advertisement

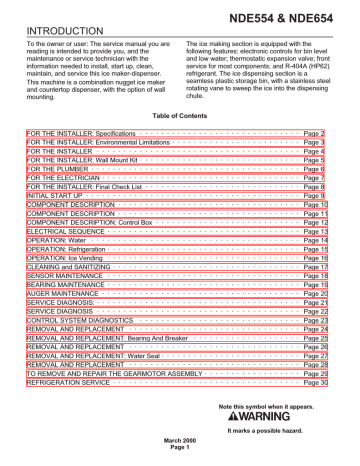

NDE554 & NDE654

INTRODUCTION

To the owner or user: The service manual you are reading is intended to provide you, and the maintenance or service technician with the information needed to install, start up, clean, maintain, and service this ice maker-dispenser.

This machine is a combination nugget ice maker and countertop dispenser, with the option of wall mounting.

The ice making section is equipped with the following features: electronic controls for bin level and low water; thermostatic expansion valve; front service for most components; and R-404A (HP62) refrigerant. The ice dispensing section is a seamless plastic storage bin, with a stainless steel rotating vane to sweep the ice into the dispensing chute.

Table of Contents

FOR THE INSTALLER: Specifications · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 2

FOR THE INSTALLER: Environmental Limitations · · · · · · · · · · · · · · · · · · · · · · · · Page 3

FOR THE INSTALLER · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 4

FOR THE INSTALLER: Wall Mount Kit · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 5

FOR THE PLUMBER · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 6

FOR THE ELECTRICIAN · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 7

FOR THE INSTALLER: Final Check List · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 8

COMPONENT DESCRIPTION · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 10

COMPONENT DESCRIPTION · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 11

COMPONENT DESCRIPTION: Control Box · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 12

ELECTRICAL SEQUENCE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 13

SENSOR MAINTENANCE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 18

BEARING MAINTENANCE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 19

AUGER MAINTENANCE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 20

CONTROL SYSTEM DIAGNOSTICS · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 23

REMOVAL AND REPLACEMENT · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 24

REMOVAL AND REPLACEMENT: Bearing And Breaker · · · · · · · · · · · · · · · · · · · · Page 25

REMOVAL AND REPLACEMENT · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 26

REMOVAL AND REPLACEMENT: Water Seal · · · · · · · · · · · · · · · · · · · · · · · · · · Page 27

REMOVAL AND REPLACEMENT · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 28

TO REMOVE AND REPAIR THE GEARMOTOR ASSEMBLY · · · · · · · · · · · · · · · · · · Page 29

REFRIGERATION SERVICE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · Page 30

Note this symbol when it appears.

It marks a possible hazard.

March 2000

Page 1

NDE554 & NDE654

FOR THE INSTALLER: Specifications

This ice maker-dispenser is designed to be mounted on a machine stand, or a countertop, or using wall mounting kit KWB3, hung from a wall.

The sink may be retained, or removed and the optional longer splash panel (KSP1B) installed in place of the original. Instructions for each kit are included in this manual.

Before beginning the installation, check that all the materials and kits required are available at the installation location.

20.5"

4.5"

3.54" ELECTRICAL JUNCTION BOX

NAMEPLATE on side panel

22.5"

14.06"

2.56"

1.88"dia

Optional for water and drain lines

Serial Number Plate inside on upper base

1/2" FPT

Cond. Drain

(Water Cooled)

3/4" FPT

Drain

3/8" FPT

Condenser

Water Inlet

(Water Cooled)

3/8" Flare

Potable Water Inlet

5.12"

12.27" 3.12"

1.12"

6.43"

SPECIFICATIONS

Model Number Dimensions w" x d" x h"

NDE554AS-1A 26 x 22

1

2

NDE554WS-1A same

NDE554AS-6A same

NDE554WS-6A same

NDE654AS-1A 26 x 22

1

2

NDE654WS-1A same

NDE654AS-6A same

NDE654WS-6A same x 41 Air

Water

Air

Water x 48 Air

Water

Air

Water

Condenser

Type

Basic Electrical Min. Circ.

