- No category

advertisement

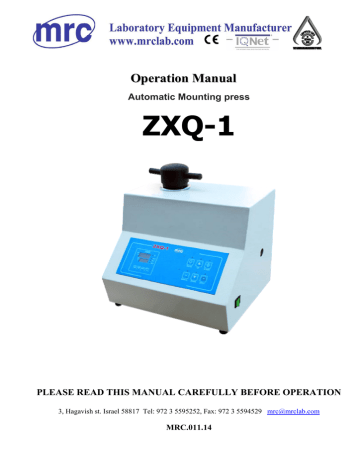

O p e r a t t i i o n M a n u a l l

Automatic Mounting press

ZXQ-1

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATION

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529 [email protected]

MRC.011.14

I The Use

ZXQ-1 Automatic Inlaying Machine is used to inlay small specimens, specimens in irregular shapes, or specimens which are not easy to take up—the preceding process before grinding and polishing metallurgical or rock specimens. The inlaying operation serves to facilitate the grinding and polishing operations of the specimens and the routine observation of the composition of the material under the metallurgical microscope.

The machine is heated, and intensified with pressure automatically. After the formation of the specimen under pressure, it stops the operation and discharges the pressure also in an automatic way. With another press of the knob, the machine automatically turns up the specimen, which may be t aken away. Note: It is only for t he hot solid materials (such as urea‐formaldehyde mould powder and bakelite powder) with the temperature automatically regulated and controlled.

II The Main Data

The Specifications of the Specimen Formed under pressure: Ф22mm,Ф30mm,Ф45mm

The Heater:220V 650W

The Total Electric Power:1000W

The Total Dimension:380×350×420mm

Net Weight:50kg

1

III The General Introduction to the Structure and the

Functions

Main structure sketch map

1 The Frontal Panel Section of the Thermo controller

2 The Data Indicator Section

3 The Date Setting‐Up Indicator Section.

4 Tthe Up‐Shifting Key

5 The Down‐Shifting Key

6 The Multi‐Functional confirmation Key

7 The Output Interface

8 The Indication of the Heating Output

9 The Indication of the Up most Temperature for the Heating Output

Note: For the temperature set‐up and its operation, see the Operation Inscription manual of the thermo controller. In general the clients need not regulate the preset‐up of the temperature as the thermo controller has been already preset‐up for the temperature before it is turned out.

10 The Indication of the Heating of the Mould Cavity

11 The Indication of the Pressure in the Mould Cavity Reaching the parameter set up

12 The Indication of the cooling and the solidification shows that the heating is finished, the

2

pressure is right as required, and the cast is in the awaiting state to be cooled and solidified.

13 After the key (MANUAL) is activated, the indicator lamp over it is lit up , showing the instrument has entered the mode of manual operation.

14 After the key (Auto) is pressed and activated, the indicator lamp over it is lit up, showing the instrument has entered the mode of automatic operation.

The Manual Mode and the Automatic Mode are intershiftable!

15 It should be noticed that one press on the key “DOWN” during the manual operation starts the downward operation while the second press on the downward operation again and still another press would stop the operation again. If it is in the state of upward operation , the last press also cuts off the upward operation mode at the same time while if it is in the automatic mode the pressing of the key would not have any response.

16 The pressing of the key “UP” in the manual operation mode one press lights up the indicator lamp and starts the upward operation; other press stops the upward operation .That

is ,the uneven numbers start the upward operation where as the even numbers stop it.

During the state of the automatic mode, the pressing of the key would not have any response.

17 As for the key “STOP”, during the manual operation mode it serves to stop the heating; during the automatic operation mode the pressing of the key stops the state of the automatic operation and activates the downward operation.

18 As for the bi‐functional key “START”, during the manual operation mode, serves to start the heating operations whereas during the automatic operation mode, with the pressing of the key, the system enters the automatic operation mode with the heating and the pressure enforcing carried out at the same time.

