advertisement

Smart

GLCD

240 x

128

TO OUR VALUED CUSTOMERS

I want to express my thanks to you for being interested in our products and for having confidence in MikroElektronika.

The primary aim of our company is to design and produce high quality electronic products and to constantly improve the performance thereof in order to better suit your needs.

Nebojsa Matic

General Manager

The PIC

®

, dsPIC

®

, PIC24

®

, PIC32

®

and Windows

®

logos and product names are trademarks of Microchip Technology

®

and Microsoft

®

in the U.S.A. and other countries.

Page 2

What is the SmartGLCD 240x128?

Package Contains

1. Key Features

System Specification

2. Power supply

3. PIC18F87K22 microcontroller

Key microcontroller features

4. Programming the microcontroller

5. Programming with bootloader mikroBootloader software

Identifying device COM port step 1 – Choosing COM port step 2 - Establishing Connection step 3 - Browsing for .HEX file step 4 – Selecting .hex file

Table of Contents

13

14

14

15

11

12

12

13

10

10

7

8

4

5

6 step 5 – Uploading .hex file step 6 – Progress bar step 7 - Finishing upload

Tips and Tricks: Speed-up UART data transfer 17

6. Programming with mikroProg

™

programmer 18

7. mikroProg Suite

™

for PIC

®

Software

8. microSD Card Slot

20

22

15

16

16

9. Touch Screen

10. RGB backlight

11. Contrast potentiometer

12. USB UART

13. Buzzer

14. Pinout

15. Dimensions

What’s next?

30

32

33

34

24

26

27

28

Page 3

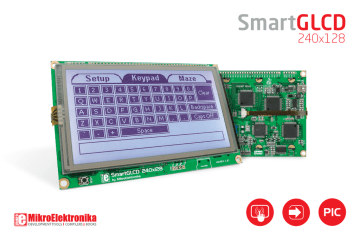

What is the SmartGLCD 240x128?

The SmartGLCD 240x128 is a compact smart display, with many on-board peripherals. It’s designed to become a control interface of your device. Main part of the board is a large 240x128 pixel graphical LCD with a 4-wire resistive touch screen. It features RGB backlight, which can greatly improve user experience, but can also be used as a signaling feature. The heart of the board is PIC18F87K22, an 8-bit microcontroller delivering 12MIPS of processing power. Other modules like USB UART, piezo buzzer, microSD slot and connection pads can be found on board as well. The board is preprogrammed with

UART bootloader. We have also provided a nice example which will give you a great out-of-thebox experience.

Page 4

Page 4

Package Contains

01

Damage resistant protective box

Smart GLCD

240x128

04

SmartGLCD 240x128 user’s guide

19122011 www.mikroe.com

Copyright ©2011 Mikroelektronika.

All rights reserved. Mikroelektronika, Mikroelektronika logo and other

Mikroelektronika trademarks are the property of Mikroelektronika.

All other tradmarks are the property of their respective owners.

Unauthorised copying, hiring, renting, public performance and broadcasting of this DVD prohibited.

03

DVD with documentation and examples

02

SmartGLCD 240x128 development board

SCHEMATICS

/ SPI I2C / SPI

AN2 AN3

INT

Digital

I/O

SDO2 SDI2

PWM Analog I/O

RA2 RA3 RA4 RA5 RB0 RB1 RB2 RB3 RB4 RC3 RC4 RC5 RD0 RD1 RD2 RD3 RD4 RD5 RD6 RD7 RE0 RE1 RE2 RE3 RE4 RE5 RE6 RE7 NC RF1 RF2 RF3 RF4 RF5 RF6 RF7

Smart

GLCD

240x128

We present you with a complete color schematics for SmartGLCD 240x128 development board. We want you to know what your board is consisted of and how it actually works.

3.3V power supply output

Ground

5V power supply

Ground

05

SmartGLCD 240x128 schematic and pinout

Page 5

06

USB cable

1. Key Features

01 GLCD 240x128 display

02

RESET button

03 Power supply pads

04 I/O pads

05

Pads for mikroProg programmer

06

USB connector

07

Touch panel connector

08

PIC18F87K22 microcontroler

09

Contrast potentiometer

10 microSD card slot

11

USB UART module

12

Buzzer

01

02

Page 6

03

12

10 09

04

07

08

Page 7

11

05 06

System Specification

power supply

Via USB cable (5V DC)

power consumption

~350mA in idle state

(backlight is ON)

board dimensions

140x90cm (5.51x3.24’’)

weight

~210g (0.46 lbs)

2. Power supply

The SmartGLCD board can be powered in two different ways: via USB connector (CN1) using MINI-B USB cable provided with the board

(Figure 2-1), or via side headers (CN2 or CN4) using external 5V power supply (Figure 2-2 and Figure 2-3).

Figure 2-1: connecting USB power supply through CN1 connector

Figure 2-2: connecting external 5V power supply through CN2 connector

Figure 2-3: connecting external 5V power supply through CN4 connector

When the board is powered up the GLCD display will be automatically turned on. The USB connection can provide up to 500mA of current which is more than enough for the operation of all on-board modules and the microcontroller as well.

Page 8

VCC

VCC-3.3

CN4

VCC-MMC

FB1

E2

10uF

FERRITE

BEAD

VCC-3.3

E1

10uF

VCC

VOUT

C11

REG1

3

VIN

2

1

MC33269DT-3.3

100nF

VCC

C10

100nF

CN1

USB MINI-B

VCC

E3

47uF

CN2

Figure 2-4: Power supply schematic

Page 9

3. PIC18F87K22 microcontroller

The SmartGLCD development tool comes with the

PIC18F87K22

microcontroller. This 8-bit microcontroller is rich with on-chip peripherals and features 128KB of Flash and 4KB of RAM. It can easily handle demanding graphical applications.

Key microcontroller features

- Up to

12 MIPS

Operation;

- 8-bit architecture;

- 128KB of Flash memory;

- 3,862 bytes of RAM;

- 1024 bytes of EEPROM;

- 80 pin TQFP;

- 24 ch, 12-bit ADC;

- UART, SPI, I 2 C; etc.

16 MIPS 8-bit Co

- nanoWatt

- Up to 64MHz re

31 Level

Stack

Program

Counter

Instruction

Data

PIC18F

Data/Memory Bus

Address

Decoder

Data

Address

Flash

(Up to 128KB)

RAM

(Up to 3.9KB)

Data Bus

SPI

I2C

I/O

Timers Comparators ADC

12-Bit USART

CCP MSSP

Page 10

4. Programming the microcontroller

Figure 4-1:

PIC18F87K22 microcontroller

The microcontroller can be programmed in two ways:

01

02

Using USB UART mikroBootloader

Using external mikroProg

™

for PIC, dsPIC, PIC32 programmer

Page 11

5. Programming with bootloader

Microcontroller is preprogrammed with USB UART Bootloader, which can be used to upload new device firmware. To transfer firmware .HEX file from a PC to MCU you need to use mikro-

Bootloader USB UART application, which can be downloaded from:

mikroBootloader software

note

Before starting mikroBootloader software, connect SmartGLCD to a PC using a USB cable provided with the package.

http://www.mikroe.com/smartglcd/

Upon download, unzip it to desired location and start the mikroBootloader application:

Page 12

Figure 5-1: mikroBootloader window

01

When you start mikroBootloader software a window should appear, as shown in the image above.

Identifying device COM port step 1 – Choosing COM port

01

02

03

Figure 5-2: Identifying COM port Figure 5-3: Choosing COM port

01

Open

Device Manager

window and expand

Ports

(COM & LPT)

section to check which COM port is assigned to SmartGLCD board (in this case it is COM18).

Page 13

01

02

03

Click the

Change Settings

button.

From the drop down list, select appropriate

Port

(in this case it is COM18) and

Baud rate

(115200).

Click

OK

.

step 2 - Establishing Connection step 3 - Browsing for .HEX file

01

01

Figure 5-4: Connecting with mikroBootloader

01

Press

the

Reset

button on SmartGLCD board and

click

Connect

within 5s, otherwise the existing microcontroller program will run. If connected, the button’s caption will be changed to

Disconnect

.

Page 14

Figure 5-5: Browse for HEX

01

Click the

Browse for HEX

button and from a pop-up window (Figure 5-6) choose a .HEX file to be uploaded in MCU memory.

step 4 – Selecting .hex file step 5 – Uploading .hex file

01

01

02

Figure 5-6: Locating and selecting .hex file

01

Select .HEX file from the

Open dialog

window.

02 Click the

Open

button.

Page 15

Figure 5-7: Begin uploading

01

In order to upload .HEX file click the

Begin uploading

button.

step 6 – Progress bar step 7 - Finishing upload

01

01

Figure 5-8: Progress bar

01

Progress bar enables you to monitor .HEX file uploading.

Page 16

Figure 5-9: Restarting MCU

01

Click

OK

button after the uploading process has been finished.

02

Press

Reset

button on SmartGLCD board and wait for 5 seconds. Your program will run automatically.

Tips and Tricks: Speed-up UART data transfer

02

03

01

04 note

If .HEX file transfer from your PC to

MCU is too slow, it’s possible to speed up data transfer by setting latency time of COM port to 1 ms. This is done in Device Manager:

01

02

03

04

Right click on the

USB Serial Port (COM18)

item and then select

Properties

.

Select

Port Settings

tab.

Click the

Advanced...

button.

Set

Latency Timer

to

1

and click

OK

.

Page 17

6. Programming with mikroProg

™

programmer

The microcontroller can be programmed with the external

mikroProg

™

programmer which can be connected to the board via CN3 connector. Before establishing this connection it is necessary to solder 1x5 male header to CN3 connection pads. This can be done in both ways: on the bottom, or the top side, as shown in Figures 6-1 and 6-2.

Figure 6-1:

The mikroProg can be attached on the back side of the board. Just solder 1x5 header to back side pads (CN3) before connecting it.

Figure 6-2:

The mikroProg can be also attached on the front side of the board. In this case, solder

1x5 header to front side pads (CN3).

note

If bootloader program is accidently erased you can upload it again through mikroProg programmer.

Program Bootloader18F87K22.hex

can be found under Firmware folder (page 12).

Page 18

CN3

VCC

PGC

PGD mRST#

R22

1K

D1

BAT43

VCC mRST#

VCC

RH2

RH3

RE1

RE0

RG0

RG1

RG2

RG3

RF3

RF2

RH7

RH6

RH0 RE2 RE3 RE4 RE5 RE6 RE7 RD0 VCC GND RD1 RD2 RD3 RD4 RD5 RD6 RD7 RJ

MCLR

RG4

GND

VDDcore/Vcap

RF7

RF6

RF5

RF4

PIC18F87K22

RB6

GND

OSC2

OSC1

VCC

RB7

RC5

RC4

RJ2

RJ3

RB0

RB1

RB2

RB3

RB4

RB5

RC3

RC2

RJ7

RJ6

RH5 RH4 RF ENVREG AVCC AGND RA3 RA2 RA1 RA0 GND VCC RA5 RA4 RC1 RC0 RC6 RC7 RJ

C5

100nF

PGC

VCC

PGD

Figure 6-3: mikroProg

™

connection schematic note

Make sure to use only the front row of mikroProg’s IDC10 connector (side with a knob and incision) when connecting it to 1x5 header on your SmartGLCD board.

Page 19

7. mikroProg Suite

™

for PIC

®

Software

The

mikroProg

™

programmer requires special programming software called

mikroProg Suite

™

for PIC

®

. It can be used for programming all Microchip

®

microcontroller families, including PIC10

®

,

PIC12

®

, PIC16

®

, PIC18

®

, dsPIC30/33

®

,

PIC24

®

and PIC32

®

. The software has intuitive interface and SingleClick

™ programming technology. Just download the latest version of

mikroProg

Suite

™

and your programmer is ready to program new devices.

mikroProg

Suite

™

is updated regularly, at least four times a year, so your programmer will be more and more powerful with each new release.

Figure 7-1: Main window of mikroProg Suite

™

for PIC

®

programming software

Software Installation Wizard

01

Start Installation

02

Accept EULA and continue

03

Install for all users

04

Choose destination folder

05

Installation in progress

Page 21

06

Finish installation

8. microSD Card Slot

Figure 8-1: microSD card slot

There is a built-in microSD card slot provided on-board. It enables the expansion of available memory space using microSD cards. Communication between the microcontroller and the card is done through Serial Peripheral Interface (

SPI

).

Page 22

C5

100nF

RH0 RE2 RE3 RE4 RE5 RE6 RE7 RD0 VCC GND RD1 RD2 RD3 RD4 RD5 RD6 RD7 RJ

RH2

RH3

RE1

RE0

RG0

RG1

RG2

RG3

MCLR

RG4

GND

VDDcore/Vcap

RF7

RF6

RF5

RF4

RF3

RF2

RH7

RH6

PIC18F87K22

RB6

GND

OSC2

OSC1

VCC

RB7

RC5

RC4

RJ2

RJ3

RB0

RB1

RB2

RB3

RB4

RB5

RC3

RC2

RJ7

RJ6

RH5 RH4 RF ENVREG AVCC AGND RA3 RA2 RA1 RA0 GND VCC RA5 RA4 RC1 RC0 RC6 RC7 RJ

MMC-CD#

VCC

RC5-MOSI

RC4-MISO

RC3-SCK

R27

2K2

R30

3K3

VCC-MMC

R28

2K2

R31

3K3

FB1

E2

10uF

FERRITE

BEAD

R29

2K2

R32

3K3

C 12

VCC-MMC

100nF

CD

CMD

VCC

CLK

GND

DAT0

CN5 microSD CARD

VCC-3.3

E1

10uF

VCC

C11

100nF

REG1

VOUT

3

2

1

MC33269DT-3.3

VIN

R33

1K

C10

100nF

VCC

E3

47uF

Figure 8-2: microSD Card Slot module connection schematic

Page 23

9. Touch Screen

Page 24

The development system features a

Graphical LCD in 240x128 pixel resolution.

Display is covered with a

4-wire resistive

touch panel. Together they form a functional unit called a touch screen, Figure 9-1. It enables data to be entered and displayed at the same time.

Figure 9-1:

Touch Screen

CN6

VCC

Q8

BC556

RIGHT

VCC

Q6

BC556

R 26

10K

R 21

1K

Q 5

BC546

R 13

10K

R 15

10K

VCC

TOP

LEFT

C6

100nF

BOTTOM

R 17

100 K

R 7

10K

Q4

BC546

R 14

10K

Q 7

BC546

R 20

100 K

R 19

10K

C9

100nF

R 18

10K

VCC

TOUCH PANEL

CONTROLLER

VCC

R34

GLCD-FS

10K

DRIVEA

GLCD-D2

GLCD-D3

DRIVEA

DRIVEB

DRIVEB

GLCD-D7

GLCD-D6

C5

100nF

RH2

RH3

RE1

RE0

RG0

RG1

RG2

RG3

RF3

RF2

RH7

RH6

RH0 RE2 RE3 RE4 RE5 RE6 RE7 RD0 VCC GND RD1 RD2 RD3 RD4 RD5 RD6 RD7 RJ

MCLR

RG4

GND

VDDcore/Vcap

RF7

RF6

RF5

RF4

PIC18F87K22

RB6

GND

OSC2

OSC1

VCC

RB7

RC5

RC4

RJ2

RJ3

RB0

RB1

RB2

RB3

RB4

RB5

RC3

RC2

RJ7

RJ6

RH5 RH4 RF ENVREG AVCC AGND RA3 RA2 RA1 RA0 GND VCC RA5 RA4 RC1 RC0 RC6 RC7 RJ

GLCD-WR#

GLCD-CE#

VCC

GLCD-FS VO

VEE

R23

GLCD-MD

10K

VR

10K

CONTRAST

RA6963

GLCD

CONTROLLER

Figure 9-2: Touch Screen connection schematic

Page 25

10. RGB backlight

Graphical LCDs are only capable of showing monochromatic pixel but not color content. The color of the pixel is determined by the color of the backlight which illuminates the display. SmartGLCD has

the

RGB color backlight

a very useful feature which can give your graphical user interfaces an astonishing look.

Display’s backlight module consists of three LEDs: red, green and blue, which can shine simoutaneously.

LED can be driven by PWM signals coming from three separate microcontroller pins. Duty ratio of the PWM signal determines the intensity of color (or brightness) of each LED. Combined together they can create more than 16 milion different backlight colors.

Page 26

Figure 10-1:

The same graphics with different backlight colors

11. Contrast potentiometer

On the backside of the board there is a small potentiometer which can be used to change contrast of the GLCD. The brighter the backlight, the less contrast you will need to properly display the graphical content.

Figure 11-1:

Constrast potentiometer

Page 27

12. USB UART

Figure 12-1:

Connecting USB cable to SmartGLCD board

19122011 www.mikroe.com

Fast on-board

FTDI

®

chip

allows you to communicate with a PC or other UART devices using USB UART connection. Before connecting the board to a PC, make sure that you have the appropriate

FTDI drivers

installed on your operating system. Drivers can be found on the Product DVD:

DVD://download/eng/software/development-tools/universal/ftdi/vcp_drivers.zip

Ava

All other tradmarks are the property of their respective owners.

Unauthorised copying, hiring, renting, public performance ilable

Copyright ©2011 Mikroelektronika.

All rights reserved. Mikroelektronika, Mikroelektronika logo and other

Mikroelektronika trademarks are the property of Mikroelektronika. and broadcasting of this DVD prohibited.

on Produc t D

VD

!

USB-B connector (

CN1

) is used for connecting the USB cable, which is delivered with the board package. Plug it in as shown in Figure 12-1.

Page 28

C5

100nF

RH2

RH3

RE1

RE0

RG0

RG1

RG2

RG3

RF3

RF2

RH7

RH6

RH0 RE2 RE3 RE4 RE5 RE6 RE7 RD0 VCC GND RD1 RD2 RD3 RD4 RD5 RD6 RD7 RJ

MCLR

RG4

GND

VDDcore/Vcap

RF7

RF6

RF5

RF4

PIC18F87K22

RB6

GND

OSC2

OSC1

VCC

RB7

RC5

RC4

RJ2

RJ3

RB0

RB1

RB2

RB3

RB4

RB5

RC3

RC2

RJ7

RJ6

RH5 RH4 RF ENVREG AVCC AGND RA3 RA2 RA1 RA0 GND VCC RA5 RA4 RC1 RC0 RC6 RC7 RJ

VC C

VCC-3.3

U12

UART-TX

TXD

UART-RX

DTR#

RTS#

VCCIO

RXD

RI#

GND

NC

DSR#

DCD#

CTS#

CBUS4

CBUS2

CBUS3

FT232RL

CBUS1

GND

VCC

RESET#

GND

3V3OUT

USBDM

USBDP

OSCO

OSCI

TEST

AGND

NC

CBUS0

C17

100nF

VCC

R9

4K7

R10

10K

VCC

C15

100nF

VCC

C16

100nF

VCC

E4

10uF

CN1

VCC

USBDP

USBDM

USB

MINI-B

Figure 12-2: USB UART module connection schematic

Page 29

13. Buzzer

Figure 13-1:

Buzzer module

The board is also equipped with piezo buzzer. It is an electric component which can be used to create sound when provided with electrical signal. This is usually a PWM signal coming from a microcontroller pin. Before entering the buzzer itself, the signal is amplified by the on-board buzzer driver circuit. Frequency of the signal determines the pitch of the sound and duty cycle of the signal can be used to increase or decrease the volume.

