- No category

advertisement

▼

Scroll to page 2

of 5

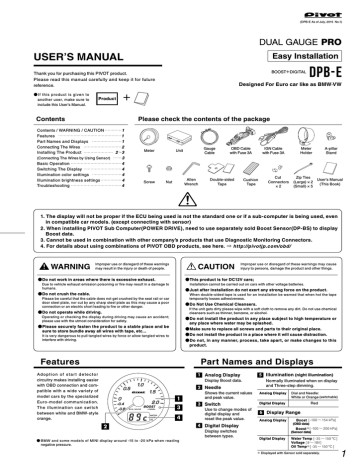

(DPB-E As of July, 2015 No.1) USER’S MANUAL Easy Installation Thank you for purchasing this PIVOT product. Please read this manual carefully and keep it for future reference. BOOST+DIGITAL ● If this produc t is given to another user, make sure to include this User’s Manual. Product DPB-E Designed For Euro car like as BMW·VW + Contents Please check the contents of the package Contents / WARNING / CAUTION …………1 Features ………………………………………1 Part Names and Displays …………………1 Connecting The Wires ………………………2 Installing The Product ………………… 2 ~3 (Connecting The Wires by Using Sensor) ……3 Basic Operation ……………………………… 4 Switching The Display ……………………… 4 Illumination color settings ………………… 4 Illumination brightness settings…………… 4 Troubleshooting ……………………………… 4 Meter Screw Gauge Cable Unit Allen Wrench Nut OBD Cable with Fuse 3A Double-sided Tape IGN Cable with Fuse 3A Cut Connectors ×2 Cushion Tape Meter Holder Zip Ties (Large) × 2 (Small) × 5 A-pillar Stand User’s Manual (This Book) 1. The display will not be proper if the ECU being used is not the standard one or if a sub-computer is being used, even in compatible car models. (except connecting with sensor) 2. When installing PIVOT Sub Computer(POWER DRIVE), need to use separately sold Boost Sensor(DP-BS) to display Boost data. 3. Cannot be used in combination with other company’s products that use Diagnostic Monitoring Connectors. 4. For details about using combinations of PIVOT OBD products, see here. ⇒ http://pivotjp.com/obd/ WARNING Improper use or disregard of these warnings may result in the injury or death of people. CAUTION Improper use or disregard of these warnings may cause injury to persons, damage the product and other things. ●This product is for DC12V cars; ●Do not work in areas where there is excessive exhaust. Installation cannot be carried out on cars with other voltage batteries. Due to vehicle exhaust emission poisoning or fire may result in a damage to humans. ●Just after installation do not exert any strong force on the product. ●Do not crush the cable. When double-sided tape is used for an installation be warned that when hot the tape temporarily losses adhesiveness. Please be careful that the cable does not get crushed by the seat rail or car door steel plate, nor cut by any sharp steel plate as this may cause a poor connection or an electric short leading to fire or other danger. ●Do Not Use Chemical Cleansers. If the unit gets dirty please wipe with a soft cloth to remove any dirt. Do not use chemical cleansers such as thinner, benzene, or alcohol. ●Do not operate while driving. Operating or checking the display during driving may cause an accident; please use with the utmost consideration for safety. ●Do not install the product in any place subject to high temperature or any place where water may be splashed. ●Make sure to replace all screws and parts to their original place. ●Do not install the product in a place where it will cause distraction. ●Do not, in any manner, process, take apart, or make changes to this product. ●Please securely fasten the product to a stable place and be sure to store bundle away all wires with tape, etc... It is very dangerous to pull tangled wires by force or allow tangled wires to interfere with driving. Features Part Names and Displays 1 Analog Display Adoption of star t detector circuitry makes installing easier with OBD connection and compatible with a wide variety of model cars by the specialized Euro -model communication. T h e illum inat i o n c an sw i tc h between white and BMW-style orange. 5 Illumination (night illumination) Display Boost data. Normally illuminated when on display and Three-step dimming. 2 Needle 1 3 4 2 Shows the current values and peak value. 3 Switch Use to change modes of digital display and reset the peak value. Dial and Needle: White or Orange (switchable) Digital Display Red 6 Display Range Analog Display Boost [ -100 〜 154 kPa] (OBD data) 4 Digital Display Display switches between types. ● BMW and some models of MINI display around -15 to -20 kPa when reading negative pressure. Analog Display Boost ※[ -100 〜 200 kPa] (Sensor data) Digital Display ※ Water Temp [ -35 〜 150 °C ] Voltage [ 8 〜 18V] Oil Temp※ [ -35 〜 150 °C ] Displayed with Sensor sold separately. 1 [ Unit ] (View from Gauge Connection) 7 Meter connector (View from Car Connection) Size Connect gauge cable [Unit:mm] Meter 8 Power connector Connect OBD cable 7 8 ø65 9 Boost connector 9 10 70 Unit 15 30 50 ø60 Connect Boost sensor Depth22 (sold separately) 10 Oil Temp connector Connect Oil Temp sensor (sold separately) Connecting The Wires ① Engine Start. ② Insert the OBD Connector to the Diagnostic Monitoring ① Connector. ENGINE START STOP Backside of the meter ③ Insert the 4-pin Connector to the backside of the meter. ④ Insert the 5-pin Connector of Gauge Cable and 6-pin Connector from the Power Cable to the Unit. 4-pin Connector If the meter not activate from individual differences in car models or some reasons after the engine starts, you need to change the power source and connect the power cable to IGN. ⇒See Separate sheet【Connect the power cable to IGN】. Diagnostic Monitoring Connector ② ③ Meter Holder Placement Diagram for Diagnostic Monitoring Connector ④ (1.5 m) ①By the accelerator pedal ②At the right foot of the driver seat (with lid) Engine Start Unit (0.5 m) 6-pin Connector 5-pin Connector ② ① ④ Notes about using the OBD Connector Make sure to grip the distended portions when pulling it out or inserting it. If you unable to get a grip on the distended portions. CAUTION D o n o t p u ll o n t h e w i r e s when trying to remove the connector; the wires may become disconnected. In such case, pull out the connector by p u l l i n g o n t h e end of the zip tie. W i t h s o m e c ar m o d e l s i t m ay b e d i f f i c u l t t o g e t a good grip on the connector. Installing The Product Installing The Meter A Installation with the Meter Holder ① Fa s t e n u s i n g t h e double-sided tape. ②After deciding the position and angle of the meter face, fasten the Hexagonal bolt on both sides to secure. ③Affix the Cushion Tape to the base of the meter, connect the Gauge Cable to the Meter, and install the Meter into the Meter Holder. Please add the Cushion Tape if the Meter not fixed. Cushion Tape Cushion Tape Meter Holder Double-sided tape Clean to remove oil and dust Note : Please be sure about where you wish to install the meter, as it is not advisable to reuse double-sided tape. Back side of Meter Cushion Tape Hexagonal bolt Gauge Cable B Installation to panel or something Connector C Installation to A-pillar using A-pillar Stand Cut the Cushion Tape in half, affix to base of the Meter to be on press fit condition with adjusting number. And connect the Gauge Cable to the Meter and insert into the panel. Make a ø5 hole on the place to install the meter of the A-pillar, and fix the Meter using A-pillar Stand with Screw and Nut. A-pillar Cushion Tape Panel A-pillar Screw Nut Gauge Cable Cut the Cushion Tape in half Cushion Tape 2 A-pillar Stand ø5 Hole Installing The Unit As shown in the below diagram , fasten the unit into positions not usually affected by water. Fastening to Flat Space (Example of Installation) Under the steering column cover On the back side of the under cover When Fastenings to a Cable or Pipe Unit Zip tie (Large) On the inside of the driver’s door Double-sided tape Through holes Thick cable or pipe Clean to remove oil and dust. Do not install into low positions Connecting The Wires by Using Sensor (Not normally required) To display Oil Temperature and Boost data from pressure sensor, you need to purchase separately sold sensor and connect as diagram. To the inside of the car Reading the part of data from sensor connection. To the engine room Wire harness grommet, etc. Nylon Hose (2m) Temperature sensor (DTS ¥3,800) Surrounded by dashed line are the contents of separately sold Temperature Sensor (DTS). Temperature Sensor Original Intake Manifold Sensor I-Joint [Connection by bullet terminal] Sensor Adapter Depending on the installation you may need a sensor adaptor. (sensor connector 1/8 PT sold separately) (sold separately) Sensor Cable (2.5 m) Conversion Joint 2-pin Connector Intake Manifold Boost Sensor (DP-BS ¥7,800) Surrounded by dotted line are the contents of separately sold Boost Sensor (DP-BS). For installation of Boost Sensor, you need a marketed sensor adaptor specialized for each car model. Original Connector Unit 3-pin Connector 3-pin Connector Sensor Cable (1.5 m) Rubber Hose Intake Pipe Boost Sensor Procedure for connecting OBD cable and Gauge Cable is same as basic wiring. Connecting Sensor Temperature Sensor Boost Sensor Oil Drain Hole Installation Connecting for Boost Sensor adapter for drain hole Oil pan drain hole (sold separately) Temperature sensor (sold separately) Standard drain packing 1⁄8PT White tape to prevent leakage In case of the sensor protruding in a downwar d d ir e c t i o n, t a ke m e a s ure s s u c h a s changing the position of the sensor. ① Cut the vacuum hose which can measure pressure directly from a surge tank or a intake manifold in the engine room. (e.g.,the hose connecting to a fuel regulator, a charcoal canister, etc.) ② Insert a T-joint and connect the various hoses and joints as shown in Figure A. ③ Pull the nylon hose to the inside of the car through a wire harness grommet, etc. ④ Using the I-joint, connect the nylon hose to the unit. (Figure B) Figure B Figure A Nylon Hose Nylon Hose Hose from the Boost Sensor Conversion Joint I-Joint Boost Sensor To the inside of the car Rubber Hose To the engine room Sensor Adaptor, etc (sold separately) Make sure that all hose and joint connections are securely fastened so as not to disconnect or cause pressure loss. (Depending on the conditions, it may be necessar y to take some action to prevent loosening and disconnection of the various connection points.) 1. Be sure install the Boost Sensor on the inside of the car. (Not in the engine room) 2. Stretch the hose that comes out from the Boost Sensor but do not pull it off. 3. If the hose can measure pressure is other than ø4, please prepare a separately sold joint that matches the size of the hose. 3 Basic Operation 1 2 Engine Start Opening Demo Opening Demo 3 4 Display Each Mode ●When the key is turned ON the needle will move to the extreme left several times for searching position. Then it will move to the maximum value and finally to reading for current measurement item. 5 Engine Stop Turning off the Display ●Due to analyzation time for the car data transmission it may take up to a few seconds from engine start before opening demo.(except wiring IGN) The needle stops in the vi c init y of lowest value. Meter OFF ●Due to analyzation time for the car data transmission, the illumination may remain on for up to 1 minutes even after the engine has been turned off; this is normal and no effect on the vehicle performance. (except wiring IGN) Switching The Display Switching The Digital Display Press switch to change the multi-digital display in operation Water Temp Water Temperature / Oil Temperature※ Reading the Display ※ Voltage [ - 35 〜 - 1 °C ] [ 0 〜 99 °C ] [ 100 〜150 °C ] The first place on the below shows “ ” (minus). The third place from the below shows “ ” (Celsius). Numerical Value Only. Oil Temp - (decimal point is lightning) ※ Not c displayed without temperature sensor. Display and Reset the Peak Value Real-time Display Peak Value Display for 3 Seconds for 3 Seconds Press Switch Press Switch ● Peak readings are reset when the key is turned OFF. ● For Boost, Water Temperature and Oil Temperature the high will be shown and for Voltage the low will With no operation 5 Seconds (Lighting) Reset the Peak Value Only the peak value on display will be reset. This will return to the Real-time Display for the currently displayed mode. be displayed. ● If you wish to check the loss of voltage upon operation of the starter, turn the key to the ON position (Blinking) and after the digital display comes on, operate the starter. Illumination color settings 1 + ENGINE START STOP 2 3 Display the current illumination color setting Engine Start (e.g. After the meter off, Engine start during pressing the switch Press the switch to change the color c-1 ) 5 Release the switch after displayed the current setting [ c-1 = White, Press the switch for 6 seconds 2 Display a peak value after 3 seconds and the current brightness after 6 seconds Holding downs the switch in operation (e.g. c-2 = Orange ] Release the switch after setting is done Back to normal display with no operation for 5 seconds Setting Completed Each pressing will change the color. Adjustment in case of anxious about reflected illumination of door mirror or something Illumination brightness settings 1 4 3 L-3 ) 4 Press the switch to change the brightness Release the switch after displayed the current setting (High) 5 Release the switch after setting is done 6 Back to normal display with no operation for 5 seconds (Mid) (Low) Each pressing will change the brightness Setting Completed Troubleshooting Trouble Does not work with Engine start. Possible Causes Possible Solutions Poor connection of Gauge cable , 6-pin Connector or OBD Connector wires. Pl e a s e r e c o n f i r m w h e t h e r w i r i n g a n d connections are correct or not. The unit has been installed into an incompatible car model. Please reconfirm the Fitting List. Upon starting up, the unit will not start in the newly changed display. Because after changing displays, if the car’ s engine is turned off within 3 seconds, the new setting will not be stored, make sure to wait at least 3 seconds before turning the engine off. Before the opening demo starts the needle briefly moves. This is due to a special characteristic of the meter and is not a malfunction. The displayed values are different from the standard meter. Due to the ECU information received, the displayed values on this product may differ from those of standard or other meters. ※Our products have already been recognized as our Industrial Property or are in the process of receiving Industrial Property status. ※We plan in the near future to take all possible legal measures to protect against unfair competition from look-alike products using similar designs, regulating characteristics, circuitry and circuitry layout. ※We strictly prohibit the unlicensed use of the PIVOT trademark and the unauthorized use of PIVOT User’s Manual. 4 PIVOT CORPORATION 87-3, Shimookada Okada, Matsumoto-shi, Nagano, 390-0313 JAPAN (DPB-E User’ s Manual Separate sheet As of July, 2015 No.1) Connect the power cable to IGN Use the saplyed IGN Cable to get power from IGN. The meter start-up and stop is differ in power connection method. IGN Cable (2.7m) Normal (not using IGN Cable) 1-pin Connector Cartridge Fuse Linked to the ECU Blade Fuse IGN (using IGN Cable) Linked to the key switch Connect IGN Cable A In case of BMW 3series, etc. ① Unplug the connector of Yellow and Red cable of OBD Cable. Diagnostic Monitoring Connector OBD Cable ② Connect Yellow cable of OBD Cable to 1-pin Connector of IGN Cable. Red ③ Connect to Blade Fuse of IGN Cable into IGN of the Fuse box. To Fuse box Yellow Yellow IGN Cable B Using commercially available Fuse power supply ① Cut the IGN Cable on the position of the below and connect to the commercially available Fuse power supply. OBD Cable Cutting position Diagnostic Monitoring Connector Red ② Unplug the connector of Yellow and Red cable of OBD Cable. ③ Connect Yellow cable of OBD Cable to 1-pin Connector of IGN Cable. ④ Connect to Blade Fuse of IGN Cable into IGN of the Fuse box in the engine room. Yellow To Fuse box Yellow Cutting IGN Cable Fuse power supply (commercially available) =Cut Connector C Directly connect to IGN of the vehicle ① Cut the IGN on the position of the below and connect to the commercially available Fuse power supply by using bullet terminal. OBD Cable Cutting position Diagnostic Monitoring Connector Red ② Unplug the connector of Yellow and Red cable Yellow Yellow IGN (12V with Key ON) of OBD Cable. ③ Connect Yellow cable of OBD Cable to 1-pin Connector of IGN Cable. Cutting IGN Cable =Cut Connector How to use the Cut Connectors 1 10 mm Peel off of the vinyl cover at connection. 2 10 mm 3 Peel off of the vinyl cover at the end of the product’ s wire. 4 Wrap around both wire coils. 5 Close tightly with cut connector. Insulate with vinyl tape. When crimping, please u s e c r i m p er s o r u s e pliers to bend and then solder together. PIVOT CORPORATION 87-3, Shimookada Okada, Matsumoto-shi, Nagano, 390-0313 JAPAN

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project