Inscriptions for the Manual operation:

1、 When the instrument is connected with the power source with the main switch on, the relative indicator lamp lights up and the thermo controller indicates the values, showing it is already connected with the mains.

2、 One press on the key ”MANUAL” lights up the indicator lamp for the manual operation mode, showing the instrument is in the manual operation mode at present.

3、 At this point with one press on the key “UP” or on the key “DOWN”, the instrument enters its relative operation mode; another press would stops the relative output. At this time, up

3

and down are inter‐shiftable.

4、 As for the key “START”, the press on the key starts the manual operation of heating while the press on the key “stop” stops the present operation.

Inscriptions for the Automatic Operation:

1、 When the instrument is connected with the power source with the main switch on , the relative indicator lamp lights up and the thermo controller indicates the values, showing it is already connected with the mains.

2、 With one press on the key “AUTO”, the indicator lamp for the automatic operation mode lights up and the instrument enters the ready state of the automatic operation mode.

3、 With one press on the key “START”, the system enters the automatic operation state with the heating and the pressure enforcing carried on at the same time.

4、 When the mould cavity reaches the required pressure, the pressure indicator lamp lights up (green) and the ascending movement stops after a few seconds; When the mould cavity reaches the required temperature, the lamp indicating the connection of the output of AL2 on the barometer lights up while the heating process stops and the heating indicator lamp goes out.

5、 When the pressure and the heating reaches the values set up, the system enters the cooling and solidification state and the cooling indicator lamp light up (yellow).

6、 When the cooling and solidification process is completed, the cooling indicator lamp goes out and the system enters the pressure descending mode, and with the discharge of the pressure completed, withdraws from all the working modes, and enters the safe and energy‐saving state.

7、 The equipment is designed to open the mould with the manual operation; screw open the upper mould cover, press the key “MANUAL”, and then press the key “UP”, the cast is ready to be taken out. When the ascending movement reaches its up most limit, take out the sample cast and whole process is completed.

8、 When the second sample cast is to be made, press down the key “DOWN” in the manual operation mode, and the mould cavity descends automatically until the descending limit when the entire operation makes an automatic stop. At this point, put in the cast powder, insert the specimen and then cover the whole mould, screw it

4

tight , press down the key “AUTO” and then press the key “START”, the system enters the working state for the second time.

Note: In the automatic operation mode, the pressing of the key ”UP” or the key “DOWN” would not have any response; when the automatic operation mode is still on, a try to shift into the manual mode and then return to the automatic one would interrupt the system. At this time , it is necessary to put off the main power source, and then connect the power again in order to restore the normal state of the system.

IV maintenance and safe operation

(1) Do cleaning work in time after using every time; Do not use clean the AMP1 with corrosive liquor. Grease lumen, up‐mould and down‐mould after cleaning to prevent it from rusting.

(2) For not to block or overload and damage, grease transmission shaft, spline sheath, cone gear and moving parts regularly.

Electricity principle diagram:

5

Product Certificate

Produce name: Automatic Inlaying Machine

Model: ZXQ-1

Inspection record:

(1) Manufacture and assemble accord with product drawing request.

(2)The clearance of up‐mould and down‐mould to steel mould sheath is 0.027~0.04mm.

(3) Safe and reliable electric performance, hot‐state insulative resistance>0.5MΩ.

Pressure indicator light lights when pressure reaches setup value.

(4) Good appearance quality.

The product is eligible after inspection.

Inspector:

Supervisor:

Date:

Packing List

Packing serial number: Contract serial number:

Model

ZXQ-1

Product Appendix

Heating apparatus

Liangbei

Bakelite powder

Shake handle technology document

Product title

Automatic Inlaying Machine

Unit piece

Unit piece

Quantity

1 piece 1 g 30 piece 1

1、user’s manual

2、certificate of product

3、intelligent digital temperature control unit user’s manual

Quantity

1

Note

6

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement