advertisement

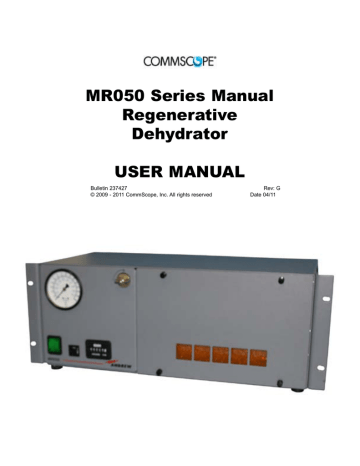

MR050 Series Manual

Regenerative

Dehydrator

USER MANUAL

Bulletin 237427

© 2009 - 2011 CommScope, Inc. All rights reserved

Rev: G

Date 04/11

MR050 SERIES DEHYDRATOR USER MANUAL

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Schematic Diagram - MR050-XXX4X, ALL ac Version. . . . . . . . . . . . . . . . . . . . . . 19

Schematic Diagram - MR050-XXX3X, dc Version . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2

MR050 SERIES DEHYDRATOR USER MANUAL

This manual contains the information you need to install, operate and maintain your MR050

Series dehydrator. Please take the time to read this manual before attempting to operate or service the unit.

MR050 Series dehydrators provide dry air for pressurizing small (280 liters or up to 10 cubic feet, in volume) antenna and transmission line systems. The dehydrators produce -40ºC (-40ºF) dewpoint dry air at an output rate of 1.4 liters

(0.05 cubic feet) per minute up to a total of 5660 liters (200 cubic feet) on a single desiccant canister.

front panels feature a pressure gauge, on/ off switch, hour meter and resettable circuit breaker. All MR050 dehydrators have a single output. Use the DP-4A-001 distribution panel, described below, for additional output connections. Other distribution products, such as a 6600D-4 Manifold or an LM400-H, -L and

-M Line Monitor may also be used to provide multiple outputs from a MR050 dehydrator. For easy serviceability, power connections, alarm output connections and the drying assembly are accessible from the front of the unit.

The drying assembly consists of transparent canister which contains color-indicating desiccant. The transparent canister makes it easy to view the condition of the desiccant and flexible tubing on barbed fittings makes the canister easy to replace.

The MR050 Series dehydrators sense transmission line pressure and automatically maintain pressure within a specified range.

The MR050-8XXXX (high pressure) maintains transmission line pressures between 21 kPa and 34 kPa (3.0 and 5.0 lb/in2). It is intended for standard microwave antenna applications and any other transmission line pressurization requirement that supports a relatively high pressure limit.

A standard LP (low pressure) alarm provides an open or closed form C “dry” contact relay in the event of a low pressure condition. The alarm for the MR050-8XXXX is set at 6.9 kPa (1.0 lb/in2).

Each dehydrator consists of an electricallydriven air compressor, a replaceable desiccant drying assembly, an automatic transmission line pressure sensing system and a low-pressure alarm output housed in a rigid metal chassis.

They are suitable for 19” rack mounting, wall mounting or free-standing applications. Their

3

MR050 SERIES DEHYDRATOR USER MANUAL

All MR050 dehydrators have a single output.

Use the DP-4A-001 distribution panel, described below, for additional output connections. Other distribution products, such as a 6600D-4

Manifold or an LM400 Series Line Monitor may also be used to provide multiple outputs from a

MR050 dehydrator.

Type LM400-X: Four Port Line Monitors, include one rear-panel 3/8” output compression fitting, one gauge, one flow meter with shutoff valve per output. The unit mounts on top of the dehydrator or to the wall using supplied hardware. Each line monitor comes complete with installation materials to connect four transmission lines.

LM400-H, LM400-L, LM400-M

Type DP-4A-001: Four-Output Distribution

Panel, includes one 3/8” output compression fitting and one shut-off valve per output. The unit mounts in a standard 19” equipment rack or to the top of the MR050 using supplied brackets.

It comes complete with an installation kit to connect up to four individual transmission lines.

Type 6600D-X: Two, Four and Six-

Output Manifolds, include one 3/8” output compression fitting, one gauge and one shutoff valve per output. The unit mounts to the wall using holes supplied through the manifold block.

Each manifold comes complete with installation materials to connect two, four or six transmission lines.

L6600D-2, -4 (for low pressure units)

6600D-2, -4, -6 (for high pressure units)

MR050 series dehydrators include a compressor, color indicating desiccant, high and low-pressure switches, check valves, and a lowpressure alarm sensor.

When system pressure falls to a preset low limit, the low-pressure sensor activates the compressor. Air is channeled through a desiccant canister, where moisture is adsorbed.

The air exits the drying canister at -40°C (-

40°F), or better, dewpoint. It is then channeled directly to a single transmission line or through a distribution panel, manifold, or line monitor to multiple transmission lines.

When system pressure reaches a preset high limit, the high-pressure sensor shuts off the compressor. A check valve prevents system dry air from retreating back through the compressor.

If system pressure falls significantly below the low-pressure trigger point, the low-pressure alarm sensor will activate an alarm contact.

This alarm is an indication of a significant system leak or a dehydrator failure.

4

This optional assembly is designed to provide the addition of Excess Run, and Power Fail alarms to CommScope Dehydrators. All alarms are Form C dry contacts and are factory set for continuity at alarm.

The external alarm monitoring system (not included) is connected to the terminal strip located at the top of the chassis. A small slotted screwdriver is necessary to make the connections.

MR050 SERIES DEHYDRATOR USER MANUAL

Excess Run:

User setable run time to be set in accordance with the normal run time for the particular application.

Selectable times are 10, 30, 120 and 240 minutes. See Figure 2 for location of JP3.

Power Fail:

Activates when power is removed from the dehydrator. This includes turning the power off at the switch.

The connection to the alarm strip is as follows, and refer to Figure 1 for correct locations and colors of the wires on the terminal strip.

*4*

*3*

*2*

*1*

*8*

*7*

*6*

*5*

ALARM

L.P.

X.R.

H.H.

P.F.

.5

Term . #

Color

1

2

3

4

5

6

7

8

Function

Power Fail Com.

Power Fail Alarm

Excess Run Com.

Excess Run Alarm

Low Press. Com.

Low Press. Alarm

Wire

White

Red

Black

Blue

Grey

Orange

Alarm

Factory setting

Where to reset

Low Pressure

Mains Power

Fail

Excess Run

Time

Normally Closed

(N.C.)

Normally Open

(N.O.)

Normally Open

(N.O.)

Alarm switch

Center term.

N.O., bottom term N.C.

Jumper JP6 on

Alarm PCB

Jumper JP5 on

Alarm PCB

Figure 3 Changing Alarm Outputs:

5

MR050 SERIES DEHYDRATOR USER MANUAL

Output Pressure

Output capacity

(total, approx.)

Output Dew Point,

Drying Capacity

[per canister]

Operating Temperature

Range

Low Pressure Alarm

Set Point (approx.)

Electrical Input

(depending on model)

Output Connector

Dimensions

Optional Alarms

Excess Run Alarm

Set Point

Power Fail Alarm

Sound Level

21 - 34 kPa

(3.0 to 5.0 ±0.3 lb/in2)

80 Iiters/h (3.0 ft3/h)

1.5 liters/m(0.05 ft3/m)

-36°C (-33°F) or better

Approx. 5664 I (200 ft3) at 80% R.H., 20°C

-10° to +40°C)

(+14° to +104°F)

6.9 kPa (1.0 lb/in2)

85-264 Vac, 47-440 Hz

12-60 Vdc Battery

3/8” polytube, compression

19” Rack, 4 RU Tall by

229 mm (9.0”) Deep

10 minutes, factory set loss of input power

67dBA @ 1 meter

6

MR050 SERIES DEHYDRATOR USER MANUAL

Open carton.

Carefully remove the installation accessories, manual and desiccant canister.

Turn the carton on its side and slide out the dehydrator and its expanded foam packing.

Check the dehydrator for shipping damage such as dents or loose parts.

Check the inside of the dehydrator for damage.

Check the canisters for damage such as cracking or displaced desiccant.

Remove the top cover. Check for loose wires hoses or components. If anything is loose, refer to the component schematic and wiring diagram for proper placement. If you find any damage or if you need assistance for reconnection of wires or hoses, contact CommScope Customer

Service Department at 1-800-255-1479.

If everything looks correct, replace the top cover.

Do not replace the dehydrator front panel at this time. It will be replaced after the dehydrator is mounted and electrical connections are complete.

Remove front cover by pulling forward on the four black snap-in fasteners. Then pull the cover forward and lift off the unit. Set the cover aside until inspection and installation are complete.

7

MR050 SERIES DEHYDRATOR USER MANUAL

Familiarize yourself with the controls and displays prior to installing or testing the dehydrator.

Circuit Breaker white tab indicates a circuit overload. Push to reset.

2 .2 .1 Dehydrator Controls/Displays

Pressure Gauge indicates dehydrator output pressure in kPa and psig.

Run-Time Meter provides a visual indication of the number of hours of compressor operation and provides validation for the 1000 hour warranty.

ON/OFF Switch controls compressor and sensors.

Desiccant Color normally orange, changes to green as it is used. Green in four of the five viewing windows indicates approximately 20% capacity remaining and time for a desiccant change.

8

2 .2 .2 Air Distribution Panel Controls

ON/OFF output port control valve. A 90° turn opens the valve. Used on both the MR050 and the DP-4A-001.

MR050 SERIES DEHYDRATOR USER MANUAL

The mounting brackets can be positioned at the front of the unit or 127 mm (5") back from the face of the unit.

0 = OFF

I = ON

2 .3 Installing the Dehydrator

MR050 Series dehydrators are designed for low vibration and low noise and can safely be placed in an existing equipment rack or cabinet. They are also suitable for wall or shelf mounting. Only minimal tools and hardware are required.

Allow at least 25 mm (1") space on both sides of the chassis for air flow.

2 .3 .1 Dehydrator Rack/Cabinet Mounting

Movable brackets are included for mounting the dehydrator directly into a standard 483 mm

(19”) equipment rack. Remove the rubber feet from the bottom of the dehydrator, if there is equipment directly below it in the equipment rack

Four #10-32 mounting screws are provided in the cloth bag attached to the dehydrator for attaching it to the rack.

9

Route electrical wiring and air line through the holes in the rear and/or side of the chassis.

2 .3 .2 Dehydrator Wall Mounting

The rack mounting brackets can be reversed and used to mount the MR050 dehydrator to a wall or other vertical surface. A paper mounting template is supplied in the manual. Use it to mark mounting hole positions on a wall or plywood backer, as described below.

MR050 SERIES DEHYDRATOR USER MANUAL

Masonry wall (concrete or cinder block), use concrete screws or screws with lead anchors or anchor bolts to attach the dehydrator directly to the wall. Alternatively, install a plywood backer to the wall and mount the dehydrator to it.

Frame wall - use a plywood backer, 3/4" thick x 24” W x 18” minimum H. Securely attach the backer to two wall studs with lag screws, then attach the dehydrator to the backer with Number

10 or 12 pan-head screws or 3/16" lag screws.

Use a 3/4" long screw to ensure a secure attachment.

Route electrical wiring and air tubing through the hole in the right side of the chassis.

2 .3 .3 Dehydrator Shelf Mounting

For shelf or stationary bench top mounting, route electrical wiring and air tubing through holes at the rear or right side of the dehydrator.

10

MR050 SERIES DEHYDRATOR USER MANUAL

2 .3 .4 Mounting The DP-4A-001 Distribution Panel

The distribution panel mounts in a standard 19” equipment rack or directly to a dehydrator.

Rack mounting. Mount the panel directly above the dehydrator to simplify connections. Screws are provided in the cloth bag attached to the panel.

Mounting to dehydrator. Secure the distribution panel to the top of the dehydrator, using brackets and screws supplied in the cloth bag. Distribution panel should be flush with dehydrator face.

Confirm your dehydrator electrical input matches the available power.

115 Vac 240 Vac 12-60 Vdc Battery

MR050-81045 MR050-81046 MR050-81037

MR050-81245 MR050-81246 MR050-81237

Turn the power switch

OFF. Locate the

rectangular IEC socket or the circular dc socket inside the desiccant canister area (refer to

Section 2.1).

AC units can be connected into a standard 15

Amp power receptacle of the proper voltage.

Make sure the power circuit is properly grounded

(see Section 2.4.3).

Verify the power switch is

OFF. Locate the ac

power cord that was supplied in the accessories bag. The cord plugs directly into the IEC socket.

A strain-relief is supplied in the cloth bag. Install the strain relief first and then connect the power cord.

Caution:

Proper electrical connection is required.

It is suggested a licensed electrician be contracted to connect the ac wiring to the unit, if it is connected directly to the mains.

Failure to properly connect the power wires could result in a dangerous electrical shock hazard.

For equipment distributed to the 115 Vac

North American market, the ac power cord is terminated in a molded NEMA 5-15 plug. If the local ac required a different plug, cut off the molded plug and install an approved type.

11

MR050 SERIES DEHYDRATOR USER MANUAL

For equipment distributed in the 240 Vac international market, the supplied ac power cord is HAR/VDE approved. It is not terminated with a plug, due to the large variety of plugs in use throughout the world. Install an approved plug at the end of the cord with stripped leads. The illustration shows two typical 240 Vac plugs

(British and Continental) for reference, but they are not included with the cord.

To avoid damage to the dehydrator, dc power from an ac to dc converter must be:

• Constant voltage between 12 and 72 Vdc.

Verify the power switch is “

OFF”. Locate

the circular connector on the left, inside the desiccant canister area. The lower terminal connector is for the power cable connection.

Use a battery or dc supply of 12 Vdc to 60

Vdc with 15 VA minimum capacity. The dc power cable is pre-wired at the factory and is approximately 6 m (20 ft) long. It terminates at connector T3.

In the European Community, the primary power wiring for dc powered units shall be made using insulated stranded copper wire rated at 300 volts and 80 degrees C minimum. Cross section of each conductor shall be 1 mm 2 minimum. For equipment distributed in the U.S. and Canada, the primary power wiring connection to the terminal block for dc powered units must be made using UL recognized and CSA certified insulated stranded copper wire rated at 300 volts and 80 degrees C minimum. Conductor size shall be 16 AWG minimum.

• T3 - Terminal 1 is ground [green wire]

• T3 - Terminal 4 is negative (-) [black wire]

• T3 - Terminal 6 is positive (+) [red wire]

12

The customer end of the dc power cable is not connectorized. Strip back the outer covering

2" and then remove 1/4" of insulation from the end of each wire before making a connection.

Cut back the white wire to the start of the outer covering as it is not used.

2 .4 .3 Grounding Instructions

MR050 SERIES DEHYDRATOR USER MANUAL

Ground the dehydrator to reduce the danger of electric shock.

AC units must be properly installed to meet local electrical codes and ordinances. AC powered units have a power ground stud located at the right rear of the desiccant canister area.

DC units also use the ground stud located at the right rear of the desiccant canister area.

Connect an 1 mm (18 AWG) wire from the ground stud to a known Earth ground.

DANGER:

Improper installation of the grounding conductor can result in the risk of electric shock. Consult a qualified electrician if you have any questions or are in doubt about your present electrical grounding.

Turn the dehydrator minute. Open the air valve on the face of the dehydrator and check the output port on the compressor housing bulkhead to make sure air is flowing.

ON and run it for one

Slowly close the valve on the front of the dehydrator. The unit should shut off. Open the valve. The dehydrator should begin running again. If these items check out, turn the power switch

OFF, and proceed with your other

connections.

If the dehydrator fails either of these tests, refer to the Troubleshooting Section in Section 4 of this manual.

13

MR050 SERIES DEHYDRATOR USER MANUAL

2 .5 Connecting the Low Pressure Alarm Output

When a low pressure alarm condition exists,

Form C dry contacts are activated at terminal

TB-1. Normally open (NO) contact terminals 7 and 8 close on alarm.

2 .6 Connecting the Dryer Assembly

The dryer input and output lines are two sections of clear plastic tubing attached to bulkhead connectors on the side wall of the dehydrator.

To connect the desiccant canister, connect the two sections of clear plastic tubing to the desiccant canister barb fittings.

An alarm condition exists when pressure falls below 6.9 kPa (1.0 lb/in2) for MR050-8XXXX models. The relay contacts are rated at 3 A

(inductive), 30 Vdc.

The canister then rests on the floor of the dehydrator enclosure between the louver slot and the front door.

14

MR050 SERIES DEHYDRATOR USER MANUAL

2 .7 Connecting Dehydrator to the Transmission

Caution:

Check the antenna and transmission line system pressure rating before connecting the dehydrator to the system. If the rating is below 35 kPa (5 lb/in2), make sure the

MR050B-3XXXX model is used. If the pressure rating is 35 kPa (5 lb/in2) or greater, use the MR050-8XXXX model.

Insert one end of the 3/8” polytube feed line tubing into the compression fitting on the dehydrator inside wall, or one of the similar fittings on the DP-4A-001 Distribution Panel.

Tighten securely with a 9/16” wrench. Be careful not to over tighten. Connect the other end of the polytube to the transmission line.

Note: If the transmission lines have not been purged, continue with section 2 .8 . Otherwise proceed to

Section 3 .

2 .8 Purging the Transmission Line

Air in the transmission line system must be replaced with dry air to ensure satisfactory operation of the transmitted signal.

1. Determine the total system volume.

2. Open the far end of the transmission line.

3. Operate the dehydrator for one purge cycle.

Refer to table for the “hours to purge”.

4. Wait 45 minutes while the air absorbs moisture in the system, then repeat steps 2 and 3 two more times.

The times to purge and pressurize are a function of the internal volume of the transmission line. The table that follows gives purge and pressurize times for various volumes of waveguide and air dielectric coaxial line.

Line Volume liters (ft3)

14 (0.5)

28 (1.0)

42 (1.5)

57 (2.0)

85 (3.0)

113 (4.0)

170 (6.0)

227 (8.0)

283 (10)

MR050-

8XXXX

Hours to

Purge

0.5

1.0

1.5

2.0

3.0

4.0

6.0

8.0

10.0

Minutes to

Pressurize

1.8

3.6

5.4

7.2

11.4

15.0

22.2

30.0

37.2

15

MR050 SERIES DEHYDRATOR USER MANUAL

When the desiccant color changes from orange to green, it requires renewal.

1. Isolate all transmission lines by turning the in-line valve(s) to the “0” position.

4. Once a desiccant canister is free of the dehydrator, replace with new canister.

2. Access the desiccant canister by removing the front panel.

3. Disconnect the desiccant canister by pulling the clear plastic tubing from the desiccant canister barb fittings.

16

MR050 SERIES DEHYDRATOR USER MANUAL

3 .2 Replacing the Compressor Air Intake Filter

Replace the compressor air intake filter every six months for proper compressor operation and maximum length of service. To gain access to the compressor air intake filter, remove the front cover as outlined in Section 2.1. Never operate the dehydrator without the intake filter intact, as this will allow dust and foreign particles to enter the compressor and reduce its operating life.

The MR050 compressors have an external air intake filter attached to a fitting on the left side wall of the desiccant side of the dehydrator. To replace this filter:

1. Turn the power switch

OFF

2. Isolate all transmission lines by turning the in line valve(s) to the “0” position.

3. Remove the front cover from the desiccant side of the dehydrator and pull the canister forward.

5. Discard the old filter and replace with a new one by pressing onto the clear tubing.

6. Turn the dehydrator

ON and replace the

front cover.

No parts of the MR050 require lubrication.

4. Pull the air intake filter off white fitting. The filter and fitting are located toward the rear of the unit on the inside left wall of the desiccant side, behind the canister. The assembly consists of a bulkhead fitting, a short length (25mm, 1") of clear tubing, a white barbed fitting with the small, white cylindrical filter.

17

MR050 SERIES DEHYDRATOR USER MANUAL

If you experience difficulty with your dehydrator, use the troubleshooting procedures described below.

Caution: Electrical troubleshooting requires access to potentially dangerous voltages and should only be performed by a licensed electrician

Problem/Condition

Dehydrator on/off switch is

ON, unit does not run.

Low-pressure alarm activated.

Compressor does not turn.

Circuit breaker tripped.

Solution

Check the breaker adjacent to the on/off switch. If the breaker is tripped, (white indicator exposed) then reset the breaker.

If the

on/off switch is ON, make sure the unit is plugged in

and power outlet is operating..

If unit still does not run, unplug the unit, remove the unit cover and check for loose connections. Refer to the wiring diagram for proper connections.

Pressurize lines with the dehydrator, turn dehydrator shut-off valve to the off position and observe pressure gauge. If pressure remains constant, apply leak detector to transmission lines(s), and repair any leaks. If leaks are not found, replace pressure switch (PS2).

If the pressure does not stay constant after shutting off the valve, apply leak detector to isolate the leak in the dehydrator (exercise care when applying solution not to wet wiring or electronics).

If no leaks are found above, replace air compressor.

Check power switch to make sure that it is

ON.

Check input power polarity and voltage per wiring diagram.

Check the voltage between pins 1 and 3 of the J50 connector on the converter board (11-13 Vdc should be present). If the voltage is not correct, replace the converter board.

Check voltage across terminals A

2 and B5 of the power

switch (SW1). If voltage is not 11-13 Vdc, check wiring or replace power switch.

Check voltage across chassis ground and common (C) terminal of pressure switch (PS1). If 11-13 Vdc is not present, replace circuit breaker.

Check voltage between chassis ground and the normally closed (NC) terminal of pressure switch (PS1). If 11-13

Vdc is available check wiring to the compressor, then replace compressor. If 11-13 Vdc is not available, replace pressure switch (PS1)

Check wiring connections per wiring diagram. If breaker trips again, replaces the breaker. If the replacement breaker trips contact CommScope Customer Service.

18

MR050 SERIES DEHYDRATOR USER MANUAL

N

T3

L

AC INPUT

85 TO 254 VAC

47 TO 400Hz

J1

1 2 3 4 5 6

CONVERTER PCBA

A1

BLK

6 5 4 3 2 1

J50

A1

SW1

POWER SWITCH

RED

B4

A2

B5

RED

BLK

AUX. or HI Press

}

PURPLE

YELLOW

LO Press

Excess Run

}

}

ORANGE

GRAY

WHITE

BLUE

PWR Fail

}

RED

BLACK

TB1

10 10

9

8

9

8

7

6

5

1

4

3

2

7

6

5

4

3

2

1

HOUR

METER

M1

COMPRESSOR

-

+

GRY

C

PS2

NC

NO

ORN

RED

RED

BLK

NC

PS1

C

NO

J7

J1 J2

J6

J3

J4

J5

RED

Schematic Diagram - MR050-XXX4X, ALL ac Version

19

CB1

3A

MR050 SERIES DEHYDRATOR USER MANUAL

DC INPUT

10 - 72 VDC

T3

1

2

5

3

4

6

7

AUX. or HI Press

}

PURPLE

YELLOW

LO Press

Excess Run

}

}

ORANGE

GRAY

WHITE

BLUE

PWR Fail

}

RED

BLACK

3

2

1

8

7

6

5

4

TB1

10

9

10

9

8

4

7

6

5

3

2

1

HOUR

METER

M1

COMPRESSOR

-

+

GRY

PS2

C

NC

NO

ORN

RED

GRN/YEL

J1

1 2 3 4 5 6

CONVERTER PCBA

A1

BLK

6 5 4 3 2 1

J50

RED

A1

SW1

POWER SWITCH

B4

A2

B5

RED

RED

NC

PS1

C

NO

BLK

RED

BLK

RED

CB1

3A

J7

J1 J2

J3

J6

J4

J5

Schematic Diagram - MR050-XXX3X, dc Version

20

MR050 SERIES DEHYDRATOR USER MANUAL

Following is a list of the replacement parts for the MR050 series dehydrators:

Check website for latest updates to manual and parts list .

Description

Compressor AE01J-A0131-001

Desiccant Canister AE01D-D1690-001

Front Door Fastener Kit

Rubber Feet (bag of 4)

AE01K-D0818-020

AE01K-D0818-040

CommScope provides in-warranty and outof-warranty repairs as well as dehydrator and compressor overhauls from several Repair

Centers. Coordination of these services is provided through the nearest Sales Office or

Customer Service Center. The Center is also prepared to help you with the following:

• Technical Assistance

• Troubleshooting

• Repairs

• Loaner Units

• Spare Parts

• Installation Materials

• System Accessories

The first step you should take if trouble develops using a dehydrator is to read the operators manual and follow the trouble isolating procedures given in it.

If the steps in the manual do not identify and remedy the problem, then contact an

CommScope Customer Service Center for 24– hour telephone assistance. Record the Model

Number (e.g. MR050) and Serial Number from the product label, as you will be asked for these when you call. Two main locations are currently available to help:

Telephone:

From North America

1-800-255-1479

Fax (U.S.A.): 1-800-349-5444

International

Telephone: +1-779-435-6500

Fax Number: +1-779-435-8579

Web Access www.commscope.com

email:

21

MR050 SERIES DEHYDRATOR USER MANUAL

6 .2 Initial Steps by CommScope

When your call or fax communication is received, the CommScope staff will work with you to pinpoint the possible cause of trouble. If the pressurization equipment is suspect, they will:

• ask for your unit Model Number and Serial

Number

• check the warranty status of the unit

• advise the availability of a loaner unit

• provide an estimate of the cost for inspection and repairs, if the unit is out–of–warranty

• fax a Return Material Authorization Sheet to you.

A method of Payment must be provided prior to issuing of RMA regardless of warranty status.

I

N–WARRANTY REPAIR: Most CommScope

pressurization products carry a warranty of one to three years, depending upon model number.

Warranty details are available on our web page. If your unit falls within its warranty period, inspection and repairs will be performed at no charge and the unit will be promptly returned to you. If a warranty unit is deemed no problem found an inspection fee and freight will be charged to the customer.

OUT–OF–WARRANTY REPAIR: We will inform

you with the cost of repair and obtain your approval to proceed with repairs or, if you elect not to have the unit repaired, your instructions on disposition of your unit. When repairs are complete, we will return your unit and invoice you for the inspection charge, materials used for the repair and labor applied to complete the repair. If you elected not to repair the unit, we will invoice you for the inspection and freight charge if unit is to be returned.

LOANER UNITS: Loaner units are available

from the repair center to maintain your system while repairs are being performed. If you feel you need a loaner, please contact us at (817)

864-4160. A P.O. for the full value of the unit must be issued prior to shipment. Also contact us when the loaner is ready to be returned so that we can issue a NEW RMA number to

22 identify your return and create the appropriate credit to your account. Damages to loaner will be deducted from the P.O.

PACKING INSTRUCTIONS: Pack your unit

securely for shipment to the Repair Center.

If you received a loaner unit, we suggest you use the box and packing materials to return your unit. Otherwise we have factory packing materials available for a nominal fee. Enclose a completed copy of this form inside the box and clearly mark your Company Name and RMA:

XXXXXXX on outside of the box. Address the box to the following Ship–To Address:

CommScope PRESSURIZATION SERVICE

CENTER

RMA# XXXXXXX

11312 S. PIPELINE RD.

EULESS, TX. 76040-6629

Please note, Units received with

Biological/animal contamination will be returned unrepaired or scraped after notification and you will be invoiced for inspection and freight.

CONTACT NUMBERS: If you have any

questions about the repair process or status of your unit, please contact us directly through one of the following methods – Telephone (below)

TEL: 817-864-4150

817-864-4155

FAX: 817-864-4179

MR050 SERIES DEHYDRATOR USER MANUAL

This page was left blank.

23

MR050 SERIES DEHYDRATOR USER MANUAL

This page was left blank.

24

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement

Table of contents

- 7 Installation

- 16 Maintenance

- 18 Troubleshooting

- 21 Section 5

- 21 Replacement Parts

- 21 Section 6

- 21 Customer Service