- No category

advertisement

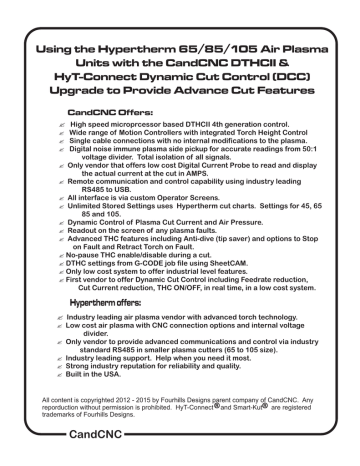

Using the Hypertherm 65/85/105 Air Plasma

Units with the CandCNC DTHCII &

HyT-Connect Dynamic Cut Control (DCC)

Upgrade to Provide Advance Cut Features

CandCNC Offers:

? High speed microprcessor based DTHCII 4th generation control.

?

Wide range of Motion Controllers with integrated Torch Height Control

?

Single cable connections with no internal modifications to the plasma.

?

Digital noise immune plasma side pickup for accurate readings from 50:1 voltage divider. Total isolation of all signals.

?

Only vendor that offers low cost Digital Current Probe to read and display the actual current at the cut in AMPS.

?

Remote communication and control capability using industry leading

RS485 to USB.

?

?

All interface is via custom Operator Screens.

Unlimited Stored Settings uses Hypertherm cut charts. Settings for 45, 65

?

85 and 105.

Dynamic Control of Plasma Cut Current and Air Pressure.

?

?

Readout on the screen of any plasma faults.

Advanced THC features including Anti-dive (tip saver) and options to Stop

?

on Fault and Retract Torch on Fault.

No-pause THC enable/disable during a cut.

?

?

DTHC settings from G-CODE job file using SheetCAM.

Only low cost system to offer industrial level features.

?

First vendor to offer Dynamic Cut Control including Feedrate reduction,

Cut Current reduction, THC ON/OFF, in real time, in a low cost system.

Hypertherm offers:

? Industry leading air plasma vendor with advanced torch technology.

?

Low cost air plasma with CNC connection options and internal voltage divider.

?

Only vendor to provide advanced communications and control via industry

?

standard RS485 in smaller plasma cutters (65 to 105 size).

Industry leading support. Help when you need it most.

?

?

Strong industry reputation for reliability and quality.

Built in the USA.

All content is copyrighted 2012 - 2015 by Fourhills Designs parent company of CandCNC. Any reporduction without permission is prohibited. HyT-Connect and Smart-Kut are registered trademarks of Fourhills Designs.

CandCNC

TABLE of CONTENTS

UPGRADING YOUR Hyperherm Plasma Cutter to DCC using CandCNC DTHCII and new software

I. DCC features and required options Chart

A. BETA release disclaime

B/ DCC Features and Required Options chart

C Hypertherm Part # for DCC Charts

D. Upgrade sequence

II. Updating/Installing MACH3 Software

A. Updating MACH3 software from download or CD.

1. Install warnings

2. Checking Install with earlier working profiles

B. Installing CandCNC drivers and Screens

1. Checking install

2. Confirm operation with earlier working Profiles

C. New Screen functions and DCC controls.

III. Loading and installing SheetCAM TNG Development Version

A. Installing the development version

1. Runs separately from SheetCAM TNG lockdown

2. Checking version numbers

3. Install License

B. Setting up Application Options and Default Directories

C. Installing CandCNC posts and toolsets

1. Setting running POST file

2. Using Toolsets

IV. Using Action Points for DCC and plasma cutting

A. Action Points

1. Defined b. Feedrate changes b. START and END points

1. Code Snips

2. DCC special codes

2. Setting Action Points (AP’s) on a contour a. Action Point Tool b. Adjusting START and END locations c. Moving, editing and deleting AP’s

B. Posting valid G-Code

1. Sample G-Code using MP3000-DTHCII-DCC+scriber scPost

2. Notes about using DCC a. Base level Presets act as Stored Settings b, Dynamic Cut Control during a cut.

1. Suggestions for DCC AP’s

CandCNC

Page

2

PRODUCT DISCLAIMER

BETA RELEASE DISCLAIMERS. PLEASE READ THIS PAGE!

The software covered in this special DCC release

may be BETA level code

. The MACH3 version an updated version and has custom features available only from the CandCNC install. The Action Point Tool and the Development version of the software is a special version of SheetCAM TNG, and is the first release of the AP tool. We have loaded and tested all of the software but only on a limited number of PC’s all running Windows XP and all setup and optimized to run MACH3.

The SheetCAM TNG version should work with later OS versions but we cannot verify that claim. Since SheetCAM TNG Development is installed as a separate application and can co-exist on a PC with the normal SheetCAM TNG it will not alter a running setup if you are using it on WIN7.

AS WITH ALL BETA SOFTWARE

: There may be bugs and changes that impact other operations or the stability of the software. If you encounter what appears to be a bug in the software and it is repeatable, document it and send it to me at: [email protected]

and I will investigate and interface to the appropriate development team.

Fourhills Designs / CandCNC makes no claim of any usability of this release and specifically disclaims ANY liability for ANY lost time. materials or profits from its use. Any disclaimers and warnings from the specific software vendors referred to pass through.

The User should read and understand each vendors disclaimers and that such disclaimers supercede any statements in this document

The use and operation of CNC machinery in general and CNC plasma cutting in specific is dangerous and can cause injury and possible death.

The CNC machine should incorporate sufficient safeties and shields to protect any operator, observers or nearby equipment from damage.

Under no circumstances is Fourhills Designs /CandCNC responsible for any damages or loss of revenue either direct or indirect or damage/injury to any person, structure or contents resulting from the installation or use of any hardware or software provided by us.

Installation and/or use of the software or hardware referred to herein is at the risk of the user and such install and/or use constitutes an acceptance of these terms.

If you are not experienced with CNC plasma cutting or not competent or unable to understand and avoid possible dangerous situations DO NOT INSTALL OR USE

THIS PRODUCT.

CandCNC

Page

3

DCC FEATURES and REQUIRED OPTIONS

OPTION

NUMBER

3

4

1

2

5

6

7

8

9

10

DESCRIPTION

Any plasma cutter.

DTHCII Digital Torch Height Control

DTHCII Digital Torch Height Control with REV 1.4 or higher firmware

Hypertherm model 45/65/85/105 plasma cutter w/CPC port

Hypertherm model 65/85/105 plasma cutter w/CPC and optional RS485 port

MACH3 update version 3.043.067 or laater

SheetCAM update/install to SheetCAM TNG Development

DTHCII screen and drivers update

CandCNC Advanced Connection Kit for Hyperthem 65/85/105

Special SheetCAM version (not yet available)

Part of HyT-Connect Update installer pavkage (CD)

WHAT OPTIONS YOU NEED FOR ADVANCED FEATURES

FEATURE:

DESCRIPTION

REQUIRES::

STORED SETTINGS

(Basic)

Real Time setting of

Preset Volts, Preset

Amps and THC Delay

Cut Current settings to

Hypertherm from

Screen

Preset Volts setting from G-CODE

Preset Volts AND

Preset AMPS setting from G-CODE

No-Pause DTHC

ON/OFF

FULL DYNAMIC CUT

CONTROL (DCC)

Library of stored settings for the DTHCII.

Allows setting of certain stored settings from the main operator screen in MACH instead of

Popup

Allows setting of Cut Current (Torch AMPS) from the screen (while cutting or from a Cut

Profile.)

Allows CAM operator to define certain plasma presets to use at run-time. Preset Volts overrides current Cut Profile settings for

Allows CAM operator to define certain plasma presets to use at run-time. Presets override current Cut Profile settings for DTHCII

Allows CAM operator to define THC ON and

THC OFF commands While cutting with no motion pause. Manual insertion or via G-Code

Allows CAM operator to define ACTION

POINTS in the contour to automatically insert

Feedrate changes, Cut Current Reduction,

DTHC ON/.OFF.

OPTION1

OPTION 2:

OPTION1

OPTION 2

OPTION 7:

OPTION 2

OPTION 5

OPTION 8

OPTION 2

OPTION 6

OPTION 7

OPTION 4

THRU

OPTION 9

OPTION 3

THRU

OPTION 8

OPTION 3

THRU

OPTION 10

CandCNC

Page

4

HYPERTHERM PART #

CROSS REFERENCE

AT THIS TIME: Hypertherm is the ONLY air plasma manufacturer that has seen the opportunity to provide advanced cutting features and remote commination to the smaller 65 to 100 A air plasma market. The HyT-

Connect technology from CandCNC was developed with the assistance of Hypertherm Enginnerig and is exclusive to their machines.

Hypertherm

MODEL #

45

No Torch

With CPC

(CNC) port only

CandCNC Part for interface

088013

With CPC +

RS485 serial

CandCNC Part for interface

N/A

N/A

NOTES

Comes stock with CPC

45

Mechanized

65

No Torch

65

Mechanized

85

No Torch

85

Mechanized

105

No Torch

105

Mechanized

088034

083266

083294

087104

087132

059731

059380

MIC-01 cable

MIC-01 cable

MIC-01 cable

MIC-01 cable

MIC-01 cable

MIC-01 cable

MIC-01 cable

MIC-01 cable

N/A

083267

087105

087105

087139

059732

059386

N/A

Advanced

Connection Kit

Advanced

Connection Kit

Advanced

Connection Kit

Advanced

Connection Kit

RS485 Serial Option not available

CPC & Voltage divider is an option

CPC & Voltage divider is an option

CPC & Voltage divider is an option

CPC & Voltage divider is an option

Advanced

Connection Kit

Advanced

Connection Kit

CPC & Voltage divider is an option

CPC & Voltage divider is an option

CPC-voltage

Divider Kit

RS485 Serial

Interface Kit

228696

228539

MIC-01 cable

Advanced

Connection Kit

These parts are for Hypertherm units that are not ordered from the factory with the listed options.

These kits can be added in the field to the listed models. Model 45 cannot be used with RS485 option.

Mechanized model part numbers shown above are for North America voltages and have the

Duramax full length mechanical torch with 25 ft leads. If you need other configurations please contact you Hypertherm reseller or Hypertherm Tech Support for the appropriate part numbers.

OLDER HYPERTHERM MODELS

None of the Older Models listed have the option to add the RS485 Serial so will not do full DCC control with Dynamic Cut Current

MODEL

600, 900,

1100

CandCNC Interface

HyT-Connect RETRO1

(Universal Connection Kit)

1000, 1250,

1650

HyT-Connect 1000 (Semi

Automated

NOTES

Has all cards and modules for connection to any plasma

Includes cabel for CPC connecter (standard) and voltage divider card

CandCNC

Page

5

Upgrade for HyT-Connect

Plasma System and DCC Option

Make sure the normal Install of your BladeRunner AIO Dragon-Cut or the MP3000-DTHCII has been done and all of the setup and calibration is finished. You should have a fully functional plasma cutting system BEFORE you attempt the upgrade to the HyT-connect DCC Dynamic Cut Control system. The HyT-Connect DCC

INSTALL updates several files and requires a different version of MACH3 provided by CandCNC. You will also need to update your SheetCAM TNG version. There is a separate installer for SheetCAM and you will need to run that on the PC workstation where SheetCAM is installed (not on the MACH3 control computer!)

