Omron MINI Hawk Series Quick Start Guide

Add to my manuals

2 Pages

The Microscan MINI Hawk Imager is a versatile device designed to decode symbols quickly and accurately in various applications. With its compact size and rugged design, it's ideal for space-constrained environments and industrial settings. The imager offers multiple connectivity options, including Ethernet and RS-232/RS-422/RS-485, making it easy to integrate into existing systems. Its ability to read both 1D and 2D barcodes, as well as direct part marks (DPM), makes it suitable for a wide range of applications, including product identification, inventory control, and quality assurance.

advertisement

Quick Start Guide

MINI Hawk Series

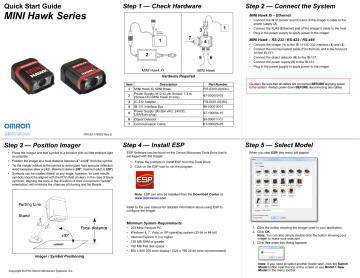

Step 1 — Check Hardware

3

1

1

7

4

2

5 6

MINI Hawk Xi

Hardware Required

MINI Hawk

Item Description

1 MINI Hawk Xi, MINI Hawk

2

Power Supply, M12 12-pin Socket, 1.3 m

(Screw-On) (MINI Hawk Xi only)

3 IC-332 Adapter

4 IB-131 Interface Box

5

Power Supply (90-264 VAC, 24VDC,

USA/Euro plug)

6 Object Detector

7 Communication Cable

Part Number

FIS-63X0-XXXXG

97-000003-03

FIS-0001-0035G

99-000018-01

97-100004-15

99-000017-01

61-300026-03

P/N 83-116302 Rev E

Step 3 — Position Imager

• Place the imager and test symbol in a location with as little ambient light as possible.

• Position the imager at a focal distance between 2” and 6” from the symbol.

• Tip the imager relative to the symbol to avoid glare from specular reflection.

Avoid excessive skew or pitch. Maximum skew is ±30° ; maximum pitch is ±30° ).

• Symbols can be rotated (tilted) at any angle; however, for best results symbols should be aligned with the FOV (field of view). In the case of linear symbols, aligning the bars in the direction of their movement (“ladder” orientation) will minimize the chances of blurring and No Reads.

Step 4 — Install ESP

ESP Software can be found on the Omron Microscan Tools Drive that is packaged with the imager.

1. Follow the prompts to install ESP from the Tools Drive.

2. Click on the ESP icon to run the program.

Note: ESP can also be installed from the Download Center at www.microscan.com

.

Refer to the user manual for detailed information about using ESP to configure the imager.

Minimum System Requirements

• 233 MHz Pentium PC

• Windows 8, 7, Vista, or XP operating system (32-bit or 64-bit)

• Internet Explorer 6.0 or higher

• 128 MB RAM or greater

• 160 MB free disk space

• 800 x 600 256 color display (1024 x 768 32-bit color recommended)

Imager / Symbol Positioning

Copyright © 201 9 Omron Microscan Systems, Inc.

Step 2 — Connect the System

MINI Hawk Xi – Ethernet

• Connect the M12 (power and I/O) end of the imager’s cable to the power supply ( 2 ).

• Connect the RJ45 (Ethernet) end of the imager’s cable to the host.

• Plug in the power supply to apply power to the imager.

MINI Hawk – RS-232 / RS-422 / RS-485

• Connect the imager ( 1 ) to the IB-131/IC-332 interface ( 4 ) and ( 3 ).

• Connect the communication cable ( 7 ) to the host, and to the host port on the IB-131.

• Connect the object detector ( 6 ) to the IB-131.

• Connect the power supply ( 5 ) to the IB-131.

• Plug in the power supply to apply power to the imager.

Caution: Be sure that all cables are connected BEFORE applying power to the system. Always power down BEFORE disconnecting any cables.

Step 5 — Select Model

When you start ESP , this menu will appear:

1. Click the button showing the imager used in your application.

2. Click OK .

Note: You can also simply double-click the button showing your imager to make your selection.

3. Click Yes when this dialog appears:

Note: If you need to select another model later, click the Switch

Model button near the top of the screen or use Model > New

Model in the menu toolbar.

Step 6 — Connect

To connect using the Connection Wizard:

• Click Connect on the menu toolbar, and then select Connection Wizard .

• Select the communication interface required by your application.

• Configure settings as required by the application, and click Connect .

Step 7 — Locate the Symbol

Locate by ESP

• In ’s EZ Mode , click the Locate button to enable the blue target pattern.

The symbol in the field of view will appear in the video view beneath the

Locate and Calibrate buttons, and you will see the blue target pattern projected from the front of the imager.

• Center the target pattern on the symbol.

At 2 to 3 inches, the pattern resembles an X . At 3 to 6 inches, the pattern resembles a V .

Important: The entire symbol should fall within the field of view (FOV) of the imager. The field of view is what appears in ESP ’s Locate/Calibrate window in EZ Mode .

Step 8 — Calibrate

Imager settings can be adjusted automatically for optimum performance by either the EZ Button or by ESP .

During the calibration routine, the imager will flash its Read Rate percent LEDs and illumination LEDs while searching camera settings and determining the best configuration for decoding symbol data. Upon successful completion of this routine, a green LED pattern will flash brightly and illuminate the symbol. If unsuccessful, the imager will emit 5 short beeps and stop searching.

• When a connection is established, the green indicator in the status bar at the bottom right of the screen will be visible:

Important: The imager is in Continuous Read Mode by default. For best connection results, be sure that no decodable symbols are within the imager’s field of view while attempting to connect.

• Click the Stop button to end the Locate function.

Locate by EZ Button

If you are not connected to a host computer, the EZ Button allows you to locate the symbol in the imager’s field of view.

• Hold down the EZ Button for about one second and release when you hear one short beep. The amber 20% LED will illuminate, and you will see the blue target pattern projected from the front of the imager.

• Center the target pattern on the symbol.

Note: To end all EZ Button functions, press the EZ Button once and quickly release.

Step 10 — Configure the Imager in ESP

Click the App Mode button to make configuration changes to the imager.

Step 9 — Test Read Rate

Read Rate indicates the number of successful decodes per second achieved by the imager.

Test Read Rate by EZ Button

1. To start the Read Rate test, hold down the EZ Button about three seconds until you hear three short beeps . The

20% , 40% , and 60% LEDs will illuminate.

While the object is being inspected, the

Read Rate LEDs will indicate the read rate percentage on the back of the unit.

2. To end the Read Rate test, press the

EZ Button and quickly release.

Test Read Rate by ESP

1. Click the Test button to start the Read

Rate test and Stop to end it.

MINI Hawk Read Rate

LEDs and EZ Button

The following modes are accessible by clicking the buttons at the top of the screen:

If a symbol has been successfully decoded, its data and related features will be presented in the field below the image display window. Also, while the object is being inspected, the Read

Rate LEDs will indicate the Read Rate percentage on the back of the unit.

MINI Hawk Xi Read

Rate LEDs and EZ

Button

2. To end the test, click the Stop button.

Note: Read Rate can also be tested using the Read Rate interface in

Utilities .

Test Read Rate by Serial Command

You can also start a test with the <C> or <Cp> command and end it with the

<J> command.

• Click the EZ Mode button to return to EZ Mode.

• Click the Autoconnect button to establish communication.

• Click the Send/Recv button to send or receive commands.

• Click the Switch Model button to open the model menu, or to return to a previous model.

• Click the Parameters button to show the tabbed tree controls for

Communication, Read Cycle, Symbologies, I/O Parameters, Symbol

Quality, Matchcode, and Diagnostics.

• Click the Setup button to access a Camera Setup tree control and Video view, Evaluate image captures, Calibrate the imager, set the Window of

Interest, load capture settings and processing settings in the Configuration

Database, set up output filters and parse symbol data in Ordered Output and Output Format, and control multiple read cycle functions in Dynamic

Setup.

• Click the Terminal button to display decoded symbol data, and to send serial commands to the imager using text or macros.

• Click the Utilities button to test Read Rate, request or clear Counters, enable or disable the imager or send output pulses in Device Control, determine the Differences from Default in the current settings, add or remove master symbol data in Master Database, and verify or update the imager’s Firmware.

Calibrate by EZ Button

1. Hold down the EZ Button for about two seconds and release when you hear two short beeps . The 20% and 40% LEDs will illuminate.

2. The imager will search camera settings to determine the best configuration for decoding symbol data.

Note: To end all EZ Button functions, press the EZ Button once and quickly release.

Calibrate by ESP

1. Click the Calibrate button.

2. The imager will search camera settings to determine the best configuration for decoding symbol data.

A successful calibration will display a green frame around the symbol, and the following message will appear: “Uploading all reader parameters.” After a moment the symbol data will be presented in the field below the image display window.

Calibrate by Serial Command

Send <@CAL> from a terminal program to begin calibration.

Step 11 —Save Changes in ESP

To make changes to a configuration setting:

1.

Left-click on the

+ to expand the desired tree.

2.

Double-click on the desired parameter and click once in the selection box to view options.

3. Place your cursor in the selection box, scroll down to the setting you want to change, and click once on the setting.

4.

Left-click again on the open screen to complete your selection.

5.

Right-click on the open screen and select Save to Reader to implement the command in the imager.

Saving Options

• Send, No Save . Changes will be lost when power is re-applied to the imager.

• Send and Save . This activates all changes in current memory and saves to the imager for power-on.

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement