- No category

advertisement

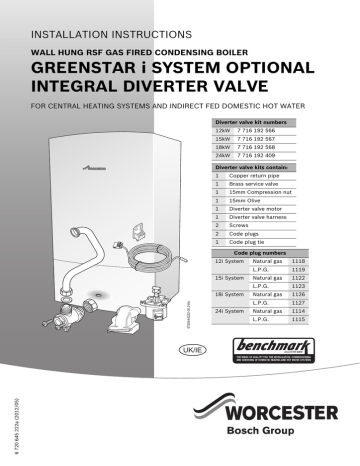

INSTALLATION INSTRUCTIONS

WALL HUNG RSF GAS FIRED CONDENSING BOILER

GREENSTAR i SYSTEM OPTIONAL

INTEGRAL DIVERTER VALVE

FOR CENTRAL HEATING SYSTEMS AND INDIRECT FED DOMESTIC HOT WATER

Diverter valve kit numbers

12kW 7 716 192 566

15kW 7 716 192 567

18kW 7 716 192 568

24kW 7 716 192 409

1

2

1

1

2

1

1

1

Diverter valve kits contain:

1 Copper return pipe

Brass service valve

15mm Compression nut

15mm Olive

Diverter valve motor

Diverter valve harness

Screws

Code plugs

Code plug tie

Code plug numbers

12i System Natural gas 1118

L.P.G.

1119

15i System Natural gas 1122

L.P.G.

1123

18i System Natural gas 1126

L.P.G.

1127

24i System Natural gas 1114

L.P.G.

1115

UK/IE

2

CONTENTS

CONTENTS

1 KEY TO SYMBOL AND SAFETY PRECAUTIONS . 3

Explanation of symbols . . . . . . . . . . . . . . . 3

Safety precautions . . . . . . . . . . . . . . . . . . 4

2 PLUMBING MANIFOLD . . . . . . . . . . . . . . . . . . . . 6

3 BOILER CONNECTIONS . . . . . . . . . . . . . . . . . . . 7

Gas and water connections . . . . . . . . . . . . 8

4 fITTING THE DIVERTER VALVE & CODE PLUG 10

Fitting the diverter valve motor: . . . . . . . 10

Access to the code plug . . . . . . . . . . . . . 10

Fitting the code plug . . . . . . . . . . . . . . . . 11

Fitting the cylinder temperature sensor . 11

Diverter valve and sensor connections . . 11

5 ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Internal diverter valve with a vented cylinder . . . . . . . . . . . . . . . . . . . . . 12

Position of wired components . . . . . . . . 14

6 PRE-COMMISSIONING CHECKS . . . . . . . . . . . 15

7 BOILER FUNCTION . . . . . . . . . . . . . . . . . . . . . . 16

Fault finding . . . . . . . . . . . . . . . . . . . . . . 16

Boiler function . . . . . . . . . . . . . . . . . . . . . 17

Protection function . . . . . . . . . . . . . . . . . 18

6 720 645 222a (2012/05)

KEY TO SYMBOLS AND SAFETY PRECAUTIONS

1 KEY TO SYMBOLS AND SAFETY PRECAUTIONS

1.1

EXPLANATION OF SYMBOLS

WARNING SYMBOLS

Safety instructions in this document are framed and identified by a warning triangle which is printed on a grey background.

Electrical hazards are identified by a lightning symbol surrounded by a warning triangle.

Signal words indicate the seriousness of the hazard in terms of the consequences of not following the safety instructions.

•

NOTICE indicates possible damage to property or equipment, but where there is no risk of injury.

•

CAUTION indicates possible injury.

•

WARNING indicates possible severe injury.

•

DANGER indicates possible risk to life.

IMPORTANT INFORMATION

Notes contain important information in cases where there is no risk of personal injury or material losses and are identified by the symbol shown on the left. They are bordered by horizontal lines above and below the text.

ADDITIONAL SYMBOLS

•

Symbol

B

Æ

–

Meaning a step in an action sequence a reference to a related part in the document or to other related documents a list entry a list entry (second level)

Tab. 1 Symbols

SYMBOLS USED IN THIS MANUAL

Domestic Hot Water

Central Heating

Hot Water Storage Cylinder

Domestic Cold Water Supply

Electrical Supply

PLEASE READ THESE INSTRUCTIONS CAREFULLY

BEFORE STARTING INSTALLATION.

THESE INSTRUCTIONS ARE APPLICABLE TO THE

WORCESTER APPLIANCE MODEL(S) STATED ON THE

FRONT COVER OF THIS MANUAL ONLY AND MUST NOT

BE USED WITH ANY OTHER MAKE OR MODEL OF

APPLIANCE.

THE INSTRUCTIONS APPLY IN THE UK ONLY AND MUST

BE FOLLOWED EXCEPT FOR ANY STATUTORY

OBLIGATION.

THIS APPLIANCE MUST BE INSTALLED BY A GAS SAFE

REGISTERED, COMPETENT PERSON. FAILURE TO

INSTALL CORRECTLY COULD LEAD TO PROSECUTION.

IF YOU ARE IN ANY DOUBT CONTACT THE WORCESTER

TECHNICAL HELPLINE.

DISTANCE LEARNING AND TRAINING COURSES ARE

AVAILABLE FROM WORCESTER.

PLEASE LEAVE THESE INSTRUCTIONS WITH THE

COMPLETED BENCHMARK CHECKLIST, (OR A

CERTIFICATE CONFIRMING COMPLIANCE WITH IS 813,

EIRE ONLY) AND THE USER MANUAL WITH THE OWNER

OR AT THE GAS METER AFTER INSTALLATION OR

SERVICING.

THE BENCHMARK CHECKLIST CAN BE FOUND IN THE

BACK PAGES OF THE INSTALLATION MANUAL.

ABBREVIATIONS USED IN THIS MANUAL:

Ø

NG

LPG

CH

DHW

PRV

NTC

Diameter

Natural Gas

Liquid Petroleum Gas

Central Heating

Domestic Hot Water

Pressure Relief Valve

Negative Temperature Coefficient (sensor)

IP

RCD

TRV

WRAS

Ingress Protection

Residual Current Device

Thermostatic Radiator Valve

Water Regulations Advisory Scheme

SEDBUK Seasonal Efficiency of Domestic Boilers in the United Kingdom

Tab. 3 Abbreviations

Gas Supply

Tab. 2 Commonly used symbols

6 720 645 222a (2012/05) 3

KEY TO SYMBOLS AND SAFETY PRECAUTIONS

1.2

SAFETY PRECAUTIONS

IF YOU SMELL GAS:

B CALL NATIONAL GAS EMERGENCY SERVICE ON

0800 111 999

B LPG BOILERS CALL THE SUPPLIER‘S NUMBER ON

THE SIDE OF THE LPG TANK

B TURN OFF THE ECV (EMERGENCY CONTROL VALVE)

AT THE METER

B DO NOT TURN ELECTRICAL SWITCHES ON OR OFF

B DO NOT STRIKE MATCHES OR SMOKE

B PUT OUT NAKED FLAMES

B OPEN DOORS AND WINDOWS

B KEEP PEOPLE AWAY FROM THE AFFECTED AREA

BOILER OPERATION:

This boiler must only be operated by a responsible adult who has been instructed in, understands, and is aware of the boiler‘s operating conditions and effects.

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer's instructions by competent persons and that it meets the requirements of the appropriate Building Regulations.

The Benchmark Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of Practice which is available from the Heating and Hotwater Industry Council who manage and promote the scheme.

Visit centralheating.co.uk for more information.

HEALTH AND SAFETY

The appliance contains no asbestos and no substances have been used in the construction process that contravene the COSHH Regulations (Control of

Substances Hazardous to Health Regulations 1988).

COMBUSTION AND CORROSIVE MATERIALS

Do not store or use any combustible materials (paper, thinners, paints etc.) inside or within the vicinity of the appliance.

Chemically aggressive substances can corrode the appliance and invalidate any warranty.

FITTING AND MODIFICATIONS

Fitting the appliance and any controls to the appliance may only be carried out by a competent engineer in accordance with the current Gas Safety (Installation and

Use) Regulations.

Flue systems must not be modified in any way other than as described in the fitting instructions. Any misuse or unauthorised modifications to the appliance, flue or associated components and systems could invalidate the warranty. The manufacturer accepts no liability arising from any such actions, excluding statutory rights.

SERVICING

Advise the user to have the system serviced annually by a competent, qualified Gas Safe registered engineer.

Approved spares must be used to help maintain the economy, safety and reliability of the appliance.

IMPORTANT

The service engineer must complete the Service Record on the Benchmark Checklist after each service.

INSTALLATION REGULATIONS

Current Gas Safety (Installation & Use) Regulations:

All gas appliances must be installed by a competent person in accordance with the above regulations.

Failure to install appliances correctly could lead to prosecution.

The appliance must be installed in accordance with, and comply to, the current: Gas Safety Regulations, IEE

Regulations, Building Regulations, Building Standards

(Scotland) (Consolidation), Building Regulations

(Northern Ireland), local water by-laws, Health & Safety

Document 635 (The Electricity at Work Regulations

1989) and any other local requirements.

4 6 720 645 222a (2012/05)

British Standards:

Where no specific instruction is given, reference should be made to the relevant British Standard codes of

Practice.

BS7074:1 Code of practice for domestic and hot water supply

BS6891 Installation of low pressure gas pipe work up to 28mm (R1)

BS5546 Installation of gas hot water supplies for domestic purposes

EN12828 Central heating for domestic premises

BS5440:1 Flues and ventilation for gas appliances of rated heating not exceeding 70kW (net) :

Flues

BS5440:2 Flues and ventilation for gas appliances of rated heating not exceeding 70kW (net) : Air

Supply

BS7593 Treatment of water in domestic hot water central heating systems

BS6798 Installation of gas fired boilers of rated input up to 70kW (net)

Irish Standards

The relevant Irish standards should be followed, including:

•

ECTI National rules for electrical installations

•

IS 813:2002 for Domestic Gas Installations.

LPG Installations

An appliance using L.P.G. must not be installed in a room or internal space below ground level unless one side of the building is open to the ground.

Timber framed building:

Where the boiler is to be fitted to a timber framed building the guidelines laid down in BS5440: Part 1 and

IGE "Gas Installations in Timber Frame Buildings” should be adhered to.

Potable water:

All seals, joints and compounds (including flux and solder) and components used as part of the secondary domestic water system must be approved by WRAS.

CH Water:

Artificially softened water must not be used to fill the central heating system.

KEY TO SYMBOLS AND SAFETY PRECAUTIONS

6 720 645 222a (2012/05) 5

PLUMBING MANIFOLD

2 PLUMBING MANIFOLD

CONNECTIONS:

•

Heating System: 22mm compression fittings

•

Gas: 22mm compression fitting

•

Cylinder Return 15mm compression fitting

•

Use the fittings supplied in the Hardware literature pack and the Optional Diverter Valve Kit.

NOTICE: Fitting the service valve

B

B The service valve (7) from the Optional

Diverter Valve Kit must be fitted and secured to the wall mounting frame with two screws (8) supplied, before the wall mounting frame is fitted to the wall.

If the boiler pipes are to be run behind the appliance ensure that the pipes pass through the slot in the guide (9). This is fitted to the boiler frame.

Further guidance on pipe routing can be found printed on the boiler template

(supplied with the boiler).

9

1 2

4 1 2 6 3 5

Fig. 1 Pipe dimensions

6

6

3

8

4

5

1

2 3

6

Fig. 2 Plumbing manifold with wall frame

6720644222-01.1Wo

# Function

1 CH and cylinder flow

2 Gas

3 CH Return

4 Condensate

5 Pressure Relief Valve

6 Cylinder return

From left case edge

70 mm

200 mm

330 mm

35 mm

367 mm

267 mm

Diameter of pipe

22 mm

22 mm

22 mm

22 mm

15 mm

15mm

6 720 645 222a (2012/05)

7

BOILER CONNECTIONS

3 BOILER CONNECTIONS

CAUTION: CYLINDER RETURN PIPE

B The following must be completed before the boiler is mounted onto the wall mounting frame

3.1

ASSEMBLY OF THE INTERNAL CYLINDER RETURN PIPE TO THE BOILER

Use the packaging as protection, turn the boiler on its left hand side to enable fitting of the hot water return pipe.

B Move the control panel into the service position by removing the screw from the retaining bracket.

2. Remove the brass bung assembly from the hydraulic block by removing the screw and sliding it free from the flange on the clamping plate. Make sure that the other brass bung assembly is retained in place.

3. Remove the copper pipe from the Optional Integral Diverter Valve Kit and feed the flat end of the pipe through the rear of the boiler as shown.

4. Before fitting the pipe, check that the seal is in position on the plastic moulding. Slide the flat end of the pipe under the flange on the hydraulic block clamping plate ensuring that pipe is located correctly.

5. Secure the clamping plate by re-tightening the two screws (1) loosened in step 1.

1.

1.

2.

Fig. 3 Hot water return pipe fitting

6 720 645 222a (2012/05)

4.

3.

5.

7

BOILER CONNECTIONS

3.2

GAS AND WATER CONNECTIONS

CAUTION:

B ISOLATE THE MAINS GAS SUPPLY

BEFORE STARTING ANY WORK AND

OBSERVE ALL RELEVANT SAFETY

PRECAUTIONS.

B Remove template and secure the wall mounting frame to the wall with the fittings supplied.

B System pipes may be run vertically upwards behind the boiler or below it.

See Plumbing Manifold Section on page 6.

1. CH and cylinder flow (22mm),

2. Gas inlet (22mm),

3. Cylinder return(15mm),

4. CH return (22mm)

If using the optional filling loop: 7 716 192 281 (not supplied with the boiler) fit it before hanging the boiler on the wall frame.

The bonded washer supplied is for the Gas connection only.

B Fit sealing washers to service valves before hanging boiler.

1.

Fig. 5 PRV connection in the down position

CAUTION: Caps or plastic strip fitted to pipes must be removed before hanging the boiler.

B Hang the boiler on to the wall mounting frame by the two brackets positioned left and right at the top rear of the appliance.

Do not lift the appliance by the air gas manifold. There are two handling holes incorporated into the inner casing left and right in the lower section of the appliance.

1.

2.

3.

4.

6720645222-04.1Wo

Fig. 4 Sealing washers

NOTICE: Before hanging the boiler onto the wall mounting frame ensure that the pressure relief valve connection is in the

DOWN position.

This is located on the right hand side of the wall frame at the rear.

1. Pull the extended tab/lever forward and down until there is no further travel.

6720643895-22.1Wo

Fig. 6 Hanging the boiler

NOTICE: The pressure relief connector must be repositioned after the boiler has been correctly mounted to the wall mounting frame.

8 6 720 645 222a (2012/05)

1. Push the lever on the pressure relief connector UP until the stop on the inside of the handle is over the shoulder of the metal bracket to secure in place.

1.

BOILER CONNECTIONS

2.

1.

Fig. 7 PRV in the up position

B Remove the screw from the control panel retaining bracket and lower the control panel into the service position.

B Make connections to the heating system and cylinder.

Connect the gas supply to the boiler gas cock 22mm compression.

To connect the expansion vessel flexible pipe to the hydraulic manifold situated to the left of the pump:

B Remove and discard the plastic cap from the expansion vessel flexible pipe.

1. Refer to figure 8, release the retaining clip.

2. Remove and discard the orange plastic blanking plug

(2) from the pressure vessel connection at the hydraulic manifold.

6720645222-05.1Wo

Fig. 8 Blanking plug removal

1. Refer to figure 9 and insert the expansion vessel

flexible pipe it to the fitting on the pump.

2. Secure in place with the wire retaining clip.

2.

1.

6720645222-06.1Wo

Fig. 9 Expansion vessel connection

B Connect the pressure relief drain pipe to 15mm compression joint using the compression nut and olive supplied in the literature/hardware pack.

6 720 645 222a (2012/05) 9

FITTING THE DIVERTER VALVE AND CODE PLUG

4 FITTING THE DIVERTER VALVE AND CODE PLUG

4.1

FITTING THE DIVERTER VALVE

MOTOR:

1. Remove the diverter blanking plate by pulling it forwards to free it from its location.

4.2

ACCESS TO THE CODE PLUG

1. Referring to figure 12, unscrew the three screws in

the control panel.

2. Pull off the connections cover.

1.

2.

1.

1.

1.

6720645222-07.1Wo

Fig. 10 Removing Diverter valve blanking plate

1. To fit the diverter valve motor, push the motor into the housing until the motor “clicks” securely into place, ensuring that the actuator arm locates into the middle of the “H” receptor on the motor.

2. Connect the plug of the diverter valve motor harness into the socket on the diverter valve motor.

3. Slide the protective cover over the diverter valve motor.

Fig. 12 Removing the connection cover

B Identify ST18, the code plug and connector.

ST6

ST10 ST8

ST18

ST15

ST17

3.

1.

2.

Fig. 11 Fitting Diverter motor and cover

6720645222-08.1Wo

Fig. 13 Connector locations

NOTICE: RESET THE CONTROL BOARD

Following changes to the wiring of ST15 and

ST8 the control board will need to be reset to recognise the new connection.

To reset the control board:

B Hold the Service mode “Spanner” and the

Eco buttons down for at least five seconds.

10 6 720 645 222a (2012/05)

4.3

FITTING THE CODE PLUG

Boiler size

12kW i System kit

15kW i System kit

18kW i System kit

24kW i System kit

Gas

NG

LPG

NG

LPG

NG

LPG

NG

LPG

Code plug no.

1118

1119

1122

1123

1126

1127

1114

1115

1. Refer to figure 14. Remove the code plug from the

controller, cut the tie securing the plug to the boiler chassis and discard the plug and tie.

2. Fit the code plug from the kit making sure that code plug is secured to the boiler chassis with the new tie.

B Confirm that the number on the code plug corresponds to the boiler type in the table above.

FITTING THE DIVERTER VALVE AND CODE PLUG

NOTICE: Figure 15 applies only to foam

covered open vent cylinders.

1.

6.

2.

3.

5.

4.

2.

1.

ST18

6720645222-10.1Wo

Fig. 14 Fitting new code plug

4.4

FITTING THE CYLINDER

TEMPERATURE SENSOR

Refer to the cylinder installation instructions for the position of the sensor, there may already be a “sensor pocket” available. If no “pocket” is available, for foam insulated cylinders only with no metal jacket, follow the steps below.

1. Mark a rectangular hole of approximately 50 by

100mm approximately one third of the cylinder length from the bottom of the cylinder.

CAUTION: Cut carefully!

B Do not to pierce the wall of cylinder.

B Do not cut any metal insulation jacket.

1. Using a sharp knife, cut through the insulation, remove and retain the piece of insulation.

2. Apply heat conductive paste to the sensor and place the sensor on the cylinder body in the middle of the cut-out.

3. Hold the sensor in position with a piece of aluminium tape.

4. Replace the insulation material.

5. Secure the insulation in place with suitable cloth tape.

6720645222-24.1Wo

Fig. 15 Sensor connection to cylinder

4.5

DIVERTER VALVE AND SENSOR

CONNECTIONS

NOTICE: Do not route low voltage cables alongside mains voltage cables.

This can cause interference on the low voltage cables.

1. Connect the Diverter valve motor harness to the edge connector ST17.

2. Connect the cylinder temperature sensor (1) to the edge connector ST15.

If the ST15 connector and sensor is being used do not connect ST8 as well.

The link is not required.

ST15

ST17

2.

1.

1

6720645222-11.1Wo

Fig. 16 Diverter motor and sensor connections

B Replace the control panel cover.

B Move the control panel to the up position and secure.

6 720 645 222a (2012/05) 11

ELECTRICAL

5 ELECTRICAL

NOTICE:

B Mains supply to the boiler must be through a fused double pole isolator situated adjacent to the appliance. The isolator must have a contact separation of 3mm minimum in both poles. External fuse rating 3A.

B When stripping wires always ensure copper strands do not fall into the control box.

B There should be no external wiring centre.

B A fascia mounted twin channel programmer must be used.

Timers available:

DT20 Twin Channel Programmer (7 716 192 038),

DT10RF Digistat (7 716 192 052),

DT20RF Digistat (7 716 192 054).

5.1

INTERNAL DIVERTER VALVE WITH A VENTED CYLINDER

ACCESS TO ELECTRICAL CONNECTIONS:

Remove boiler casing to access control panel.

1. Unscrew the single screw and lower the control box into the horizontal position.

2. Unscrew the three screws in the control panel and pull off the connections cover.

3. 230V room thermostat with timer 7 716 192 038

(ST10):

B Remove link - L

S

/L

R

B Connect room stat LIVE supply to terminal (L

S

)

B Connect room stat LIVE return to terminal (L

R

)

B Connect room stat NEUTRAL to terminal (N

S

)

Room Thermostat

DT20 Twin Channel

Programmer

Cylinder temperature sensor neutral live switched live

L

R

L

S N S

N

ST10 NOTICE:

B If the timer 7 716 192 052 or 7 716 192

054 is used, the room thermostat is incorporated in the transmitter.

Therefore keep link fitted across L

S

/L

R

.

4. Hot water channel

5. Optional external frost stat connection (ST6):

B Connect frost stat wires to terminal (F

S

) and (F

R

)

6. Diverter valve motor (ST17):

B Connect electrical harness from diverter valve motor to ST17 (see following page).

Fig. 17

230V

MAINS

SUPPLY

N E L

L

6720645222-17.1Wo

12 6 720 645 222a (2012/05)

5.2

INTERNAL DIVERTER VALVE WITH AN UNVENTED CYLINDER

Twin Channel

Programmer

Cylinder temperature sensor

*

DUAL THERMOSTAT

HIGH LIMIT HOT WATER CONTROL

THERMAL CUT-OUT THERMOSTAT

230V

MAINS

SUPPLY

L

E

N brown green/yellow blue

Room Thermostat neutral live switched live

L R L S N

S

N L

6720645222-20.1Wo

OPTIONAL EXTERNAL FROST STAT CONNECTION ST6

Frost Thermostat

ELECTRICAL

FR FS NP LP

ST6

6720643895-43.1Wo

Fig. 18 Frost Thermostat

B Connect frost thermostat cables to terminals F

S

B These are not polarity sensitive.

& F

R

.

CONNECTOR LOCATIONS

ST6

ST10 ST8

ST18

Fig. 19 Electrical connector information

6 720 645 222a (2012/05)

ST15

ST17

13

ELECTRICAL

5.3

POSITION OF WIRED COMPONENTS

FAN

† Fan wiring:

Live = purple

Neutral = brown

SPARK

ELECTRODES

FLOW TEMP.

SENSOR (NTC)

FLAME SENSE

ELECTRODE

OVERHEAT

STAT

GAS

VALVE

SAFETY

SOLENOID

SAFETY

SOLENOID

FLUE

OVERHEAT

STAT

PUMP

DIVERTER

VALVE

MAINS

SUPPLY

Wall plate contacts

(for FX controls)

B B Earth

230V

EXTERNAL

ROOM STAT

WHEN USED

WITH DT20

Neutral Supply

Live Supply

Live Return

CH TEMPERATURE

CONTROL

*

L R L S N S N

ST10

L

Colour sequence †

ST5

SPARK

TRANSFORMER

SI1

Fuse F1, slow

2.5 A, AC 230 V

9V 25V

230V/AC

ST1

PUMP

SUPPLY

EXTERNAL

FROST STAT

(OPTIONAL)

ST4 FR FS

DHW TEMPERATURE

CONTROL (CYLINDER)

NP LP ST6 1

A

F

B

B

4

2

Outside sensor

(FW 100)

ST8

ST17

EMS BUS contacts

(for FX controls)

WORCESTER 24V CONTROLS, PLUG IN POINT

OPTIONS: DT20 OR DT20 RF OR DT10 RF

(under blanking cover on fascia)

ST9

DIAGNOSTIC

INTERFACE

Fuse F3, slow T 0.5 A

SI2

Fuse F2, slow T1 .6 A

SI3

ST18

CODE PLUG

Red

Orange

Blue

Yellow

Green

Black

Blue

Blue

Purple

Purple

Orange

Orange

Green

Red

Red

Cylinder temperature sensor

Fig. 20 Wired components

14 6 720 645 222a (2012/05)

*

PRE WIRED LINK

6720645222-22.1Wo

6 PRE-COMMISSIONING CHECKS

NOTICE: If the boiler is not to be commissioned immediately then:

B after successfully completing all of the checks and any rectification work, close the gas and water valves, shut off the gas supply, electrically isolate the boiler and label appropriately.

1. Check that the service and water pipes are connected to the correct position on the manifold.

–

A - Flow (22mm)

–

B - CH Return (22mm)

–

C - Gas inlet (22mm)

–

D - Cylinder Return (15mm)

2. Check the gas type specified on the identification plate matches that of the gas supply. Turn on the main gas supply, check the gas pipework, connections and rectify any leaks.

3. Check that the condensate pipe has been connected to the syphon.

4. Check pressure relief drain pipe is correctly fitted and securely tightened.

NOTICE:

B NOW RETURN TO THE I SYSTEM

INSTRUCTION MANUAL (FILLING THE

SYSTEM) TO CONTINUE INSTALLATION.

PRE-COMMISSIONING CHECKS

6 720 645 222a (2012/05) 15

BOILER FUNCTION

7 BOILER FUNCTION

7.1

FAULT FINDING

If in the unlikely event the boiler does not give complete satisfaction, before calling for a service engineer, the installer should check the following:-

FOR BOILERS WITH INTEGRAL DIVERTER VALVE AND

CONTROLS

NO CENTRAL HEATING, BUT HOT WATER OK

Remove the room stat wiring from Ls, LR and N from terminal block ST10. Fit a link between Ls and LR, if the

CH now works there is likely to be a problem with the room stat or wiring to it.

NO HOT WATER, BUT CENTRAL HEATING OK

If a cylinder stat is used, remove the cylinder stat wiring from 7 and 9 on the terminal block ST8. Fit link across 7 and 9.

If the HW now functions, there is likely to be a problem with the cylinder stat or wiring to the stat.

FOR ALL BOILERS WITH INTERNAL OR EXTERNAL

CONTROLS

Burner lights then goes out in DHW or CH mode

Does the boiler run normally with the front cover off and then fail when the cover is put back on?

If yes there is likely to be a flue problem - either the air inlet is blocked or the inner flue is leaking flue gases into the air inlet.

BOILER NOISY OR GOING TO OVERHEAT

1. Was the system flushed?

2. Has the pump been bled and the dust cap released.

GENERAL CHECKS

1. Is all the air bled from the gas supply?

2. Is all the air bled from the primary water system?

3. Is there 230v ac across the boiler live and neutral terminals?

(L & N on ST10)

4. Is the polarity correct?

5. Is the incoming gas pressure at least 18mbar with the boiler at maximum output?

16 6 720 645 222a (2012/05)

7.2

BOILER FUNCTION

BOILER FUNCTION

Fig. 21 Boiler function

6 720 645 222a (2012/05) 17

BOILER FUNCTION

7.3

PROTECTION FUNCTION

AUTOMATIC INTERNAL FROST FUNCTION

Internal boiler temperature between

8°C & 5°C

Boiler automatic frost function

(monitors internal boiler primary temperature)

Pump runs

Internal boiler temperature rises above 9°C

Pump switches off after a 3 minute overrun period

Internal boiler temperature below 5°C

Central heating demand is activated

Internal boiler temperature rises above 12°C

Central heating demand switches off

Pump switches off after a 3 minute overrun period

PUMP OVERRUN FUNCTION

End of boiler demand

(central heating or domestic hot water)

Pump runs for 3 minutes to dissipate heat from the boiler into the system

PUMP ANTISEIZE FUNCTION

No central heating demand after a 24hr period

Pump runs 5 seconds every 24hrs from last time pump ran

A central heating demand activated, pump runs normally

6720643895-111.1Wo

Fig. 22 Protection function

18 6 720 645 222a (2012/05)

NOTES

BOILER FUNCTION

6 720 645 222a (2012/05) 19

Worcester, Bosch Group

Cotswold Way, Warndon, Worcester WR4 9SW.

Tel. 0844 892 9900

Worcester, Bosch Group is a brand name of Bosch Thermotechnology Ltd.

worcester-bosch.co.uk

6 720 645 222a (2012/05)

WORCESTER, BOSCH GROUP:

TECHNICAL SUPPORT: 0844 892 3366

APPOINTMENTS:

SPARES:

0844 892 3000

01905 752571

LITERATURE:

TRAINING:

SALES:

0844 892 9800

01905 752526

01905 752640

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement

Table of contents

- 2 Contents

- 3 1 Key to symbols and safety precautions

- 3 1.1 Explanation of symbols

- 3 Warning symbols

- 3 Important information

- 3 Additional symbols

- 3 SYMBOLS USED IN THIS MANUAL

- 3 PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION.

- 4 1.2 Safety precautions

- 6 2 PLUMBING MANIFOLD

- 7 3 bOILER CONNECTIONS

- 7 3.1 Assembly of the internal cylinder return pipe to the boiler

- 8 3.2 Gas and water connections

- 10 4 fITTING THE DIVERTER VALVE AND CODE PLUG

- 10 4.1 Fitting the diverter valve motor:

- 10 4.2 Access to the code plug

- 11 4.3 Fitting the code plug

- 11 4.4 Fitting the cylinder temperature sensor

- 11 4.5 Diverter valve and sensor connections

- 12 5 ELECTRICAL

- 12 5.1 Internal diverter valve with a vented cylinder

- 12 Access to electrical connections:

- 13 5.2 Internal diverter valve with an unvented cylinder

- 13 optional external frost stat connection st6

- 13 Connector locations

- 14 5.3 Position of wired components

- 15 6 PRE-COMMISSIONING CHECKS

- 16 7 BOILER FUNCTION

- 16 7.1 Fault finding

- 16 For boilers with integral diverter valve and controls

- 16 No central heating, but hot water ok

- 16 No hot water, but central heating ok

- 16 For all boilers with internal or external controls

- 16 Boiler noisy or going to overheat

- 16 General checks

- 17 7.2 Boiler function

- 18 7.3 Protection function