BEFORE YOU START THE UPGRADES and INSTALLS:

another folder or memory stick

Make SURE you do a complete backup to a

of the ENTIRE MACH3 folder. Rename the Folder so it will not conflict with the

MACH3 folder and you can open and retrieve files if necessary. Keeping backups of your setup(s) is vital to save hours or even days of trying to recover.

INSTALL INSTRUCTIONS FOR UPDATING THE MACH3 PROFRAM to use DCC

CandCNC has updated the version of MACH on the Support CD and Software CD to MACH release 3.043.067. so you MAY NOT NEED TO PREFORM THE UPDATE STEPS 1 - 9 below.

Check your installed version of MAch by opening MACh and using the HELP/ABOUT top menu/

1. NOTE: Install this on the CNC Control computer already running MACH3 and the CandCNC setup.

2. BACKUP your existing MACH3 folder on the C:\ drive to an external storage device

(memory stick?)

3. Make a new folder on the C;\ named MACHUpgrade

4. If you have an older existing version of MACH3 installed Unzip the MACHUpgrade.zip file into that folder. You should have one file: MachVer3.043.067.exe (final two numbers may be higher)

5. Run the update by clicking on the MachVer3.043.067.exe file

6. During the Update do not let it create any profiles

7. During the install be SURE to let it load the Parallel Port Driver

8. Open MACH and run your existing profile and make sure everything is working

9 Close MACH

INSTALLING NEW DCC UPDATE

Create a folder on the C: drive named DCC-Upgrade

2. Unzip the DTHCII-DCC-Update file into the new folder

3. You will have one file in the folder named HyT_DynamicCutControl_Install.exe

4 RUN the HyT_DynamicCutControl_Install.exe to add in the new DCC screens and drivers for MACH

5. Start MACH and use the MACH LOADER to select the DTHCII-HyTConnect Profile

6. You will need to transfer the motor tuning and any other setting that were changed

(like PORT 1 address) from your older Profile

7. The new profile is used with both BladeRunner and MP3000/Plazpak units

8. If you run router profiles you can continue to use the older profile for that operation

CandCNC

Page

6

NOTE: MACH3 REL 3.043.067 is a standard release from MACH and may not display the special labels above

PROGRAM TO RUN Located at: Actions - Results

MACH3 UPDATE version

3.043.067

www.candcnc.com/Downloads

/MACH-Update.zip

OR

On HyT-Connect DCC

Support CD

HyT_DynamicCutControl_Inst all.exe

www.candcnc.com/Downloads

/DTHCII-DCC-Update.zip

OR

On HyT-Connect DCC

Support CD

Unzip and read the

MACHUpdate-Instructions File

Unzip and READ THE

OPENING Instructions FILE during the install. This adds drivers and custom screens for MACH

AFTER YOU RUN THE MACH3 UPDATE

. Start MACH3 and run your prior BladeRunner or MP3000 profile with the new version and make sure everything still works

Check the chart on page 4 To use some of the FEATURES you must have a recent version of the DTHCII

Firmware. The firmware version sticker is on the top of the DTHCII module (inside the BladeRunner AIO or the MP3000DTHCIUI case).

To get updated firmware the module must be returned. We have setup a web based page to allow several return methods at http://www.candCNC.com/DTHCII_Firmware.html

OTHER THINGS TO CONSIDER:

IF YOU HAVE THE HYT-CONNECT RS485 SIM KIT from CandCNC and have installed it using the

HyT_CONNECTRS485_Install.exe (or PN200 version of that installer) and you have connection to your

Hypertherm 65/85.105 than you need not do any other installs other than those above,

IF YOU DO NOT HAVE the RS485 option on your Hypertherm or you DO NOT HAVE the CandCNC HyT-

Connect RS485 SIM OR it is NOT INSTALLED than you will not be able to use

some of the features of DCC

.

If you have a Hypertherm model 65/85 or 105 and want to upgrade it to have full DCC features contact your

Hypertherm reseller/dealer or Hypertherm Support and order the RS485 Interface Kit to update your machine.

Contact CandCNC and order the Advanced Connection Kit for the 65.95.105 OR if you already have the basic connection kit (single cable MIC-01) than order the RS485 SIM module and the DCP-01 Digial Current Probe lower down the page.

CandCNC

Page

7

MACH3 Screen for HyT-Connect

Plasma System and DCC Option

UP/DOWN Preset Volts

Adjust

Buttons. Bumps Preset value UP or DOWN on volt per click. Applied instantly

CURRENT FAULT

Indicates a condition where the actual Cut

Current is higher/lower than the

PRESET AMPS by the percentage set in Current

Tolerance. DCP-01 Digital

Current Probe required .

PRESET AMPS. This is the current you want the plasma to cut at. It sets the point for the

Current Fault. IF you have the

Hypertherm 65/95/105 with

RS485 and HyT-Connect SIM this sets the Cut Current on the plasma cutter

PRESET VOLTS

DRO

. Shows value for Preset (target) torch volts.

Most important parameter.

This is the value the DTHC will attempt to adjust the torch UP or

DOWN to match.

TORCH VOLTS

DRO

Shows actual volts while cutting. Torch

Volts are displayed constantly and may show zero with torch off. This value will vary with the ARC

GAP

This is the DTHC section of the new screen set that is installed with the

HyT_DynamicCutControl Install program

Interaction of PRESET VOLTS and

TORCH VOLTS: During cutting with the THC engaged and DTHC active the TORCH VOLTS should stay within 1 or 3 volts of the PRESET

VOLTS. MACH will adjust the Z based on commands from the

DTHC. ARC VOLTS is proportiaonal to the ARC GAP so moving the torch

UP incresase the voltage whie moving down decreases the voltage

TORCH AMPS

. This is the actual current in AMPS that is flowing in the cut.

DCP-01 must be installed and working

for this to display the acutal cutting current.

DTHC STATUS

when on indicates the DTHC is enabled

(active) DTHC can be disabled from G-Code

DTHC DELAY

Shows when the THC DELAY is active

(tyoically during the pierce

% of PRESET

DRO (no input)

This DRO is only used with the

DCC function and shows the

percentage of reduction

in

CUT CURRENT being used during a DCC cut. See DCC

THC ON.OFF Button

. Turns on/off the THC logic in MACH.

When off MACH ignores commands from DTHC to move the Z.

AUTO button/LED

turns on./off tje AUTO THC ON

TORCH FIRE BUTTON. Manual torch fire. Turns on OUTPUT1 in

MACH and activates the Torch

Relay in the THC SENSOR

PWM MODULE

TIP SAVER LED & ON-OFF

BUTTON.

Tip saver is a dynamic anti-dive that keeps the torch from diving into the work if a sudden voltage change is detected. It senses running across a void and the end of a cut where the torch hits the lead in area.

UP & DOWN LEDS

the UP and DOWN

Show commands coming from the

DTHC as seen by MACH3 at the UP and Down inputs.

ARC OK

Indiactes a valid arc has been sensed Lack of arc when THC is active will stop motion

DTHC ONLINE.

Shows valid communication between MACH3 (PC) and DTHC module.

REQUIRED for DTHC operation

HT ONLINE

Shows valid communication from

MACH3 to Hypertherm

RS485 port

ACTION CODE. Part of new DCC system.

Shows action codes being passed from the running G-Code to

MACH and to the

DTHC to control cut parameters in real time.

SMART-KUT (Auto Laern)

Allows DTHCII to “Learn” the proper PRESET VOLTS for a given cut by measuring the first

2 secs (after the pierce cycle) of a cut and changing the PRESET

VOLTS dynamically. Torch must be setup and cutting properly with the correct touch-off (IHS) and Cut Height set fro Auto

LEGEND: SYMBOLS USED

Inducates a new control feature added.

Indicates a feature needed for Dynamic Cut Control

(DCC)

Some existing controls have

For an interactive help web page go to http://www.candcnc.com/HyT-ConnectScreen-help.html

CandCNC

Page

8

The DCC in conjunction with

SheetCAM can store the

PRESET VOLTS value and loads it when the G-code starts

UP/DOWN Preset Volts

Adjust Buttons. Bumps Preset value UP or DOWN on volt per click. Applied instantly

Tolerance. This action will overide any previous settings either from the Cut Profile or from the DCC G-Code.

MACH3 Screen for HyT-Connect

DCC Specific functions

PRESET VOLTS

DRO

. Shows value for Preset (target) torch volts.

Most important parameter.

This is the value the DTHC will attempt to adjust the torch UP or

DOWN to match.

TORCH VOLTS

DRO

Shows actual volts while cutting. Torch

Volts are displayed constantly and may show zero with torch off. This value will vary with the ARC

This is the DTHC section of the new screen set that is installed with the

HyT_DynamicCutControl

PRESET AMPS. IF you have the Hypertherm 65/85/105 with

RS485 and HyT-Connect SIM this sets the Cut Current on the plasma cutter. The DCC will generate code that sets this value when the code starts

DTHC STATUS

when on indicates the DTHC is enabled

(active) DTHC can be disabled from G-Code

DTHC DELAY

Shows when the THC DELAY is active

(tyoically during the pierce

TORCH AMPS

. This is the actual current in AMPS that is flowing in the cut.

DCP-01 must be installed and working

for this to display the actual cutting current.

% of PRESET DRO (no input)

This DRO is only used with the

DCC function and if you have the Full DCC with active current control of a Hypertherm It shows the percentage of reduction in

CUT CURRENT being used during a DCC cut. The ACTUAL cut current will show in the

TORCH AMPS DRO IF you have the DCP-01 installedand working

THC ON.OFF Button

. Turns on/off the THC logic in MACH.

When off MACH ignores commands from DTHC to move the Z.

AUTO button/LED

turns on./off tje AUTO THC ON function that turns on the THC

Button automatically when the torch is fired. THIS function is different than the new DTHC

ON/OFF from the G-Code. It is

recommended you keep the

THC button on all of the time when using DCC

ACTION CODE.

Shows action codes being passed from the running G-Code to

MACH and to the DTHC to control cut parameters in real time.

See DCC details

About DTHC ON/OFF versus

THC ON/OFF: THC on/off turns the logic for THC in

MACH on or off whereas the

DTHC on/off sends a signal to the DTHCII module to quit sending commands. YOU

MUST have REV1.4 or higher firmware in your DTHCII module.

The Stored Settings (Cut Profile). The Stored settings button opens a popuup window of all the DTHCII settings. There are several, but in most circumstances the default settings are fine. The three most critical settings are: PRESET VOLTS.

PRESET AMPS and DTHC DELAY. (THC Fault delay) These settings will vary based on the material being cut and the plasma settings. The new DCC in conjunction with

SheetCAM TNG outlined in thsi document allows the CAM operator to call out those three settings as part of the Toolset parameters. The three settings are then part of the JOB and do not need to be selected or changed by the machine operator/

For an interactive help web page go to http://www.candcnc.com/HyT-ConnectScreen-help.html

CandCNC

Page

9

What you will do with the SheetCAM TNG upgrade depends on which version of SheetCAM you are currently running. You MUST have a licensed copy of some version of SheetCAM TNG to do the Development install and use it to produce code for DCC plasma.

IF YOU ARE RUNNING SHEETCAM TNG Stable Version than you will need to download the

SheetCAM TNG Development Version and run a full install. You can run both versions on the same computer but the Development version has it’s own environment and folder structure.

PROGRAM TO RUN Located at: Actions - Results

SheetCAM TNG Development version 4.1.14

http://www.sheetcam.com/downloads

.shtml

Or HyT-Connect DCC Support

CD

SheetCAM-updater.exe

www.candcnc.com/Downloads

/SheetCAM-Update.zip

OR

On HyT-Connect DCC

Support CD

Download and Do a base level install unless you already have the development version installed. This goes on the PC used for CAM operations

This adds in custom toolsets and posts for use with DCC

CandCNC

Page

10

SELECTING THE RIGHT POST

PROCESSOR

SHEETCAM TNG (Special Version) showing Post Processor That includes added TOOL parameters to assign Preset Volts and Preset AMPs. NOTE you must be running the

CandCNCDCC version of MACH3 and matching CandCNC Plug-ins for this feature to work. The MP3000-DTHCII-DCC+Scriber.scPOST must be used.

refDistance:

Is the distance in MM you allow of XY motion (total) before doing a Z REF (touch off) default is 500 mm (20 inches)

refFeed.

Sets the Z speed in IPM when doing a REF (touch-off) move

switchOffset.

The overtravel distance of the Z touch off switch. See DTHCII User manual for setup and calibration/

slowRadius:

Sets the arc radius below which the feedrate is lowered. If set to 0 the slowdown function is ignored

slowPercent :

The percentage (in decmial ) the slow Radius will slow the feedrate to (.4 = 40%) for

100 IPM .4 would slow to 40 IPM on the arc section

Disabled if slowRadius = 0

markerZ

Sets travel height during rapids when a Marker Tool is being used.

“true” means lift the Z to full Rapid Height during a rapid. NOT USED with plasma.

CandCNC

Page

4

DCC CUSTOM PARAMETERS for DCC

NOTE: Three new Custom TOOL parameters added using the specified

MP3000-DTHCII-DCC+scriber

POST.

If you do not have the input boxes shown you either do not have the correct SheetCAM version running or you have not selected the correct

POST to generate code in SheetCAM.

for the equipment you have.

Not All of the parameters are added as shown and listed below. The values of

PRESET CURRENT and Preset Air

PRessure only appear if you are using the

MP3000-DTHCII-DCC-

HYT+scriber This post is for users that have the Hypertherm RS485

Option installed and the CandCNC

HyT-Connect RS485 Sim Kit

(included in the Advanced

Connection Kit for the 65/85/105)

DCC Custom Parameters Added via Special POST

KERF WIDTH.

Based on the nozzle orifice you are using. The width of the cut used for calculating offsets for inside or outside type cuts. Actual kerf width can vary based on the feedrate, current setting, air pressure and age of the consumables.

FEEDRATE. The speed in IPM the job will be cut at. This does not set rapid speed and feedrate can vary based on the ability of the machine and the toolpath. Plasma cutting has recommended feedrate values for each type of material and current setting

PIERCE HEIGHT

This is the height above the material the arc is started and and a pierce of the metal is started. On material thicker than 063 (1.5mm) that height is normaly 2X or more the normal Cut Height.

It is done to prevent molten metal form splashing back and fouling the nozzle (tip).

PLUNGE RATE

The speed in IPM you move from Pierce Height to Cut Height. The slower this rate the longer the delay is before the torch reaches proper cutting height and horizontal motion starts.

Excessive delay will cause the starting hole to grow in size and the ARC VOLTS to start to climb. Typical rates are from 1./2 to 3/4 of the Z max velocity as set in motor tuning

PIERCE DELAY.

The amount of time the motion is paused AFTER the torch fires but

BEFORE the plunge to Cut Height. Total delay is a sum of all delays before XY motion has started. Be sure to reduce the pierce delay so the plunge time (from pierce to cut height) is included

TIPSIZE. The AMP rating of the consumable tip (Nozzle). It is stored in the G-Code and just reminds the operator the check for the correct tip. It has no other function.

DTHC DELAY; Sets the total delay time from when the torch fires until the DTHC takes over Z control. Time should allow cut to start and motion to reach full speed.

CandCNC

CUT HEIGHT This is the height the torch moves to begin the cut. Normally the recommend ARC GAP from the plasma manufacturer. Sometimes called Beginning

Cut Height it defines where the torch is above the material when a horizontal cut is

NO DTHC. Overrides ALL DTHC signals for THIS TOOL so the DTHC will be turned off for the entire run of this tool if the value is set to “0”.

Default is 1 so DTHC IS on

PRESET AIR PRESSURE

: Sets air pressure in PSI on Hypertherm’s with

RS485

Pause at End of Cut. Sets the end of cut delay. The time between when theTORCH OFF signal and the Z lift at the end of a cut. Most plasma arcs needs from .2 to .5 seconds to die out

PRESET VOLTS.