Ampacity

115/60/1 same

230/50/1 same

115/60/1 same

230/50/1 same

19.1

17.9

19.3

17.8

Max

Fuse

Size

25

20

25

20

March 2000

Page 2

Ref. Charge

R-404A (oz)

24

18

24

18

24

18

24

18

NDE554 & NDE654

FOR THE INSTALLER: Environmental Limitations

Installation Limitations

This ice system is designed to be installed indoors, in a controlled environment.

Minimum

Air Temp

Water Temp

50

40

0

0

F.

F.

Water Pressure 20 PSI

Maximum

100 0 F.

100 0 F.

80 PSI

Voltage (115v) 104

Voltage (240v) 207

126

253

Operating the machine outside of the above limitations, or outdoors, is potentially damaging to the machine; also it is misuse of the machine, which may void the warranty.

Scotsman Ice Systems are designed and manufactured with the highest regard for safety and performance. They meet or exceed the standards of UL, NSF, and CUL.

Scotsman assumes no liability or responsibility of any kind for products manufactured by Scotsman that have been altered in any way, including the use of any part and/or other components not specifically approved by Scotsman.

Scotsman reserves the right to make design changes and/or improvements at any time.

Specifications and design are subject to change without notice.

WALL

CUT AWAY

Service Limitations

Do not install in a location where the top of the machine is within 6" of a fixed ceiling. Do not install air cooled models in a location where there is less than 6" clearance to the left and right of the cabinet.

CEILING

CUT AWAY

SPACE

ABOVE

FOR

SERVICE

Water Limitations

An ice machine is a food manufacturing plant; it takes a raw material, water, and turns it into a food product, ice. The purity of the water is very important in obtaining pure ice and in maximizing product life. This section is not intended as a complete resource for water questions, but it does offer these general recommendations:

1. Filter the water used to produce ice. That is the water going to the “potable” water connection.

Water filters vary greatly in ability and function.

Install one that filters out suspended solids to a dimension of 5 microns or smaller. The finer the filter the better, but finer filters will clog sooner than course ones. It may be necessary to add a course filter ahead of the fine filter to prolong filter life.

2. Check with a water treatment specialist for a water test, and recommendations regarding filters and treatment.

Airflow

SPACE

FOR

UTILITIES

6" SPACE

FOR AIR

6" SPACE

FOR AIR

(A/C)

March 2000

Page 3

NDE554 & NDE654

FOR THE INSTALLER

Location

After uncrating and inspection, the unit is ready for installation. It is important that the machine be installed in a location where it has enough space above and behind it for service. Air cooled models require a minimum of 6 inches to the left and right of the machine for air circulation.

Machine Stand Installation

Tip the stand on its back and install the legs, return the stand to the upright position. Adjust leg levelers so that the stand does not “rock”.

Counter Top or Machine Stand Installation

The base of the icemaker-dispenser must be sealed to the object it rests upon. Food grade silastic sealant such as Scotsman part number

19-0529-01 is recommended.

Place a bead of the sealant on the machine stand or counter top to match the outside edge of the cabinet base and sink.

The icemaker-dispenser is heavy: use of a mechanical hoist is recommended to lift it to the height required to install it.

Follow the instructions packed with the machine stand for proper connection to the dispenser. The dispenser must be bolted to the machine stand from inside the stand.

In both counter top and machine stand installations, wipe off and neatly smooth any excess sealant. Level the machine stand and cabinet.

Unpack and install the sink brackets.

The hardware for the sink brackets is packed with the sink. Screw one bolt into all four holes to tap them BEFORE attaching the brackets. Attach the brackets and place the sink assembly onto the two sink brackets. Push down at the back to seat the sink onto the brackets.

Press the sink onto the bead of sealant. Wipe off and neatly smooth any excess sealant from under the sink edge.

March 2000

Page 4

SEAL THE

UNIT TO

THE

COUNTER

OR STAND

NDE554 & NDE654

FOR THE INSTALLER: Wall Mount Kit

CAUTION

It is recommended that the wall mounting installation be done by an experienced contractor.

The weight of the machine when in use may exceed 350 pounds. The unit should be mounted on a solid, rigid wall with proper fasteners for that type of wall and of adequate strength to support the weight of the machine when in use.

BASE

HOLE

SIDE

ROUTING

Clearance between the wall and the icemaker is a maximum of 1 inch. Check utility connections first.

The electrical junction box will have to be removed, and the electrical connections made inside the cabinet in compliance with local codes. The plumbing connections may be made through the base, or at either side through the pre-punched holes, using standard plumbing practices.

Interior plumbing lines must be disconnected from the original connections and plugged when routing through the side or base.

1. Remove machine top. Attach bracket “A” to machine using (3) nuts, (3) flat washers, (3) lock washers, and (3) 5/16-18 bolts received with the kit.

X"

7.58

1" CLEARANCE

X = 30" for NDE554

X = 38.6" for NDE654

16"

DO NOT LIFT ON SINK

16" A

2. Mount brackets “B” and “C” to the wall at the dimensions shown for the unit. (hardware for this is not included).

B

Use fasteners and wall of sufficient strength to carry the use and weight of the icemaker-dispenser.

12"

12"

3. Lift unit up and hook bracket “A” over bracket

“B”. Slide unit until the two remaining holes are aligned and secure with the remaining (2) 1/4-20 bolts, flat washers and lock washers.

C

March 2000

Page 5

NDE554 & NDE654

FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

Water Inlet

Air Cooled Models: Connect a potable, cold water supply to the 3/8" male flare at the back of the cabinet. Install a hand valve near the machine to control the water supply. 3/8" O.D. copper tubing is recommended.

Water Treatment: In most areas, a water filter of some type will be useful. In areas where the water is highly concentrated with minerals the water should be tested by a water treatment specialist, and the recommendations of the specialist regarding filtration and/or treatment should be followed.

Water Cooled Models: Connect a separate 3/8"

O.D. copper line with a separate hand valve to control it to the 3/8" FPT condenser inlet at the back of the cabinet. The water pressure to all lines must always be above 20 psig, and below 80 psig.

Drains

Air Cooled Models: There is one ¾ " FPT drain at the back of the cabinet, the drain line is of the gravity type, and ¼ inch per foot fall is an acceptable pitch for the drain tubing. There should be a vent at the highest point of the drain line, and the ideal drain receptacle would be a trapped and vented floor drain. Use only ¾ " rigid tubing.

Water Cooled Models: In addition to the above mentioned drain, a separate condenser drain must be installed. Connect it to the ½ " condenser drain connection at the back of the cabinet.

WATER INLET

CABINET

DRAIN

OPTIONAL

WATER

FILTER

WATER INLET

SHUT OFF

VALVE

VENTED

DRAIN TUBE

WATER COOLED DETAIL

CONDENSER

WATER INLET

FLOOR DRAIN

March 2000

Page 6

POTABLE

WATER INLET

CONDENSER

DRAIN

CABINET

DRAIN

NDE554 & NDE654

FOR THE ELECTRICIAN

CONFORM TO ALL APPLICABLE CODES

Connect the electrical power to the unit to the power leads in the junction box at the rear of the machine.

Check the nameplate (located on the back panel) for the voltage requirements, and for the minimum circuit ampacity. The machine requires a solid chassis to earth ground wire.

The ice maker should be connected to its own electrical circuit so it would be individually fused. Voltage variation must remain within design limitations, even under starting conditions.

All external wiring must conform to national, state, and local electrical codes. The use of a licensed electrician is required to perform the electrical installation.

ELECTRICAL

POWER

JUNCTION

BOX

March 2000

Page 7

NDE554 & NDE654

FOR THE INSTALLER: Final Check List

1. Is the icemaker-dispenser installed indoors, in a location where the air and water temperatures are controlled, and where they do not go beyond design limitations?

BACK VIEW OF COMPLETED INSTALLATION

ELECTRICAL?

2. Is there an electrical service disconnect within sight of the installed machine? Is the machine on a separate circuit? Has the voltage been checked and compared to nameplate requirements?

LEVELED?

3. Have all of the plumbing connections been made and checked for leaks?

4. Has the machine been leveled?

ICEMAKER

DISPENSER

5. Is there a minimum of 6 inches of clearance at the left and right sides of an air cooled machine?

6. Is there a minimum of 6 inches of clearance at the top and back of the machine for service and utility connections?

PLUMBING?

Wall mounted only: Is the machine properly installed and secured to the wall?

7. Is there a water shut off valve installed near the machine?

8. Have all of the shipping blocks been removed?

MACHINE

STAND

March 2000

Page 8

NDE554 & NDE654

INITIAL START UP

Pre Start Inspection

1. Remove the two front panels.

2. Check that all shipping blocks have been removed.

3. Remove any and all packing tape (check inside the storage bin).

4. Inspect the interior of the machine for loose screws or wires. Check that no refrigerant lines are rubbing each other. Check that the fan blade on air cooled models turns freely.

5. Check that the machine is installed correctly according to the final check list.

Start Up

1. Go through the pre start inspection.

2. Open the water hand valve, observe that water enters the water reservoir, fills the tube from the reservoir to the evaporator and then shuts off.

Check for leaks.

3. Switch the master switch on. The electrical start up sequence is automatic:

A. There will be a short (15 second) delay before the gearmotor starts.

B. After the gearmotor starts, the compressor will start.

4. On air cooled models, warm air will begin to flow from the condenser. Water cooled models will begin to discharge warm water down the drain.

5. The unit should soon be making ice. If desired, the low side pressure may be checked: it should be

38 PSIG + or - 2 PSIG.

The air cooled discharge pressure will depend upon air and water temperatures, but should be between 240 PSIG and 340 PSIG.

Water cooled discharge pressure should be about

245 PSIG. If needed, adjust the water regulating valve.

The above numbers are for new, clean machines.

Field values may be somewhat higher or lower.

6. There are no adjustments to make, so replace the panels.

7. Check ice dispensing by pushing in on the glass filler lever.

March 2000

Page 9

8. Switch off the icemaker-dispenser, remove the top panel and the top of the ice storage bin.

Sanitize the interior of the ice storage bin with a locally approved sanitizer. A possible sanitizer is a mixture of 1 ounce of household bleach to 2 gallons of water. Wash the interior of the bin with the sanitizer. Replace all covers and panels.

Switch the icemaker-dispenser back on.

9. Give the owner/user the service manual, instruct him/her in the operation and maintenance requirements of the unit. Make sure they know who to call for service.

10. Fill out the Customer Evaluation and Warranty

Registration form, and mail it in to Scotsman.

NDE554 & NDE654

COMPONENT DESCRIPTION

Control Box: Contains the electrical controls that operate the machine.

High Pressure Cut Out Switch: An automatic reset switch sensing the high side refrigeration pressure. It is set to shut the machine off if the discharge pressure should ever exceed 450 psig.

Evaporator: A vertical stainless steel tube, refrigerated, and water filled. In it there is a stainless steel auger.

Reservoir: Float operated, it maintains the water level in the evaporator at a constant level, it also contains the water level sensor.

Water Level Sensor: Senses if there is water in the reservoir to make ice out of. Will shut the machine off it there is none.

Ice Level Sensor: An electronic “eye”, it senses the presence of ice in the bottom of the ice discharge chute.

Operates to turn the ice machine on and off automatically as the level of ice in the bin changes.

Drain Tube: When uncapped and lowered, drains the evaporator.

Condenser: Air or water cooled, where the heat removed in ice making is discharged.

Ice Storage Bin Assembly: A plastic lined, insulated cylinder that receives, stores and dispenses the ice. Fresh ice enters at the top, and when the bin is full enough the ice will be between the ice level sensors, and the ice making will stop. Ice is dispensed through a chute at the bottom front when the bin vane sweeps the ice over the chute.

ICE LEVEL SENSORS

Glass Filler Lever: Pushing in on this lever causes the ice dispensing cycle to occur.

Low Pressure Cut Out Switch: An automatic reset control that shuts off the ice machine when the low side pressure drops below a preset point,

15 psig.

WATER LEVEL

SENSOR

EVAPORATOR

RESERVOIR

DRAIN TUBE

CONTROL

BOX

HIGH PRESSURE

CUT OUT

ICE STORAGE BIN

CONDENSER

LOW PRESSURE

CUT OUT

March 2000

Page 10

GLASS FILLER LEVER

COMPONENT DESCRIPTION

Evaporator: A refrigerated vertical tube filled with water and containing a water seal and auger.

Auger: A solid stainless steel double spiral auger, it pushes the ice crystals up to the top of the evaporator.

Water Seal: A two part “face” seal, the top half rotating with the auger, the bottom half stationary, the sealing action being where the two seal “faces” meet.

Ice Sweep: A plastic cap with “fingers”. It revolves with the auger to “sweep” the ice into the ice chute.

Breaker: Where the ice is compressed and much of the extra water is squeezed out of it before it is discharged into the bin.

NDE554 & NDE654

Motor: A split phase motor that drives the gear reducer.

Thrust Bearing: As the ice is pushed up the evaporator, the auger is thrust down, and pressure from the auger thrust is taken up by this bearing.

ICE SWEEP

BEARING

BREAKER

MOTOR

EVAPORATOR

AUGER

WATER SEAL

March 2000

Page 11

NDE554 & NDE654

COMPONENT DESCRIPTION: Control Box

Contactor: A definite purpose contactor connecting the compressor to the power supply.

Control Board: Controlling the ice machine through sensors and relays. The sensors are for ice level and water level. The relays are for the gear motor (with a built in time delay to clear the evaporator of ice when the unit turns off) and for the compressor.

Mode Switch: Manual control for the machine.

Potential Relay: The compressor start relay.

Control Board

Water OK Light

Power Light

Service Light

Freeze Light

Bin Full

Light

LED1

Compressor

Relay

LED3

March 2000

Page 12

Auger

Relay

NDE554 & NDE654

ELECTRICAL SEQUENCE

There are 7 indicator lights on the control board:

· WTR-OK (Water OK). Green.

Normal =

Glowing. Glows when there is water in the reservoir.

· PWR-OK (Power OK).

Green.

Normal =

Glowing. Glows when the control board has

power and is functional.

· Service.

Red.

Normally Off.

· Freeze.

Red.

Normally glowing when making ice.

· Bin Full.

Red.

Normally Off when making ice.

· LED1. White. Located next to the board’s

Compressor Relay. Normally Glowing when making ice.

· LED3. White. Located next to the board’s Auger

Motor Relay. Normally Glowing when making ice.

If the machine is switched off at the mode switch, but is otherwise ready to go, switching the mode switch to ON does the following:

· The PWR-OK light glows.

· If there is water in the reservoir the WTR-OK light glows.

· After 10 seconds the Freeze, LED1 and LED3 lights glow and the machine starts up.

Start Up:

· The compressor relay and auger motor relay become energized, connecting power to the windings of the auger motor and contactor coil.

· The contactor is energized, connecting power to the compressor, and the compressor starts.

· As ice is made it passes between the ice level sensors but because it is not a continuous stream it only interrupts the sensor’s infrared beam momentarily. The bin full light remains off and the machine stays on until ice builds up in the bin and blocks the path between the sensors for 6 seconds or longer. When that occurs the bin full light glows and the machine shuts down.

Shut Down:

· The compressor relay opens, LED1 goes out.

· The compressor contactor opens

· The compressor stops

· The auger motor stays on for 1 more minute, clearing out ice in the evaporator, and then

· The auger motor relay opens, LED3 goes out and the auger motor stops.

The compressor will not restart until 2 minutes or more have passed after the last shut down.

If the path between the ice level sensors remains clear for more than 10 seconds the ice machine will restart.

Control Board Protection Devices

· When the water level in the reservoir falls below the water level sensor’s tip, the WTR-OK light goes out and the machine shuts down.

When water refills the reservoir the WTR-OK light glows and the machine starts up again.

· If the auger drive motor current becomes excessive the compressor and auger drive motor will be switched Off and the Service light will blink. The control board will restart the auger drive motor in 4 minutes. If during the first 60 seconds after restart the auger motor current stays within limits, the compressor is restarted and the machine returns to normal operation. If the auger motor’s current is excessive within 60 seconds after the restart, the process will be repeated once more. If during that try the current is still excessive the machine shuts down and must be manually reset. The service light will then be glowing continuously.

To Reset: Disconnect and reconnect electrical power to the machine.

Other Protection Devices:

· If the high pressure cut out switch opens the machine will stop immediately. It will automatically reset when the pressure falls below its cut in pont.

· If the low pressure cut out switch opens the machine will stop immediately. It will automatically reset when the pressure rises above its cut in point.

· The mode (on - off) switch is the manual

March 2000

Page 13 control for the complete machine, but it is not a service disconnect.

NDE554 & NDE654

OPERATION: Water

Water enters the machine through the 3/8" male flare at the rear of the cabinet, goes to the water reservoir which it enters through the float valve.

The water then goes out the bottom of the reservoir tank to the bottom of the evaporator.

Reservoir overflow, evaporator condensation, bin drainage and water from the sink are all routed to a common drain. Water cooled models have a separate water circuit for the cooling water: it enters the fitting at the rear, goes to the water regulating valve, then to the water cooled condenser and down the drain.

There is also an additional water circuit to an electric valve. When the water station glass filler lever is pushed, a switch closes a circuit to the electric water valve, and water is dispensed.

Note: The correct water level is determined when the machine is operating. Check the water level and compare it to the line molded into the side of the reservoir. The water level should be between 1

8

“ above and

1

4

" below the line.

If needed, adjust the water level by bending the float arm.

WATER RESERVOIR

WATER

LEVEL

WATER INLET

WATER DRAIN

WATER LINE FOR

WATER STATION

March 2000

Page 14

OPERATION: Refrigeration

Beginning at the compressor, the refrigerant is compressed into a high temperature gas. The discharge line directs this gas to the condenser. At the condenser (air or water cooled) the gas is cooled by either air or water and it then condenses into a liquid. This high pressure liquid then goes through the liquid line to the expansion valve.

The thermostatic expansion valve meters liquid refrigerant into the evaporator, the volume of liquid refrigerant depending upon the temperature of the evaporator; warmer evaporators get more refrigerant and colder evaporators get less.

NDE554 & NDE654

At the evaporator, the refrigerant enters an area of relatively low pressure, where it can easily “boil off” or evaporate. As it evaporates, it absorbs heat from the evaporator and whatever is in contact with it (such as the water inside it). After the evaporator, the refrigerant, now a low pressure vapor, goes through the suction line back to compressor, where the cycle is repeated.

SUCTION LINE

REFRIGERATION

SCHEMATIC

LIQUID LINE

EVAPORATOR

DISCHARGE

LINE

CONDENSER

COMPRESSOR

THERMOSTATIC

EXPANSION VALVE

March 2000

Page 15

NDE554 & NDE654

OPERATION: Ice Vending

When the ice dispensing glass filler lever is pushed, an electrical circuit is made the dispense drive motor which turns, rotating the dispensing vane.

