advertisement

Freescale Semiconductor

Technical Data

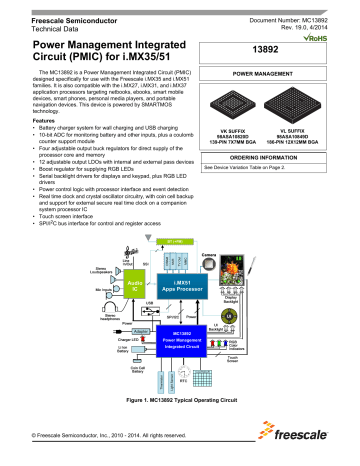

Power Management Integrated

Circuit (PMIC) for i.MX35/51

The MC13892 is a Power Management Integrated Circuit (PMIC) designed specifically for use with the Freescale i.MX35 and i.MX51 families. It is also compatible with the i.MX27, i.MX31, and i.MX37 application processors targeting netbooks, ebooks, smart mobile devices, smart phones, personal media players, and portable navigation devices. This device is powered by SMARTMOS technology.

Features

• Battery charger system for wall charging and USB charging

• 10-bit ADC for monitoring battery and other inputs, plus a coulomb counter support module

• Four adjustable output buck regulators for direct supply of the processor core and memory

• 12 adjustable output LDOs with internal and external pass devices

• Boost regulator for supplying RGB LEDs

• Serial backlight drivers for displays and keypad, plus RGB LED drivers

• Power control logic with processor interface and event detection

• Real time clock and crystal oscillator circuitry, with coin cell backup and support for external secure real time clock on a companion system processor IC

• Touch screen interface

• SPI/I

2

C bus interface for control and register access

Document Number: MC13892

Rev. 19.0, 4/2014

13892

POWER MANAGEMENT

VK SUFFIX

98ASA10820D

139-PIN 7X7MM BGA

VL SUFFIX

98ASA10849D

186-PIN 12X12MM BGA

ORDERING INFORMATION

See Device Variation Table on Page 2.

Stereo

Loudspeakers

Line

In/Out

Audio

IC

Stereo headphones

Li Ion

Battery

Coin Cell

Battery

MC13892

Power Mgmt &

AP

Aud& Pwr Mgmt

UI

Backlight

RGB

Color

Indicators

Touch

Screen

Figure 1. MC13892 Typical Operating Circuit

© Freescale Semiconductor, Inc., 2010 - 2014. All rights reserved.

DEVICE VARIATIONS

DEVICE VARIATIONS

Table 1. MC13892 Device Variations

Part Number

Notes Package

Temperature

Range (T

A

)

Pin Map Description

MC13892CJVK

MC13892AJVK

MC13892DJVK

MC13892BJVK

MC13892VK

MC13892JVK

MC13892CJVL

MC13892AJVL

MC13892DJVL

MC13892BJVL

MC13892VL

MC13892JVL

139-PIN

7x7 mm BGA

186-PIN

12x12 mm BGA

-40 to +85 °C

Global Reset Function Default ON

Global Reset Function Default OFF

No Global Reset Function

Global Reset Function Default ON

Global Reset Function Default OFF

No Global Reset Function

Notes

1.

For Tape and Reel product, add an “R2” suffix to the part number.

2.

Recommended for all new designs

3.

Not recommended for new designs

4.

Backward compatible replacement part for MC13892VK, MC13892JVK, MC13892VL, MC13892JVL, MC13892BJVK, and

MC13892BJVL

MC13892

2

Analog Integrated Circuit Device Data

Freescale Semiconductor

INTERNAL BLOCK DIAGRAM

INTERNAL BLOCK DIAGRAM

GNDADC

ADIN5

ADIN6

ADIN7

TSX1

TSX2

TSY1

TSY2

TSREF

ADTRIG

BATTISNSCC

CFP

CFM

Battery Interface &

Protection

Charger Interface and Control:

4 bit DAC, Clamp, Protection,

Trickle Generation

LICELL, UID, Die Temp, GPO4

Voltage /

Current

Sensing &

Translation

Touch

Screen

Interface

BATT

MUX

Coulomb

Counter

10 Bit GP

ADC

Trigger

Handling

CCOUT

To SPI

A/D Result

A/D

Control

SPIVCC

CS

CLK

MOSI

MISO

GNDSPI

VCORE

VCOREDIG

REFCORE

GNDCORE

UID

UVBUS

VBUSEN

VINUSB

VUSB

OTG

5V

VUSB

Regulator

LICELL

BP

Li Cell

Charger

SPI

Interface

+

Muxed

I2C

Optional

Interface

Reference

Generation

Backlight

LED Drive

Die Temp &

Thermal Warning

Detection

To Interrupt

Section

Tri-Color

LED Drive

SW1

1050 mA

Buck

SW2

800 mA

Buck

SW3

800 mA

Buck

SW4

800 mA

Buck

DVS

CONTROL

VBUS/ID

Detectors

LCELL

Switch

Package Pin Legend

MC13892

IC

Output Pin

Input Pin

Bi-directional Pin

SWBST

300 mA

Boost

Shift Register

SPI

Registers

Shift Register

32 KHz

Internal

Osc

32 KHz

Crystal

Osc

To Enables & Control

MC13892

SPI

Control

Logic

Trim-In-Package

PUMS

Startup

Sequencer

Decode

Trim?

