- No category

advertisement

No. SS2-8310-0200

Single Acting Type

Pneumatic Valve Positioner

Model HTP

OVERVIEW

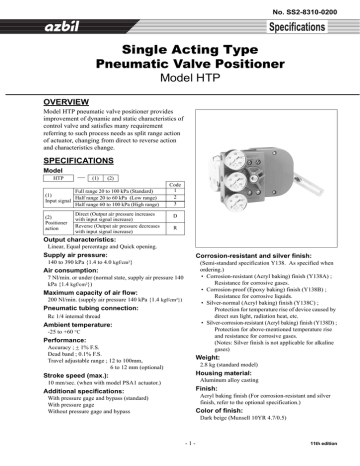

Model HTP pneumatic valve positioner provides improvement of dynamic and static characteristics of control valve and satisfies many requirement referring to such process needs as split range action of actuator, changing from direct to reverse action and characteristics change.

SPECIFICATIONS

Model

HTP (1) (2)

(1)

Input signal

Full range 20 to 100 kPa (Standard)

Half range 20 to 60 kPa (Low range)

Half range 60 to 100 kPa (High range)

Code

1

2

3

(2)

Positioner action

Direct (Output air pressure increases with input signal increase)

Reverse (Output air pressure decreases with input signal increase)

Output characteristics:

Linear, Equal percentage and Quick opening.

D

R

Supply air pressure:

140 to 390 kPa {1.4 to 4.0 kgf/cm² }

Air consumption:

7 Nl/min. or under (normal state, supply air pressure 140 kPa {1.4 kgf/cm² })

Maximum capacity of air flow:

200 Nl/min. (supply air pressure 140 kPa {1.4 kgf/cm²})

Pneumatic tubing connection:

Rc 1/4 internal thread

Ambient temperature:

-25 to +60 °C

Performance:

Accuracy ; + 1% F.S.

Dead band ; 0.1% F.S.

Travel adjustable range ; 12 to 100mm,

6 to 12 mm (optional)

Stroke speed (max.):

10 mm/sec. (when with model PSA1 actuator.)

Additional specifications:

With pressure gage and bypass (standard)

With pressure gage

Without pressure gage and bypass

Corrosion-resistant and silver finish:

(Semi-standard specification Y138. As specified when ordering.)

• Corrosion-resistant (Acryl baking) finish (Y138A) ;

Resistance for corrosive gases.

• Corrosion-proof (Epoxy baking) finish (Y138B) ;

Resistance for corrosive liquids.

• Silver-normal (Acryl baking) finish (Y138C) ;

Protection for temperature rise of device caused by direct sun light, radiation heat, etc.

• Silver-corrosion-resistant (Acryl baking) finish (Y138D) ;

Protection for above-mentioned temperature rise and resistance for corrosive gases.

(Notes: Silver finish is not applicable for alkaline gases)

Weight:

2.8 kg (standard model)

Housing material:

Aluminum alloy casting

Finish:

Acryl baking finish (For corrosion-resistant and silver finish, refer to the optional specification.)

Color of finish:

Dark beige (Munsell 10YR 4.7/0.5)

- 1 11th edition

No. SS2-8310-0200

70

60

50

100

90

80

20

10

40

30

CAM 3

CAM 1

CAM 2

0

100

10 20

90 80

30 40 50 60 70

Direct acting positioner

70 60 50 40 30

Reverse acting positioner

Travel (%)

80

20

Figure 1 Cam characteristics

90 100

10 0

Azbil Corporation

Cam characteristics:

Linear (cam 1, standard) and two other kinds. By selecting the other two cams, valve characteristics can be approximated as follows:

(1) For reverse acting valve

Cam 2

• Linear characteristic valve plug

--> Quick opening characteristic

• Equal percentage characteristic valve plug

--> Linear characteristic

Cam 3

• Linear characteristic valve plug

--> Equal percentage characteristic

• Quick opening valve plug

-->Linear characteristic

(2) For direct acting valve

The effect of cams 2 and 3 applied to direct action valves is reversed as compared with the case of reverse action valves.

(Unit: mm)

151

100

16

64

M8 Screw 2

10

MAX.120

MIN.26

Bypass switch

300

137

Air conn.

to actuator Rc1/4

178

Figure 2 External dimensions

117

Input air conn. Rc 1/4

Supply air conn. Rc 1/4

Rotate 90 C when equiped for G-O-Motor

Please, read ‘Terms and Conditions’ from following URL before the order and use.

http://www.azbil.com/products/bi/order.html

Specifications are subject to change without notice.

1-12-2 Kawana, Fujisawa

Kanagawa 251-8522 Japan http://www.azbil.com/

(11)

- 2 -

11th edition: Aug. 2015

No part of this publication may be reproduced or duplicated without the prior written permission of Azbil Corporation.

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement

Table of contents

- 1 OVERVIEW

- 1 SPECIFICATIONS

- 1 Model

- 1 Output characteristics:

- 1 Supply air pressure:

- 1 Air consumption:

- 1 Maximum capacity of air flow:

- 1 Pneumatic tubing connection:

- 1 Rc 1/4 internal thread

- 1 Ambient temperature:

- 1 Performance:

- 1 Stroke speed (max.):

- 1 Additional specifications:

- 1 Corrosion-resistant and silver finish:

- 1 Weight:

- 1 Housing material:

- 1 Finish:

- 1 Color of finish:

- 2 Cam characteristics:

- 2 (1) For reverse acting valve

- 2 Cam 2

- 2 Cam 3

- 2 (2) For direct acting valve