Page 30

C5

100nF

RH2

RH3

RE1

RE0

RG0

RG1

RG2

RG3

RF3

RF2

RH7

RH6

RH0 RE2 RE3 RE4 RE5 RE6 RE7 RD0 VCC GND RD1 RD2 RD3 RD4 RD5 RD6 RD7 RJ

MCLR

RG4

GND

VDDcore/Vcap

RF7

RF6

RF5

RF4

PIC18F87K22

RB6

GND

OSC2

OSC1

VCC

RB7

RC5

RC4

RJ2

RJ3

RB0

RB1

RB2

RB3

RB4

RB5

RC3

RC2

RJ7

RJ6

RH5 RH4 RF ENVREG AVCC AGND RA3 RA2 RA1 RA0 GND VCC RA5 RA4 RC1 RC0 RC6 RC7 RJ

VCC

R37

1K

R36

R35

1K

10K

VCC

BZ1

Q9

BC546

Figure 13-2: Buzzer module schematic

Page 31

14. Pinout

INT

AN2 AN3

RA2 RA3 RA4 RA5 RB0 RB1 RB2 RB3 RB4 RC

I2C / SPI I2C / SPI

Digital

I/O

SDO2 SDI2

PWM Analog I/O

RD0 RD1 RD2 RD3 RD4 RD5 RD6 RD7 RE0 RE1 RE2 RE3 RE4 RE5 RE6 RE7 NC RF1 RF2 RF3 RF4 RF5 RF6 RF7 mikroProg

3.3V power supply output

Ground

5V power supply

Ground

Page 32

Analog Lines

Interrupt Lines

SPI Lines

I2C Lines

UART lines

15. Dimensions

16.3

642

11,6

457

12,7

500

140

5512

114

4488

107.5

4232

12,7

4000

11,56

455

Legend

Pad hole size

ø

1.14 mm

ø

45 mils

Mounting hole size

ø

4 mm

ø

157 mils

Tolerance +/- 0.5mm

1.6

63

13.12

516

4.8

190

Page 33

128

5040 active surface display margin display

12.57

500

30

1181

2 (79)

7

276

What’s next?

Your journey through each and every feature of SmartGLCD board ends here. You got to know it’s modules and organization. Now you are ready to use it. We are suggesting several steps which are probably the best way to begin with. We invite you to join the users of SmartGLCD brand.

You will find very useful projects and tutorials and can get help from a large ecosystem of users. Welcome!

Compiler

You still don’t have an appropriate compiler? Locate PIC

®

compiler that suits you best on the

Product DVD provided with the package:

DVD://download/eng/software/compilers/

Choose between mikroC

™

, mikroBasic

™

and mikroPascal

™

and download fully functional demo version, so you can begin building your first applications.

Projects

Once you have chosen your compiler, and since you already got the board, you are ready to start writing your first projects.

Visual GLCD software

for rapid development of graphical user interfaces enables you to quickly create your GUI. It will automatically create necessary code which is compatible with mikroElektronika compilers. Visual GLCD is rich with examples, which are an excellent starting point for your future projects. Just load the example, read well commented code, and see how it works on hardware. Visual GLCD is also available on the Product DVD.

Page 34

DISCLAIMER

All the products owned by MikroElektronika are protected by copyright law and international copyright treaty. Therefore, this manual is to be treated as any other copyright material. No part of this manual, including product and software described herein, may be reproduced, stored in a retrieval system, translated or transmitted in any form or by any means, without the prior written permission of MikroElektronika. The manual PDF edition can be printed for private or local use, but not for distribution. Any modification of this manual is prohibited.

MikroElektronika provides this manual ‘as is’ without warranty of any kind, either expressed or implied, including, but not limited to, the implied warranties or conditions of merchantability or fitness for a particular purpose.

MikroElektronika shall assume no responsibility or liability for any errors, omissions and inaccuracies that may appear in this manual. In no event shall

MikroElektronika, its directors, officers, employees or distributors be liable for any indirect, specific, incidental or consequential damages (including damages for loss of business profits and business information, business interruption or any other pecuniary loss) arising out of the use of this manual or product, even if

MikroElektronika has been advised of the possibility of such damages. MikroElektronika reserves the right to change information contained in this manual at any time without prior notice, if necessary.

HIGH RISK ACTIVITIES

The products of MikroElektronika are not fault – tolerant nor designed, manufactured or intended for use or resale as on – line control equipment in hazardous environments requiring fail – safe performance, such as in the operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, direct life support machines or weapons systems in which the failure of Software could lead directly to death, personal injury or severe physical or environmental damage (‘High Risk Activities’). MikroElektronika and its suppliers specifically disclaim any expressed or implied warranty of fitness for High

Risk Activities.

TRADEMARKS

The MikroElektronika name and logo, the MikroElektronika logo, mikroC

™

, mikroBasic

™

, mikroPascal

™

, mikroProg

™

, mikroBUS

™

, Click Boards

™

, EasyPIC and mikromedia

™ are trademarks of MikroElektronika. All other trademarks mentioned herein are property of their respective companies.

All other product and corporate names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies, and are only used for identification or explanation and to the owners’ benefit, with no intent to infringe.

Copyright © MikroElektronika, 2013, All Rights Reserved.

Page 35

If you want to learn more about our products, please visit our website at www.mikroe.com

If you are experiencing some problems with any of our products or just need additional information, please place your ticket at www.mikroe.com/esupport

If you have any questions, comments or business proposals, do not hesitate to contact us at [email protected]

SmartGLCD 240x128 Manual

ver. 1.51

0 100000 024430

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement