advertisement

CONDOR

®

CHOPPER CHOCK USER INSTRUCTION MANUAL

STOP! WARNING: READ THIS FIRST!

First Read and Understand the Instruction manual and product labels for important safety, set-up and troubleshooting information. If you have problems setting up or using the Condor® Chopper Chock, contact customer service @

1-815-754-7418 or contact us via e-mail @ www.condor-lift.com

. The Condor® Chopper Chock is not intended for use by children.

Assembly Instructions :

Remove all parts from shipping box. Check the parts below to make sure you have all the parts needed to assemble your Condor® Chopper Chock before beginning.

In the unlikely event that you find a part damaged or missing, please call customer service @ #1-815-754-7418.

Parts Key Description

A 1 Condor® Main Unit

B 1 Condor® Front Base Support Bar

Condor® Maximum Retention Chopper Cradle

C 1

(CHCKCRAD-90, CHCKCRAD-120)

(P-94254)

E 1

Condor® Boomerang Rear Support Bar

(SC-VSTRIP-C)

(Z118)

3/8" x 10" Cradle Pin w/ Hitch Pin Clip 16

G 1

(Z101)

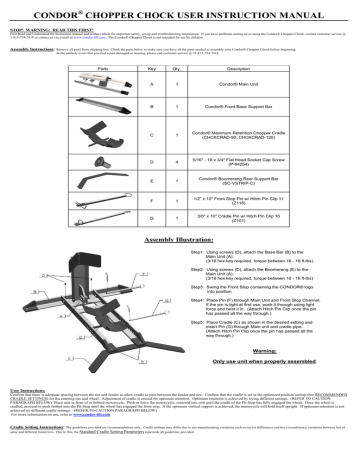

Assembly Illustration:

Step1: Using screws (D), attach the Base Bar (B) to the

Main Unit (A).

(3/16 hex key required, torque between 16 - 18 ft-lbs)

Step2: Using screws (D), attach the Boomerang (E) to the

Main Unit (A).

(3/16 hex key required, torque between 16 - 18 ft-lbs)

Step3: Swing the Front Stop containing the CONDOR® logo

into position

Step4: Place Pin (F) through Main Unit and Front Stop Channel.

If the pin is tight at first use, push it through using light

force and twist it in. (Attach Hitch Pin Clip once the pin

has passed all the way through.)

Step5: Place Cradle (C) as shown in the desired setting and

insert Pin (G) through Main unit and cradle pipe.

(Attach Hitch Pin Clip once the pin has passed all the

way through.)

Warning:

Only use unit when properly assembled

.

User Instructions:

Confirm that there is adequate spacing between the tire and fender to allow cradle to pass between the fender and tire. Confirm that the cradle is set in the optimized position setting (See RECOMMENDED

CRADLE SETTINGS) for the entering tire and wheel. Adjustment of cradle is crucial for optimum retention. Optimum retention is achieved by trying different settings. (REFER TO CAUTION

PARAGRAPH BELOW): Place unit in front of or behind motorcycle. Push or drive the motorcycle, centered into unit until the cradle of the Pit-Stop has fully engaged the wheel. Once the wheel is cradled, proceed to push further into the Pit-Stop until the wheel has engaged the front stop. If the optimum vertical support is achieved, the motorcycle will hold itself upright. If optimum retention is not achieved try different cradle settings. (REFER TO CAUTION PARAGRAPH BELOW)

For more information on use, refer to www.condor-lift.com

Cradle Setting Instructions :

The guidelines provided are recommendations only. Cradle settings may differ due to tire manufacturing variations such as tire lot differences and tire circumference variations between lots of same and different brand tires. Due to this, the Standard Cradle Setting Parameters supersede all guidelines provided.

Standard Cradle Setting Parameters :

**The optimum setting for a specific tire would be the setting that allows the cradle to tilt as far forward as possible

without making contact with the unit’s mounting surface, or the ground.**

The Condor® Cradle Mechanism is designed so that for every tire/wheel size within the ranges specified a minimum of 2 cradle settings are suitable.

The 2 nd

optimum setting would be the setting forward from the optimum setting which is away from the entry directions of the unit. If less retention is desired at any time due to too much sticking, the 2 nd may be more suitable. Racing tire settings for GP or low durometer tire compounds would be the 5 th

and 6 th

. This allows for the least amount of sticking when using the CHCK-1500 free standing.

optimum setting

For bikes with very low fenders and or cowlings, a custom cradle may be purchased fitted to a specific tire size, so as not to make contact.

Cradle Setting Guidelines :

Due to the numerous tire wheel combinations available, these guidelines will provide in a general manner the placements of the most common sizes seen on the market. These setting are recommended guidelines, they are not specific guidelines. The Standard Cradle Setting Parameters should be followed to customize the setting for your particular vehicle.

Front / Rear

FRONT

FRONT

Width‐Diameter

80, 90 ‐ 21"

100, 120 ‐ 21"

1st Opt. Setting

1

1

2nd Opt. Setting

2

2

Optimized Setting

FRONT

FRONT

FRONT

FRONT

FRONT

100 ‐ 18"

100 ‐ 19"

120 ‐ 17"

130 ‐ 16"

140 ‐ 17"

2

2

3,4

2

1

3

3

5

3

2

SEE "STANDARD CRADLE SETTING

PARAMETERS"

FRONT

REAR

FRONT

150 ‐ 17"

150+

21" +

1

1

A,B,C**

2

1

A,B,C**

**For Tire Diameters larger than 21", apply "STANDARD CRADLE SETTING PARAMETERS" guidelines to determine setting in A,B,C.

Chopper Chock (CHCK-1500) Side View & Hole Placement Illustration

(Note: Units with additional holes A/B/C should use these holes only fortire sizes 22” and larger.)

CAUTION:

Always make sure that all fasteners are tight and all pins are in place prior to use. Understand the limitations of this product and do not exceed these limitations. Always make sure that the unit’s cradle settings are optimum for the tire size of the motorcycle before use. For standard sport bike front wheel combinations, the 1, 2, 3, front settings may be suitable. If instructions are not clear, additional information is available at www.condor-lift.com

or call 1-800-461-1344. Technical Components Development & Design is not responsible for any damage incurred by exceeding this product’s limitations in structure and/or functionality.

One Year Limited Warranty:

This Condor® Chopper Chock product warranty extends to the original consumer purchaser of the product. All illustrations and specifications contained in this manual are based on the latest product information available at the time of printing. Technical Components Development & Design, Inc. reserves the right to make changes at any time, without notice, in color, materials, equipment, options, specifications and models. Models may be shown with optional equipment. Further information may be obtained by contacting Technical Components Development & Design, Inc. @ #1-815-754-7418.

Warranty Duration:

This product is warranted to the original consumer purchase for a period of one (1) year from original purchase date.

What is not covered:

Our warranty for your product will not cover abnormal wear of parts, damage resulting from negligent use or misuse of the product, use contrary to operating instructions, or disassembly, repair or alteration by any person other than an authorized service station. We shall not be liable for any incidental or consequential damages for breach of by express or implied warranty on your product.

Return Policy:

15 day return policy applies. Merchandise may be returned within 15 days of purchase. Merchandise must be unused and in its original packaging. Customer will call TC Development for a Return

Authorization number. Customer pays for freight return. Credit is given upon inspection of returned goods. A 15% re-stocking fee applies to all returned merchandise.

How your state’s law may apply:

Some states do not allow limitations on how long any implied warranty lasts or the exclusion or limitation of incidental or consequential damages. So the above limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which may vary from state to state.

Thank you for purchasing the Condor Chopper Chock.

Patent Number: RE 42,735

Condor®

is a trademark of Technical Components Development & Design, Inc.

The Condor Chopper Chock is US Patented & International Patent Pending.

210 W. Stephenie Drive

Cortland, IL 60112

Phone: (815) 754-7418

Fax: (815) 754-7419

Web Site: www.condor-lift.com

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project