Sets the value for

PRESET VOLTS if you are running a

DTHCII system and the DCC drivers.

Overrides a PRESET VOLTS value from the

Cut Profile when code starts. It provides a way to set the parameter at the time the job is defined. If the value is set to 0 the value is ignored.

This value will be picked up in the G-CODE and displayed in the G-Code comments.

PRESET CURRENT .

Sets the value for

PRESET AMPS (Cut Current) if you are running a DTHCII system and the DCC drivers. If you are running a HyT-Connect

RS485 SIM install with a compatible plasma it will automatically set the plasma cut current. If you are using the DCP-01 the

Preset Amps also sets the trip point for a

Current Fault. This set the BEGINNING cut current in the code. That value can be changed during a cut but is the Default value if the override is canceled

Yellow Highlights indicate DCC values.

ORANGE Titles indicate values only available to RS485 equipped Hardware

Page

12

USING NEW SHEETCAM TNG WITH DCC

The following pages will show you how you can use a special version of SheetCAM to take advantage of Dynamic Cut Control. If you have the full DCC set of options (including the

RS485 options with a Hypertherm 65/85/105) than you can do some interesting cut control during a cut. There are two parts of the DCC for SheetCAM. The first is the ability to define PRESETS (same as calling up a CUT PROFILE. The previous page shows the custom parameters added to the tool table (toolset). If your setup will use Preset AMPS than that value can be used to setup the default job Cut Current.

The Preset Volts and

DTHC Delay values will work with any DTHCII based system and the DTHC ON/OFF function will work if you have a DTHCII REV1.4 or higher rev level card.

Setting up a new toolset

?

Open SheetCAM TNG Development and make sure you have applied the license using the Help/Install License File

?

Open OPTIONS/Application Options/Default Directories

? Once you have the Default Directory set for Toolsets (other directories are optional) than you can have access to the custom toolsets we have provided for the Hypertherm

45/85/85/105. You also have toolsets for older 1000, 1250 and 1650 and you can build your own tool tables in SheetCAM (or make chages to ours) and store them under new names.

Since you can now do the major parameter setting for plasma cutting in the G-Code you no longer need to match the CUT PROFILE in MACH to the job.

CandCNC

Page

13

With SheetCAM setup and before you import a drawing (DXF, SVG) to process you should setup the environment. The setup of the Machine Options is essential. The values for Working envelope and Table display is setup for your specific table and covered in the SheeTCAM instructions. The important parameter for the DCC is to select the correct POST PROCESSOR before you start building Operations and using tools. Open the Post processor tab

1

Because this version of SheetCAM is a development version, if you have the standard version of SheetCAM installed you have a different application environment where all of the files are in a folder structure like (not all folders shown);

C:\Program Files

SheetCam TNG Development

Posts

The installer will put the MP3000-DTHCII-DCC+Scriber.scPost in that folder and the list of post processors if you click on button 1 will contatin that POST. Select it and then hit the OK button

CandCNC

Page

14

SETTING A PAIR OF

ACTION POINTS

? Select the Operation you wish to add the Action Popints to in the OPERATIONS list on the lower left of the screen. When you select an operation it will highlight the contours associated with that operation and any custom operations like start points, and Action Points will show. Only one operation can be selected at a time and the other operations wil not show special operations, The Action points DO show on the contours as “X” points .

OPERATIONS WINDOW lower left of screen

This example is not intended to be a tutorial on how to use SheetCAM and how to build

OPERATIONS and assign TOOLS to a LAYER to build an operation. You should already know how to do that,

CandCNC

Page

15

1. To understand how action points work open the TestCut-Basicshapes-APTest.job file in SheetCAM using FILE.Open Job and go to the C:\ SheetCAM-CandCNC\TestFiles

Folder and load that job. You will see a job setup with several basic shapes that we use for test cuts. There are a series of squares and in the job file the outside two sqaures have been put on different named LAYERS and using the Hypertherm 45 Toolset two operations have been defined.

START

POINT

This example is not intended to be a tutorial on how to use SheetCAM and how to build

OPERATIONS and assign TOOLS to a LAYER to build an operation. You should already know how to do that,

CandCNC

Page

16

.

?

Go to the Cursor Menu and select the Action Points arrow cursor.

?

Click on the Contour where you want to set the points the direction (Start and End arrows will show as a hollow (START) and solid (END) arrow.

?

The width of the span from START to END will be the last value used. Do not worry if it is not the right size for what you want.

?

Note the direction of the Action Points will match the cut direction of the contour.

?

Move the Cursor around the contour (you can move around corners or features which is handy) and left click to set the Action Points. If you move you mouse over the

START or END Coursor and pause (no click) you will see a popup selection box like the one below.

The same box pops up regardless if you hover over the START or the END Arrows.

(may change in later releases of the software). Each field in the box is used to set a

Action to happen at that point.

Feedrate

Start Code

End Code

this value sets a

PERCENTAGE of the normal feedrate you have definedfor this OPERATION (slected at the time you build the

OPERATION. This can let you define a slowdown point and will slow the commanded feedrate to that percentage.

The END value for

FEEDRATE ALWAYS returns the feedrate back to the original value

Do not use this to set the feedrate of your whole operation...it is temporary

This allows a “Code Snip “ to be used at that point. We have included a large set of canned codes The button allows a selection of different codes. Using a special code system the DCC can turn the

DTHC on or off and (in the same code), set a

PERCENTAGE of the normal

PRESET AMPS (Cut Current) for the Hypertherm units with the RS485 option.. Other

“actions” can be defined in the toolset. If you change a value via a CODE then it stays that value until you change it back

This allows a “Code Snip “ to be used at that point. It is used to cancel any Start

Code action. The values DO

NOT return to default automatically

EXCEPTIONS: The

Feedrate is always returned to the last running value before the reduction if used.

The DTHC is automatically turned back on at the beginning of the next cut. If you have set the tool to have no DTHC (No DTHC= 0) that

OVERRIDES the automatic re-set of the DTHC

CandCNC

Page

17

? In the toolbar located at the top there are a series of Cursor Tools. A new Cursor Tool has been added to this version and it is highlighted

END

ACTION

POINT

CandCNC

START

ACTION

POINT

THE TWO POINTS

TOGETHER MAKE UP AN

ACTION POINT PAIR

To move/position the START (Hollow) and END (solid)

ACTION POINTS after they are set, simply have the Action

Point Cursor selected and move over an arrow, click and hold the left mouse button and drag the arrow along the contour and release to reset it at the new locations. You can do this with any arrow on the contour if there are multiple

Action Point pairs

If you “hover” over an action point with it unselected for abut 1 sec the Parameters window will popup and you can see the LENGTH of the Span between the points (this number will change if drag the points) and Both the Start Mode and End Mode

Code Snip names. In this example we have define a set of action points and selected a canned code from the Hyperthem-45_Plasma Tools toolset. The code reduces the feedratte at the START arrow to

70% of the normal feetrate for this operation (from

225 IPM to 157 IPM) and leaves the DTHCII active

(ON) and reduces the cut current to 70% of the defined PRESET AMPS. The END Code leaves the

DTHC active and takes the cut current back to

100%

Page

18

Special Notes about the Action Tool:

1. The action tool “remembers” the last settings (Length, Feedrate and

START and End Codes) so when building a cut file if you have several points you want to treat the same way (like corners) you can select the

Action Point Tool, left click along an active contour, drag the action

PAIR, and release and they will have the same settings as the last pair you used. This can let you build a multi-pair operation very quickly. If there are other points you want that are different you can come back and add them in after the repeat points are put down.

2. At this time you can drag a set of Action Points around a START point on a contour and it will perform the END action BEFORE it performs the START Action. This may cause some confusing code.

This is a bug that will be fixed in a later release.

3. You cannot select the lead-in as part of the Action Point area.

4. The Feedrate and Cut Current are REDUCTION percentages so you cannot define values > 100% to INCREASE the base level

Feedrate or Cut Current.

BUILDING CUSTOM CODE SNIPS FOR DCC

We have provided most of what you will need in the toolsets loaded during the install. It is recommended that if you want to build a new toolset you use one of the provided toolsets , edit it and save it off as another name in the same location. That way the existing The CODE Snips can be retained..

To build a CODE SNIP of your own remember the following.

1. It has to be a valid G-code command. IF you don’t know what you are doing in G-Code BE CAREFUL!.

2. The Action Point processes that G-CODE at the exact spot in the toolpath shown on the screen. Some codes can cause the motion to hesitate while that line of code is processed. Calling a MACRO (M code) is an example.

10 - 19.

SPECIAL S Codes used by the DTHCII:

The first digit (1) turns the DTHC off. The second digit

20 - 29

. The first digit (2) turns sets the percentage times 10.

the DTHC ON. The second

Example: S!5 would turn the digit sets the percentage times

DTHC off (stop Z axis UP and

10.

DOWN commands) and set the

Example: S!5 would turn the

Cut Current to 50% of the

DTHC off (stop Z axis UP and normal PRESET AMPS

DOWN commands) and set the

NOTE: The letter “I” in

Cut Current to 50% of the elecronics is “Current “ normal PRESET AMPS measured in AMPS

CandCNC

Continued next page

Page

19

SPECIAL S Codes used by the DTHCII:

310 - 3300. The first digit (3)Indicates this is a volts Preset value. The next 3 digits set the actual value (in volts).

Example: S3117 send 117 volt value to the

PRESET VOLTS DRO and transfer that value to the memory of the DTHCII. This is done using the value defined in the Toolset parameters window for Preset Volts/ This is automatically put at the beginning of the

Code to set the values BEFORE cutting starts. The POST translates the value sent into the correct code. Wile it is possible to send a new Preset value during a cut using this code it is NOT RECOMMENDED since it changes the actual job (tool) preset value and has to be reversed out by changing it back in a code snip that could change with every tool

410 - 4200. (Hypertherm RS485 equipped

models only)The first digit (4)indicates this is a cureent (amps) Preset Value. The next three digits sets the actual value (in AMPS)

Example: S445 would send 45 amps to the

PRESET AMPS DRO. IF you have a Hypertherm plasma cutter with the optional RS485 port and the

CandCNC RS485 SIM Kit that value would be loaded into the Hypertherm automatically. This is put at the beginning of the Code to set the values

BEFORE cutting starts. The POST translates the value sent into the correct code. While this code could be used in a Code snip to send a specific value and cahnge the Cut Current DURING a cut it is nuch better to use the PERCENTAGE reduction in the 10 or 20 type codes.

50 - 520.9

. The first digit (5)Indicates this is a DTHCII Delay (in seconds) value. The next 2 digits plus decimal sets the actual value.

