- Home

- Domestic appliances

- Climate control

- Split-system air conditioners

- Carrier

- 38TDB

- Troubleshooting guide

Carrier 38TDB Troubleshooting guide

Add to my manuals22 Pages

Carrier 38TDB is a 2-stage variable-speed air conditioner that offers superior comfort, energy efficiency, and quiet operation. With its advanced technology, it can save up to 50% on energy costs compared to a standard air conditioner. It features a Greenspeed™ intelligence that constantly adjusts its operation to maintain a consistent temperature and minimize energy usage. The unit is also equipped with a ComfortFan™ technology that provides continuous air circulation for improved comfort even when the cooling or heating cycle is off.

advertisement

Software Revs 3,5,6,8, 10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10/12/2006

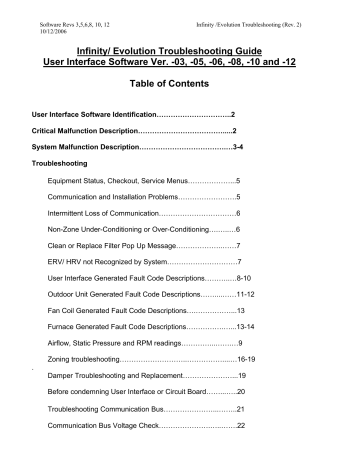

Infinity/ Evolution Troubleshooting Guide

User Interface Software Ver. -03, -05, -06, -08, -10 and -12

Table of Contents

User Interface Software Identification…………………………..2

Critical Malfunction Description……………………………….....2

System Malfunction Description……………………………….…3-4

Troubleshooting

Equipment Status, Checkout, Service Menus………………...5

Communication and Installation Problems…………………….5

Intermittent Loss of Communication……………………………6

Non-Zone Under-Conditioning or Over-Conditioning….…..…6

Clean or Replace Filter Pop Up Message………………..……7

ERV/ HRV not Recognized by System…………………………7

User Interface Generated Fault Code Descriptions………..…8-10

Outdoor Unit Generated Fault Code Descriptions……....……11-12

Fan Coil Generated Fault Code Descriptions….……………...13

Furnace Generated Fault Code Descriptions…………….…...13-14

Airflow, Static Pressure and RPM readings…………...…….…9

Zoning troubleshooting………………………..……………....…16-19

.

Damper Troubleshooting and Replacement…………………...19

Before condemning User Interface or Circuit Board……...…..20

Troubleshooting Communication Bus…………………...……..21

Communication Bus Voltage Check………………….…..…….22

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

User Interface Software Identification

This guide covers Infinity and Evolution zoning and non-zoning systems with versions CESR131339-03, -

05, -06, -08, -10, and -12 software (versions 7, 9, and 11 were not put into production) . The model numbers included are listed below:

Carrier: SYSTXCCUIZ01, SYSTXCCUIZ01-A, SYSTXCCUID01, SYSTXCCUID01-A

Bryant: SYSTXBBUIZ01, SYSTXBBUIZ01-A , SYSTXBBUID01, SYSTXBBUID01-A

There are two ways to determine the software version: enter the Service menus with a 10 second push of the Advance button, or cycle power to the User Interface. When power is re-applied, the User Interface will re-establish communications with the equipment and display the software version as shown below:

ESTABLISHING

COMMUNICATIONS

WITH EQUIPMENT

PLEASE WAIT

WORKING

SOFTWARE VERSION

CESR131339-06

The first Service menu screen will show the software version near the bottom of the screen. Infinity and

Evolution systems are designed to alert the equipment owner of a potential system problem, and help guide the servicer in determining a system problem. Two types of alerts can pop up on the User Interface screen when a system problem or potential system problem exists. These alerts are described below.

Critical Malfunctions (software versions 3,5,6,8 only)

Certain system problems will result in the message “CRITICAL MALFUNCTION CALL TECHNICIAN”.

A critical malfunction is a system problem that will result in no system operation, and must be addressed immediately. It usually means there is a problem related to the indoor unit blower motor.

The message will be displayed as shown in the figure below. The following will cause this message:

Fan Coil generated Critical Malfunctions

:

OUTSIDE: 94 o

Code 44 – Motor Communication Fault

Code 41 – Blower Motor Fault

FAN: AUTO

ALERT !

Furnace generated Critical Malfunctions:

CRITICAL MALFUNCTION

CALL TECHNICIAN

Code 15 – Blower Motor Lockout

Code 41 – Blower Motor Fault

JOE'S HVAC SERVICE

(317) 555-1234

The mode LEDs will alternately flash red on/blue off for 0.5 seconds, then blue on/red off for 0.5 seconds.

2

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

User Interface generated Critical Malfunctions:

No communication with indoor unit

System Malfunction

Certain system events can result in the pop-up message “SYSTEM MALFUNCTION CALL TECHNICIAN”.

A system malfunction is an event that could be related to a failed component, or an event that may not necessarily indicate an equipment problem. If this message clears on its own and the equipment operates normally, it should be ignored. If it does not clear, or comes back repeatedly after being dismissed, the system should be checked at the owner’s earliest convenience.

The user can press the right side button to dismiss the notice. The regular run mode screen will then appear except “SYSTEM MALFUNCTION” will appear in place of the day/time. If the error has not disappeared within 24 hours, the above display will return.

If the error code disappears, “SYSTEM MALFUNCTION” will disappear and the day/time will reappear.

OUTSIDE: 94 o FAN: AUTO

JOE'S HVAC SERVICE

(317) 555-1234

SYSTEM MALFUNCTION

CALL TECHNICIAN

DISMISS

NOTICE >

This message may be generated from any of the communicating system components, and will be displayed as shown in Figure 2. The following events may generate this message:

Fan Coil generated System Malfunction events:

Code 37 – Heater output sensed On when not energized (User interface will only display the pop-up

message, modifications to fan/staging operation will not occur)

Code 44 – Motor Communication Fault (version 10)

Code 41 – Blower Motor Fault (version 10)

Furnace generated System Malfunction events:

Code 13 – Limit Circuit Lockout

Code 14 – Ignition Lockout

Code 21 - Gas Heating Lockout

Code 22 - Abnormal Flame Proving Signal

Code 23 – Pressure Switch Did Not Open

Code 24 – Secondary Voltage Fuse Open

Code 33 – Limit Circuit Fault AND high heat only is active

Code 45 – Control Circuitry Lockout

Code 41 – Blower Motor Fault ((-A) models only)

2-Stage outdoor unit generated System Malfunction events (38TDB, YDB,

598B, 698B):

-VC VOLTAGE AT STANDBY (versions 8 and earlier)

-HI CAPACITY COMPRESSOR LOCKOUT (versions 8 and earlier)

3

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

(-A) Models( Ver. 10 & 12 Software )Outdoor Unit System Malfunction Events

74

76

78

79

81

82

83

84

85

86

87

88

89

Outdoor board Flash Code

(2006 Platform units)

45

47

Fault Description

Control Fault

No 230v

User Interface Display in Service Screen

CONTROL FAULT

NO 230V AT UNIT

No high voltage

Low speed didn’t start 3 times

High speed didn’t start 3 times

Run Capacitor Failed

NO 230V AT COMPRESSOR

LOW STAGE REPEAT NO START

HIGH STAGE REPEAT NO START

RUN CAPACITOR FAILED

Low capacity thermal lockout

Hi capacity thermal lockout

THERMAL LOCKOUT IN LOW STAGE 4 HOURS

THERMAL LOCKOUT IN HIGH STAGE 4 HOURS

Low Capacity Compressor Lockout LOW PRESSURE LOCKOUT 4 HOURS

Hi Capacity Compressor Lockout HIGH PRESSURE LOCKOUT 4 HOURS

Low Contactor Open

Low Contactor Shorted

High Contactor Open

LOW CONTACTOR OPEN

LOW CONTACTOR SHORTED

HIGH CONTACTOR OPEN

High Contactor Shorted HIGH CONTACTOR SHORTED

Start Capacitor/Relay Failed START CAPACITOR/RELAY FAILED

Zone board generated System Malfunction events:

-Fuse Open

User Interface generated System Malfunction events:

-Indoor unit communication fault

-Outdoor unit communication fault

-NIM communication fault

- Zone board communication fault

-

Defrost Locked

-SAM communication fault

-Frozen indoor coil detected (version 10)

SAM generated System Malfunction events

-Code 62-Loss of communication with the radio: No communication with device for 2 minutes(Version 10 only)

4

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Troubleshooting

The Infinity and Evolution Systems are designed to record and store system faults and events that may be used to help lead a servicer to the root cause of a real or perceived system problem. It should be understood that not all recorded events necessarily represent system problems. These should be used as a clue to guide the servicer to the appropriate part of the system.

Equipment Status

To check equipment status, push and hold the right side button for 3 seconds. This will show what the

User Interface is telling the system to do. Compare this information to what is actually happening. This can help lead you to a component problem.

Checkout

This system gives you the ability to exercise all the system components and accessories to verify proper operation. Access this by pressing the Advanced button for 10 seconds.Select CHECKOUT, then select the component you wish to exercise and follow screen prompts.

NOTE: Airflow during in Checkout mode is defaulted to Efficiency regardless of AC Airflow setting

Service Menus

The Service Menus provide system information to aid in troubleshooting. To access, press and hold the

Advanced button for 10 seconds and select “Service”. This will allow you to check status of individual system components, view the Last 10 System Faults, the Run/Fault History and more.

Checking system status should be one of the first steps in troubleshooting these systems.

Troubleshooting Communication and Installation Problems

This system uses digital communication on a communication bus (A and B wires) to send commands to operate equipment and send error messages to the User Interface to display. At initial installation, the system first finds all “communicating” equipment on the bus, and self configures to the appropriate equipment attached. If a piece of equipment is non- communicating such as an older outdoor unit or accessory, the size or type will need to be input by the installer during the learning process.

Each communicating device contains a green communication light to verify if communication has been established. This is a clue to where a potential problem lies.

Component not found at initial installation:

first attempt to reinstall by entering the service screens and selecting INSTALL. Try this several times before proceeding with troubleshooting

A communication error exists, or equipment cannot be found by the User Interface:

This may be due to a wiring problem with any of the components or accessories of the system. For example, a short in the wiring to the outdoor unit or accessory, may block communication with the indoor unit. In the majority of instances, using the step by step method described on page 21 will isolate the problem to the appropriate piece of equipment. If during Start up: CANNOT COMMUNICATE WITH EQUIPMENT is displayed on a furnace installation, make sure all dipswitches on SW-4 are turned off.

If a problem is isolated to the outdoor unit (comm error only occurs when outdoor unit is connected to the bus), the problem may be in the thermostat wire, or the outdoor unit wiring. If thermostat wire checks out

OK, check wiring inside the unit control box. Make sure all wires are tightly attached, and run to the appropriate terminal.

Mis-wiring in outdoor unit will cause loss of communication and operational problems in this system.

5

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Intermittent loss of communication

If communication errors occur at random intervals, and no system problems can be found by using the troubleshooting method described above, there may be a problem with outside electrical noise that affects system communication. First, trace all wires and ensure they are not in close proximity to high voltage, or other electrical equipment wiring such as alarm systems, fluorescent lighting, or recording equipment. Ensure there is sufficient separation between these wires, and a good common connection all the way through.

If this does not correct the situation, properly installing shielded thermostat wire may be required to stop external interference from affecting system communications.

Situation: Non-Zoned system over-conditioning or under-conditioning

Options:

•

Evaluate User Interface location. Make sure nothing is influencing temperature reading such as heat from direct sunlight. Make sure hole in wall behind User Interface is plugged.

•

If the system is over-conditioning, increase the anticipator setting. This adjustment is located in the Thermostat Setup, Cycles per Hour screen

•

If the system is under-conditioning, lower the anticipator setting and if necessary, increase the cycles per hour. This adjustment is located in the

Thermostat Setup, Cycles per Hour screen

6

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Situation: Clean or Replace Filter is displayed after a short period of time

These systems have a feature called TrueSense filter detection. This feature reads the change in static pressure caused by the filter accumulating dirt. At 1:00 pm each day the system will take a reading and record the change in static pressure. The clean or replace filter message will pop up when the filter is full.

This feature operates by setting a base line static pressure based on the highest airflow the system could run (this could be heat or cool airflow). The measurement is taken at a low airflow, and then calculated up to the highest airflow the system could see. An enhancement to the (-A) model was that if a furnace is used and it is locked in low fire, the calculation will use the higher of the cooling airflow or low furnace heat airflow. In previous versions, it used the higher of high furnace airflow or cooling airflow even if the furnace was locked in low fire.

In (-A) models (version 10 and 12 software), clean filter routine was changed to eliminate nuisance pop up messages when a marginal duct system is used. When the initial static pressure is 0.7 inches or higher, a modified calculation is used to allow this feature to be used at higher static pressures. With –A models, it will only pop up immediately if the initial static is 1.5 inches or higher.

This truly indicates a ductwork problem that must be addressed.

Options if this pops up quickly:

•

Evaluate duct work and make improvements to lower static pressure where possible

•

Change filter type to EAC. This will display the message based on time instead of static pressure change

•

Turn the filter reminder to off in the homeowner’s Advance Setup

Situation: ERV/ HRV Not Recognized By System

A ventilator may be connected to the system by wiring directly to a Damper Control Module (DCM) in a zoned system, or an Network Interface Module (NIM) in a non-zoned system. The system recognizes a ventilator is connected when the ventilator is wired to the YEL, RED, GRN, and BLU terminals of the NIM or DCM, and the ventilator is powered.

If the ventilator is not found, check for 12 volts DC between Y (+12 vdc) and B (ground) terminals of the ventilator. If voltage is not detected, the ventilator will not be found by the system. Make sure ventilator is powered.

7

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Fault

Description

User Interface Generated Fault Descriptions

User Interface Display Action

Onboard temp/humidity sensor error

Blower cutback from indoor unit

Remote Room

Sensor failed

Models

NO SENSOR TEMP/HUMIDITY

DATA on main screen

SENSOR FAULT

EXCESS STATIC PRESSURE in fault history

No error displayed on main screen

ZONE SENSOR in fault history NO

SENSOR DATA on main screen for that zone

REMOTE SENSOR

FAULT in fault history

NO SENSOR DATA on main screen for that zone

Sensor on User Interface has failed.

Replace User Interface or use remote sensor for zone 1

Max RPM was reached due to high static pressure. In cooling and heat pump heating, the airflow will step down in an attempt to maintain system operation. In furnace heating, if minimum airflow cannot be achieved, the Zoning Control will dump air where possible or shut down the furnace until more zones call for heat. In nonzoned systems, the UI will not shut the equipment down. See details in next section.

Check wiring and ohm out sensor.

Smart sensor zone x communication fault

Indoor unit communication fault

SMART SENS ZONEx COMM in fault history

NO SENSOR DATA on main screen for that zone

System cannot communicate with smart sensor. Check bus voltages and wiring.

IDU COMM

FAULT in fault history

CRITICAL

MALFUNCTION on main

INDOOR UNIT

COMMUNICATION

FAULT in fault history

SYSTEM

MALFUNCTION on main screen

User interface has lost communication with indoor unit. Check voltages and wiring. Perform communication bus troubleshooting procedure shown on page 21.

8

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

User Interface Generated Fault Descriptions cntd.

Fault

Description

User Interface Display Action

Outdoor unit communication fault

Zone board 1 communication fault

Zone board 2 communication fault

NIM communication fault

Defrost error

Models

ODU COMM

FAULT in fault history

SYSTEM

MALFUNCTION on main screen

OUTDOOR UNIT

COMMUNICATION FAULT fault history

SYSTEM MALFUNCTION on main screen

ZONE 1-4 COMM FAULT in fault history

SYSTEM MALFUNCTION on main screen

ZONE 5-8 COMM FAULT in fault history

SYSTEM MALFUNCTION on main screen

NIM COMM FAULT in fault history

SYSTEM MALFUNCTION on main screen

DEFROST LOCKED in fault history

SYSTEM MALFUNCTION on main screen

User interface has lost communication with outdoor unit. Check wiring between user interface and outdoor unit. Check bus voltages on user interface and outdoor unit. Also check for low voltage short in outdoor unit control wiring.

User interface cannot communicate with damper control module. Check bus voltages and wiring.

User interface cannot communicate with damper control module. Check bus voltages and wiring.

User interface cannot communicate with

NIM. Check bus voltages and wiring.

The outdoor unit has been in defrost for

15 minutes.

Stage down due to noise control

Zone Board Fuse blown

Zone X Sensor

LAT/HPT Sensor

AIRFLOW

LIMITED. STAGE

DOWN

OCCURRED in fault history

No display on main screen

AIRFLOW LIMITED.

SHUTDOWN OCCURRED

In fault history

No display on main screen

24 - ZONE BOARD FUSE in fault history

SYSTEM MALFUNCTION on main screen

55 - ZONE SENSOR in fault history

NO SENSOR DATA on main screen for that zone

A zone has reached its airflow limit setting and the system has compensated by staging down or shutting down. The system is designed to do this to control air noise, and this does not necessarily reflect a problem with the system. See detailed description in Zoning

Troubleshooting section.

Change fuse

Check zone sensor

LAT/HPT SENSOR in fault history

No display on main screen.

Check sensor. These sensors are optional and are for display purposes only. The system does not react to LAT or

HPT temperature inputs.

9

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

User Interface Generated Fault Descriptions cntd.

Fault Description User Interface Display

Original

Models

-A models

SAM radio test failed Not applicable to original models

SAM RADIO

TEST FAILED

Action

SAM profile failed Not applicable to original models

Frozen coil detected Not applicable to original models

SAM PROFILE

FAILED

POSSIBLE

FROZEN COIL in fault history.

SYSTEM

MALFUNCTION on main screen

Radio not able to access Skytel satellite. Ensure full coverage is available by checking Skytel web site. If available, try another location closer to outside wall.

SAM not able to communicate equipment profile to Skytel satellite

Static pressure change related to frozen coil detected. Unit will shut down outdoor unit and run indoor fan at low speed for 1 hour. Cooling will then resume if call exsists

Utility Curtailment

16 (Zone Board status light)

User Interface not communicating with

Zone board

Not applicable to original models

UTILITY

CURTAILMENT

EVENT in fault history

CURTAILMENT

ACTIVE on main screen

No display in fault history or on main screen

Utility relay in outdoor unit has opened from utility signal.

Or Utility Saver option has been enabled in the

Setup menu, but utility relay has not been installed or is wired incorrectly.

Check for proper Utility Relay wiring, if no relay is installed, enter Setup menu and disable Utility

Saver option.

Zone board not communicating with UI. Possibly added after initial power up. Re-install the system, check wiring between user interface and zone board. Need sensor connected to at least 2 zones.

10

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Outdoor Unit Generated Fault Descriptions

Flash Code on Outdoor

Board

38TDB, YDB

598B, 698B

51

24ANA, 25HNA

187A, 180A,

286A, 288A

32

Fault Description User Interface Display

Models

Action

52

3

31

53

Low Pressure Switch trip

LOW PRESS

SWITCH in fault

LOW PRESS Switch is monitored at all times.

SWITCH OPEN These may show up due to history

No display on main screen in fault history

No display on main screen low-pressure trips in low outdoor temperature conditions.

High Pressure Switch trip

HIGH PRESS

SWITCH in fault history

HIGH PRESS

SWITCH OPEN in fault history

No display on main screen

Outside Temp Sensor OAT SENSOR in fault history

SENSOR

ERROR shown in place of the

OAT value on the main screen not display on main screen

OUTDOOR AIR

ERROR shown in place of the

OAT value on the main scree

High-pressure switch trip.

Check refrigerant charge and coils for airflow restrictions.

Ohm out sensor and check

TEMP SENSOR wiring. Could also be an

FAULT in history

SENSOR indication of los of communication with outdoor unit.

Ohm out sensor and check wiring

4 55 Coil Temp Sensor COIL SENSOR in fault history

No display on main screen

COIL TEMP

SENSOR

FAULT in fault history.

No display on main screen

34 56 Thermistor RANGE ERROR in fault history

Error

No display on main screen

Improper relationship between coil sensor and outdoor sensor.

Make sure outdoor sensor is located outside cabinet. Ohm out sensors and check wiring.

6 73 Contactor Shorted VC STANDBY

VOLTS in fault

CONTACTOR

SHORTED in

Voltage sensed at run capacitor when no call for compressor history SYSTEM fault history

MALFUNCTION SYSTEM on main screen MALFUNCTION operation. Could be due to stuck contactor, of if contactor is manually pushed in by on main screen technician

NA 85 Low

Open to original models

LOW

CONTACTOR

Compressor voltage not detected when call for

OPEN in fault operation and high voltage history SYSTEM exits

MALFUNCTION on main screen

11

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Outdoor Unit Generated Fault Descriptions Cntd.

Flash Code on Outdoor

Board

38TDB, YDB

598B, 698B

24ANA, 25HNA

187A, 180A,

286A, 288A

Fault Description User Interface Display

Original

Models

-A models

Action

6

6

47

82

Thermal Cutout

Thermal Cutout

No high voltage to outdoor unit

Lockout

Hi Capacity thermal

Lockout

CUTOUT in fault history

No display on main screen

CUTOUT in fault history

No display on main screen

THERMAL

CUTOUT IN

LOW STAGE in fault history

No display on main screen

Voltage present on run capacitor in lo speed then disappears. Possible causes are internal compressor overload trip or start relay not releasing.

THERMAL

CUTOUT IN

HIGH STAGE in fault history

Voltage present on run capacitor in hi speed then disappears. Possible causes are internal compressor

No display on main screen overload trip or start relay not releasing.

VC STARTUP

VOLTS in fault history

No display on main screen

NO 230V AT

COMPRESSOR in fault history

SYSTEM

MALFUNCTION on main screen

Voltage not present on run capacitor when compressor should be starting. Possible causes: disconnect removed or high voltage not connected.

CUTOUT in fault history

No display on main screen for older platform outdoor unit

THERMAL

LOCKOUT IN

LOW STAGE 4

HOURS in fault history

SYSTEM

MALFUNCTION on main screen

Control detectes thermal cutout in 3 consicutive low stage. On cyles

HI COMP

CUTOUT in fault history

HERMAL

LOCKOUT IN

HIGH STAGE 4

SYSTEM

HOURS in fault history platform 2-stage units, or a combination of 3 hi and low

MALFUNCTION on main screen SYSTEM

MALFUNCTION cycles will cause this event. on main screen

Thermal cutout occurs in three consecutive high cycles in new platform outdoor units. On older

12

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Fan Coil Generated Fault Descriptions

Flash

Code

Fault Description User Interface Display

16 System Communication Fault COM_FAULT in fault history

No display on main screen (16 code on fan coil board)

25 Invalid Model/Motor Selection INVALID MODEL on main screen during installation

26 Invalid Heater Size INVALID HTR SIZE on main screen during installation

27 Invalid Outdoor Unit Size

36 Heater output not sensed when energized

INVALID ODU SIZE on main screen during installation

HTR NOT SENSED in fault history

No display on main screen

37 Heater output sensed On when not energized

41 Blower Motor Fault

HTR STUCK ON in fault history

SYSTEM MALFUNCTION on main screen

BLOWER FAULT in fault history

CRITICAL MALFUNCTION on main screen

44 Motor Communication Fault BLWR COM FAULT in fault history

CRITICAL MALFUNCTION on main screen

46 Brown Out Condition BROWN OUT

Note: User Interface selections override furnace board dipswitch settings

Furnace Generated Fault Descriptions

Code Fault Description

12 Blower On After Power Up

User Interface Display

BLOWER ON AFTER POWER UP in fault history

No display on main screen

Action

See Fan coil

Installation

Instructions for error descriptions.

Action

Occurs when call for heat satisfies during blower on delay.

13 Limit Circuit Lockout

(Auto reset in 3 hours)

LIMIT CIRCUIT LOCKOUT in fault history

SYSTEM MALFUNCTION on main screen

14

15

23

24

25

31

Limit Circuit Lockout

(Auto reset in 3 hours)

Limit Circuit Lockout

(Auto reset in 3 hours)

IGNITION LOCKOUT in fault history

SYSTEM MALFUNCTION on main screen

BLOWER MOTOR LOCKOUT in fault history

CRITICAL MALFUNCTION on main screen

GAS HEAT LOCKOUT in fault history

SYSTEM MALFUNCTION on main screen (Control will not auto reset)

Flame-Proving FLAME SENSE ERROR in fault history

Signal

Pressure Switch Did Not

SYSTEM MALFUNCTION on main screen

LPS OR HPS CLOSED in fault history

Open

Secondary Voltage Fuse

Open

SYSTEM MALFUNCTION on main screen

24VAC FUSE OPEN in fault history

SYSTEM MALFUNCTION on main screen

Model Selection Or Setup

Error

MODEL/SETUP ERROR in fault history.

No display on main screen.

High-Heat Pressure Switch

Or Relay Did Not Close Or

Reopened

HPS OR RELAY OPEN in fault history.

No display on main screen

See Service / Status

Code label in furnace or

Furnace troubleshooting guide

May see this fault during quick power interruptions

See Service / Status

Code label in furnace or furnace troubleshooting guide

13

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Note: User Interface selections override furnace board dipswitch settings

Furnace Generated Fault Descriptions cntd.

Flash

Code

32

33

34

41

42

43

45

Fault

Description

Low-Heat Pressure Switch

Did Not Close Or Reopened

Limit Circuit Fault

Ignition Proving Failure

Blower Motor Fault

Inducer Motor Fault (VS

Inducers Only)

Low-Heat Pressure Switch

Open While High-Heat

Pressure Switch Closed

Control Circuitry Lockout

User Interface Display

fault history

No display on main screen screen

No display on main screen

No display on main screen

LOW PRESSURE SWITCH OPEN in

LIMIT CIRCUIT FAULT in fault history

SYSTEM MALFUNCTION on main

IGNITION FAULT in fault history

No display on main screen

BLOWER FAULT in fault history

CRITICAL MALFUNCTION on main screen

INDUCER FAULT in fault history

LPS OPEN HPS CLOSED in fault history

CONTROL LOCKOUT in fault history

CRITICAL MALFUNCTION on main screen

Action

This fault may show up in the fault history of condensing furnaces due to unprimed trap at start up, wind, or other factors temporarily affecting the vent system. It is not necessarily a system problem. If troubleshooting does not determine a problem, turn on low heat rise in furnace set up to boost inducer airflow by 15%.

See Service / Status

Code label in furnace or furnace troubleshooting guide

41 codes may show up in fault history, but if system is operating properly, this can be ignored.

See Service / Status

Code label in furnace or furnace troubleshooting guide

14

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Checking Airflow, Static Pressure and RPM in the Service Menu

•

The airflow displayed in the Service screen is requested airflow, not actual airflow.

•

The static pressure displayed in the Service Screen is calculated based on requested airflow, RPM and known system characteristics.

•

The RPM displayed in the Service screen is actual RPM.

•

Accuracy of static pressure readings is limited on some furnaces when RPM reaches

1100

RPM data can be used as an indicator of restrictive ductwork. When RPM maxes out, the Blower

Cutback flag is communicated to the furnace or fan coil control. This begins the Blower Cutback algorithm which protects the motor from running at extreme conditions. The cutback algorithm is explained in this document in the description of the EXCESS STATIC PRESSURE system event.

Most furnaces and fan coils will deliver the requested airflow up to the maximum RPM. When a system is not able to deliver the requested CFM at high static pressures, the accuracy of the static pressure calculation is limited. See airflow information in Product Data to determine airflow performance.

15

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Infinity / Evolution Zoning Troubleshooting

The Infinity and Evolution Zoning systems are unique, in that they prohibit a bypass damper from being installed. This is a new technology that is possible due to the fact that only variable speed blower motors are used in these systems. These motors allow control of airflow in every situation.

Most problems that will be encountered with this system will be airflow related. It is imperative that the duct system be sized properly, and thought out in such a way that will accommodate the customer’s requirements.

NOTE

: Some structures are not suitable for zoning applications. Do not assume that this system can be installed to

FIX

a ductwork related problem.

Troubleshooting Over Conditioning Zones

First check sensor locations and ensure they are not being influenced by air drafts behind the wall. Make sure hole is plugged behind sensor or User Interface if the problem is in zone 1.

Next perform Damper/ Sensor check in Zoning Checkout screens to ensure dampers and sensors are properly wired, to the damper control module.

If these are satisfactory, proceed to the steps below.

An important step in troubleshooting the Infinity / Evolution zoning system is to understand what the system is being told to do, and what it is actually doing. Several features are available to assist you in this task:

1. Check system status

Don’t assume a zone is not calling for heat or cooling because the set point matches the actual temperature reading. The system controls in 16ths of a degree, but only displays in whole numbers. There could be as much as 0.9 degree demand in a zone when the readings match.

This is enough demand to bring on high stage heat or cool.

Go into the service screens and check indoor unit status to determine current heat or cool stage.

2. Check Zoning Status

Proceed to zoning status to view damper positions. This is the best way to determine if the system is calling for heat or cool into a zone. If a damper is open, and the system is running, there is a probably a call for conditioning in that zone(unless it is opened slightly due to airflow limit management or excess static pressure– see airflow limit description later in manual). If the damper position is 0, and the zone is overconditioned, there may be an application problem.

3. Possible application issues causing over conditioned zone

If a zone is over conditioning and the damper position is 0, then you may have a damper problem such as leakage issue, or conditioning from an andjacent zone may be carrying over into the problem zone.

4. A zone may be overconditioned within limits due to Airflow Limit and Excess static pressure issues. If a zone is set back more than 3 degrees from the most conditioned set point, and the system needs to dump air to continue operating, that zone may be used as a dump zone. See

Airflow Limit and Excess Static Pressure

5. Other possible causes of over-conditioned zones

•

Partially broken damper wire intermittently losing connection.

•

Partially stuck damper

16

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Options to control over zone conditioning:

•

Set airflow limits in small zones to MAX if air noise is acceptable

•

Set points should be set no more than 3 degrees different from zone to zone

•

Evaluate duct system and upsize or add supplies and returns where required

•

Evaluate structure design for zoning suitability

The system will allow some over conditioning to ensure minimum airflow through the equipment and maintain selected airflow limits. The system may not be capable of wide set point differences. For example, if a customer wants the upstairs bedroom at 62 degrees in heating and the downstairs zone at 70, the upstairs zone may be allowed to over condition (up to 67 deg) in order to satisfy minimum airflow requirements through the equipment, and /or selected airflow limits. Below is a description of this process.

Airflow limits and equipment protection

The maximum airflow allowed into a zone is based on the relative size of the zone determined by the duct assessment, and the airflow limits selected for each zone. Airflow limits are set to high as factory default. This means that 200% of the assessed air flow is allowed into the zone.

Example if a zone size is determined to be 25% of the entire system, and the maximum airflow

(heating or cooling) is 2000 cfm, the maximum airflow into this zone is 2000 x 25% x 200% =

1000cfm.

This airflow limit multiplier can be adjusted to reduce or increase allowable noise levels; Low =

100%, Med = 150%, Max = 210% (will not cause stage down when reached).

If the system determines that it cannot deliver the airflow into a zone that needs conditioning, and that zone has an airflow limit selected, the system will take the following 4 steps:

1. Reduce airflow if possible a. 275 CFM per ton minimum in high stage cooling (325 if Dehum airflow set to

High). 175 CFM per ton in low stage cooling for Bristol units. Minimum airflow for

Copeland 2-stage outdoor units will vary. b. Comfort Heat airflow is minimum for heat pump heating (3.5 x outdoor temp +

137) cfm /ton c. Use heat pump comfort airflow as minimum if AC Airflow is Efficiency or MAX c. No adjustment for furnace heating

2. Dump air to zones set to Unoccupied a. Unoccupied zones can be conditioned up to the most conditioned set point

3. Dump air to zones with lower set points a. Zones with lower set points may be conditioned to within 3 deg of the most conditioned set point. b. Increase or decrease all zones an additional 0.75 deg

4. Stage down equipment a. Equipment will stage down or shut off if necessary b. Fault history will record an event of (AIRFLOW LIMITED SHUTDOWN

OCCURRED) c.

If shut down occurs, other zones need to call before equipment will resume operation

Options if Airflow Limits are not satisfactory and AIRFLOW LIMITED events are occurring

:

•

Increase airflow setting to MAX in suspect zones if air noise is acceptable. The system will not stage down when the airflow limit is set to MAX. In extreme cases, even a zone set to MAX may cause a shut down on static pressure if the minimum airflow through the equipment cannot be maintained. “EXCESS STATIC PRESSURE” will be recorded in these cases.

•

Evaluate duct design and make improvements where necessary

17

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

•

Evaluate structure for zoning suitability

Zoning system will not run or shuts down intermittently. “EXCESS STATIC PRESSURE” appears in the last 10 faults

System may be held off until more zones are calling. If the zone or zones calling are not capable of delivering the minimum required airflow, the system will wait until more zones call for conditioning.

This system contains a Blower Cutback algorithm that will not allow the system to run in extremely restrictive conditions. Blower Cutback is initiated when the blower has reached its maximum RPM, and is unable to deliver the requested airflow. The blower sends a signal at the maximum RPM which varies depending on the equipment installed. This usually occurs at around 1200-1300 RPM.

The steps below occur when Blower Cutback has been initiated:

In furnace heating, or heat pump comfort heating, the system will stage down or shut down immediately until more zones call for heat. In heat pump Efficiency heating, the airflow will be reduced heat pump Comfort levels and stage down if that is not possible

In cooling, there is more airflow flexibility. The following process occurs in cooling mode:

•

CFM request is reduced in 50 CFM increments (this reduction is visible in the status screens) Static pressure display is not valid in this range and should be ignored since the unit cannot deliver the requested airflow.

•

If blower RPM is still above cutback levels, continue reducing CFM request about once a minute

•

Reduce CFM request down to minimum CFM described above

•

If CFM is at minimum, and cutback is still in effect, begin the same airflow relief process used for Airflow Limits and record EXCESS STATIC PRESSURE fault in last 10 system events

•

If minimum airflow cannot be achieved after this process, stage down to low and continue until Cutback is no longer active, or shut off if necessary

Options if EXCESS STATIC PRESSURE is active in Last 10 Events:

•

Decrease airflow limit setting to from MAX to something else. This will engage the airflow management algorithm sooner and may allow the system to run longer.

•

Evaluate duct design and make improvements where necessary

•

Evaluate structure for zoning suitability

Zoning Situation: “AIRFLOW LIMITED, STAGEDOWN/SHUTDOWN OCCURRED” appears in the Last 10 Faults:

Factory default airflow limit is High in each zone. This means that the zone is allowed to deliver 200% of the maximum assessed airflow. For example, if the maximum heating airflow is 2000 CFM and a zone’s relative size is 25%, the maximum airflow for that zone when set to

High is calculated to be 2000 CFM * 25% * 200% = 1000 CFM

If the airflow limit is set to MED, the max allowable airflow is 150%, if set to LOW; 100%. If set to MAX, there is no airflow limit, but the system could still shut down in heating if the maximum motor RPM is reached due to EXCESS STATIC PRESSURE.

If the equipment owner is not complaining about zones being under conditioned, then this message should be ignored. It indicates that the airflow limit was exceeded for a zone and the

18

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006 system needed to stage down. If the homeowner is complaining, then the airflow limit for that zone should be raised. However, the homeowner may now experience excessive noise for that zone. It should be communicated to the equipment owner that there is a trade-off between comfort and noise when these airflow limits are adjusted.

Zoning Situation: When increasing the set temperature for a zone, the heating does not come on until the set temperature is 3 degrees over all of the other zones.

The system may not allow equipment to turn on after a set point adjustment if there are not enough zones calling. Once a difference of 3 degrees exists between zones, the system can then use those setback zones as dump zones, and the system may now turn on. Lowering the set point back to within 3 degrees may cause the equipment to turn off. If the airflow limits are set to Maximum, then this problem does not occur.

Zoning Situation: Continuous Fan used in some zones but not in others. Dampers are opening in zones where fan is set to Auto

Each indoor unit must deliver a minimum airflow in continuous fan mode. If the system determines that this airflow cannot be met due to duct capacity to zones requiring air, it will open zones set to Auto in order to deliver the required air. This is designed into the system and is not an equipment problem.

Damper output check

Carrier and Bryant residential zoning dampers are designed to move from full open to full close or vice versa in 15 seconds. They are driven by 24vac triac inputs. When checking the zone board for damper outputs, a voltmeter can be used to check between common –open or common-closed while the damper is driving. Since the output is driven by triacs, some voltage may be present when the dampers are not driving due to triac leakage. This voltage will is not capable of driving a load.

When checking outputs on the damper control module, you may notice that voltage is present on both open-common and closed-common when the damper should be moving. This is not a problem with the damper control module. The circuitry in the actuator determines which direction the actuator will move.

Replacing Damper actuators

The range of motion for rectangular dampers is different from round dampers. A rectangular damper moves through 90 degrees and the round damper moves through 45 degrees. Both will open or close fully in 15 seconds, thus the rectangular actuator rotates twice as fast as a round actuator. Ensure the proper actuator is selected.

19

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Before condemning the User Interface or circuit board

Re-install the system:

In some situations, there may have been changes and additions to the system set up after initial installation. This can cause problems because the system has not been “told” of the changes, and it does not recognize them.

Cycling power does not tell the system a new component has been installed.

Follow the steps below:

-Push and hold Advance for 10 seconds

-Install

Follow prompts

Reset Factory Defaults:

This will put you back to the beginning and could avoid confusion from unknown changes to the system configuration. Follow steps below:

•Push and hold Advance for 10 seconds

•Setup

Thermostat

Reset Factory Default

Changing components

YES

Last 10 Faults – YES

If a circuit board is changed, remember that the fault history is maintained in the User Interface Last 10

System Events. Faults from the previous failed components will remain in the history unless cleared.

20

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

Troubleshooting Communication Bus

CAN NOT FIND INDOOR UNIT

Disconnect O.D. unit and all other devices on ABCD bus

except indoor unit and UI.

Cycle system power.

Indoor unit found?

NO

Connect UI to indoor unit at the indoor unit.

YES

Reconnect one device at a time to

ABCD bus.

Device found?

NO

Check device wiring.

YES

Indoor unit found?

NO

YES

Check wiring to UI mounting location.

YES

Try another

UI?

NO

Measure voltage on ABC terminals at indoor unit (see

Table-1) Possible indoor unit problem.

Wiring

OK?

NO

Correct wiring and reinstall system.

YES

Measure voltage on

ABC terminals at device (see

Table- 1)

Possible device problem.

21

Software Revs 3,5,6,8,10, 12 Infinity /Evolution Troubleshooting (Rev. 2)

10-12-2006

TABLE 1

Advance Troubleshooting

Fan Coil / Furnace / 2-stage Communication Bus

FE Control Board

Furnace Control Board

Two-Speed Control Board

-Voltage Readings -

With board Power applied, and No U.I. connected, all other devices disconnected

A to B

A to C

B to C

C to D

~3 vdc

~3 vdc

~.01 to 0.3 vdc

24 vac

The above readings are meant to prove that the communication driver is not dead or shorted.

It does not guarantee that the unit will communicate. If communication problems exist and voltage read good, an external short in the thermostat wiring, or a mis-applied accessory may be the cause.

-Voltage Readings -

With board Power applied, and U.I. Applied, all other devices disconnected

A to B

A to C

B to C

C to D

~2.5 to 3.9 vdc (pulsating)

~2.5 to 3.9 vdc (pulsating)

~0.1 to 0.9 vdc (pulsating)

24 vac

The above readings are meant to prove the communication drivers are functioning, are not open or shorted, and wiring between devices is OK. If voltages check out OK and communication problems still exist, it could be a board problem.

22

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project