, Rear Axle.>

2) Using ST, press the rear bushing out of place.

ST 927730000

INSTALLER &-REMOVER

SET

(1) Press

(2)

Trailing link

(1) Press

(2) Housing

RS-12

c-

D: ASSEMBLY

1. FRONT BUSHING

Using ST, press the bushing into trailing link.

ST 927720000 INSTALLER & REMOVER

SET

CAUTION:

When installing the bushing, turn ST plunger upside down and press it until plunger end sur- face contacts trailing link end surface.

‘ir

REAR TRAILING LINK

REAR

SUSPENSION

2. REAR BUSHING

1)

Using ST, press the bushing into trailing link.

ST 927730000 INSTALLER & REMOVER

SET

NOTE:

If it is difficult to press the bushing into trailing link, apply water-diluted TIRE LUBE to the inner surface of ST as a lubricant.

S

PE ClFlE

D lubricant:

TIRE

LUBE :

=

1

:

I

( 2 )

\

( 3 )

\

S4M0360E

(1) Press

(2) Front bushing

(3)

Trailing link

CAUTION:

Install the front bushing in proper direction, as shown in the figure.

(1) Press

I

(1) Front

RS-13

REAR TRAILING LINK

REAR SUSPENSION

2) Press the ST pluger until bushing flange pro- trudes beyond trailing link.

ST

927730000 INSTALLER & REMOVER

SET

3) Turn the trailing link upside down. Press the ST plunger in the direction opposite that outlines in the former procedure until bushing is correctly posi- tioned in trailing link.

ST 927730060 INSTALLER

&

REMOVER

SET

r .

.

( 1 )

Plunger

(2)

Flange

( 1 )

(2)

Press

Plunger

4)

Install the housing. <Ref. to DS-26, INSTALLA-

TION, Rear Axle.>

E: INSPECTION

Check the trailing links for bends, corrosion or dam- age.

RS-14

I

5.

Rear

Strut

A: REMOVAL

1)

Remove the rear seat cushion and backrest.

(Sedan model)

2)

Remove the strut cap of quarter trim. (Wagon model)

3) Loosen the rear wheel nuts.

4) Jack-up the vehicle, support it with safety stands

(rigid racks) and remove the rear wheels.

5 )

Remove the brake hose clip and remove the brake hose from rear strut.

REAR STRUT

REAR SUSPENSION

B: INSTALLATION

1)

Tighten the self-locking nut used to secure strut mount to car body.

CAUTION:

Discard the loosened self-locking nut, and re- place with a new one.

Tightening torque:

(1) Brake hose clip

(2) Brake hose

6) Remove -the bolts which secure rear strut to housing.

7)

Remove the nuts securing strut mount to body.

2)

Tighten the bolts which secure rear strut to hous- ing.

Tightening torque:

220 N.m (22.4 kgf-m, 162 ft-lb)

CAUTION:

Discard the loosened self-locking nut, and re- place with a new one.

3)

Install the brake hose to lower side of strut, then insert brake hose clip.

CAUTION:

Check that the hose clip is positioned proper- ly-

Check the brake hose for twisting, or exces- sive tension.

(Model equipped with ABS)

Do not subject the ABS sensor harness to exc- es-sive tension.

4)

Lower the vehicle and tighten wheel nut.

Tightening torque:

90 N-m (9.2 kgf-m, 66 ft-lb)

5 )

Sedan model:

Install the rear seat backrest and rear seat cushion.

Wagon model:

Install the strut cap to rear quarter trim.

NOTE:

Check wheel alignment and adjust if necessary.

C: DISASSEMBLY

For disassembly of rear strut, refer to procedures outlined under front strut as a guide. <Ref. to FS-

21, DISASSEMBLY, Front Strut.>

D: ASSEMBLY

Refer to Front Strut as a guide for assembly proce- dures.

<Ref. to FS-22, ASSEMBLY, Front Strut.>

E: INSPECTION

Refer to Front Strut as a guide for inspection proce- dures.

<Ref. to FS-23, INSPECTION, Front Strut.>

F:

DISPOSAL

Refer to Front Strut as a guide for disposal proce- dures.<Ref. to FS-23, DISPOSAL, Front Strut.>

RS-15

I

LATERAL LINK

REAR SUSPENSION

6.

Lateral link

A: REMOVAL

1) Loosen the wheel nuts. Lift-up the vehicle and remove wheel.

2 )

Remove the stabilizers. (Turbo model)

3) Remove the ABS sensor harness from trailing link.

(Models eqipped with ABS)

4)

Remove the bolt securing trailing link to housing.

r .

(1) Rear housing

(2) Trailing link

5) Remove the bolts which secure lateral link as- sembly to rear housing.

6) Remove the DOJ from rear differential using ST.

ST 28099PA100 DRIVE SHAFT REMOVER

NOTE:

The side spline shaft circlip comes out together with the shaft.

Bushing

Bushing A

Bushina B

I

BushinaC

I

ST:INSTALLER & REMOVER SET

927700000

927690000

927700000

I

(1)

Bolt

(2) DOJ

CAUTION:

Be careful not to damage the side bearing re- tainer. Always use bolt shown in figure, as sup- porting point for ST during removal.

7) Scribe an alignment mark on the rear lateral link adjusting bolt and crossmember.

RS-16

(1)

Bushing

A

(2) Bushing B

(3) Bushing C

(4)

Front

( 5 )

Outside of body

S4MQIQQ

LATERAL LINK

REAR

SUSPENSION

D: ASSEMBLY

1)

Using ST, press the bushing into place.

CAUTION:

Select the ST according to the type of bushings used.

NOTE:

Use the same ST as that used during disassem- bly.

If it is difficult to press the bushing into trailing link, apply water-diluted TIRE LUBE to the inner surface of ST as a lubricant.

Specified lubricant:

TIRE

LUBE :

=

1

:

(1)

Press

(2) Bushing

(3) Lateral link

(1)

Press

(2) Lateral link

S4MQ365

RS-17

I

LATERAL LINK

REAR SUSPENSION

2) Press the ST plunger until bushing flange pro- trudes beyond lateral link.

NOTE:

Use the same ST as that used during disassembly.

3)

Turn the lateral link upside down. Press the ST plunger in the direction opposite that outlined in the former procedure until bushing is correctly posi- tioned in trailing link.

NOTE:

Using the same ST as that used during dissassem- bly.

.

(1)

Press

(2)

Plunger

(3)

Lateral link

(4)

Flange

(1)

Press

(2) Plunger

(3)

Lateral link

E: INSPECTION

Visually check the lateral links for damage or bends.

RS-18

I

7. Rear Crossmember

REAR CROSSMEMBER

A: REMOVAL

CAUTION:

Do not subject the ABS sensor harness to ex- cessive tension. (Models equipped with ABS)

1) Separate the front exhaust pipe and rear ex- haust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the rear differential.

<Ref. to DI-19, REMOVAL, Rear Differential.>

4)

Place a transmission jack under rear crossmem- ber.

REAR SUSPENSION

B:

INSTALLATION

1) Install in the reverse order of removal.

2) For installation and tightning torque of rear differ- ential:

<Ref. to DI-20, INSTALLATION, Rear Differential.>

3) Always tighten the rubber bushing when wheels are in full contact with the ground and vehicle is curb weight.

NOTE:

Check the wheel alignment and adjust if necessary.

C: INSPECTION

Check the removed parts for wear, damage and cracks, and correct or replace if defective.

I

5)

Remove the bolts securing crossmember to ve- hicle body, and remove the crossmember.

6)

Scribe an alignment mark on the rear lateral link cam bolt and crossmember.

7) Remove the front and rear lateral links by loos- ening nuts.

RS-19

GENERAL DIAGNOSTIC TABLE

REAR SUSPENSION

8.

General Diagnostic Table

A: INSPECTION

1.

IMPROPER VEHICLE POSTURE

OR

IMPROPER WHEEL ARCH HEIGHT

Possible causes

(1)

Permanent distortion or breakage of coil spring

(2) Unsmooth operation of damper strut and/or shock absorber

I

(3) Installation of wrong strut and/or shock absorber

I

(4)

Installation of wrong coil spring

Countermeasures

Replace.

Replace.

I

Replace with proper parts.

I

Replace with proper parts.

2. POOR RIDE COMFORT

1)

Large rebound shock

2)

Rocking of vehicle continues too long after running over bump and/or hump.

3) Large shock in bumping

I

(1) Breakage of coil spring

I

(2)

Overinflation Dressure of tire

(3) Improper wheel arch height

44)

\ ,

Fault in operation of damper strut and/or shock absorber t(5)

Damaae or deformation of strut mount and/or shock absorber mount

(6) Unsuitability of maximum and/or minimum length of damper strut and/or shock absorber

I

Replace.

I

Adiust.

I

Adjust or replace coil springs with new ones.

I

I

Replace.

'

I

Replace.

Replace with proper parts.

(7) Deformation or loss of bushing

(8) Deformation or damage of helper in strut assembly and/or shock absorber

I

(9) Oil leakage of damper strut and/or shock absorber

Replace.

Replace.

1

Replace.

3. NOISE

Possible causes

(1)

Wear or damage of damper strut and/or shock absorber component parts

(2) Loosening of suspension link installing bolt

Replace.

Countermeasures

(3)

Deformation or loss of bushing

(4) Unsuitability of maximum and/or minimum length of damper strut and/or shock absorber

I

Retighten to the specified torque.

I

Replace.

Replace with proper parts.

( 6 )

Wear or damage of ball ioint

I

(7)

Deformation of stabilizer clamp

Replace.

I

Replace.

I

Replace.

I

I

I

I

I

I

I

RS-20

~~

WHEEL AND TIRE SYSTEM

~

WT

page

1

.

General Description

....................................................................................

2

2

.

3

.

4

.

6

.

7

.

Steel Wheel

.................................................................................................

5

Aluminum Wheel

.........................................................................................

6

Wheel Balancing

.........................................................................................

7

“T-type” Tire

................................................................................................

8

Full Wheel Cap

............................................................................................

9

General Diagnostics Table

........................................................................

10

~

WHEEL AND TIRE SYSTEM

~

1.

General

Description

A: SPECIFICATIONS

GENERAL DESCRIPTION

I

Front and rear

-*

.

T-Type tire

Front and rear

T-Type ti re

S4M0367A

I

P195/60R1587H

I

1 5 x 6 J J

I

P205/55 R16 89V 16 x 6 1/2JJ

21 5/45 R17 87W

T I 35/70 D16

1

17 x 7JJ

16 x

4T

Tire size

P I 95/60

R15

P205155 R16 89V

21 5/45 R17 87W

T135ffO D16 100M

55 (2.17)

50 (1.97)

I

100

(3.94) Dia.

Tire inflation pressure kPa

(kg/cm2,

psi)

Fr: 220 (2.2, 32)

Rr: 200 (2.0, 29)

Fr: 220 (2.2, 32) Fir: 200 (2.0, 29)

Fr: 230 (2.3, 33) Rr: 220 (2.2, 32)

420 (4.2, 60)

I

I

WT-2

I

GENERAL DESCRIPTION

WHEEL AND TIRE SYSTEM

1.

SERVICE DATA

~

I

Item

Steel wheel

Aluminum wheel

I

Axial runout

I

Radial runout

1.5 mm (0.059

in)

1

.O

mm (0.039 in)

2.

ADJUSTING PARTS

B: PREPARATION TOOL

1

1.

GENERAL PURPOSE TOOLS

TOOL NAME

Air pressure gauge

Dial gauge

REMARKS

Used for measuring tire air pressure.

Used for measuring wheel runout.

I

Less than 5 g (0.1 8

02)

Balance weight part number

Weight

I

I

723141 320

7231 41 330

7231 41 350

I

20 g (0.71

02)

I

723241 380

723241 590

Balance weight part number

(For aluminum wheel)

231 41 GA462

231 41 GA482

Weight r

23141GA512

I

30 g (1.06

02)

I

I

231 41 GA522

-I

35 g (1.23

02)

I

231 41 GA532 40 g (1.41

02)

23141 GA552

-

45

" a (1 5 9

02)

>

50 g (I

02)

55 g (1.94

0 2 )

23141 GA572 60

g

(2.12

02)

WT-3

I

WHEEL AND TIRE SYSTEM

2.

Tire

A: INSPECTION

1) Take stone, glass, nail etc. off the tread groove.

2) Replace the tire:

CAUTION:

When replacing a tire, make sure to use only the same size, construction and load range as originally installed.

Avoid mixing radial, belted bias or bias tires on the vehicle.

(1) when large crack on side wall, damage or crack on tread is found.

(2) when the “tread wear indicator” appears as a solid band across the tread.

TIRE

-

r .

.

I

S4M0377A

(1 ) Tread wear indicator

(2)

Tire tread

1. TIRE ROTATION

If tires are maintained at the same positions for a long period of time, uneven wear results. There- fore, they should be periodically rotated.

This lengthens service life of tires.

CAUTION:

When rotating tires, replace unevenly worn or damaged tires with new ones.

WT-4

I

3.

Steel

Wheel

A: REMOVAL

1)

Apply the parking brake, and position select le- ver to “P” or “LOW”.

2)

Set the shop jacks or a lift to the specified point, and support the vehicle with its wheels slightly con- tacting the floor.

3)

Loosen the wheel nuts.

4)

Raise the vehicle until its wheels take off the ground using a jack or a lift.

5) Remove the wheel nuts and wheels.

NOTE:

While removing the wheels, prevent hub bolts from damage.

NOTE:

Place the wheels with their outer sides facing up- ward to prevent wheels from damage.

B: INSTALLATION

--

I ) Attach the wheel to the hub by aligning the wheel bolt hole with the hub bolt.

2)

Temporarily attach the wheel nuts to the hub bolts. (In the case of aluminum wheel, use SUBA-

RU genuine wheel nut for aluminum wheel.)

3)

Manually tighten the nuts making sure the wheel hub hole is aligned correctly to the guide portion of hub.

4)

Tighten the wheel nuts in a diagonal selection to the specified torque. Use a wheel nut wrench.

Wheel nut tightening torque:

90

N.m (9. I kgf-m, 65.7 ff-lb)

CAUTION:

Tighten the wheel nuts in two or three steps by gradually increasing the torque and working diagonally, until the specified torque is reached. For drum brake models, excess tight- ening of wheel nuts may cause wheels to “jud- der”.

Do not depress the wrench with a foot;

Al- ways use both hands when tightening.

Make sure the bolt, nut and the nut seating surface of the wheel are free from oils.

5) If a wheel is removed for replacement or for re- pair of a puncture, retighten the wheel nuts to the specified torque after running 1,000 km (600 miles).

STEEL WHEEL

WHEEL AND TIRE SYSTEM

C: INSPECTION

1)

Deformation or damage on the rim can cause air leakage. Check the rim flange for deformation, crack or damage, and repair or replace as neces- sary.

2) Jack-up the vehicle until wheels clear the floor.

3) Slowly rotate the wheel to check rim “runout” us- ing a dial gauge.

APP

/

1.5 mm (0.059 in)

G4M029E

I

G4M0299

4)

If the rim runout exceeds specifications, remove the tire from rim and check runout while attaching dial gauge to positions shown in figure.

5) If the measured runout still exceeds specifica- tions, replace the wheel.

I

WT-5

I

ALUMINUM WHEEL

WHEEL

AND

TIRE SYSTEM

4.

Aluminum Wheel

A: REMOVAL

Refer to Steel Wheel for removal procedure of a h - minum wheels. <Ref. to WT-5, REMOVAL, Steel

Wheel. >

B: INSTALLATION

Refer to Steel Wheel for installation procedure of aluminum wheels.cRef. to WT-5, INSTALLATION,

Steel Wheel.>

C: INSPECTION

Refer to Steel Wheel for inspection procedure of aluminum wheels. <Ref. to WT-5, INSPECTION,

Steel Wheel.>

Rim runout:

I

Axial runout limit

I

Radial runout limit

I

1

.O

mm (0.039 in)

D:

-CAUTION

Aluminum wheels are easily scratched. To main- tain their appearance and safety, do the following:

1) Do not damage the aluminum wheels during re- moval, disassembly, installation, wheel balancing, etc. After removing the aluminum wheels, place them on a rubber mat, etc.

2)

While the vehicle is being driven, be careful not to ride over sharp obstacles or allow aluminum wheels to contact the shoulder of the road.

3) When installing a tire chain, be sure to install it properly not to have a slack; otherwise it may hit the wheel while driving.

4)

When washing the aluminum wheel, use neutral synthetic detergent and water. Avoid using the cleanser including abrasive, hard brushes or an automatic car washer.

WT-6

I

I

c-

~

5. Wheel

Balancing

I

I

A: REPLACEMENT

1)

Remove the balance weights.

2) Using the dynamic balancing, measure wheel balance.

3) Select a weight close to the value measured by dynamic balancing.

Balance weight part number

I

(For steel wheel)

7231 41 300

7231 41 31 0

7231 41 320

7231 41 330

723141 340

7231 41 350

723141360

7231 41 370

723241 380

723241 580

723241 590

I

I

I

I

Weight

10 g (0.35

02)

15 g (0.53

02)

20 g (0.71

02)

25 g (0.88

02)

30 g (1.06

02)

35

CI

(1.23 oz)

40

g

(1.41

02)

45 g (1.59

0 2 )

50 g (1.76

02)

55 g (1.94

02)

60 g (2.12

02)

WHEEL BALANCING

I

I

WHEEL AND TIRE SYSTEM

B: INSPECTION

1)

Proper wheel balance may be lost if the tire is re- paired or if it wears. Check the tire for dynamic bal- ance, and repair as necessary.

2) To check for dynamic balance, use a dynamic balancer. Drive in the balance weight on both the top and rear sides of the rim.

3)

Some types of balancer can cause damage to the wheel. Use an appropriate balancer when ad- justing the wheel balance.

4)

Use genuine balance weights.

CAUTION:

55 g

(1.94

02)

weight used with aluminum wheel is not available.

Balance weights are available for use with any of 14- to 16-inch wheels.

I

I

Balance weight part number

(For aluminum wheel)

231 41 GA472

Weight

5

g (0.18

02).

10 a

(0.35

02)

I

I r -

231 41 GA492

I

20

CI

(0.71

02)

I

I

231 41 GA502

231 41 GA512

I

I

25 g (0.88

02)

30 g (1.06

02)

I

I

231 41 GA522

35 g (1.23

02)

231 41 GA532 40 g (1.41

02)

231 41 GA542

231 41 GA552

45 g (1.59

0 2 )

50

Q

(1.76

02)

-

231 41 GA572

I

55 g

(1.94

02)

60 g (2.12

02)

I

B4M0053B

(1) Weight for aluminum wheel

(2) Weight for steel wheel

Service limit: A

Weight for steel wheel;

2.16 mm (0.085 in)

Weight for aluminum wheel;

4.5 mm (0.177 in)

I

WT-7

I

“T-TY PE” TIRE

WHEEL AND TIRE SYSTEM

6.

“T-type” Tire

A: NOTE

“T-type” tire for temporary use is prepared as a spare tire.

CAUTION:

Do not use a tire chain with the “T-type” tire.

Because of the smaller tire size, a tire chain will not fit properly and will result in damage to the vehicle and the tire.

Do not drive at a speed greater than 80 km/h

(50 MPH).

Drive as slowly as possible and avoid pass- ing over bumps.

B:

REPLACEMENT

Refer to Removal and Installation of Steel Wheel for removaVinstallation of “T-type” tires. <Ref. to

WT-5, Steel Wheel.>

CAUTION:

Tiepiace with a conventional tire as soon as possible since the “T-type” tire i s only for tem- porary use.

C: INSPECTION

1) Check the tire inflation pressure.

Specification:

420 kPa (4.2 kg/cn?, 60 psi)

2) Take the stones, glass, nails, etc. out of the tread groove

.

3)

Check the tires for deformation, cracks, partial wear, or wear.

CAUTION:

Replace the tire with a new one.

WT-8

FULL WHEEL CAP

7.

Full Wheel Cap

A: REMOVAL

Pry off the full wheel cap with a wheel cap remover inserted between openings in the cap.

WHEEL AND TIRE SYSTEM

I

B: INSTALLATION

Align the valve hole in the wheel cap with the valve on the wheel and secure the wheel cap by tapping

*.

-

.

C: INSPECTION

1)

Check the wheels for missing wheel caps.

2)

Check the pawls of wheel caps for damage or bend.

3) Check the wheel caps for cracks.

WT-9

GENERAL DIAGNOSTICS TABLE

WHEEL

AND

TIRE SYSTEM

8.

General Diagnostics Table

A:

INSPECTION

I

Front wheel shimmy

I

Abnormal tire wear

Sways/pitches

Wander/pulls

I

Worn or improperly inflated of tire.

I

Wheel is out of balance.

I

Improperly inflated of tire.

Worn or improperly inflated of tire.

Worn or improperly inflated of tire.

I

Replace

I

Adjustment

I

Replace

Replace

Replace

I

I

I

3

WT-10

DIFFERENTIALS

Dl

5.

6.

7.

8.

1.

2.

3.

4.

~~~~~~~~ ~

Page

General Description

....

. . ..

. .

...

. .

..

.

...

. ...

. .

...

. .. .

...

. .

..................................

. ..

.

..

.

..

..2

Differential Gear Oil

...................................................................................

17

Front Differential

........................................................................................

18

Rear Differential

........................................................................................

19

Rear Differential Front Oil Seal

......................................

....

. ...

.. .

.

...

.

... .

...

.

..

.35

Rear Differential Side Oil Seal

..................................................................

37

Rear Differential Member

..........................................................................

40

General Diagnostic Table

..........................................................................

41

E

DIFFERENTIALS

1.

General Description

A: SPECIFICATIONS

I

I

MODEL

I

Waaon

GENERAL DESCRIPTION

Non-Turbo

Sedan Waaon Sedan

I

Type of gear

Gear ratio (Number of gear teeth)

Oil capacity

Rear differential gear oil

3.900 (39/10)

MT

Turbo

AT

4.1 11 (37/9)

Hypoid gear

4.444 (40/9) 3.545 (39/11) 4.1 11 (37/9)

0.8

0

(0.8 US qt, 0.7 Imp qt)

GL-5

I

I causes the drive line and tires to "drag" or emit abnormal noise when AWD is selected.

I \ I f=

DROOOI

1. SERVICE

DATA

Front and rear bearing preload at companion flange bolt hole N (kgf, Ib)

Side aear backlash mm (in)

I

Side bearina standard width mm (in)

I

Crown gear to drive pinion backlash mm (in)

I

Crown gear runout on its back surface mm (in)

New bearing

Used bearing

2.

ADJUSTING PARTS

I

I

I

ITEM

Rear differential gear oil

API

Classification tiL-5

SAE Viscosity No. and Application Temperature

("C) -30 -26

-15 -5 0 15

25

30

I

( O F )

-22 -15 5 23 32

I I I

L '

59 77 86

I

1 2

75W-90

I

I

I I I I

I

H3M1272A

19.6

- - -

8.34-16.67(0.85-1.7, 1.87-3.75)

0.10

-

-

20.00 (0.7874)

0.10 - 0.0079)

Less than 0.05 (0.0020)

Front and rear bearing preload at com- panion flange bolt hole

Preload adjusting spacer

I

I

New bearing

Used bearing

Part No.

383695201

383695202

383695203

383695204

383695205

383695206

I

I

19.6 -

(2.0

-

6.4 Ib)

8.34 -

(0.85

-

3.75 Ib)

Lenath

56.2 mm (2.21 3 in)

56.4 mm (2.220 in)

56.6 mm (2.228 in)

56.8 mm (2.236 in)

57.0 mm (2.244 in)

57.2 mm (2.252 in)

I

I

I

DI-2

I

Preload adjusting washer

I

GENERAL DESCRIPTION

Part No.

383705200

38371 5200

383725200

I

DIFFERENTIALS

Length

2.59 mm (0.1 020 in)

2.57 mm (0.1012 in)

2.55 mm (0.1 004 in)

I

. .

Pinion height adjusting shim

Side gear backlash

Side gear thrust washer

(Non-Turbo model)

Side bearina standard width

I

Side bearing retainer shim

&own gear to drive pinion backlash

Crown gear runout on its back sunface

I

1- t t

383575200

383585200

383595200

383605200

38361 5200

383625200

383635200

383645200

383655200

383665200

383675200

383685200

3.33 mm (0.1 31 1 in)

3.36 mm (0.1323 in)

3.39 mm (0.1 335 in)

3.42 mm (0.1 346 in)

3.45 mm (0.1 358 in)

3.48 mm (0.1 370 in)

3.51 mm (0.1382 in)

3.54 mm (0.1 394 in)

3.57 mm (0.1406 in)

3.60 mm (0.1 41 7 in)

3.63 mm (0.1 429 in)

3.66 mm (0.1441 in)

0.1

-

0.0079 in)

Part No.

383445201

383445202

I

0.75 -

Thickness

I

0.80 mm (0.0295

- in)

I

I

0.80

-

-

~

-

Part No.

383475201

383475202

383475203

383475204

383475205

Limit

I

I

20.00 mm (0.7874 in)

Thickness

0.20 mm (0.0079 in)

0.25 mm (0.0098 in)

0.30 mm (0.01 18 in)

0.40 mm (0.0157 in)

0.50 mm (0.01 97 in)

0.1 0

-

-

0.05 mm (0.0020 in)

I

I

DI-3

I

GENERAL DESCRIPTION

DIFFERENTIALS

B: COMPONENT

1. REAR DIFFERENTIAL WITHOUT LSD

I

(1) Pinion crown gear set (13) Side bearing

(2) Pinion height adjusting washer

(3) Rear bearing

(14) O-ring

(15) Side bearing retainer shim

(4) Bearing preload adjusting spacer (16) Side bearing retainer

(5) Bearing preload adjusting washer (17) Side oil seal

. , Differential carrier

(7) Front bearing

. , ..

(8) Spacer

(20) Pinion mate gear

(9) Pilot bearing

(21) Pinion mate gear washer

(IO)

Front oil seal

(22) Pinion shaft lock pin

(23) Circlip

(12) Self-locking nut

(24) Pinion mate shaft

DI-4

(25) Air breather cap

(26) Stud bolt

(27) Oil filler plug

(28) Oil drain plug

(29) Rear cover

\

(301 Differential case

I

Tightening torque: N-m (kgf-m, ft-lb)

T1: 10.3 (1.05, 7.6)

T2: 29.4 (3.00,21.7)

T3: 49.0 (5.0, 36.2)

T4: 103.0 (10.50, 75.9)

T5: 181.4 (18.50, 133.8)

GENERAL DESCRIPTION

2.

REAR DIFFERENTIAL WITH LSD

DIFFERENTIALS

I

(1 ) Pinion crown gear set

(2)

Pinion height adjusting shim

Rear bearing

Bearing preload adjusting spacer

Bearing preload adjusting washer

Differential carrier

Front bearing

Collar

Pilot bearing

Front oil seal

Companion flange

(12) Self-locking nut

(13) Side bearing

O-ring

Side bearing retainer shim

Side bearing retainer

Side oil seal

Gasket

Differential case

Rear cover

Air breather cap

Stud bolt

(23) Oil filler plug

(24)

Oil drain plug

Tightening torque: N.m (kgf-m, ft-lb)

T1: 10.3 (1.05, 7.6)

TZ: 29.4 (3.00,21.7)

T3: 49.0 (5.00, 36.2)

T4: 103.0 (10.50, 75.9)

T5: 181.4 (18.50, 133.8)

DI-5

I

GENERAL DESCRIPTION

DIFFERENTIALS

3.

REAR DIFFERENTIAL MOUNTING SYSTEM

I

(1)

Differential front member

(2)

Plate

(3) Crossmember

(4)