To

Trimmed

Circuits

Control

Logic

SPI Result

Registers

Interrupt

Inputs

Enables &

Control

Core Control Logic, Timers, & Interrupts

PLL

Monitor

Timer

RTC +

Calibration

32 KHz

Buffers

Switchers

Best of

Supply

VSRTC

SPI Control

VVIDEO

VUSB2

VAUDIO

VIOHI

VPLL

VDIG

VCAM

VSD

VGEN1

VGEN2

VGEN3

GPO

Control

PWR Gate

Drive & Chg

Pump

PWGTDRV1

PWGTDRV2

O/P

Drive

O/P

Drive

O/P

Drive

O/P

Drive

SW1IN

SW1OUT

GNDSW1

SW1FB

SW2IN

SW2OUT

GNDSW2

SW2FB

SW3IN

SW3OUT

GNDSW3

SW3FB

SW4IN

SW4OUT

GNDSW4

SW4FB

DVS1

DVS2

O/P

Drive

SWBSTIN

SWBSTOUT

SWBSTFB

GNDSWBST

GNDREG1

GNDREG2

GNDREG3

Pass

FET

Pass

FET

Pass

FET

Pass

FET

Pass

FET

Pass

FET

Pass

FET

VCAM

VSDDRV

VSD

VGEN1DRV

VGEN1

VGEN2DRV

VGEN2

VINGEN3DRV

VGEN3

VVIDEODRV

VVIDEO

VINUSB2

VUSB2

VINAUDIO

VAUDIO

VINIOHI

VIOHI

VINPLL

VPLL

VINDIG

VDIG

VINCAMDRV

Figure 2. MC13892 Simplified Internal Block Diagram

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

3

PIN CONNECTIONS

PIN CONNECTIONS

1 2 3 4 5 6 7 8 9 10 11 12 13

A VUSB2 VUSB2 VINUSB2 SWBSTIN GNDSWBST GNDBL NC MODE VCORE BATT CHRGRAW CHRGCTRL2 CHRGCTRL2

B VUSB2 GPO1 DVS2 SWBSTOUT LEDB LEDKP LEDR GNDCORE VCOREDIG BP CHRGCTRL1 BATTISNSCC CHRGCTRL2

C VINPLL VSDDRV

D VUSB VSD SWBSTFB LEDMD DVS1 REFCORE CHRGSE1B LICELL BATTFET

CHRGISNS BATTISNS

BPSNS PWRON1

E

F

G

UVBUS VPLL

GNDSW3 VBUSEN

SW3OUT VINUSB

LEDG GNDLED UID PUMS2 GNDCHRG CHRGLED PWRON2 ADTRIG INT GNDSW1

SW3FB LEDAD GNDSUB GNDSUB GNDSUB GPO3 GPO2 RESETBMCU RESETB SW1OUT

SW4FB GNDREG2 GNDSUB GNDSUB GNDSUB PUMS1 WDI GPO4 SW1IN

H

J

SW3IN

SW4IN

MISO

MOSI

GNDSPI GNDREG3

CLK32KMCU STANDBY

GNDSUB GNDSUB GNDSUB

GNDADC GNDREG1 PWRON3

GNDCTRL

TSX1

SW1FB

SW2FB

STANDBYSEC SW2IN

TSX2 SW2OUT

VVIDEODRV GNDSW2 K SW4OUT SPIVCC

L GNDSW4 CS

PWGTDRV1 CLK32K VCAM CFP CFM ADIN5 ADIN6

TSY2 VVIDEO

M VGEN3 CLK VGEN2 VSRTC GNDRTC VINCAMDRV PWGTDRV2 VDIG VINDIG VGEN1DRV ADIN7 TSY1 TSREF

N VGEN3 VGEN3 VINGEN3DRV VGEN2DRV XTAL2 XTAL1 VINAUDIO VAUDIO VIOHI VINIOHI VGEN1 TSREF TSREF

Regulators

Switchers

Backlights

Control Logic

Charger

RTC

Grounds

USB

ADC

SPI/I2C

No Connect

Figure 3. MC13892VK Pin Connections

MC13892

4

Analog Integrated Circuit Device Data

Freescale Semiconductor

PIN CONNECTIONS

1 2 3 4 5 6 7

VUSB2 VINUSB2 SWBSTOUT SWBSTIN GNDSUB NC A

B VSDDRV GPO1 GNDSUB GNDSUB LEDR UID

8 9

MODE VCORE

10 11

DVS1 REFCORE GNDCORE CHRGSE1B BP

12 13

BATT CHRGRAW CHRGCTRL2 CHRGISNS

14

GNDCHRG BATTISNSCC BATTISNS

C

D

VSD DVS2 SWBSTFB LEDB LEDG LEDKP LEDAD PUMS2 VCOREDIG LICELL BATTFET BPSNS GPO3 PUMS1

VUSB VPLL GNDSUB GNDSUB GNDSWBST GNDLED LEDMD GNDBL CHRGCTRL1 CHRGLED PWRON1 PWRON3 ADTRIG GPO4

UVBUS GNDREG2 VINPLL GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB PWRON2 GPO2 INT RESETBMCU E

F SW3OUT VBUSEN VINUSB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDCTRL WDI RESETB SW1OUT

G GNDSW3 GNDSW3 SW3FB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB SW1FB GNDSW1 GNDSW1

H SW3IN SW3IN GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB SW1IN SW1IN

J

K

SW4IN SW4IN SW4FB

GNDSW4 GNDSW4 SPIVCC GNDSUB

GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB

GNDSUB GNDSUB GNDSUB GNDSUB GNDSUB

SW2FB SW2IN SW2IN

VVIDEODRV GNDSW2 GNDSW2

L SW4OUT CS GNDSPI GNDSUB GNDSUB GNDSUB VCAM VINAUDIO VDIG GNDSUB TSY2 STANDBYSEC VVIDEO SW2OUT

M

N

P

CLK VINGEN3DRV CLK32KMCU CLK32K VSRTC STANDBY VINCAMDRV CFP CFM VGEN1DRV VGEN1 TSX1 TSX2 TSY1

VGEN3 MOSI VGEN2 GNDREG3 XTAL2 XTAL1 VAUDIO PWGTDRV2 VIOHI VINIOHI GNDADC ADIN5 ADIN7 TSREF

MISO PWGTDRV1 VGEN2DRV GNDSUB GNDRTC GNDSUB GNDSUB GNDSUB GNDSUB VINDIG GNDREG1 ADIN6

Figure 4. MC13892VL Pin Connections

RTC

Grounds

USB

ADC

SPI/I2C

No Connect

Regulators

Switchers

Backlights

Control Logic

Charger

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

5

PIN CONNECTIONS

Table 2. MC13892 Pin Definitions

A functional description of each pin can be found in the Functional Description

.

Pin Number on the

13982VK

7x7 mm

Pin Number on the 13982VL

12x12 mm

Pin Name

Rating

(V)

Pin Function Formal Name

A1, A2, B1

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12, A13, B13

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

C1

C2

C12

C13

D5

D8

A7

A8

A2

A3

A5

A9

A10

A11

A12

B2

C2

A4

C4

C6

B5

B9

C9

B11

D9

B13

E3

B1

A13

B14

VUSB2

VINUSB2

SWBSTIN

GNDSWBST

GNDBL

NC

MODE

VCORE

BATT

CHRGRAW

CHRGCTRL2

GPO1

DVS2

SWBSTOUT

LEDB

LEDKP

LEDR

GNDCORE

VCOREDIG

BP

CHRGCTRL1

BATTISNSCC

VINPLL

VSDDRV

CHRGISNS

BATTISNS

–

–

–

9.0

3.6

5.5

5.5

3.6

5.5

20

5.5

3.6

3.6

7.5

7.5

5.5

20

4.8

5.5

5.5

4.8

4.8

28

7.5

–

1.5

Output

Power

Power

Ground

Ground

–

Input

Output

Input

I/O

Output

Output

Input

Power

Input

Input

Input

Ground

Output

Power

Output

Input

Power

Output

Input

Input

Definition

USB 2 Supply

Output regulator for USB PHY

USB 2 Supply Input

Input regulator VUSB2

Switcher Boost Power

Input

Switcher BST input

Switcher Boost Ground Ground for switcher BST

Backlight LED Ground Ground for serial LED drive

No Connect

Do not connect

Mode Configuration

USB LBP mode, normal mode, test mode selection,& anti-fuse bias

Core Supply

Regulated supply output for the IC analog core circuitry

Battery Connection

1. Battery positive pin

2. Battery current sensing point 2

3. Battery supply voltage sense

Charger Input

1. Charger input

2. Output to battery supplied accesories

Charger Control 2

General Purpose

Output 1

Driver output for charger path FETs M2

General purpose output 1

Dynamic Voltage

Scaling Control 2

Switcher 2 DVS input pin

Switcher Boost Output Switcher BST BP supply

LED Driver

General purpose LED current sink driver

Blue

LED Driver

Keypad lighting LED current sink driver

LED Driver

General purpose LED current sink driver Red

Core Ground

Ground for the IC core circuitry

Digital Core Supply

Regulated supply output for the IC digital core circuitry

Battery Plus

1. Application supply point

2. Input supply to the IC core circuitry

3. Application supply voltage sense

Charger Control 1

Driver output for charger path FETs M1

Battery Current Sense Accumulated current counter current sensing point

PLL Supply Input

VSD Driver

Input regulator processor PLL

Drive output regulated SD card

Charger Current Sense Charge current sensing point 1

Battery Current Sense Battery current sensing point 1

MC13892

6

Analog Integrated Circuit Device Data

Freescale Semiconductor

PIN CONNECTIONS

Table 2. MC13892 Pin Definitions (continued)

A functional description of each pin can be found in the Functional Description .

Pin Number on the

13982VK

7x7 mm

Pin Number on the 13982VL

12x12 mm

Pin Name

Rating

(V)

Pin Function Formal Name

D1

D2

D4

D5

D6

D7

D8

D9

D10

D12

D13

E1

E2

E4

E12

E13

F1

F2

E8

E9

E10

E11

F4

F5

E5

E6

E7

F6

D1

C1

C3

D7

B7

C11

C12

D11

E1

D2

C5

D6

B6

C8

B8

B10

C10

B12

D10

E11

D13

E13

G13, G14

G1, G2

F2

G3

C7

A6, B3, B4, D3,

D4, E4, E5, E6

VUSB

VSD

SWBSTFB

LEDMD

DVS1

REFCORE

CHRGSE1B

LICELL

BATTFET

BPSNS

PWRON1

UVBUS

VPLL

LEDG

GNDLED

UID

PUMS2

GNDCHRG

CHRGLED

PWRON2

ADTRIG

INT

GNDSW1

GNDSW3

VBUSEN

SW3FB

LEDAD

GNDSUB1

28

3.6

3.6

3.6

3.6

4.8

4.8

3.6

20

3.6

7.5

3.6

–

–

3.6

–

20

3.6

3.6

3.6

28

3.6

3.6

3.6

–

5.5

3.6

–

Output

Output

Input

Input

Input

Output

Input

I/O

Output

Input

Input

I/O

Output

Input

Ground

Input

Input

Ground

Output

Input

Input

Output

Ground

Ground

Input

Input

Input

Ground

Definition

USB Supply

SD Card Supply

USB transceiver regulator output

Output regulator SD card

Switcher Boost

Feedback

LED Driver

Switcher BST feedback

Main display backlight LED current sink driver

Dynamic Voltage

Scaling Control 1

Switcher 1DVS input pin

Core Reference

Main bandgap reference

Charger Select

Charger forced SE1 detection input

Coin Cell Connection

1. Coin cell supply input

2. Coin cell charger output

Battery FET

Connection

Driver output for battery path FET M3

Battery Plus Sense

1. BP sense point

2. Charge current sensing point 2

Power On 1

USB Bus

Power on/off button connection 1

1. USB transceiver cable interface

2. VBUS & OTG supply output

Voltage Supply for PLL Output regulator processor PLL

PWM Driver for Green

LED

General purpose LED current sink driver

Green

LED Ground

Ground for LED drivers

USB ID

Charger Ground

USB OTG transceiver cable ID

Power Up Mode Select

2

Power up mode supply setting 2

Ground for charger interface

Charger LED

Trickle LED driver output 1

Power On 2

Power on/off button connection 2

ADC Trigger

ADC trigger input

Interrupt Signal

Interrupt to processor

Switcher 1 Ground

Ground for switcher 1

Switcher 3 Ground

Ground for switcher 3

VBUS Enable

External VBUS enable pin for OTG supply

Switcher 3 Feedback

Switcher 3 feedback

Auxiliary Display LED Auxiliary display backlight LED sinking current driver

Ground 1

Non critical signal ground and thermal heat sink

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

7

PIN CONNECTIONS

Table 2. MC13892 Pin Definitions (continued)

A functional description of each pin can be found in the Functional Description .

Pin Number on the

13982VK

7x7 mm

Pin Number on the 13982VL

12x12 mm

Pin Name

Rating

(V)

Pin Function Formal Name

F7 GNDSUB2 – Ground Ground 2

F8

F9

E7, E8, E9, E10,

F4, F5, F6

F7, F8, F9, F10,

G4, G5, G6, G7,

G8

C13

GNDSUB3

GPO3

–

–

Ground

Output

Ground 3

F10

G4

G5

G6

F11

F12

F13

G1

G2

G7

G8

G9

E12

E14

F13

F14

F1

F3

J3

E2

G9, G10, G11,

H3, H5, H6, H7,

H8

H9, H10, H12,

J5, J6, J7

J8, J9, J10, K4,

K5, K6, K7

C14

GPO2

RESETBMCU

RESETB

SW1OUT

SW3OUT

VINUSB

SW4FB

GNDREG2

GNDSUB4

GNDSUB5

GNDSUB6

PUMS1

3.6

3.6

–

–

3.6

3.6

5.5

5.5

7.5

–

–

3.6

Output

Output

Output

Output

Output

Input

Input

Ground

Ground

Ground

Ground

Input

Definition

Non critical signal ground and thermal heat sink

Non critical signal ground and thermal heat sink

General Purpose

Output 3

General purpose output 3

General Purpose

Output 2

General purpose output 2

MCU Reset

Reset output for processor

Peripheral Reset

Reset output for peripherals

Switcher 1 Output

Switcher 1 output

Switcher 3 Output

Switcher 3 output

VUSB Supply Input

Input option for UVUSB; tie to SWBST at top level

Switcher 4 Feedback

Switcher 4 feedback

Regulator 2 Ground

Ground for regulators 2

Ground 4

Non critical signal ground and thermal heat sink

G10

G12

G13

H1

H2

H4

H5

H6

H7

H8

H9

F12

D14

H13, H14

H1, H2

P2

L3

N4

K8, K10, L4, L5,

L6, L10

P5, P7, P8, P9,

P10

–

F11

WDI

GPO4

SW1IN

SW3IN

MISO

GNDSPI

GNDREG3

GNDSUB7

GNDSUB8

GNDSUB9

GNDCTRL

3.6

3.6

5.5

5.5

3.6

–

–

–

–

–

–

Input

Output

Input

Power

I/O

Ground

Ground

Ground

Ground

Ground

Ground

Ground 5

Ground 6

Non critical signal ground and thermal heat sink

Non critical signal ground and thermal heat sink

Power Up Mode Select

1

Power up mode supply setting 1

Watchdog Input

Watchdog input

General Purpose

Output 4

General purpose output 4

Switcher 1 Input

Input voltage for switcher 1

Switcher 3 Input

Switcher 3 input

Master In Slave Out

Primary SPI read output

SPI Ground

Ground for SPI interface

Regulator 3 Ground

Ground for regulators 3

Ground 7

Non critical signal ground and thermal heat sink

Ground 8

Ground 9

Non critical signal ground and thermal heat sink

Non critical signal ground and thermal heat sink

Logic Control Ground Ground for control logic

MC13892

8

Analog Integrated Circuit Device Data

Freescale Semiconductor

PIN CONNECTIONS

Table 2. MC13892 Pin Definitions (continued)

A functional description of each pin can be found in the Functional Description .

Pin Number on the

13982VK

7x7 mm

Pin Number on the 13982VL

12x12 mm

Pin Name

Rating

(V)

Pin Function Formal Name

H10

H12

J5

J6

J7

J8

J9

H13

J1

J2

J4

J10

J12

K9

K10

K12

K13

L1

L2

L12

K5

K6

K7

K8

J13

K1

K2

K4

L13

M1, N1, N2

M2

M3

G12

L12

J13, J14

J1, J2

N2

M3

M6

N11

P12

D12

M12

J12

M13

N12

P13

K12

K13, K14

K1, K2

L2

L11

M4

L7

M8

M9

L14

L1

K3

P3

L13

N1

M1

N3

SW1FB

STANDBYSEC

SW2IN

SW4IN

MOSI

CLK32KMCU

STANDBY

GNDADC

GNDREG1

PWRON3

TSX1

SW2FB

TSX2

SW2OUT

SW4OUT

SPIVCC

PWGTDRV1

CLK32K

VCAM

CFP

CFM

ADIN5

ADIN6

VVIDEODRV

GNDSW2

GNDSW4

CS

TSY2

VVIDEO

VGEN3

CLK

VGEN2

3.6

3.6

Input

Input

Output

Ground

Ground

Input

Input

Output

Output

Input

Output

Output

Output

Passive

Passive

–

3.6

3.6

4.8

4.8

5.5

–

3.6

3.6

4.8

4.8

5.5

5.5

3.6

4.8

3.6

–

–

3.6

3.6

5.5

5.5

3.6

3.6

3.6

3.6

3.6

3.6

3.6

3.6

Input

Input

Input

Power

Input

Output

Input

Ground

Ground

Input

Input

Input

Input

Output

Output

Input

Output

Definition

Switcher 1 Feedback

Switcher 1 feedback

Secondary Standby

Signal

Standby input signal from peripherals

Switcher 2 Input

Input voltage for Switcher 2

Switcher 4 Input

Switcher 4 input

Master Out Slave In

Primary SPI write input

32 kHz Clock for MCU 32 kHz clock output for processor

Standby Signal

Standby input signal from processor

ADC Ground

Ground for A to D circuitry

Regulator 1 Ground

Ground for regulators 1

Power On 3

Power on/off button connection 3

Touch Screen

Interface X1

Switcher 2 Output

Touch screen interface X1

Switcher 2 Feedback

Switcher 2 feedback

Touch Screen

Interface X2

Touch screen interface X2

Switcher 2 output

Switcher 4 Output

Switcher 4 output

Supply Voltage for SPI Supply for SPI bus and audio bus

Power Gate Driver 1

Power gate driver 1

32 kHz Clock

32 kHz clock output for peripherals

Camera Supply

Output regulator camera

Current Filter Positive Accumulated current filter cap plus pin

Current Filter Negative Accumulated current filter cap minus pin

ADC Channel 5 Input ADC generic input channel 5

ADC Channel 6 Input ADC generic input channel 6

VVIDEO Driver

Drive output regulator VVIDEO

Switcher 2 Ground

Ground for switcher 2

Switcher 4 Ground

Ground for switcher 4

Chip Select

Primary SPI select input

Touch Screen

Interface Y2

Touch screen interface Y2

Video Supply

Output regulator TV DAC

General Purpose

Regulator 3

Output GEN3 regulator

Clock

Primary SPI clock input

General Purpose

Regulator 2

Output GEN2 regulator

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

9

PIN CONNECTIONS

Table 2. MC13892 Pin Definitions (continued)

A functional description of each pin can be found in the Functional Description .

Pin Number on the

13982VK

7x7 mm

Pin Number on the 13982VL

12x12 mm

Pin Name

Rating

(V)

Pin Function Formal Name

M4

M5

M6

M7

M8

M9

M10

M11

M12

M13, N12,

N13

N3

N8

N9

N10

N4

N5

N6

N7

N11

M5

P6

M7

N14

M2

P4

N5

N6

L8

N7

N9

N10

N8

L9

P11

M10

N13

M14

M11

VSRTC

GNDRTC

VINCAMDRV

PWGTDRV2

VDIG

VINDIG

VGEN1DRV

ADIN7

TSY1

TSREF

VINGEN3DRV

VGEN2DRV

XTAL2

XTAL1

VINAUDIO

VAUDIO

VIOHI

VINIOHI

VGEN1

Definition

3.6

–

5.5

3.6

3.6

5.5

5.5

2.5

2.5

5.5

3.6

Output

Ground

I/O

Output

Input

Input

Power

Output

Output

Input

Output

SRTC Supply

Output regulator for SRTC module on processor

Real Time Clock

Ground

Ground for the RTC block

Camera Regulator

Supply Input and Driver

Output

1. Input regulator camera using internal

PMOS FET.

2. Drive output regulator for camera voltage using external PNP device.

4.8

3.6

5.5

5.5

Output

Output

Input

Output

Power Gate Driver 2

Power gate driver 2

Digital Supply

Output regulator digital

VDIG Supply Input

Input regulator digital

VGEN1 Driver

Drive output GEN1 regulator

4.8

3.6

3.6

Input

Input

Output

ADC Channel 7 Input ADC generic input channel 7, group 1

Touch Screen

Interface Y1

Touch screen interface Y1

Touch Screen

Reference

Touch screen reference

5.5

Power/Output VGEN3 Supply Input and Driver Output

1. Input VGEN3 regulator

2. Drive VGEN3 output regulator

VGEN2 Driver

Drive output GEN2 regulator

Crystal Connection 2

32.768 kHz oscillator crystal connection 2

Crystal Connection 1

32.768 kHz oscillator crystal connection 1

Audio Supply Input

Input regulator VAUDIO

Audio Supply

Output regulator for audio

High Voltage IO Supply Output regulator high voltage IO, efuse

High Voltage IO Supply

Input

Input regulator high voltage IO

General Purpose

Regulator 1

Input GEN1 regulator

MC13892

10

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

MAXIMUM RATINGS

Table 3. Maximum Ratings

All voltages are with respect to ground unless otherwise noted. Exceeding these ratings may cause a malfunction or permanent damage to the device.

Ratings Symbol Value Unit

ELECTRICAL RATINGS

MODE pin Voltage

Main/Aux/Keypad Current Sink Voltage

Battery Voltage

Coin Cell Voltage

Human Body Model - HBM with Mode pin excluded

Charge Device Model - CDM

V

CHRGR

V

MODE

V

LEDMD,

V

LEDAD,

V

LEDKP

V

V

V

BATT

LICELL

ESD

-0.3 to 20

-0.3 to 9.0

-0.3 to 28

-0.3 to 4.8

-0.3 to 3.6

±1500

±250

V

V

V

V

V

V

THERMAL RATINGS

Ambient Operating Temperature Range

Operating Junction Temperature Range

Storage Temperature Range

T

A

T

J

T

STG

-40 to +85

-40 to +125

-65 to +150

°C

°C

°C

THERMAL RESISTANCE

Peak Package Reflow Temperature During Reflow

,

T

PPRT

°C

Notes

5.

USB Input Voltage applies to UVBUS pin only

6.

ESD testing is performed in accordance with the Human Body Model (HBM) (CZAP = 100 pF, RZAP = 1500

) and the Charge Device

Model (CDM), Robotic (CZAP = 4.0 pF).

7.

Pin soldering temperature limit is for 10 seconds maximum duration. Not designed for immersion soldering. Exceeding these limits may cause malfunction or permanent damage to the device.

8.

Freescale’s Package Reflow capability meets Pb-free requirements for JEDEC standard J-STD-020C. For Peak Package Reflow

Temperature and Moisture Sensitivity Levels (MSL), Go to www.freescale.com, search by part number [e.g. remove prefixes/suffixes and enter the core ID to view all orderable parts. (i.e. MC33xxxD enter 33xxx), and review parametrics.

9.

Mode Pin is not ESD protected.

Table 4. Dissipation Ratings

Rating Parameter

Junction to Ambient Natural Convection

Junction to Ambient Natural Convection

Junction to Ambient (@200 ft/min)

Junction to Ambient (@200 ft/min)

Junction to Board

Junction to Case

Junction to Package Top

Condition

Single layer board (1s)

Four layer board (2s2p)

Single layer board (1s)

Four layer board (2s2p)

Natural Convection

Symbol

R

JA

R

JMA

R

JMA

R

JMA

R

JB

R

JC

JT

VK Package

104

54

88

49

32

29

7.0

VL Package

28

22

5.0

65

42

55

38

Unit

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

11

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

CURRENT CONSUMPTION

RTC Mode

All blocks disabled, no main battery attached, coin cell is attached to

LICELL

RTC

OFF Mode (All blocks disabled, main battery attached)

MC13892 core and RTC module

I

RTC

I

OFF

–

–

Power Cut Mode (All blocks disabled, no main battery attached, coin cell

MC13892 core and RTC module

I

PCUT

–

ON Standby mode - Low-power mode

4 buck regulators in low-power mode, 3 regulators

I

STBY

–

ON Mode - Typical use case

4 buck regulators in PWMPS mode, 5 Regulators

I

ON

–

PWRON1, PWRON2, PWRON3, Pull-up

Input Low, 47 kOhm

Input High, 1.0 MOhm

CHRGSE1B, Pull-up

Input Low

Input High

STANDBY, STANDBYSEC, WDI, ADTRIG, Weak Pull-down

Input Low

Input High

0.0

1.0

0.0

1.0

0.0

1.0

CLK32K, CMOS

Output Low, -100

Output High, 100

A

A

0.0

SPIVCC -0.2

CLK32KMCU, CMOS

Output Low, -100

A

Output High, 100

A

RESETB, RESETBMCU, Open Drain

Output Low, -2.0 mA

Output High, Open Drain

0.0

VSRTC- 0.2

0.0

0.0

Notes

10.

Valid at 25 °C only.

11.

VPLL, VIOHI, VGEN2

12.

VPLL, VIOHI, VGEN2, VAUDIO, VVIDEO

13.

SPIVCC is typically connected to the output of buck regulator: SW4 and set to 1.800 V

14.

Input has internal pull-up to VCOREDIG equivalent to 200 kOhm

15.

Input has internal pull-up to VCORE equivalent to 100 kOhm

16.

SPIVCC needs to remain enabled for proper detection of WDI High to avoid involuntary shutdown

17.

A weak pull-down represents a nominal internal pull down of 100 nA, unless otherwise noted

18.

RESETB & RESETBMCU have open drain outputs, external pull-ups are required

3.00

10

3.0

230

459

–

–

–

–

–

–

–

–

–

–

–

–

6.00

30

6.0

295

1500

0.3

VCOREDIG

0.3

VCORE

0.3

3.6

0.2

SPIVCC

0.2

VSRTC

0.4

3.6

µA

µA

µA

µA

µA

V

V

V

V

V

V

MC13892

12

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Unit Characteristic Symbol Min Typ Max

I/O CHARACTERISTICS (CONTINUED)

VSRTC, Voltage Output

Input Low

Input High

1.1

0.0

0.7* SPIVCC

–

–

–

1.3

0.3* SPIVCC

3.1

GPO1, CMOS

Output Low, -400

Output High, 400

To VCORE

A

A

0.0

VCORE- 0.2

200

–

–

–

0.2

VCORE

500

GPO2, GPO3, GPO4, CMOS

Output Low, -100

Output High, 100

A

A

0.0

VIOHI - 0.2

0.0

–

–

–

0.2

VIOHI

VCORE+0.3

GPO4, Analog Input

CS, CLK, MOSI, VBUSEN, Weak Pull-down on CS and VBUSEN

Input Low

Input High

CS, MOSI (at Booting for SPI / I

2

C decoding), Weak Pull-down on CS

Input Low

Input High

MISO, INT, CMOS

Output Low, -100

A

Output High, 100

A

PUMS1, PUMS2

PUMSxS = 00

PUMSxS = 01, Load < 10 pF

PUMSxS = 10

PUMSxS = 11

0.0

0.7* SPIVCC

0.0

0.7 * VCORE

0.0

SPIVCC -0.2

–

–

–

–

–

–

0.3* SPIVCC

SPIVCC+0.3

0.3 * VCORE

VCORE

0.2

SPIVCC

0.0

Open

1.3

2.5

–

–

–

–

0.3

Open

2.0

3.1

MODE

Input Low

Input Med

Input High

0.0

1.1

VCORE

–

–

–

Notes

19.

SPIVCC is typically connected to the output of buck regulator: SW4 and set to 1.800 V

20.

A weak pull-down represents a nominal internal pull down of 100 nA unless otherwise noted

21.

The weak pull-down on CS is disabled if a VIH is detected at startup to avoid extra consumption in I

2

C mode

22.

The output drive strength is programmable

23.

Input state is latched in first phase of cold start, refer to

for description of PUMS configuration

24.

Input state is not latched

0.4

1.7

9.0

V

V

V

V

V

Ohm

V

V

V

V

V

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

13

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

32 KHZ CRYSTAL OSCILLATOR

Operating Voltage

Oscillator and RTC Block from BP

Coincell Disconnect Threshold

At LICELL

Output Low CLK32K, CLK32KMCU

Output sink 100 µA

Output High

CLK32K Output source 100 µA

CLK32KMCU Output source 100 µA

VSRTC GENERAL

Operating Input Voltage Range V

INMIN

Valid Coin Cell range

to V

INMAX

Or valid BP

Operating Current Load Range IL

MIN

to IL

MAX

Bypass Capacitor Value

VSRTC ACTIVE MODE – DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MIN

< IL < IL

MAX

CLK AND MISO

Input Low CS, MOSI, CLK

Input High CS, MOSI, CLK

Output Low MISO, INT

Output sink 100 µA

Output High MISO, INT

Output source 100 µA

SPIVCC Operating Range

V

XTAL

V

LCD

V

CLKLO

V

CLKHI

V

CLKMCUHI

V

LICELL

BP

I

SRTC

C

SRTC

V

SRTC

V

INCSLO

V

INMOSILO

V

INCLKLO

V

INCSHI

V

INMOSIHI

V

INCLKHI

V

OMISOLO

V

OINTLO

V

OMISOHI

V

OINTHI

SPIV

CC

1.2

1.8

0.0

SPIV

CC

V

SRTC

-0.2

-0.2

1.8

UVDET

0.0

–

1.15

0.0

0.7*SPIV

CC

0.0

SPIV

CC

-0.2

1.75

–

–

–

–

–

–

–

–

1.0

1.20

–

–

–

–

–

4.65

2.0

0.2

SPIV

CC

V

SRTC

3.6

4.65

50

–

1.25

0.3*SPIV

CC

SPIV

CC

+0.3

0.2

SPIV

CC

3.1

V

V

V

V

V

µA

µF

V

V

V

V

V

V

MC13892

14

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

BUCK REGULATORS

Operating Input Voltage

PWM operation, 0 < IL < I

MAX

PFM operation, 0 < IL < I

MAX

Extended PWM or PFM operation

Output Voltage Range

Switcher 1

Switchers 2, 3, and 4

Output Accuracy

PWM mode including ripple, load regulation, and transients

PFM Mode, including ripple, load regulation, and transients

Maximum Continuous Load Current, I

MAX

, V

INMIN

<BP<4.65 V

SW1 in PWM mode (SWILIMB = 0, no max current limit)

SW1 in PWM Mode (SWILIMB = 1, no max current limit)

SW2, SW3, SW4 in PWM mode (SWILIMB = 0, no max current limit)

SW2, SW3, SW4 in PWM mode (SWILIMB = 1, no max current limit)

SW1, SW2, SW3, SW4 in PFM mode

Maximum Peak Load Current, I

PEAK

, BP

4.2 V,

SW1 in PWM Mode (SWILIMB = 1, no max current limit)

SW4 in PWM Mode (SWILIMB = 1, no max current limit)

V

SWIN

V

SW1

V

SWLOPP

V

SWLIPPI

I

SW1

I

SW2,3,4

I

SW2,3,4

I

SW1, 2, 3, 4

I

SW1

I

SW4

3.0

2.8

UVDET

0.6

0.6

Nom-50

Nom-50

800

1050

800

800

–

1250

1000

–

–

Nom

Nom

–

–

–

–

50

–

–

–

–

–

4.65

4.65

4.65

1.375

1.850

Nom+50

Nom+50

–

–

–

–

–

–

–

V

V mV mA mA

Notes

25.

In the extended operating range the performance may be degraded

26.

Transient loading for load steps of ILmax/2

27.

In this mode, current limit protection is disabled for SW1 - SW4 by setting SWILIMB = 1. Therefore, the load on SW1-4 should not exceed the conditions specified in the table above. Application needs to provide current limit protection circuitry either in battery or as preregulated supply to BP.

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

15

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

BUCK REGULATORS (CONTINUED)

Automatic Mode Change Threshold, Switchover between PFM and PWM modes

Efficiency

PFM, 0.9 V, 1.0 mA

PFM, 01.8 V, 1.0 mA

PWM Pulse Skipping, 1.25 V, 50 mA

PWM Pulse Skipping, 1.8 V, 50 mA

PWM, 1.25 V, 500 mA

PWM, 1.8 V, 500 mA

External Components, Used as a condition for all other parameters

Inductor for SW2, SW3, SW4

Inductor for SW1

Inductor Resistance

Bypass Capacitor for SW2, SW3, SW4

Bypass Capacitor ESR

Input Capacitor

AMC

L

C

L

R

C

ESR

TH

SW234

SW1

WSW

OSW234

OSW1

SW

–

–

–

–

–

–

–

-20%

-30%

–

-35%

-35%

5.0

1.0

50

75

85

78

82

78

82

2.2

1.5

–

10

2x22

–

4.7

–

–

–

–

–

–

–

+20%

+30%

0.16

+35%

+35%

50

– mA

SWBST

3.0 V < V

IN

< 4.65 (1), 0 < IL < IL

Output Ripple

3.0 V < V

IN

< 4.65, 0 < IL < IL

Schottky diode

MAX

, Excluding reverse recovery of

V

V

BST

BSTPP

Nom-5%

–

5.0

–

Nom+5%

120

V mVpp

Average Load Regulation

V

IN

= 3.6 V, 0 < IL < IL

MAX

Average Line Regulation

3.0 V < V

IN

< 4.65 V, IL = IL

MAX

V

V

BSTLOR

BSTLIR

–

–

–

–

0.5

50 mV/mA mV

Notes

28.

Preferred device TDK VLS252012 series at 2.5x2.0 mm footprint and 1.2 mm max height

29.

Preferably 0603 style 6.3 V rated X5R/X7R type at 35% total make tolerance, temperature spread and DC bias derating such as TDK

C1608X5R0J106M

30.

Preferably 0805 style 6.3 V rated X5R/X7R type at 35% total make tolerance, temperature spread and DC bias derating such as TDK

C2012X5R0J226M

31.

Preferably 0603 style 6.3 V rated X5R/X7R type at 35% total make tolerance, temperature spread and DC bias derating such as TDK

C1608X5R0J475

32.

Output voltage when configured to supply VBUS in OTG mode can be as high as 5.75 V

33.

Vin is the low side of the inductor that is connected to BP.

µH

µH

µF

µF m

µF

MC13892

16

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

SWBST (CONTINUED)

Maximum Continuous Load Current IL

MAX

3.0 V < V

IN

< 4.65, V

OUT =

5.0 V

Start-up Overshoot

IL = 0 mA

Efficiency, IL = IL

MAX

External Components - Used as a condition for all other parameters

Inductor

Inductor Resistance

Inductor saturation current at 30% loss in inductance value

Bypass Capacitor

Bypass Capacitor ESR at resonance

Input Capacitor

Diode current capability

Diode current capability

NMOS Off Leakage, SWBSTIN = 4.5 V, SWBSTEN = 0

V

I

BST

BSTOS

SWBST

L

BST

R_W

IL

SAT

CO

ESR

I

I

C

EFF

BST

BST

BST

BSTD

BSTDPK

BSTDPK

300

–

–

-20%

–

1.0

-60%

1.0

1.0

850

1500

–

–

80

2.2

–

–

10

–

4.7

–

–

–

500

–

+20%

0.2

–

+35%

10

–

–

– mA mV

%

I

BSTIK

– 1.0

5.0

µA

VVIDEO

Operating Input Voltage Range V

INMIN

to V

INMAX

Operating Current Load Range IL

MIN

(Not exceeding PNP max power)

to IL

MAX

Minimum Bypass Capacitor Value

Used as a condition for all other parameters

Bypass Capacitor ESR

10 kHz -1.0 MHz

V

I

INVIDEO

VIDEO

CO

VIDEO

ESR

VIDEO

V

NOM

+0.25

0.0

1.1

–

–

2.2

4.65

350

–

V mA

µF m

20 – 100

VVIDEO ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, For any V

INMIN

< V

IN

< V

INMAX

V

V

VIDEO

VIDEOLOPP

V

NOM

–

- 3% V

NOM

–

V

NOM

+ 3%

0.20

V mV/mA

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, For any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

V

VIDEOLIPP

I

VIDEOSHT

– 5.0

8.0

mV mA

IL

MAX

+20% – –

Notes

34.

Preferred device TDK VLS252012 series at 2.5x2.0 mm footprint and 1.2 mm max height

35.

Applications of SWBST should take into account impact of tolerance and voltage derating on the bypass capacitor at the output level.

µH

A

µF m

µF mAdc mApk

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

17

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

VVIDEO LOW-POWER MODE DC - VVIDEOMODE = 1

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MINLP

< IL < IL

MAXLP

Current Load Range ILminlp to IL

MAXLP

VAUDIO

Operating Input Voltage Range V

INMIN

to V

INMAX

Operating Current Load Range IL

MIN

to IL

MAX

Minimum Bypass Capacitor Value

Bypass Capacitor ESR

10 kHz -1.0 MHz

VAUDIO ACTIVE MODE DC

Output Voltage V

OUT

(V

INMIN

< V

IN

< V

INMAX

, IL

MIN

< IL < IL

MAX

)

Load Regulation (1.0 mA < IL < IL

MAX

, For any V

INMIN

< V

IN

< V

INMAX

)

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, For any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

VPLL AND VDIG

Operating Input Voltage Range V

INMIN

VDIG, VPLL all settings, BP biased

to V

INMAX

VPLL, VDIG [1:0] = 00,01

VPLL, VDIG [1:0] = 10, 11, External Switcher

Operating Current Load Range IL

MIN

to IL

MAX

Minimum Bypass Capacitor Value

Used as a condition for all other parameters

Bypass Capacitor ESR

10 kHz -1.0 MHz

VPLL AND VDIG ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX for any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX for any IL

MIN

< IL < IL

MAX

VIOHI

Operating Input Voltage Range V

INMIN

V

NOM

= 2.775 V

to V

INMAX

Operating Current Load Range IL

MIN

to IL

MAX

Minimum Bypass Capacitor Value

Bypass Capacitor ESR

10 kHz -1.0 MHz

V

VIDEOLO

I

VIDEOLO

V

AUDIO

I

AUDIO

C

OAUDIO

ESR

AUDIO

V

AUDIO

V

AUDIOLOR

V

AUDIOLIR

I

AUDIOSHT

V

INPLL,

V

INDIG

I

PLL,

I

DIG

C

OPLL,

C

ODIG

ESR

PLL

,

ESR

DIG

V

PLL

, V

DIG

V

PLLLOR

,

V

DIGLOR

V

PLLLIR

,

V

DIGLIR

V

INIOHI

I

IOHI

C

OIOHI

ESR

IOHI

V

NOM

-3%

0.0

V

NOM

+0.25

0.0

0.65

0.0

V

NOM

- 3%

–

–

IL

MAX

+20%

UVDET

1.75

2.15

0.0

0.65

0.0

V

NOM

- 0.05

–

–

V

NOM

+0.25

0.0

0.65

0.0

V

NOM

–

–

V

NOM

–

5.0

–

–

SW4 = 1.8

2.2

–

2.2

–

V

NOM

–

5.0

–

–

2.2

–

–

2.2

–

V

NOM

+3%

3.0

4.65

150

–

0.1

V

NOM

+ 3%

0.25

8.0

–

4.65

4.65

4.65

50

–

0.1

V

NOM

+ 0.05

0.35

8.0

4.65

100

–

100

V mA

V mA

µF

V mV/mA mV mA

V mA

µF

V mV/mA mV

V mA

µF m

MC13892

18

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

VIOHI ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

- (V

NOM

= 2.775)

< V

INMAX

, IL

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, for any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, for any IL

MIN

< IL < IL

MAX

VCAM

Operating Input Voltage Range V

INMIN

to V

INMAX

Operating Current Load Range IL

MIN

Internal pass FET

to IL

MAX

External PNP

Minimum Bypass Capacitor Value

Internal pass device

External PNP (not exceeding PNP max power)

Bypass Capacitor ESR

10 kHz -1.0 MHz

VCAM ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

(V

< V

INMAX

NOM

, IL

= 2.775)

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, for any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, for any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

VCAM LOW-POWER MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MINLP

< IL < IL

MAXLP

Current Load Range IL

MINLP

to IL

MAXLP

VSD

Operating Input Voltage Range V

INMIN

VSD[2:0] = 010 to 111

to V

INMAX

VSD[2:0] = 010 to 111, Extended Operation

VSD[2:0] = 000, 001 [000] BP Supplied

VSD[2:0] = 000 External Switcher Supplied

Operating Current Load Range IL

MIN

Not exceeding PNP max power

to IL

MAX

Minimum Bypass Capacitor Value

Bypass Capacitor ESR

10 kHz -1.0 MHz

V

IOH

V

IOHLOR

V

IOHLIR

V

INCAM

I

CAM

C

OCAM

ESR

CAM

V

CAM

V

CAMLOR

V

CAMLIR

I

CAMSHT

V

CAMLO

I

CAMLO

V

INSD

I

SD

C

OSD

ESR

SD

V

NOM

-3%

–

–

V

NOM

+0.25

0.0

0.0

0.65

1.1

20

V

NOM

- 3%

–

–

IL

MAX

+20%

V

NOM

-3%

0.0

V

NOM

+0.25

UVDET

UVDET

2.15

0.0

1.1

20

V

NOM

–

5.0

–

–

–

2.2

2.2

–

V

NOM

–

5.0

–

V

NOM

–

–

–

–

2.20

–

2.2

–

V

NOM

+3%

0.35

8.0

4.65

65

250

–

–

100

V

NOM

+ 3%

0.25

8.0

–

V

NOM

+3%

3.0

4.65

4.65

4.65

4.65

250

–

100

V mV/mA mV

V mA

µF m

V mV/mA mV mA

V mA

V mA

µF m

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

19

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

VSD ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, for any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, for any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

VSD LOW-POWER MODE DC - VSDMODE = 1

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MINLP

< IL < IL

MAXLP

Current Load Range IL

MINLP

to IL

MAXLP

VUSB GENERAL

Operating Input Voltage Range V

INMIN

Supplied by VBUS

to V

INMAX

Supplied by SWBST

Operating Current Load Range IL

MIN

to IL

MAX

Bypass Capacitor Value Range

Bypass Capacitor ESR

10 kHz -1.0 MHz

VUSB ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MIN

< IL < IL

MAX

Load Regulation

0 < IL < IL

MAX

from DM/DP for any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, for any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

VUSB2

Operating Input Voltage Range V

INMIN

Extended operation

to V

INMAX

Operating Current Load Range IL

MIN

to IL

MAX

Minimum Bypass Capacitor Value

Used as a condition for all other parameters

Bypass Capacitor ESR

10 kHz -1.0 MHz

V

SD

V

SDLOR

V

SDLIR

I

SDSHT

V

SDLO

I

SDLO

V

INUSB

I

USB

C

OUSB

ESR

USB

V

USB

V

USBLOR

V

USBLIR

V

USBSHT

V

INUSB2

I

USB2

C

OUSB2

ESR

USB2

V

NOM

- 3%

–

–

IL

MAX

+20%

V

NOM

-3%

0.0

4.4

–

0.0

0.65

0.0

V

NOM

- 4%

–

–

IL

MAX

+20%

V

NOM

+0.25

UVDET

0.0

0.65

0.0

V

NOM

–

5.0

–

V

NOM

–

5.0

–

–

2.2

–

3.3

–

–

–

–

–

–

2.2

–

V

NOM

+ 3%

0.25

8.0

–

V

NOM

+3%

3.0

5.25

5.75

100

–

0.1

V

NOM

+ 4%

1.0

20

–

4.65

4.65

50

–

0.1

V mV/mA mV mA

V mA

V mA

µF

V mV/mA mV mA

V mA

µF

MC13892

20

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

VUSB2 ACTIVE MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

< V

INMAX

, IL

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, for any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, for any IL

MIN

< IL < IL

MAX

UVBUS

Operating Input Voltage Range V

INMIN

VINUSB supplied by SWBST

to V

INMAX

Operating Current Load Range IL

MIN

to IL

MAX

Minimum Bypass Capacitor Value

Bypass Capacitor ESR

10 kHz -1.0 MHz

UVBUS ACTIVE MODE DC

Output Voltage Vout

V

INMIN

< V

IN

< V

INMAX

, IL

MIN

< IL < IL

MAX

VGEN1

Operating Input Voltage Range V

INMIN

to V

INMAX

All settings, BP biased

V

V

V

C

V

USB2LOR

I

V

INUVBUS

INUVBUS

V

USB2

USB2LIR

UVBUS

OUVBUS

UVBUS

V

INGEN1

V

NOM

–

–

-3%

4.75

0.0

4.4

V

NOM

–

5.0

5.0

–

5.0

V

NOM

+ 3%

0.35

8.0

5.25

100

6.5

5.25

V mV/mA mV

V mA

µF

V

V

UVDET <

V

NOM

+0.25

– 4.65

VGEN1=00,01, External switcher supplied

Operating Current Load Range IL

MIN

(not exceeding PNP max power)

to IL

MAX

Extended input voltage range (BP biased, performance may be out of specification for output levels VGEN1[1:0] = 10 to 11)

Minimum Bypass Capacitor Value

Bypass Capacitor ESR

10 kHz -1.0 MHz

I

GEN1

C

OGEN1

ESR

GEN1

2.15

0.0

UVDET

1.1

2.2

–

–

2.2

4.65

200

4.65

+35% mA

V

µF m

20 – 100

VGEN1 ACTIVE MODE DC

Output Voltage V

OUT

VGEN1 = 00, 01, V

INMIN

< V

IN

< V

INMAX

IL

VGEN1 = 10, 11, V

INMIN

< V

IN

< V

INMAX

IL

MIN

< IL < IL

MAX

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, for any V

INMIN

< V

IN

< V

INMAX

V

V

GEN1

GEN1LOR

V

NOM

V

NOM

– 0.05

– 3%

–

V

V

NOM

NOM

–

V

V

NOM

NOM

+ 0.05

+ 3%

0.25

V mV/mA

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, for any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

V

GEN1LIR

V

GEN1SHT

– 5.0

8.0

mV mA

IL

MAX

+20% – –

Notes

36.

Filtering is shared with CHRGRAW (shorted at board level). 2.2 µF is typically included at the CHRGRAW pin.

37.

6.5 µF is the maximum allowable capacitance on VBUS including all tolerances of filtering capacitance on VBUS and CHRGRAW (which are shorted at the board level).

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

21

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

VGEN1 LOW-POWER MODE DC - VGEN1MODE = 1

Output Voltage V

OUT -

V

VGEN1 = 00, 01

INMIN

< V

IN

< V

INMAX

, IL

MINLP

< IL < IL

MAXLP

VGEN1 = 10, 11

Current Load Range IL

MINLP

to IL

MAXLP

VGEN2 GENERAL

Operating Input Voltage Range V

INMIN

to V

INMAX

All settings, BP biased

VGEN2=000,001, External switcher supplied

Operating Current Load Range IL

MIN power)

to IL

MAX

(Not exceeding PNP max

Minimum Bypass Capacitor Value

Bypass Capacitor ESR

10 kHz -1.0 MHz

VGEN2 ACTIVE MODE DC

Output Voltage V

OUT

VGEN2 = 000, 001, 010, V

INMIN

< V

IN

< V

INMAX

IL

VGEN2 = 011, 100, 101, 110, 111, V

IL

MAX

INMIN

< V

MIN

< IL < IL

MAX

IN

< V

INMAX

IL

MIN

< IL <

Load Regulation

1.0 mA < IL < IL

MAX

, For any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, For any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short-circuit V

OUT

to GND

VGEN2 LOW-POWER MODE DC - VGEN2MODE=1

Output Voltage V

OUT

- V

VGEN2 = 000 to 010

INMIN

< V

IN

< V

INMAX

, IL

MINLP

< IL < IL

MAXLP

VGEN2 = 011 to 111

Current Load Range IL

MINLP

to IL

MAXLP

VGEN3 GENERAL

Operating Input Voltage Range V

INMIN

VGEN3CONFIG, VGEN3 = 01, 11

to V

INMAX

VGEN3CONFIG, VGEN3 = 00, 10

Operating Current Load Range IL

MIN

Internal Pass FET

to IL

MAX

External PNP (Not exceeding PNP max power)

Minimum Bypass Capacitor Value

Internal pass device

External pass device

Bypass Capacitor ESR

10 kHz -1.0 MHz

V

GEN1LO

I

GEN1LO

V

INGEN2

I

GEN2

C

OGEN2

ESR

GEN2

V

GEN2

V

GEN2LOR

V

GEN2LIR

V

GEN2SHT

VGEN2LO

I

GEN2LO

V

INGEN3

I

GEN3

C

OGEN3

ESR

GEN3

V

NOM

- 0.05

V

NOM

-3%

0.0

UVDET<

V

NOM

+0.25

2.15

0.0

1.1

20

V

NOM

V

NOM

-0.05

-3%

–

–

IL

MAX

+20%

V

NOM

V

NOM

-0.05

-3%

0.0

V

NOM

+0.2

UVDET

0.0

0.0

0.65

1.1

20

V

NOM

V

NOM

–

–

2.2

–

2.2

–

V

NOM

V

NOM

–

5.0

–

V

NOM

V

NOM

–

–

–

–

–

2.2

2.2

–

V

NOM

+ 0.05

V

NOM

+3%

3.0

4.65

4.65

350

+35%

100

V

NOM

V

NOM

+0.05

+3%

0.20

8.0

–

V

NOM

V

NOM

+0.05

+3%

3.0

4.65

4.65

50

200

–

–

100

V mA

V mA

µF m

V mV/mA mV mA

V mA

V mA

µF m

MC13892

22

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

VGEN3 ACTIVE MODE DC

Output Voltage V

OUT

VGEN2 = 000, 001, 010, V

INMIN

< V

IN

< V

INMAX

IL

MIN

< IL < IL

MAX

Load Regulation

1.0 mA < IL < IL

MAX

, For any V

INMIN

< V

IN

< V

INMAX

Line Regulation

V

INMIN

< V

IN

< V

INMAX

, For any IL

MIN

< IL < IL

MAX

Short-circuit Protection Threshold

V

INMIN

< V

IN

< V

INMAX

, Short circuit V

OUT

to GND

VGEN3 LOW-POWER MODE DC

Output Voltage V

V

INMIN

< V

IN

OUT

- (Accuracy)

< V

INMAX

, IL

MINLP

< IL < IL

MAXLP

Current Load Range IL

MINLP

to IL

MAXLP

CHARGE PATH REGULATOR

Input Operating Voltage - CHRGRAW

Output Voltage Spread - VCHRG[2:0]=011, 1XX

Charge current 1.0 mA to 100 mA

Charge current 100 mA and above

Current Limit Tolerance

ICHRG[3:0] = 0001

ICHRG[3:0] = 0100

ICHRG[3:0] = 0110

All other settings

Start-up Overshoot - Unloaded

Configuration

Cable length

THERMAL

Thermal Warning Lower Threshold

Thermal Warning Higher Threshold

Thermal Warning Hysteresis

Thermal Protection Threshold

BACKLIGHT LED DRIVERS

Absolute Accuracy - All current settings

Matching - At 400 mV, 21 mA

Leakage - LEDxDC[5:0] = 000000

SIGNALING LED DRIVERS

Absolute Accuracy - All current settings

Matching - At 400 mV, 21 mA

Leakage - LEDxDC[5:0] = 000000

V

GEN3

V

GEN3LOR

V

GEN3SHT

V

GEN3SHT

V

GEN3LO

I

GEN3LO

V

INCHRG

BP

SP

I

LIM

BP

OS-START

C

INCHRG

C

BP

L

C

T

WL

T

WH

T

WHYS

T

PT

V

NOM

-3%

–

–

IL

MAX

+20%

V

NOM

-3%

0.0

BATT

MIN

-1.5

-3.0

–

–

–

–

–

–

–

–

–

–

68

360

500

– v

–

10

–

V

NOM

–

5.0

–

V

NOM

1.0

–

–

–

–

–

–

–

–

–

80

400

560

–

–

2.2

–

–

100

120

3.0

140

V

NOM

+ 3%

0.40

9.0

–

V

NOM

+3%

3.0

5.6

1.5

1.5

92

440

620

15

2.0

–

47

3.0

15

10

1.0

15

3.0

1.0

–

–

–

–

V mV/mA mV mA

V mA

V

%

%

%

µA

%

%

µA

°C

°C

°C

°C mA mA mA

%

%

µF

µF m

Analog Integrated Circuit Device Data

Freescale Semiconductor

MC13892

23

ELECTRICAL CHARACTERISTICS

STATIC ELECTRICAL CHARACTERISTICS

Table 5. Static Electrical Characteristics (continued)

Characteristics noted under conditions 40

C

T

A the approximate parameter means at T

A =

85

C, GND = 0 V unless otherwise noted. Typical values noted reflect

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

ACTIVE MODE DC

Output Voltage V

OUT

- (V

NOM

< IL

MAX

= 2.775), V

INMIN

< V

IN

< V

INMAX

, IL

MIN

< IL

ADC

Converter Core Input Range

Single ended voltage readings

Differential readings

Channels ADIN5, ADIN6 and ADIN7

Integral Nonlinearity

Differential Nonlinearity

Zero Scale Error (Offset) after auto calibration

4.4

0.0

-1.2

–

–

–

–

–

–

5.0

–

–

–

–

–

–

–

–

5.25

2.4

1.2

BP

3

1

1

5

1

V

V

V

Full Scale Error (Gain) after auto calibration

Drift Over-temperature - Including scaling

Source Impedance

No bypass capacitor at input

Bypass capacitor at input 10 nF

–

–

–

–

5.0

30

TOUCH SCREEN

Plate Maximum Voltage X, Y

Plate Resistance X, Y

Resistance Between Plates Settling Time - Contact

Position measurement

TOUCH SCREEN IN STAND ALONE MODE

–

100

180

3.0

–

–

–

–

VCORE

1000

1200

5.5

V

µs

Max Load Current - Active Mode

Output Voltage - 0.0<IL<20 mA

PSRR - IL=15 mA

Bypass Capacitor ESR

Bypass Capacitance

–

-3%

50

0.0

0.65

–

1.20

–

–

2.2

20

+3%

–

0.1

+35% mA

V dB

µF

Notes

38.

Excludes spread and tolerance due to board and 100 mOhm sense resistor tolerances.

39.

An additional derating of 35% is allowed.

40.

ADIN5, 6 and 7 inputs must not exceed BP voltage.

41.

TS[xy][1,2] inputs must not exceed BP or VCORE

42.

All characteristics in this table are applicable only for non touch screen operation. This applies to Touch Screen in Standalone mode and below.

LSB

LSB

LSB

LSB

LSB

K

MC13892

24

Analog Integrated Circuit Device Data

Freescale Semiconductor

ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

DYNAMIC ELECTRICAL CHARACTERISTICS

Table 6. Dynamic Electrical Characteristics

Characteristics noted under conditions 3.1 V

BATT

4.65

V, -40

T

A values noted reflect the approximate parameter means at T

A =

85 °C, GND = 0 V, unless otherwise noted. Typical

25 °C under nominal conditions, unless otherwise noted.

Characteristic Symbol Min Typ Max Unit

32 KHZ CRYSTAL OSCILLATOR

RTC oscillator start-up time

Upon application of power

CLK32K Rise and Fall Time - CL = 50 pF

CLK32KDRV[1:0] = 00 (default)

CLK32KDRV[1:0] = 01

CLK32KDRV[1:0] = 10

CLK32KDRV[1:0] = 11

CLK32KMCU Rise and Fall Time

CL = 12 pF

CLK32K and CLK32KMCU Output Duty Cycle

Crystal on XTAL1, XTAL2 pins

CLK AND MISO

MISO Rise and Fall Time, CL = 50 pF, SPIVCC = 1.8 V

SPIDRV [1:0] = 00 (default)

SPIDRV [1:0] = 01

SPIDRV [1:0] = 10

SPIDRV [1:0] = 11

BUCK REGULATORS

Turn-on Time, Enable to 90% of end value, IL = 0

SWBST

Turn-on Time

Enable to 90% of V

OUT

, IL = 0

Transient Load Response, IL from 1.0 mA to 100 mA in 1.0 µs steps

Maximum transient Amplitude

Time to settle 80% of transient

Transient Load Response, IL from 100 mA to 1.0 mA

Maximum transient Amplitude

Time to settle 80% of transient

VVIDEO ACTIVE MODE - AC

PSRR - IL = 75% of IL

MAX

V

IN

= V

INMIN

+ 100 mV

, 20 Hz to 20 kHz

V

IN

= V

NOM

+ 1.0 V

Max Output Noise - V

IN

100 Hz – 1.0 kHz

= V

INMIN

, IL = 75% of IL

MAX

>1.0 kHz – 10 kHz

>10 kHz – 1.0 MHz

Turn-on Time