Example: S51.5 sends the value of 1.5

seconds to the DTHCII delay DRO and transfers that value to the memory of the

DTHCII. This is done using the value defined in the Toolset parameters window for DTHC delay-sec This is automatically put at the beginning of the Code to set the values BEFORE cutting starts A value of

ZERO (50) is ignored by the control and it uses the stored Setting from Cut Profiles for the DTHC Delay.

NOTE: a value of 0.5 is

VALID and shows a fractional (½) second.

60 - 699.

Sets the number of volts (in volts) the Preset Volts can be

changed

DURING a cut. This is an

INCREASE that in value to change in the event of a feedrate reduction. Example” a Code Snip with the code S65 would raise the PRESET VALUE by

5 volts. So a PRESET of 117 would raise it to

122. This has the effect of canceling the down motion of going into a feedrate slowdown.

CAUTION: be careful with this tool. Each plasma cutter will behave somewhat different and moving the PRESET VOLTS too far can have ugly consequences. NOTE 699 cancels the command and reverts back to normal PRESET value (in this case 117) Be SURE to cancel and increase on the END point.

70 - 7199 (Hypertherm RS485 equipped models only)

Not currently used at this time. Will be used to provide variable current piercing (ramped current during a pierce cycle)

80 - 8199 (Hypertherm RS485 equipped models only)

Sets the AIR PRESSURE in PSI for cutting.

This setting does nothing on Plasma Cutters that do not support remote setting of air pressure

900

Turns ON the DTHCII signals (typically used to reset the DTHCII to ON after it has been turned off by a 999 code. This is a GLOBAL command meaning it overrides any other DTHC off.

999

Turns OFF the DTHCII signals This is a GLOBAL command meaning it overrides any other DTHC on. Command. It is set in the Tool Table as the

DTHC OFF parameter. It disables the DTHC signals

for that tool

.

It will override a 10 or 20 command as far as the DTHC being turned on/off

CandCNC

Page

20

USING SHEETCAM WITH DCC

TOOLSETS & DCC VALUES

? Once you have the new SheetCAM TNG Development REV 4.1.14 (or higher) loaded and setup and the acces to the new toolsets, use the FILE/Open Toolset menu and find the toolset that matches your plasma. Yopuw will se something similar to the screen below

The screen above is a toolset for a Hypertherm 45 and we have selected the 10Ga Steel setting. Note that the tool definition window shows a range of parameters that are set. Anny value can be changed by the user and if you save the toolset before you close SheetCAM that value will be stored in that toolset for futire use. For DCC the three lower values will allow you to store the DTHC settings for that material.

It is importatn to understand how the DTHCII stores and uses the settings.

1. The DTHCII has numersous settings that can be changed by the user. Most of the settings will remain at the default (like the SPAN VOLTS, ARC OK Value and Min-MAX values for faults.

2. The DTHCII module has it’s pwn processor and memory independent of MACH or the application. The CUT PROFILES show the “Current Settings” (Current meaning the settings in the memory) and that is what the DTHCII uses to cut from. When you make a change it gets loaded inot the DTHCII memory via a SERIAL (COM) which why you MUST have the DTHC ONLINE indicator ON so the DTHCII talks to the PC. The changes canbe made via the cut profile of the specific DRO or buttons on the screen. See your DTHCII

USer Manual for a more in depth explaination.

3. When you load a g-code generated by this version of SheetCAM and the special

MP3000-DTHCII-DCC+Scriber POST included with this version than it will display the

DTHC para,eters as information text in the G-code (Window in MACH Screen).

CandCNC

Page

21

SAMPLE G-CODE using MP3000-DTHCII-DCC+Scriber POST

N0000 (Filename: TestCut-Basicshapes-APTest.txt)

N0010 (Post processor: MP3000-DTHCII-DCC+scriber.scpost)

N0020 (Date: 07/09/2012)

N0030 G20 (Units: Inches)

N0040 F1

N0050 G53 G90 G40

N0060 S10 (DTHC off)

N0070 (Part: TestCut-Basicshapes)

N0080 (Operation # : 1)

N0090 G00 X0.0000 Y0.0000 Z2.2500

N0100 (Tool Name: HT-45 {45 amp} 10ga Steel .135 Tool number: 5 Feedrate: 225)

N0110 (Pierce Height: 0.15 Arc Gap: 0.06)

N0120 (DTHCII Settings: Preset Volts: 117 Preset AMPS: 45)

N0130 S3117 (set volts)

N0140 S445 (set Amps)

N0150 (Default DTCH Delay )

N0160 G00 X4.6304 Y6.9833 Z2.2500

N0170 Z0.1500

N0180 G28.1 Z0.12 F19.685 (Touch-off sequence)

N0190 G92 Z0.0

N0200 G00 Z0.0591

N0210 G92 Z0.0

N0220 G00 Z0.1500

N0230 M03

Note the opening lines of G-code through line N0150 above. The values defined in the ToolSet will show up in the information section. Anything in a pair of () brackets is information and is ignored by the G-Code engine when running. The values indicated will be sent to MACH and to the DTHCII memory through MACH from ablove. You will see the changes happen in the MACH Screen and the matching

DRO’s *i.e. PRESET VOLTS and PRESET AMPS.

NOTE IF YOU DO NOT HAVE THE HYPERTHERM RS485 PORT AND THE

CANDCNC ADVANCED CONNECTION KIT YOU CANNOT SET THE ACTUAL

CUT CURRENT EVEN THOUGH IT WILL CHANGE THE VALUE IN THE CUT

CURRENT (RESET AMPS) ON THE MACH SCREEN,

CandCNC

Page

22

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement