- No category

advertisement

The Dangerous Monitor Manual

Thank you for choosing products from the exciting line of Dangerous recording equipment. Many years of dependable and trouble free service can be expected from our gear. This has been made possible by careful design, construction, and top shelf component choices by recording industry veterans. We are committed to providing equipment that brings you the highest quality for your purchase.

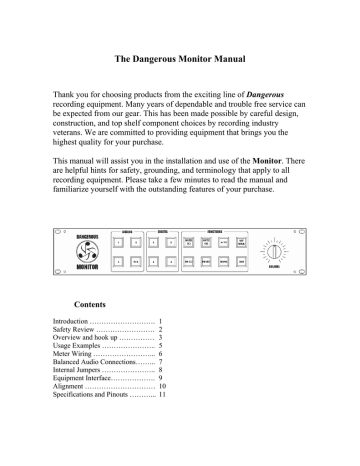

This manual will assist you in the installation and use of the Monitor. There are helpful hints for safety, grounding, and terminology that apply to all recording equipment. Please take a few minutes to read the manual and familiarize yourself with the outstanding features of your purchase.

Contents

Introduction ………………………. 1

Safety Review ……………………. 2

Overview and hook up …………… 3

Usage Examples ………………….. 5

Meter Wiring ……………………... 6

Balanced Audio Connections……... 7

Internal Jumpers ………………….. 8

Equipment Interface………………. 9

Alignment ………………………… 10

Specifications and Pinouts ………... 11

Safety Review

Certain precautions should be taken when using electrical products. Please observe the safety hints by reading the manual and obtaining qualified help if necessary to adhere to the precautions. The power

supply must be switched to the proper mains voltage. Please check the red window on the power supply’s IEC mains input module to verify the correct setting for your location before connecting the mains plug.

1. Always use a properly grounded power supply cord with this product. Please do not defeat the ground pin on the mains plug. This connection provides earth to the chassis and signal grounds inside the device for clean and quiet operation. The “Grounding and interface” section can help the user/installer clear up a buzz problem if one develops.

2. Avoid high temperature operation in equipment racks by providing air

circulation

. The number one killer of electronic gear is HEAT. Vented rack panels may look like wasted space to an interior decorator, but they look like beauty to a technician or equipment designer! If the front panel is hot, it is roasting inside the box.

3. Avoid areas of high magnetic fields. The steel chassis of Monitor is designed to shield the circuits from EMI and RFI (magnetic and radio interference). When installing equipment in racks, it is prudent to put power amplifiers and large power supplies at least several rack spaces, if not in a different rack, away from equipment that deals with low level signals.

Separation of high level and low level equipment can pre-empt trouble caused by heat and EMI.

4. Care should be taken to avoid liquid spills around equipment. If a spill occurs, please shut off the gear and disconnect the mains. A qualified technician should investigate accidents to prevent further equipment damage or personnel hazards caused by spills.

5. If one is uncomfortable with opening gear and changing jumpers or making

adjustments, please seek qualified help if necessary.

6. If adjustments or jumper changes are required, please disconnect the mains plug

before opening the top

. Dropped screws or tools on a live circuit board can manifest themselves as burn marks and smoked components. While we feel your pain, (been there) subsequent damage is not covered by the warranty.

Dangerous Music Incorporated reserves the right to change the specifications or modify the designs of its equipment.

Sending in the registration card is our way of keeping in touch with users of our equipment should this become necessary. Registration information is always kept confidential and never disclosed to third parties for any reason. Company contact information is on the last page of this manual.

The CE sign on this product signifies the fact that the Monitor has been tested and verified to conform to the applicable standards of 89/336/EEC. EN55103-1

(emissions) EN61000-2 (immunity) and EN60065:2002 (safety requirements)

-2-

Overview

The Monitor is designed to be the cornerstone of a recording studio by providing a convenient method for listening to and metering the different stages of the recording process. Careful attention to detail has resulted in a unit of stunning ergonomic clarity and unprecedented performance in a compact enclosure. The user will discover that the ability to select between different analog and digital sources as implemented in Monitor allows accurate assessment of program material without quality differences in the signal paths clouding the user’s judgment.

The built in digital to analog converter provides a solid basis for comparing digital sources directly without being subjected to the inevitable differences in calibration and sound quality between the converters in separate pieces of gear. Many times, the engineer can be fooled by differences in sound quality of “clones” (DAT from a CD) because the different brands of equipment don’t sound the same even though the data on the carriers is the same. The topology of Monitor lets the engineer concentrate on the music and not the process.

Hooking up your Dangerous Monitor

The connectors on the back of Monitor are arranged into 5 groups. The first is the AES IN and THRU connectors. The user is to plug AES signals into the female XLR connectors. Up to four devices are selectable for routing to the built in D/A converter and digital meter feed. The XLR male connector provide an uninterrupted through.

The second connector group is the “meter feeds” group. These jacks allow the selected analog and digital sources to be sent to meters and/or phase scopes to allow visual aid to the monitoring process. A breakout cable is provided for the A-MTR feed.

-3-

The pinout of this connector is in the “Specifications” section of this booklet and there is a circuit example for those who wish to set up a pair of VU meters in the “Metering Circuits” section. The D-MTR jack feeds the selected AES signal to a digital meter or phase scope.

The 3 rd

group of connectors is the ANALOG IN group. There are three stereo inputs selectable by the switch group marked “ANALOG” on the front panel. Note that the fourth switch selects the built in D/A converter.

Next are the OUPUT amplifier feeds. There is a MAIN and MINI set of sends to drive power amplifiers. These feeds are balanced and low impedance feeds capable of driving long cables.

The AC IN jack is where the power supply cable goes. It is best to make sure that the power supply is turned off before connecting this cable to avoid arcing the contacts. There are banana jacks provided for accommodating different grounding schemes. The chassis and audio grounds are strapped together at the factory. This works for most cases but the jacks are provided for situations needing a different grounding scheme. If hum or buzz problems are encountered, please consult the chapter on “Internal Jumpers” for hints to clear up the situation.

The 25 way ‘D’ connector is to connect the Dim Command from a

Dangerous MQ and other expansion capabilities.

-4-

Usage Examples

The ANALOG switches select from four sources to be listened to. The selected source is sent to the “Functions” group and the “A-MTR” feed on the back panel. The fourth analog selection is a built in D/A converter which is fed by the selected “Digital” switch.

The “Functions” group allows channel phase reversal, speaker mutes, mono, volume dim, alternate speaker selection, and a VU meter offset (to keep from thrashing the meter movements when listening to high level program material). The volume control is a 21 position stepped attenuator. It was decided in the design process to use an attenuator for its accuracy and repeatability. It was also found that attenuators provide consistent sound quality at all volume settings whereas pots tend to change sonic characteristics and balance depending on the setting. Pots also require DC blocking to reduce scratching noises on adjustment. The gain of most power amps today is set very high so the attenuator range is set for about 30 dB of loss. Since it is desirable to occasionally listen to the noise floor, which requires unity gain at the volume control, the last two steps are pretty big.

Please use caution near the top of the volume control.

-5-

Meter wiring

The “A-MTR” feed is a buffered output designed to drive the VU meters and headphone amp in the MQ metering and cue box. The feed can also drive a standard VU meter circuit. The Monitor’s D/A is calibrated so that a digital sine wave of 1 kHz frequency at -14dBfs will provide a +4dBu signal level. Calibration tones are available from the oscillator in the DAW or a test CD.

Standard VU meter circuit

The selected Digital Input to be monitored is fed to the “D-MTR” XLR on the rear panel.

This output is a standard AES digital output that goes to MQ’s AES input or another digital meter or phase scope.

Interface

The following section is intended to help installers set the system up for quiet, dependable operation. If trouble is encountered setting up the Monitor, the suggestions may help in understanding the issues and resolving the problems. The techniques discussed while not infallible, have been used for many years by the engineers at

Dangerous Music with a fantastic success rate setting up dozens of world class facilities.

6-

Balanced Audio Connections

The beauty of balanced connections is that they promote the idea that current should be prevented from flowing down cable shields while letting the audio pass. Pins 2 and 3 carry a signal across them (transverse mode) and any interference that gets through the shield is picked up equally by the wires (common mode). The common mode noise is canceled by the differential action of the instrumentation amplifiers in the first stage of the Monitor. Signal gets through and the grounds stay put inside their respective pieces of gear.

Unbalanced Audio Connections

An unbalanced source driving a Monitor input usually presents no problem because of the differential action of the input stage.

It is a good idea to use 3 wire cables even in an unbalanced situation because the

Monitor input can keep stray noise away from the signal even without the benefit of common mode rejection. If an unbalanced source gives one trouble, then this is usually because the source doesn’t have a proper ground reference. This is why there are Input

Shield Lift

jumpers inside the Monitor (and many other pieces of professional audio gear).

The next section covers how to access the jumpers and how they work.

-7-

Internal Jumpers

Monitor is shipped from the factory with its internal jumpers set to interface with balanced equipment. There are rare cases that certain gear may cause a buzz in the speakers with the factory presets. The following sections have information that can help the installer achieve quiet performance.

If one is uncomfortable with opening gear and changing jumpers or making

adjustments, please seek qualified help if necessary.

If adjustments or jumper changes are required, please disconnect the mains plug

before opening the top

. Dropped screws or tools on a live circuit board can manifest themselves as burn marks and smoked components. This type of damage is not covered by the warranty.

Input cable Shield Header Jumpers are on the main circuit board to facilitate proper system shielding. If a speaker buzzing problem is encountered, the method to trouble shoot this situation is to disconnect input wires until the buzz disappears. The cable pulled when the problem cleared up tells one which shield header jumper should have its position changed. The jumpers are clearly marked on the main circuit board.

If disconnecting all the inputs does not clear the trouble but disconnecting the amp feeds does, then there is a ground loop or missing ground reference to the power amplifiers.

The following section on interface may give some clues as to how to solve these types of problems.

-8-

Equipment Interface

The Difference between Grounds and Shields

While the usual scenario in hooking up equipment is that one plugs in the cables and starts to work, the more complicated a system, the more likely it is that something will not work correctly as far as hum and noise performance is concerned. While some would blame the equipment, this is the equivalent of blaming the eggs for a bad soufflé. Usually, hum and noise problems (and jitter or clock troubles in digital interfaces) can be traced to poor planning and implementation of the studio’s grounding situation.

It is illuminating to realize that the engineers of yore in the recording, broadcast, and communications industries have been through these troubles and figured out the solutions. History can teach us a lot about how to avoid ground loops and their associated problems. The manuals of many test instrument and recording equipment manufacturers from the ‘50’s to the 80’s had chapters on how to fix hum and noise problems and it is from this wealth of information that this writer draws ideas from for trouble free grounding schemes.

To comply with international standards and wiring practices, recording equipment manufacturers are required to connect all the shield pins of audio and data connectors to the chassis grounds of their gear. Sometimes, this can cause noise problems in large systems where pieces of equipment are spread out around a facility because two

‘grounds’ are never quite at the same potential. This can cause ground loops (hums or buzzing in the speakers) if the cable shields are allowed to connect two chassis that are at different potentials due to location, circuit wiring, or induction.

If the audio cables between the racks connect the equipment grounds together via the shields and the racks are at even slightly different potentials (on different circuits with different loads, long distance, etc) the shields will try to equalize the potential difference.

-9-

Juice will flow down the shields and broadcast hum into the signal wires they were supposed to protect or wind up imposed on the reference ground of the receiving equipment. This situation manifests itself as the all too familiar buzz of a ‘ground loop’.

The intensity depends on many variables but can go from unnoticeable to raging. Some people in desperation resort to using AC plug “ground lifts” to defeat the mains safety grounds in a random fashion until the system quiets down a bit. This in our view (and the view of the safety standards organizations) is an unacceptable method of taming ground buzzes. The simpler way is to make sure that all the gear has a good mains ground and to lift the shields on the receiving ends of the audio cables. The principals at Dangerous

Music have wired up large, world class facilities using this scheme and have brought room after room online with no buzz problems from the moment of power up. This is why many gear manufacturers have shield lift jumpers inside their equipment. If a noise problem crops up, changing the jumper position will almost always cure the problem.

Planning out the wiring system to minimize the formation of ground loops solves problems before they happen.

Many powered speakers seem to get their audio reference ground from the input cable. This means that these shields should not be lifted at the XLR. One favored technique for trouble shooting buzz issues is to make a short XLR cable with the shield lifted on the male connector and use this to test whether or not an XLR interface warrants a shield lift.

Alignment

The Dangerous Music Monitor is carefully aligned at the factory. The alignment procedure is provided here in case the user wants different levels on the D/A, Meter, or

Dim circuitry. Please don’t attempt to align this unit without proper laboratory equipment and knowledge of its use. Refer to the main board diagram on page 8 for pot locations.

1. Set an analog oscillator to deliver +4dBu output and patch it to Analog Input 1.

2. Select Analog Input 1 and turn the speaker level control all the way up.

3. Meter the Main Speaker Output and note the level and press the Mono button.

4. Adjust P1 for the same level noted above. Release the Mono button.

5. Turn the oscillator up to +18dBu and press the Dim button.

6. Adjust P2 and P3 for 0dBu output. Release the Dim button.

7. Unplug the oscillator. Obtain a digital oscillator and set it to -14dBfs.

8. Feed the oscillator to Digital Input 1 and select Digital Input 1 and D/A.

9. Meter the Main output and adjust P8 and P9 to the levels measured in step 3.

10. Meter the A-MTR feed and adjust P4 and P5 for +4dBu output.

11. Push the -6VU button and adjust P6 and P7 -2dBu output.

To set other reference levels for the D/A converter, run the preferred digital level and adjust P8 and P9 (along with the gain ranging jumpers H8 and H9) to read +4dBu at the meter feed. Remember to have the -6VU button disengaged while aligning the converter.

(How many times have I forgotten that one, Doh!)

-10-

Specifications

Frequency response ……………………….. 1Hz – 100 kHz within 0.2dB

THD+Noise ……………………………….. 0.003%

IMD60 4:1 ………………………………… 0.002%

Interchannel crosstalk …………………….. -113dB

Dynamic range …………………………… 119dB

Maximum level …………………………… +27dBu

Nominal operating level …………………... +4dBu

Power consumption ……………………….. 50 watts

Warranty …………………………………...

Free 2 year extended warranty with online registration.

Standard warranty: 90 days parts and labor, subject to inspection.

Does not include damage incurred through abusive operation or modifications/attempted repair by unauthorized technicians.

Connector Pinouts

All of the 3 pin XLR’s are wired to the standard convention (one of several, really).

Pin 1 shield

Pin 2 + signal

Pin 3 - signal

The “A-MTR” jack is a male 6 pin XLR. A breakout cable is provided with the unit but one can roll one’s own with the following pinout.

Pin 1 Left shield

Pin 2 Left +

Pin 3 Left –

Pin 4 Right shield

Pin 5 Right +

Pin 6 Right –

Solder Pin 6 first when terminating the cable. The cup is easy to get to until the other wires get in the way.

The writer still occasionally makes that mistake.

The ‘D’-sub connector is used for access to the Dim function by the Dangerous MQ.

Pin# function

1

14

Dim (for connection to MQ)

Relay common

USA

Dangerous Music, Inc.

231 Stevens Road

Edmeston, NY 13335

Email: [email protected]

-11-

Europe

Dangerous Music, Inc.

Stieleichenweg 55

50999 Köln

Tel: +49 2236 393731

E-mail: [email protected]

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project