- Computers & electronics

- Computer components

- System components

- Processors

- Ransburg

- Voltage Master 2 Power Supply

- Service manual

Ransburg Voltage Master 2 Power Supply Service Manual

Add to My manuals51 Pages

Ransburg Voltage Master 2 Power Supply is a high-voltage power supply system designed for use in a variety of industrial applications. It is capable of providing up to 500 kV of power, and it features a number of advanced safety features to protect users from electrical hazards. The Voltage Master 2 is also highly efficient, and it can operate at a wide range of input voltages. It comes with overload adjustment procedures and many I/O ports for easy integration.

advertisement

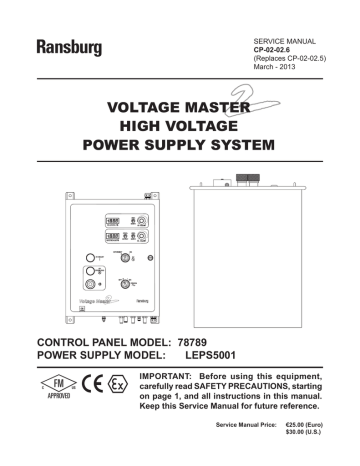

Ransburg

SERVICE MANUAL

CP-02-02.6

(Replaces CP-02-02.5)

March - 2013

VOLTAGE MASTER

HIGH VOLTAGE

POWER SUPPLY SYSTEM

CONTROL PANEL MODEL: 78789

POWER SUPPLY MODEL: LEPS5001

IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS, starting on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: €25.00 (Euro)

$30.00 (U.S.)

Ransburg

Voltage Master 2 - Contents

NOTE: This manual has been changed from revision CP-02-02.5 to revision CP-02-02.6.

Reasons for this change are noted under “Manual Change Summary” inside the back cover of this manual.

CP-02-02.6

Voltage Master 2 - Contents

Ransburg

CONTENTS

SAFETY:

PAGE

1-6

SAFETY PRECAUTIONS.........................................................................................................

HAZARDS / SAFEGUARDS.....................................................................................................

1

2-5

ATEX:

6-7

EUROPEAN ATEX DIRECTIVE...............................................................................................

EUROPEAN ATEX LABELS.....................................................................................................

6

7

INTRODUCTION:

8-11

GENERAL DESCRIPTION.......................................................................................................

SPECIFICATIONS.....................................................................................................................

ELECTRICAL NOISE................................................................................................................

CABLE CONNECTION EXAMPLES........................................................................................

8-9

9

10

11

INSTALLATION:

12-23

BLOCK DIAGRAM OF TYPICAL REA III AUTOMATIC

APPLICATOR INSTALLATION.................................................................................................

12

BLOCK DIAGRAM OF TYPICAL AEROBELL 33

INSTALLATION..........................................................................................................................

LOCATION.................................................................................................................................

SAFETY GROUND....................................................................................................................

INPUT POWER..........................................................................................................................

SYSTEM INSTALLATION..........................................................................................................

78789-XX CONTROL PANEL SCHEMATIC............................................................................

POWER SUPPLY CONNECTIONS.........................................................................................

INTERLOCK CONNECTIONS..................................................................................................

AC REMOTE I/O........................................................................................................................

DC PUMP I/O.............................................................................................................................

DC REMOTE I/O........................................................................................................................

PNEUMATIC CONNECTIONS.................................................................................................

HIGH VOLTAGE CABLE...........................................................................................................

MOTOR CONTROL BOARD CONFIGURATION....................................................................

MASTER CONTROL BOARD CONFIGURATION..................................................................

19

19

19-20

21

21-22

23

23

13

14

14

14-15

15

16

17

17-18

OPERATION:

24-32

HIGH VOLTAGE ON CONTROL SEQUENCE........................................................................

HIGH VOLTAGE OFF CONTROL SEQUENCE......................................................................

OVERLOAD SEQUENCE.........................................................................................................

MOTHER BOARD FUNCTIONS...............................................................................................

MASTER CONTROL BOARD FUNCTIONS............................................................................

FRONT PANEL BOARD FUNCTIONS.....................................................................................

MOTOR CONTROL BOARD....................................................................................................

26

26

26

24

24

24

25

(Continued On Next Page)

CP-02-02.6

Ransburg

Voltage Master 2 - Contents

CONTENTS (Cont.)

OPERATION (Cont.):

PAGE

24-32

FRONT PANEL BOARD FUNCTIONS.....................................................................................

MOTOR CONTROL BOARD....................................................................................................

FRONT PANEL BOARD............................................................................................................

FRONT PANEL CONTROLS AND INDICATORS...................................................................

LEPS5001 HIGH VOLTAGE POWER SUPPLY.......................................................................

OVERLOAD ADJUSTMENT PROCEDURES.........................................................................

26

26

27

28-29

30

31-32

MAINTENANCE:

33-38

GENERAL..................................................................................................................................

OVERLOAD PROCEDURE......................................................................................................

TROUBLESHOOTING..............................................................................................................

TROUBLESHOOTING GUIDE.................................................................................................

33-34

34

35-36

37-38

PARTS IDENTIFICATION:

39-44

CONTROL PANEL PARTS LIST - FRONT VIEW...................................................................

CONTROL PANEL PARTS LIST - INSIDE DOOR VIEW.......................................................

CONTROL PANEL PARTS LIST - INSIDE VIEW....................................................................

78789 CONTROL PANEL PARTS LIST...................................................................................

POWER SUPPLY / PARTS LIST..............................................................................................

RECOMMENDED SPARE PARTS LIST..................................................................................

39

40

41

42

43-44

44

WARRANTY POLICIES: 45

LIMITED WARRANTY...............................................................................................................45

CP-02-02.6

1

Voltage Master 2 - Safety

Ransburg

SAFETY

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and understand all of the technical and safety literature for your Ransburg products. This manual contains information that is important for you to know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention to these sections.

A WARNING! states information to alert you to a situation that might cause serious injury if instructions are not followed.

A CAUTION! states information that tells how to prevent damage to equipment or how to avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

While this manual lists standard specifications and service procedures, some minor deviations may be found between this literature and your equipment. Differences in local codes and plant requirements, material delivery requirements, etc., make such variations inevitable. Compare this manual with your system installation drawings and appropriate Ransburg equipment manuals to reconcile such differences.

Careful study and continued use of this manual will provide a better understanding of the equipment and process, resulting in more efficient operation, longer trouble-free service and faster, easier troubleshooting. If you do not have the manuals and safety literature for your Ransburg system, contact your local Ransburg representative or

Ransburg.

!

W A R N I N G

The user

MUST read and be familiar with

the Safety Section in this manual and the

Ransburg safety literature therein identified.

This manual

MUST be read and thor-

oughly understood by

ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that the

WARNINGS and safety requirements for

operating and servicing the equipment are followed. The user should be aware of and adhere to ALL local building and fire codes and ordinances as well as

NFPA-33 SAFE-

TY STANDARD, LATEST EDITION, prior

to installing, operating, and/or servicing this equipment.

!

W A R N I N G

The hazards shown on the following pages may occur during the normal use of this equipment. Please read the hazard chart beginning on page 2.

CP-02-02.6

Ransburg

Voltage Master 2 - Safety

AREA

Tells where hazards may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation and maintenance procedures will cause a fire hazard.

Protection against inadvertent arcing that is capable of causing fire or explosion is lost if any safety interlocks are disabled during operation. Frequent Power Supply or Controller shutdown indicates a problem in the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the spray area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be turned off prior to cleaning, flushing or maintenance.

When using solvents for cleaning:

•

Those used for equipment flushing should have flash points equal to or higher than those of the coating material.

•

Those used for general cleaning must have flash points above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates required by NFPA-33, OSHA, country, and local codes. In addition, ventilation must be maintained during cleaning operations using flammable or combustible solvents.

Electrostatic arcing must be prevented. Safe sparking distance must be maintained between the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage is required at all times.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as instructed.

Non-factory replacement parts or unauthorized equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use only during setup operations. Production should never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be set up and operated in accordance with NFPA-

33, NEC, OSHA, local, country, and European

Health and Safety Norms.

CP-02-02.6

2

Voltage Master 2 - Safety

Ransburg

AREA

Tells where hazards may occur.

Spray Area

HAZARD

Tells what the hazard is.

SAFEGUARDS

Tells how to avoid the hazard.

Explosion Hazard

Improper or inadequate operation and maintenance procedures will cause a fire hazard.

Electrostatic arcing must be prevented. Safe sparking distance must be maintained between the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage is required at all times.

Protection against inadvertent arcing that is capable of causing fire or explosion is lost if any safety interlocks are disabled during operation.

Unless specifically approved for use in hazardous locations, all electrical equipment must be located outside Class I or II, Division 1 or 2 hazardous areas, in accordance with NFPA-33.

Frequent Power Supply or

Controller shutdown indicates a problem in the system requiring correction.

Test only in areas free of flammable or combustible materials.

The current overload sensitivity (if equipped)

MUST be set as described in the corresponding section of the equipment manual. Protection against inadvertent arcing that is capable of causing fire or explosion is lost if the current overload sensitivity is not properly set. Frequent power supply shutdown indicates a problem in the system which requires correction.

Always turn the control panel power off prior to flushing, cleaning, or working on spray system equipment.

Before turning high voltage on, make sure no objects are within the safe sparking distance.

Ensure that the control panel is interlocked with the ventilation system and conveyor in accordance with NFPA-33, EN 50176.

Have fire extinguishing equipment readily available and tested periodically.

3

General Use and

Maintenance

Improper operation or maintenance may create a hazard.

Personnel must be properly trained in the use of this equipment.

Personnel must be given training in accordance with the requirements of NFPA-33, EN 60079-0.

Instructions and safety precautions must be read and understood prior to using this equipment.

Comply with appropriate local, state, and national codes governing ventilation, fire protection, operation maintenance, and housekeeping. Reference OSHA, NFPA-33, EN Norms and your insurance company requirements.

CP-02-02.6

Ransburg

Voltage Master 2 - Safety

AREA

Tells where hazards may occur.

HAZARD

Tells what the hazard is.

Spray Area /

High Voltage

Equipment

Electrical Discharge

There is a high voltage device that can induce an electrical charge on ungrounded objects which is capable of igniting coating materials.

Inadequate grounding will cause a spark hazard. A spark can ignite many coating materials and cause a fire or explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed and operators in the spray area must be properly grounded.

Parts being sprayed must be supported on conveyors or hangers that are properly grounded. The resistance between the part and earth ground must not exceed 1 meg ohm. (Refer to

NFPA-33.)

Operators must be grounded. Rubber soled insulating shoes should not be worn. Grounding straps on wrists or legs may be used to assure adequate ground contact.

Operators must not be wearing or carrying any ungrounded metal objects.

When using an electrostatic handgun, operators must assure contact with the handle of the applicator via conductive gloves or gloves with the palm section cut out.

NOTE: REFER TO NFPA-33 OR SPECIFIC

COUNTRY SAFETY CODES REGARDING

PROPER OPERATOR GROUNDING.

All electrically conductive objects in the spray area, with the exception of those objects required by the process to be at high voltage, must be grounded. Grounded conductive flooring must be provided in the spray area.

Always turn off the power supply prior to flushing, cleaning, or working on spray system equipment.

Unless specifically approved for use in hazardous locations, all electrical equipment must be located

outside Class I or II, Division 1 or 2 hazardous areas, in accordance with NFPA-33.

CP-02-02.6

4

5

Voltage Master 2 - Safety

Ransburg

AREA

Tells where hazards may occur.

Electrical

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

SAFEGUARDS

Tells how to avoid the hazard.

High voltage equipment is utilized in the process. Arcing in the vicinity of flammable or combustible materials may occur. Personnel are exposed to high voltage during operation and maintenance.

Protection against inadvertent arcing that may cause a fire or explosion is lost if safety circuits are disabled during operation.

Frequent power supply shutdown indicates a problem in the system which requires correction.

An electrical arc can ignite coating materials and cause a fire or explosion.

Unless specifically approved for use in hazardous locations, the power supply, control cabinet, and all other electrical equipment must be located outside Class I or II, Division 1 and 2 hazardous areas in accordance with NFPA-33 and EN

50176.

Turn the power supply OFF before working on the equipment.

Test only in areas free of flammable or combustible material.

Testing may require high voltage to be on, but only as instructed.

Production should never be done with the safety circuits disabled.

Before turning the high voltage on, make sure no objects are within the sparking distance.

Toxic Substances

Certain material may be harmful if inhaled, or if there is contact with the skin.

Follow the requirements of the Material Safety

Data Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of inhaling sprayed materials. The mask must be compatible with the material being sprayed and its concentration. Equipment must be as prescribed by an industrial hygienist or safety expert, and be NIOSH approved.

Spray Area

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon solvents for example: methylene chloride and 1,1,1,-Trichloroethane are not chemically compatible with the aluminum that might be used in many system components. The chemical reaction caused by these solvents reacting with aluminum can become violent and lead to an equipment explosion.

Aluminum is widely used in other spray application equipment - such as material pumps, regulators, triggering valves, etc. Halogenated hydrocarbon solvents must never be used with aluminum equipment during spraying, flushing, or cleaning. Read the label or data sheet for the material you intend to spray. If in doubt as to whether or not a coating or cleaning material is compatible, contact your coating supplier. Any other type of solvent may be used with aluminum equipment.

CP-02-02.6

Ransburg

Voltage Master 2 - Atex

EUROPEAN ATEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

The following instructions apply to equipment covered by certificate number Sira 08ATEX5040X:

1. The equipment may be used with flammable gases and vapors with apparatus groups II and with temperature class T6.

2. The equipment is only certified for use in ambient temperatures in the range +12.8°C to +40°C and should not be used outside this range.

8. The certification of this equipment relies upon the following materials used in its construction:

If the equipment is likely to come into contact with aggressive substances, then it is the responsibility of the user to take suitable precautions that prevent it from being adversely affected, thus ensuring that the type of protection provided by the equipment is not compromised.

3. Installation shall be carried out by suitably trained personnel in accordance with the applicable code of practice e.g. EN 60079-14:1997.

4. Inspection and maintenance of this equipment shall be carried out by suitably trained personnel in accordance with the applicable code of practice e.g. EN 60079-17.

Aggressive substances: e.g. acidic liquids or gases that may attack metals, or solvents that may affect polymeric materials.

Suitable precautions: e.g. regular checks as part of routine inspections or establishing from the material's data sheets that it is resistant to specific chemicals.

5. Repair of this equipment shall be carried out by suitable trained personnel in accordance with the applicable code of practice e.g. EN 60079-19.

6. Putting into service, use, assembling, and adjustment of the equipment shall be fitted by suitably trained personnel in accordance with the manufacturer's documentation.

Refer to the "Table of Contents" of this service manual:

a. Installation

b. Operation

c. Maintenance

d. Parts Identification

7. Components to be incorporated into or used as replacement parts of the equipment shall be fitted by suitably trained personnel in accordance with the manufacturer's documentation.

Refer to "Specifications" in the "Introduction" section:

a. All fluid passages contain stainless steel

or nylon fittings.

b. High voltage cascade is encapsulated with

a solvent resistant epoxy.

9. A recapitulation of the certification marking is detailed in the "Atex" section, on the next page, drawing numbers: 78886 and 78894-04.

10. The characteristics of the equipment shall be detailed e.g. electrical, pressure, and voltage parameters.

The manufacturer should note that, on being put into service, the equipment must be accompanied by a translation of the instructions in the language or languages of the country in which the equipment is to be used and by the instructions in the original language.

CP-02-02.6

6

7

Voltage Master 2 - Atex

Voltage Master 2 High Voltage

Power Supply System ATEX

Product Marking Definitions

Ex Certificate Number: Sira 08ATEX5040X

Sira = Notified Body performing EC-type examination

08 = Year of certification

ATEX = Reference to ATEX Directive

5 = Protection Concept Code (code 5 is titled

Encapsulation)

040 = Document serial number

X = Special conditions for safe use apply

Product Marking

II 2 G

Ex = Specific marking of explosive protection

II = Equipment Group hazardous area charac-teristics

2 = Equipment Category

G = Type of explosive atmosphere (gases, vapors, or mists)

EEx 0.24mJ = The 78789 and LEPS5001 Pow-

er Supplies are suitable for use in electrostatic spraying installations complying with EN 50050 as they are a Type A class with a discharge energy limit of 0.24mJ.

Label 78789

Label LEPS5001

Ransburg

CP-02-02.6

Ransburg

Voltage Master 2 - Introduction

INTRODUCTION

GENERAL DESCRIPTION

The

Voltage Master 2 high voltage power

supply system includes a control panel and power supply unit in combination to produce up to 100kV

DC continuous operating voltage while delivering up to 1,500 microamps load current. This heavy duty, high power system provides for rugged and reliable operation in a variety of industrial finishing applications. The Voltage Master 2 system also includes the necessary system interfaces for complete remote control and monitoring functions.

Voltage Master 2 systems can include, but are not limited to, the following:

•

Power Supply Control Panel

The control panel contains all of the necessary control circuitry, operator interface controls and remote I/O interfaces. A single cable connects the control panel to the power supply unit.

•

LEPS5001 HV Power Supply Tank

The power supply tank contains the high voltage transformer, voltage multiplier, and other components necessary to generate a high voltage output and to return actual voltage and current feedback signals to the control panel. All components of the power supply were design selected for reliable, heavy duty service. The components, including the high voltage transformer, operate immersed in high quality (non-pcb) dielectric oil for electrical insulation and to provide heat dissipation. The power supply is supplied as a separate unit in order that it can be installed as close to the applicators as possible. This minimizes the amount of high voltage cable and routing hardware, resulting in improved system safety and reliability.

•

HV Junction Tanks

High voltage junction tanks receive an input from the power supply, split the input, and provide multiple outputs. Each junction tank output can be connected to a single applicator or station of applicators. The internal components of the each junction tank are immersed in high quality

CP-02-02.6

(non-pcb) dielectric oil. Consult the appropriate junction tank service manual or your authorized

Ransburg representative for further information.

•

HV Cable

The Ransburg high voltage cable is specially formulated and constructed to offer a maximum level of dielectric protection while maintaining a small diameter and bending radius for easy routing.

•

Remote Pneumatic ON/OFF Switch Station

This is provided to serve as a simple, industrial

ON/OFF control that can be located at the system operator stations in a convenient location, including classified areas. (Contact your Ransburg representative or Ransburg customer service for details.)

•

Air Logic Stations

These standard system panels include all of the necessary controls for disk or bell system integration. (Contact your Ransburg representative or Ransburg customer service for details.)

The Voltage Master 2 system supplies a high degree of safety by continuously monitoring the output current and rapidly de-energizing high voltage in the event that the user selected maximum output current level (overload setting) is exceeded. The safety circuit is sufficient to eliminate most possible arcing conditions,

however, the overload current setting must be properly set as described in

"Overload Adjustment Procedures" in the

"Operation" section of this manual, to ensure

safe operation.

The Voltage Master 2 system, with control panel

78789-02, is listed by Factory Mutual for use with

8

9

Voltage Master 2 - Introduction

Ransburg

Aerobell 33 and REA-III automatic systems. Additional features, described later in this manual, include remote analog control of the high voltage and overload setpoints. Analog output signals are also supplied for remote monitoring of the actual high voltage and current outputs.

SPECIFICATIONS

Environmental / Physical

Operating Temperature:

0°C to 45°C

Storage Temperature: -40°C to 85°C

Humidity:

CONTROL PANEL

85% non-condensing

Size: 20" H x 16" W x 8" D

(50.8cm x 40.6cm x 20.3cm)

Weight: 76 lbs. (20.4kg)

Input Pressure: 100 psi max. (6.9 bar)

POWER SUPPLY

Size: 21" Dia. x 28" H

(.53m Dia. x .71m H)

Weight: 254 lbs. (115.2 kg)

Electrical

CONTROL PANEL

AC Input: Model 78789-02 (Standard)

105-130 Volts AC

50/60 Hz, Single Phase

Fuse Protected at 5 Amps

Model 78789-04*

210-260 Volts AC

50/60 Hz, Single Phase

Fuse Protected at 2.5 Amps

* Not Listed With Factory Mutual

AC Output:

0-120 Volts AC at 4 Amps max.

(To Power Supply)

Dry Contacts: 10A, 1/3HP, 120VAC max.

Analog

Inputs:

0-10 Volts DC or 4-20ma

(Jumper Selectable)

Analog

Outputs:

0-10 Volts DC or 4-20ma

(Jumper Selectable)

POWER SUPPLY

AC Input: 0-120 Volts AC at 4 Amps max.

(From Control Panel)

HV Output: 0 to negative 100kV DC

Current

Output: 1,500 microamps max. at 100kV

Analog

Outputs: 0-10 Volts DC

CP-02-02.6

Ransburg

Voltage Master 2 - Introduction

ELECTRICAL NOISE

Electrical noise refers to stray electrical signals in the atmosphere at various signal strengths and frequencies that can affect the operation of equipment. One of the best ways to prevent this is to shield the equipment and cables within a

continuous ground envelope, such that any

incident noise will be conducted to earth ground before it can affect the circuit conductors.

For conductors inside the control panel and power supply tank, the grounded enclosures provide this envelope. A conductive gasket has been used on the control panel door to ensure a continuous ground envelope between the door and cabinet.

For the control cable that runs from the control panel to the power supply tank, a shielded cable has been used. The shield consists of an overall foil shield in combination with an overall braided shield. This provides the most effective shielding, as the foil covers the "holes" in the braid, and the braid allows for practical 360° termination at both ends of the cable.

The AC input cord is not shielded, but instead is directed to an AC line filter as soon as it enters the cabinet. This filter filters out any noise that comes in on the AC line. For maximum noise immunity the AC line should connect to the filter as soon as it enters the cabinet with as short of leads as pos-sible. Additional noise protection is provided by running the AC input line to the control panel in grounded conduit, which is the recommended method and is required by most codes.

For maximum noise protection any user supplied input/output (I/O) wiring should be made using shielded cable or conduit which is connected to earth ground in a continuous 360° fashion at both ends. The best way to do this is to use a connector/ fitting at each end of the cable/conduit that makes contact to the grounded enclosure in this manner.

Connecting the drain wire of a shield to a ground point on or in the cabinet (usually referred to as pigtailing) is not an effective method of shielding and actually making things worse (see Figure 1).

It is recommended tha all AC I/O (interlocks, DC pump control, eternal HV ON/OFF, external alarm) be run in conduit. If desired and codes permit, cabling may be used for these signals, but for maximum noise immunity the cabling must contain overall foil and braided shields and be terminated as described in the previous paragraph.

Cable is recommended for the DC I/O (analogkV setpoint in, overload current setpoint in, analog kV out, analog current out). Again, for maximum noise immunity the cabling must contain overall foil and braided shields and be terminated in a continuous 360° manner as previously described.

Special fittings have been provided on the control panel for termination of these cables where they enter the cabinet. The use of these fittings is described under "DC Remote I/O" in the "Installation" section of this manual. Using the methods described above, the Voltage Master 2 has been successfully tested to the stringent standards of the Electromagnetic Compatibility Directive of the

European Union. The results conclude that the

Voltage Master 2 is neither a source of electrical noise nor affected by electrical noise when the previous methods are utilized.

CP-02-02.6

10

Voltage Master 2 - Introduction

Ransburg

11

Figure 1: Cable Connection Examples

CP-02-02.6

Ransburg

INSTALLATION

Voltage Master 2 - Installation

CP-02-02.6

Figure 2: Block Diagram Of A Typical Rea Iii Automatic Applicator Installation

12

Voltage Master 2 - Installation

Ransburg

13

Figure 3: Block Diagram Of A Typical Aerobell 33 Installation

CP-02-02.6

Ransburg

Voltage Master 2 - Installation

LOCATION

!

W A R N I N G

>

The 78789 control panel and the

LEPS5001 power supply MUST be located outside the hazardous area (see NFPA-33).

Power Supply Tank

Ground the power supply tank by connecting the supplied ground wire assembly from the power supply ground stud to the nearest true earth ground

(structural steel, pipes, or driven ground rod). For maximum protection from electrical noise make this connection as short as possible.

>

This manual MUST be read and thoroughly understood by ALL personnel who operate, clean, or maintain this equipment.

Special care should be taken to ensure that the WARNINGS and requirements for operating and servicing safely, are followed.

NOTE

>

To shorten the ground wire assembly, use a screwdriver to remove the lug (at end opposite clamp) from the end of the assembly, cut the wire to the length needed, strip insulation 1" from cut and reattach the lug.

Install the control panel in a convenient area outside the hazardous location, where it will be protected from the possibility of any contact with water, vapor or high humidity, and ambient temperatures in excess of 120 o

F. The area should be clean, dry, and well ventilated.

Locate the power supply tank in a convenient area as close to the applicator(s) as possible in order to minimize the amount of high voltage cable required.

INPUT POWER

!

C A U T I O N

>

Do not locate the control panel or power supply near or adjacent to heat producing equipment such as ovens, high wattage lamps, steam pipes, etc.

!

C A U T I O N

>

Ensure that the control panel and power supply tank are properly grounded to a true earth ground as described above.

SAFETY GROUND

Control Panel

Ground the control panel by mounting to structural steel that is at earth ground potential. If this is not possible, ground the control panel by connecting the supplied ground wire assembly from the control panel ground stud to the nearest true earth ground

(structural steel, pipes, or driven ground rod). For maximum protection from electrical noise make this connection as short as possible.

The AC Input power routing and connections to the control panel should be supplied from a

FUSED

DISCONNECT and should meet all applicable

National Electrical Code (NEC) guidelines and any other requirements as suitable for the location.

LOCKOUT/ TAGOUT procedures should be put in place for the fused disconnect. Using conduit, route the input power wiring through the AC power opening in the top left corner of the control panel.

For greatest noise immunity the AC input should be located as close as possible to the AC line filter

(see Figure 4). For this reason, it is recommended that the AC input

not be relocated to another

position on the control panel. Route the input wiring through the conduit and attach to terminal block TB7 as shown in Figure 4.

CP-02-02.6

14

Voltage Master 2 - Installation

Ransburg

The use of a constant voltage transformer (CVT) is recommended. This will improve high voltage regulation, especially if there are large AC line voltage fluctuations or voltage transients such as those typically produced by heavy electric machinery or welding equipment. CVT's are available from local electrical suppliers and can be used between the fused disconnect and the control panel. The CVT should be rated for 750VA or greater and be properly rated for the voltage and frequency of the source power supplied by the fused disconnect.

SYSTEM INSTALLATION

The 78789 control panel can be interfaced with

Ransburg Air Logic Stations. Air Logic Stations send and receive pneumatic signals for the purpose of remote control from hazardous locations such as inside the spray booth. Contact your local

Ransburg representative or customer support for more detailed information on the Air Logic Stations or additional control options.

Figure 4: AC Power Input Connections

15

CP-02-02.6

Ransburg

Voltage Master 2 - Installation

CP-02-02.6

Figure 5: 78789-Xx Control Panel Schematic

16

Voltage Master 2 - Installation

Ransburg

POWER SUPPLY

CONNECTIONS

Route the control cable from the power supply tank through the connector opening labeled HV

POWER SUPPLY at the top right of the control panel and connect to TB4 (see Figure 6 for TB4 location) of the Mother Board printed circuit assembly as detailed in Table 1.

It may be necessary to remove the cable grommet to fit the control cable through the opening. If so, slide the grommet hardware onto the control cable in the order shown in Figure 6 before pulling the cable through the connector housing.

Tighten the cable grommet ensuring the grommet spring makes 360° contact with the exposed braid of the control cable fro maximum noise immunity.

Route the interlock wiring through the connector opening labeled INTERLOCK I/O on the bottom of the cabinet and make the appropriate connections as described above. Since the interlock wiring will be carrying 120 volts AC it should be run in con-duit.

INTERLOCK

CONNECTIONS

Interlock terminals are provided for external fans, conveyors, etc. Section 9-3.5 of NFPA- 33 requires that automatic electrostatic equipment be interlocked with the exhaust air and conveyor. These terminals are factory jumpered for test purposes and identified by orange wire. The corresponding factory installed jumper must be removed when installing the desired interlock.

Refer to system installation drawings, the schematic in Figure 5, and the electrical system connections shown in Table 2 to determine the appropriate exhaust air and conveyor interlocks for your system.

All electrical interlocks are externally activated by dry contact closure to the interlock terminals.

The dry contacts of the external interlock device should have a contact resistance of no more than

1000 ohms and a minimum current rating of 2

Amps. The combined series contact resistance should not exceed 3000 ohms if multiple devices are used in series.

Figure 6: Inside View of Control Panel

!

C A U T I O N

>

The high voltage ON signal supplied across terminals TB2 #3 to TB2 #5 or TB6

#3 to TB6 #5 MUST be a momentary contact closure and not a maintained closure.

The overload circuit is inhibited as long as the high voltage ON signal is supplied and does not time-out until the signal is removed. Therefore, if the HV ON contacts remain closed, the power supply will

not

overload.

17

CP-02-02.6

Ransburg

Voltage Master 2 - Installation

TABLE 1 - POWER SUPPLY CONNECTIONS

Wire #

Color To Control Panel

1

17

31

34

Shield

White

Black

Black

Red

Bare

TB4-1

TB4-17

TB4-31

TB4-34

TB4-GND

TABLE 2 - ELECTRICAL SYSTEM CONNECTIONS

Description

External HV ON (PLC or Panel Switch)

External HV OFF/RESET (PLC or Panel Switch)

External System Interlocks (Exhaust Air, Conveyor, Reciprocator, etc.)

External Alarm

DC Pump Control Output kV Setpoint IN (0-10 VDC = 0-100 kV) kV Setpoint IN (4-20 ma = 0-100 kV)

Actual kV OUT (0-10 VDC = 0-100 kV)

OL Setpoint IN (0-10 VDC or 4-20 ma = 0-1500 µa)

Actual Current OUT (0-10 VDC or 4-20 ma = 0-2000 µa)

Actual kV OUT (4-20 ma = 0-100 kV)

Terminal Number

TB2-3 to TB2-5

TB2-8, TB2-8A, TB2-9, TB2-10

TB2-12, TB2-13, TB2-14

TB2-15

TB2-20

TB3-58

TB3-59

TB3-60

TB3-63

TB3-64

TB3-65

TABLE 3 - PNEUMATIC SYSTEM CONNECTIONS

Description

External HV ON

External HV OFF/RESET

External Interlock

HV ON Output (Normally used for Air Logic Station HV ON indicator)

Terminal Number

PS1

PS2

PS3

SOL1

CP-02-02.6

18

Voltage Master 2 - Installation

Ransburg

AC REMOTE I/O

DC REMOTE I/O

If required by the application, the following AC remote I/O connections can be made. The wiring for these connections should be supplied through conduit to the REMOTE I/O (AC) opening in the bottom left corner of the control panel.

High Voltage On

As shown in Table 2 and the schematic of Figure

5, an external momentary, normally open switch or PLC contact can be wired from terminals TB2-3 to TB2-5 to initiate turn on of high voltage. The switch or contact should be rated for at least 2 amps at 120 VAC.

High Voltage Off

As shown in Table 2 and the schematic of Figure

5, an external momentary, normally closed switch or PLC contact can be wired from terminals TB2-

8A to TB2-10 to initiate turn off of high voltage.

The switch or contact should be rated for at least

2 amps at 120 VAC.

External Alarm

As shown in Table 2 and the schematic of Figure

5, an external alarm horn can be wired from terminals TB2-15 to TB2-chassis. This external, user supplied alarm must be rated for 120 VAC and have an operating current of less than 0.5 amps.

DC PUMP I/O

In applications utilizing the Ransburg 9966 DC

Fluid Pump Drive Assembly, terminal TB2-20 (see

Table 2 and Figure 5) can be connected to the controller of the DC Pump. In this manner, the DC pump is activated whenever high voltage (CR2) is on. Also, by supplying air to pressure switch PS2, the high voltage can be disabled while keeping the DC pump on. This allows for checking of flow rates without high voltage. The wiring for the DC pump should be supplied through conduit to the

DC PUMP I/O opening in the bottom left corner of the control panel.

If required by the application, the following DC remote I/O connections can be made.

High Voltage Setpoint Analog Input

When the front panel kV Local/Remote switch is in the Remote position and high voltage is enabled, a 0 to 10 VDC or 4 to 20 mADC signal (see Table

4) on this input produces 0 to 100 kV output from the power supply tank.

Current Overload Setpoint Analog

Input

When the front panel OL Local/Remote switch is in the Remote position, a 0 to 10 VDC or 4 to 20 mADC signal (see Table 4) on this input produces a 0 to 1500 microamp current overload setpoint.

Actual kV Analog Output

Output signal which varies proportionately from

0 to 10 VDC or 4 to 20 mA DC (see Table 4) as power supply tank output voltage varies from 0 to 100 kVDC.

Actual Current Analog Output

Output signal which varies proportionately from

0 to 10 VDC or 4 to 20 mA DC (see Table 4) as power supply tank output current varies from 0 to

2000 microamps DC.

For maximum noise immunity, all analog I/O wiring should be run in cable having a foil shield with an overall braided shield. The foil shield provides

100% shielding, while the braid provides a means of making proper 360° shield terminations at the cable to cabinet connection points. To make analog control connections perform the following:

1. Remove the cable grommet hardware from the connector housing(s) labeled REMOTE I/O (DC) on the bottom of the control panel (see Figure

6). Two connectors are provided so 2 separate cables can be used if the connections opposite to the control panel are in different locations.

19

CP-02-02.6

Ransburg

Voltage Master 2 - Installation

2. Route the desired length of analog I/O cables(s) through the connector housing(s) and mark 1" span of cable that passes through connector housing to be stripped to braid (see Figure 7).

Figure 7: Stripping of DC I/O Cable

3. Remove cable and strip marked 1" section to cable braid.

4. Slide the cable grommet hardware onto the cable in the order shown in Figure 6.

5. Route the cable(s) back through the connector housing(s) and connect to TB3 (see Figure 6 for

TB3 location) as detailed in Table 4.

6. Tighten the cable grommet ensuring the grommet spring makes 360° contact with the exposed braid of the cable for maximum noise immunity.

7. For maximum noise immunity, connect the braid of the cable to earth ground at the end opposite to the control panel.

8. Ensure switches and jumpers are set as described in Table 4 for the correct input/output

(0-10 VDC or 4-20 mADC). The safety cover shown in Figure 6 must be removed in order to gain access to the Motor and Master Control PC boards.

!

W A R N I N G

>

Removing the safety cover allows exposure to hazardous potentials. Ensure

AC power is OFF and locked out before removing the safety cover.

TABLE 4 - ANALOG CONTROL SETTINGS

Signal

*KV Setpoint IN

(0-10 V = 0-100 kV)

KV Setpoint IN

(4-20 ma = 0-100 kV)

*OL Setpoint IN

(4-20 ma = 0-1500 µa)

OL Setpoint IN

(0-10 V = 0-1500 µa)

Actual KV OUT

(0-10 V = 0-100 kV)

Actual KV OUT

(4-20 ma = 0-100 kV)

*Actual I OUT

(4-20 ma = 0-2000 µa)

Actual I OUT

(0-10 V = 0-2000 µa)

Earth Ground

Terminal #

TB3-58

TB3-59

TB3-63

TB3-63

TB3-60

TB3-65

TB3-64

TB3-64

TB3-GND

Setting

*Motor control board SW1 in left position

(See Figure 8)

Motor control board SW1 in right position

(See Figure 8)

*Master control board JP4, 1-2

(See Figure 9)

Master control board JP4, 2-3

(See Figure 9)

No setting required

No setting required

*Master control board JP5, 1-2

(See Figure 9)

Master control board JP5, 2-3

(See Figure 9)

No setting required

* Factory default setting

CP-02-02.6

20

Voltage Master 2 - Installation

Ransburg

PNEUMATIC

CONNECTIONS

HIGH VOLTAGE CABLE

If required by the application, the following pneumatic connections can be made using 1/4" OD tube. Reference Figure 5 and Table 3.

Pneumatic High Voltage On

Assuming AC power is on and no faults are present, momentary activation of pressure switch PS1 will turn high voltage on.

Pneumatic High Voltage

Off/Reset

Momentary activation of pressure switch PS2 will turn high voltage off or reset faults. If a DC pump is used in the application, maintained activation of pressure switch PS2 will turn high voltage off while maintaining voltage to the DC pump. This is convenient for fluid flow rate checks without high voltage.

Air Interlock

Pressure switch PS3 can be used to interlock the high voltage with some other function using a pneumatic signal. This interlock is most commonly used in isolated waterborne systems where the air signal to PS3 is lost when the safety enclosure around the isolated fluid is opened, thereby disabling high voltage.

Pneumatic High Voltage On

Output

Solenoid SOL1 turns on whenever high voltage

(CR2) is on, thereby passing air from its input to its output. This output is most commonly used to connect to the high voltage indicator of Ransburg pneumatic panels to indicate when high voltage is active.

According to OSHA standard 1910.107,(h)(5), high voltage cable “shall be properly insulated and protected from mechanical injury or exposure to destructive chemicals”. It is extremely important to route the high voltage cable according to the following guidelines and to maintain the cables properly. This is due to the fact that dielectric type high voltage breakdowns of high voltage cables

CANNOT be detected in time to prevent an arc

from occurring. To facilitate compliance with this code, the following recommendations

MUST be

followed:

1.

NEVER route cables so that they lie on the

floor or are subject to vehicular traffic.

2.

NEVER route cables from different power

!

W A R N I N G

>

Sheathing is NOT a safe method of protecting a cable from wear or traffic!

supplies along parallel paths unless they are separated by at least 18 inches.

3.

ALWAYS route cable along appropriate in-

sulators.

4.

ALWAYS properly support cables at least

12 inches from metal beams. The support should be made of a material that does not conduct electricity, such as most plastics. Ransburg part number 45773-011 is one such support.

5.

ALWAYS route cables from overhead, down

to the applicator(s).

Cut the high voltage cable (SSW-1064) according to the length required and screw an EPS-4245

21

CP-02-02.6

Ransburg

Voltage Master 2 - Installation

!

C A U T I O N

>

Do NOT make the approach to the applicator at or below floor level. Route high voltage cables from overhead down to the applicator. Routing the cables up and out of the way will result in less exposure to dirt and traffic.

!

W A R N I N G

>

Whenever removing high voltage cable(s) from equipment, ground the plug end of the cable(s) by contacting the plug to electrical ground. Do not touch the plug until it has been grounded. This will eliminate the possibility of residual charge, causing electrical shock.

6. If an insulating sheathing is used around the cable, it

MUST be of a non-absorbent material,

such as polyethelyne, and should be routed to prevent contact with, or entrapment of, solvents or cleaning solutions. The cable should

NOT be

sheathed from its last point of physical support after it enters the spray area, to the applicator!

7. If a cable must be routed through a metal

(or conductive) surface, cut an opening with a minimum radius of five inches and mount a nonconductive bulkhead therein. Route the cable through the center of the bulkhead and secure it with a suitable, nonconductive strain relief. (The opening may be any configuration as long as there is at least five inches from the nearest conductor.)

8. Make cable runs as short as possible by mounting the power supply as close to the spray device(s) as codes and the physical envionment allow.

Important: For initial installation, add approxi-

mately 1/2 to 1 ounce of dielectric oil in each high voltage tube. Use only the oil as supplied with the power supply, part number 70863-00. Reference the "Maintenance" section for more details.

connector (included with the power supply or as part of the LKIT0003 Connection Kit) onto the cable end which will be inserted into the power supply.

Be careful to keep the connector centered in the middle of the cable as it is installed. Thread the cable end through the metal nut and then through the rubber bushing. Insert the cable fully into a high voltage output of the power supply and then tighten the nut until the cable is secure. Tighten the nut retaining screw with very light force (see

Figure 8).

NOTE

>

If a high voltage junction tank is used in the system, refer to the appropriate service manual for cable terminations and installation requirements.

CP-02-02.6

Figure 8: High Voltage Connections

22

Voltage Master 2 - Installation

Figure 9: Motor Control Board Configuration

Ransburg

23

Figure 10: Master Control Board Configuration

CP-02-02.6

Ransburg

Voltage Master 2 - Operation

OPERATION

Reference the control panel schematic in Figure

5, the power supply schematic in Figure 14 and any system installation drawings.

The following explanations assume that all external interlocks or jumpers are installed and that the power supply is operating normally. The following is intended for those that have a basic understanding of electrical circuits and schematics.

causing nuisance or unpredictable overloads at start-up. The LED, located on the Master Control board (see Figure 10), indicates that the inhibit condition is active.

HIGH VOLTAGE OFF

CONTROL SEQUENCE

HIGH VOLTAGE ON

CONTROL SEQUENCE

When the front panel HV ON/OFF/RESET, external pushbutton, external interlock, or external PLC

HV OFF opens the circuit to wire #10, voltage is removed from the coil of CR2. Thus, the NO CR2 contacts open and remove voltage from VAT1 to the power supply and the HV ON indicator.

When the front panel HV ON/OFF momentary switch or external HV ON signal (PLC or push-button) is supplied across terminals TB2-3 and TB2-5, voltage is supplied to the CR1 coil through the

Master Control circuit board interlock (J3-1 &

J3-4) and one set of normally closed (NC) CR3 contacts. Voltage is also supplied through a series of interlocks, pressure switch(es), and operator controls, depending on the system installation requirements, to CR2 and the HV ON lamp, any of which will turn HV OFF or not allow HV to be turned ON if broken. The voltage supplied to

CR1 energizes the coil causing NO CR1 contacts

(#11 to #12) to close, which then energizes the

CR2 coil and the HV ON indicator. Activation of

CR2 then causes one set of NO CR2 contacts to close (#11 to #12) which latches the CR2 coil ON.

Another set of NO CR2 contacts supply voltage from a set of NC CR3 contacts through the Motor

Control PCB interlock (J2-5 to J2-6) to the variable control transformer (VAT1). VAT1 then supplies

AC voltage to the Power Supply via TB4 and then through the control cable (supplied as part of the power supply).

The overload circuit is activated upon application of a momentary HV ON contact closure across wires

#3 and #5. When the contact closure opens, the inhibit timer keeps the overload circuit disabled for approximately 3-4 seconds, allowing the power supply to reach normal operating voltage without

OVERLOAD SEQUENCE

The current return from the power supply tank is compared to the overload setting within the Master

Control board circuit. If the actual output current exceeds the overload setting, then a set of the

Control board overload relay contacts open (wire

#10 to J3-25, 27) disconnecting voltage from the

CR2 coil through the latched CR2 contacts (wire

#11 to #12) to VAT1 and therefore the power supply tank. Another set of Control PCB overload contacts close (wire #10 to #15) supplying voltage to the

CR3 coil, HV OL light, Horn, and external alarm.

One set of NO CR3 contacts (wire #10 to #15) will then latch CR3 ON until a RESET command is given which removes voltage at wire #10 and therefore the CR3 coil. Another set of NC CR3 contacts open to ensure that the CR1 coil cannot be energized again with a HV ON command until a HV RESET (HV OFF) command has first been received.

CP-02-02.6

24

Voltage Master 2 - Operation

MOTHER BOARD

FUNCTIONS

The Mother PC Board simply supplies a convenient means to mount and interconnect the different control components such as the relays, Master and Motor Control PC Boards. It contains the low voltage power supply fuse (F2). The power supply generates +15VDC and -15VDC required by the Control and Front Panel PC Boards. The

+15VDC and -15VDC outputs each have an LED to indicate that they are functioning properly.

Ransburg

25

Figure 11: Motherboard PCB

CP-02-02.6

Ransburg

Voltage Master 2 - Operation

MASTER CONTROL

BOARD FUNCTIONS

MOTOR CONTROL

BOARD

A general description of the Master Control Board operation only is included in the following. The

Master Control PC Board performs the following functions:

1. Filtering and transient protection of the power supply KV and current feedback signals.

2. Properly scaled and buffered output signals to the front panel digital displays.

3. Conversion and buffering of the remote control input and output signals.

4. Supplies the HV ON overload inhibit timer so that the system can initially charge to voltage without nuisance overloads. An LED located on the board is active during the inhibit cycle.

5. Compares the overload setting with the actual high voltage output current and generates a latched overload condition that results in high voltage shutdown. A factory set potentiometer is located on the board that fine tunes the overload trip point.

This should only be adjusted by trained Ransburg personnel or with instruction from Ransburg or an

Ransburg representative.

FRONT PANEL BOARD

FUNCTIONS

(Refer to Figure 12)

The front panel Door Board contains the local operator controls, digital display interfaces, display scaling adjustments (factory set), and the overload full scale range select switch. A buffered +5VDC supply voltage is generated from

+15VDC input for the displays.

The LECU4013-00 Motor Control PC Board Assembly receives the 0-10VDC KV feedback signal from the power supply through wire #34. This signal is compared to the requested KV setpoint signal supplied from the control unit front panel or from a remote source. The resulting error signal is used to drive the bi-directional motor, that is connected to the variable transformer (VAT1) shaft, in the direction required to produce the requested high voltage.

A limit switch, located in the box that surrounds the variable transformer, rides on a cam that is attached to VAT1. The cam will activate the limit switch in the “home” position and in the “over-voltage” position. The motor control board will always rotate VAT1 counterclockwise to the “home” position when KV is turned OFF or AC power is supplied to the control panel. It is important to note that the overload inhibit timer is activated only on the HV ON command signal and not at the point where VAT1 starts from the “home” position. Therefore, if a HV ON command is given

BEFORE VAT1 has had a chance to reach “home” from a previous HV OFF or overload reset, the inhibit timer may elapse before VAT1 can reach the “home” position and return to the HV setting.

This may cause an overload to occur since the overload timer elapsed before the system has had a chance to initially charge.

The Motor Control Board will cause a power supply overload in the event of an overvoltage condition or if there is a loss of the power supply feedback signal.

Also located on the Motor Control board is a selector switch that determines if the analog output signal for actual KV is 0-10VDC or 4-20ma. Refer to "Analog Control and Monitoring Signals" in the

"Installation" section of this manual and Figure 9.

CP-02-02.6

26

Voltage Master 2 - Operation

Ransburg

27

Figure 12: Front Panel Board

CP-02-02.6

Ransburg

Voltage Master 2 - Operation

FRONT PANEL

CONTROLS AND

INDICATORS

KV ON, OFF/RESET Switch

This is a three position, spring return switch for manually turning high voltage on and off. The OFF position is also used to reset the power supply in the event of an overload alarm condition. The switch is illuminated red when high voltage is ON.

Digital Displays

The KILOVOLTS and MICROAMPS meters are both 3-½ digit, high intensity LED digital displays.

The kilovolt meter displays voltage in thousands of volts (kV) present at the power supply tank output. The microamp meter displays current in millionths of amps (µA) leaving the power supply output.

KV Adjust Knob

When the KV Local/Remote Switch is in the local position, the KV adjust knob supplies a command voltage to the Motor Control PC Board. The motor control board then regulates the high voltage output accordingly.

Power ON/OFF Switch

Supplies incoming AC power to the control panel.

The switch is illuminated green to indicate voltage is present.

Horn

The alarm horn sounds when an overload condition occurs.

Overload Indicator

This indicator glows red when an overload condition occurs.

High Voltage Ready Indicator

This indicator glows yellow when the system is in ready mode. Ready mode occurs when AC power is on, high voltage is not yet enabled and no faults are present.

KV Local/Remote Switch

When placed in the LOCAL (up position), the KV output is controlled by the KV ADJUST knob.

When placed in the REMOTE (down position), the KV output is controlled by the remote analog input supplied by an external source.

OL Adjust Knob

When the OL Local/Remote Switch is in the local position, this knob sets the current level at which the power supply will enter an overload condition.

OL Local/Remote Switch

When placed in the LOCAL (up position), the overload setpoint is controlled by the OL ADJUST knob.

When placed in the REMOTE (down position), the setpoint is controlled by the remote analog input supplied by an external source.

ACTUAL/SETPOINT Switch

This switch simply determines whether the actual

HV output current or the overload setpoint is displayed on the MICROAMPS meter.

Overload Range Select Switch

(Refer to Figure 12)

This is a small slide switch located behind the control panel door on the printed circuit board. It is identified as SW4, OVERLOAD ADJUST RANGE.

The purpose of this switch is to give the operator a greater level of adjustment sensitivity at lower current levels. The switch setting DOES NOT effect the remote analog control scaling. Placing this switch in the LOW (up) position results in a full scale OL current range of approximately

500 microamps. Placing this switch in the HIGH

(bottom) position results in a full scale OL current range of approximately 1500 microamps. When using overload setpoints of 500 microamps or less, the LOW setting allows more resulution of the µA Adjust Knob potentiometer, so that desired settings can be more easily obtained.

CP-02-02.6

28

Voltage Master 2 - Operation

Ransburg

29

Figure 13: Front Panel Controls And Indicators

CP-02-02.6

Ransburg

Voltage Master 2 - Operation

LEPS5001

HIGH VOLTAGE

POWER SUPPLY

0-120 VAC is supplied to power supply terminals, wires #1 (neutral) and #17 (hot) from the control panel through the cable supplied with the power supply. The input voltage is connected to the primary of the high voltage transformer, T1. Diode banks D1 and D2 in conjunction with capacitors

C1 and C2 form a full-wave voltage doubling circuit. Alternate halves of the AC voltage output, from the secondary of T1, charge the capacitors.

Since the capacitors are in series, the resulting high voltage output is nearly double the peak voltage from the transformer.

High voltage from the doubling circuit is connected to an output series resistor, R2, as protection against output transients. A voltage feedback signal is supplied through R1, which is connected to the control panel through wire #34. The ground return from the isolated transformer secondary, wire #31, supplies the current feedback signal.

Zener diodes, connected across the terminal blocks, serve as voltage limiting and transient suppressors in the event that the KV or current feedback wires become disconnected from the control panel. This prevents further damage to the power supply system in the case of a failure.

CP-02-02.6

Figure 14: Power Supply Schematic

30

Voltage Master 2 - Operation

Ransburg

OVERLOAD

ADJUSTMENT

PROCEDURES

!

W A R N I N G

>

Since most coating materials are flammable and the possibility of arcing may exist during this adjustment procedure, DO NOT trigger the fluid on during this procedure.

The overload adjustment is not as critical for FM listed systems such as the Aerobell 33 or REA- III atomizers since safety is built into the applicators through the use of fixed resistors and/or specially formulated semi-conductive bell cup coatings.

However, the overload circuit is still important, even if set to the least sensitive setting, in the event that a HV cable should fail or other electrical discharge should occur, or if the output current increases due to contamination of the applicators or an abnormal increase through the fluid supply lines to the applicators.

Procedure for FM Listed

Systems

For FM listed systems, it is only necessary to set the current overload to approximately 50 microamps above the highest observed operating current.

2. Position production parts in front of the applicator at the distance that will be used during production.

If more than one applicator or applicator station is connected to the power supply, then position parts in front of all applicators.

3. Place the ACTUAL/SETPOINT switch in the

SETPOINT position. Set the current overload range switch to HIGH (see following note). Turn the control panel on. Set the current overload adjustment fully clockwise to the maximum reading of approximately 1500.

Procedure for Unlisted Systems

The following presumes that all components of the system have been correctly installed and checked.

1. Fill all fluid lines with the material that will be used to coat the production parts.

NOTE

>

There are two full-scale overload current ranges available, 0-500 microamps and 0-1,500 microamps. The ranges are selected by a slide switch located on the inside of the control unit door on the printed circuit board (see Figure 12). The switch setting indicated by LOW corresponds to the 0-500 micro-amp range and HIGH corresponds to the 0-1,500 microamp range.

!

W A R N I N G

>

The current overload MUST be adjusted as described in the following. Protection against inadvertent arcing that is capable of causing a fire or explosion is lost if the current overload is not properly set. Frequent power supply overloads indicate a problem in the system that requires immediate correction.

4. Adjust the KV ADJUST knob fully counter-clockwise to the minimum setting.

5. Make sure all system interlocks to the power supply are activated. The yellow HV READY indicator should be on.

6. Turn HV on by rotating the HV ON/OFF switch to the HV ON position and release. The yellow KV

READY indicator should turn off and the HV ON/

OFF switch should be illuminated red. KV should now be displayed on the KILOVOLTS meter.

31

CP-02-02.6

Ransburg

7. Turn the KV ADJUST knob until the desired production voltage is reached.

8. Place the ACTUAL/SETPOINT switch in the

ACTUAL position. Observe the actual output current as displayed on the MICROAMP meter. This should now represent the approximate operating output current during production.

9. Turn HV off by rotating the HV ON/OFF switch to the HV OFF position.

10. If the actual output current was below approx-imately 400 microamps, move the CURRENT

OVERLOAD RANGE switch to the LOW position.

11. Put the ACTUAL/SETPOINT switch in the

SETPOINT position and adjust the OVERLOAD adjust knob to approximately 50 micro-amps above the actual current observed in step 8.

The overload setting may need to be increased if

normal production current draw varies enough to

cause overloads or in higher current applications.

Voltage Master 2 - Operation

!

W A R N I N G

>

The overload circuit is inhibited for approximately 3-4 seconds each time high voltage is turned on. This is necessary due to the larger output currents required to initially charge a system. Care should be taken to make sure that the system is properly inspected and configured before each startup.

!

C A U T I O N

>

Coating material electrical conductivity, different part-to-applicator distances, and varying part geometries will all effect the resulting output current and therefore may impact the required current overload setting to achieve maximum safety. The current overload adjustment procedure should be repeated for changes in any of the above.

If normal operating current increases and none of the above system parameters have changed, then there could be a problem.

Perform maintenance and/or troubleshooting before increasing the overload setpoint. Adjusting the overload setting is critical for systems that are NOT FM listed such as Turbodisk

TM

installations. For FM listed systems, it is still recommended to set the current overload to approximately

50 microamps above the highest observed operating current.

CP-02-02.6

32

Voltage Master 2 - Maintenance

MAINTENANCE

!

W A R N I N G

>

Electrical shock hazard. ALWAYS turn power OFF prior to cleaning or servicing any part of the system. Failure to do so could result in serious injury or death.

>

Whenever removing high voltage cable(s) from equipment, ground the plug end of the cable(s) by contacting the plug to electrical ground. Do not touch the plug until it has been grounded. This will eliminate the possibility of residual charge causing electrical shock.

>

Whenever the high voltage cable is removed from the Power Supply tank,

ALWAYS discharge any residual electrical

charge from the power supply by attaching an appropriate ground wire to the grounded power supply container and then inserting it down the free end of the high voltage output tube.

>

To ensure continuous, efficient, trouble-free operation of the Power Supply and to extend its service life, keep the exterior clean and dry. It is also very important to keep the areas around the high voltage cable connections clean to protect against static discharges.

Ransburg

GENERAL

Developing a good preventive maintenance (PM) program is key to keeping any system operating properly, the frequency of which is determined by each individual installation. Contact your Ransburg representative or the Service department for guidelines or assistance for establishing a preventative maintenance program.

There is very little maintenance for the Control

Panel or the Power Supply tank other than good housekeeping practices. These include:

1. Keeping the control panel door closed at all times. This will maintain the dust-tight environment required by the electronic printed circuit boards.

2. Plug all unused access holes into the control panel in order to keep contamination out.

3. Use the following guidelines for cleaning the

Control Panel and Power Supply tank.

• Ensure that the high voltage is OFF and turn

OFF the power source to the

Control Panel.

• Clean the exterior with a clean, dry, lint-free cloth. If necessary, isopropyl alcohol or other mild cleaning solutions can be used.

• Open the panel door and clean internally by using a stream of clean, dry factory air to remove any traces of moisture and foreign matter.

• Check interior for evidence of contamination from either moisture or foreign matter.

• Visually inspect components. Look for loose wiring connections and for visible evidence of component deterioration.

• Restore the unit to operation.

33

CP-02-02.6

Ransburg

Voltage Master 2 - Maintenance

For maintenance of system components other than the Voltage Master 2 Power Supply, refer to the appropriate manual or contact your Ransburg representative or Ransburg Customer Service.

Remove any high voltage cables and make sure that they are clean and undamaged. The oil level in the HV tubes should be high enough to cover the metal plug located on the end of each HV cable. The oil level can be seen on the cables as they are removed, much like a dipstick. Use only the dielectric oil (70863-00) as supplied with the power supply. Clean the cables and reinsert into the power supply. Make sure to tighten the high voltage cable nuts.

1. Turn ON high voltage to the applicator.

2. Adjust the KV and Current Overload setting to that normally encountered during production.

3. Slowly approach the applicator with a grounded wand and verify that an overload occurs.

!

>

Ensure that the ground wand is sufficiently grounded before performing this test. Approaching the applicator with an improperly grounded wand can result in serious injury or even death.

NOTE

>

Make sure that the high voltage cables are fully inserted into the power supply and that any strain relief connections are secure.

OVERLOAD PROCEDURE

4. Turn off high voltage to the applicator.

If an overload does not occur or significant arcing is evident before an overload occurs, reduce the overload setting as described in “Overload

Adjustment Procedures” in the "Operation" section of this manual and repeat the above test. If this does not solve the problem, the Control PC

Board Assembly may need to be replaced and/or the Control Panel or Power Supply tank serviced.

Periodically check for proper operation of the overload circuit as follows:

!

W A R N I N G

>

Since most coatings are flammable and arcing may occur during this test, do NOT trigger fluid of any kind on during this test.

Ensure that the atmosphere is free of flammable vapors before performing this test.

!

W A R N I N G

>

Electrical shock hazard. Always turn power to equipment OFF before cleaning or servicing any part of the system. Failure to do so could result in serious injury or death.

CP-02-02.6

34

Voltage Master 2 - Maintenance

Ransburg

TROUBLESHOOTING

!

W A R N I N G

>

Field repair and troubleshooting of the Voltage Master 2 system may require exposure to potentials that can cause

SERIOUS BODILY INJURY or DEATH if proper procedures are not followed. For this reason, troubleshooting and field repair should only be accomplished with specific test equipment by qualified electronics technicians or authorized Ransburg representatives.

>

All safety precautions listed in the

"Safety" section of this manual must be followed.

>

Field repair of the Power Supply tank is

NOT to be performed unless by specifically trained and qualified Ransburg personnel with access to instrumentation that is certified traceable to NIST standards. Removal of the lead seal located on the power supply tank voids warranty unless the above is followed.

!

>

DO NOT attempt to remove or insert printed circuit board assemblies when power is supplied to the control panel.

Contacting your Ransburg Representative or Ransburg Customer

Service

Before contacting your Ransburg repre-sentative or the customer service department, be prepared with the following specific information that will help resolve problems quicker.

• Control panel model and serial numbers.

• The basic system configuration including typeof applicators, coating used, etc.

• The type of problem that is occurring and the frequency that it occurs if applicable.

• Anything in the system that has changed when the problem started.

• Any troubleshooting that has already been attempted.

Basic System Troubleshooting

When tracing problems, refer to the control panel schematic in Figure 5, the Troubleshooting Guide in this section, the “Operation” section, and the

“Parts Identification” section of this manual. The following section outlines the most common problems encountered and gives suggestions that may shorten the time involved in troubleshooting the system. More detailed information is offered in the troubleshooting guide.

Most Common Problems

Most problems encountered with the high voltage supply do not involve faulty equipment but are attributed to one of the following:

1. Coating/paint buildup or residue on system

components

2. Fluid supply or dump lines

3. Improper part grounding

4. High voltage cable failure

5. Improper power supply overload setting or

system interface problems

If a high voltage output problem is suspected such as low output voltage, no voltage, or repeated overloads, perform the following basic trouble-shooting procedure.

Equipment Required: Ransburg High Voltage

Test Probe and Meter (76652-01) and an AC

RMS Voltmeter.

A high voltage problem may be associated with any one of the components that make up the entire electrostatic system. First, try to isolate generally where in the system that the problem lies.

35

CP-02-02.6

Ransburg

1. With voltage turned OFF, disconnect the high voltage output cable(s) from the power supply tank. Inspect the high voltage cable end for contamination or any unusual signs of wear such as pitting or discoloration. Clean or replace as necessary.

2. Turn high voltage ON while the high voltage cables are still disconnected. If there is still a problem with high voltage or overloads then refer to the troubleshooting guide, otherwise, if the power supply now seems to be operating properly, continue to the next step.