When the dispensing vane sweeps the ice over the ice dispensing chute ice is released from the bin.

Ice will continue to discharge out this chute as long as the vane is turning. It stops when the dispensing vane stops.

VEND SWITCH

ICE CHUTE

GLASS FILLER

LEVER

SINK

March 2000

Page 16

DRIVE

MOTOR

Ice Dispensing

Vane

BIN BOTTOM

NDE554 & NDE654

CLEANING and SANITIZING

A Scotsman Ice System represents a sizable investment of time and money in any company’s business. In order to receive the best return for that investment, it MUST receive periodic maintenance.

It is the USER’S RESPONSIBILITY to see that the unit is properly maintained. It is always preferable, and less costly in the long run, to avoid possible down time by keeping it clean; adjusting it as needed; and by replacing worn parts before they can cause failure. The following is a list of recommended maintenance that will help keep the machine running with a minimum of problems.

Maintenance and Cleaning should be scheduled at a minimum of twice per year.

Sanitizing of the ice storage bin should be scheduled for a minimum of 4 times a year.

Electrical power will be ON when doing in place cleaning.

ICEMAKING SYSTEM: In place cleaning

1. Check and clean any water treatment devices, if any are installed.

2. Remove screws and remove the upper front panel.

3. Move the ON-OFF switch to OFF.

4. Remove the cover to the ice storage bin, and remove the ice.

5. Remove the cover to the water reservoir and block the float up.

6. Drain the water reservoir and freezer assembly using the drain tube attached to the freezer water inlet. Return the drain tube to its normal upright position and replace the end cap.

7. Prepare the cleaning solution: Mix eight ounces of Scotsman Ice Machine Cleaner with three quarts of hot water. The water should be between 90-115 degrees F.

Scotsman Ice Machine

Cleaner contains acids.

These compounds may cause burns. If swallowed,

DO NOT induce vomiting.

Give large amounts of water or milk. Call

Physician immediately. In case of external contact, flush with water. Keep out of the reach of children.

8. Slowly pour the cleaning solution into the water reservoir until it is full. Wait 15 minutes, then switch the master switch to ON.

9. As the ice maker begins to use water from the reservoir, continue to add more cleaning solution to maintain a full reservoir.

10. After all of the cleaning solution has been added to the reservoir, and the reservoir is nearly empty, switch the master switch to OFF.

11. After draining the reservoir, as in step 6, wash and rinse the water reservoir.

To Sanitize:

Repeat steps 8-11, only use an approved sanitizing solution in place of the cleaning solution.

A possible sanitizing solution to use could be 1 ounce of household bleach mixed with 2 gallons of warm (95 o F. - 115 o F.) water.

12. Remove the block from the float in the water reservoir.

13. Switch the master switch to ON

14. Continue ice making for at least 15 minutes, to flush out any cleaning solution. Check ice for acid taste - continue icemaking until ice tastes sweet.

DO NOT USE any ice produced from the cleaning solution.

Be sure no ice remains in the bin.

15. Remove all ice from the storage bin.

16. Add warm water to the ice storage bin and thoroughly wash and rinse all surfaces within the bin.

17. Sanitize the bin cover, dispensing vane, bin bottom, and interior with an approved sanitizer using the directions for that sanitizer.

18. Replace the ice storage bin cover, and the front panel.

March 2000

Page 17

NDE554 & NDE654

SENSOR MAINTENANCE

Moving Parts Hazard.

Disconnect electrical power to the icemaker dispenser before beginning.

1. The bin control uses devices that sense light, therefore they must be kept clean enough so that they can “see”. At least twice a year, remove the bin control sensors from the grommets in the ice chute, and wipe them clean.

BIN CONTROL

SENSOR

BIN CONTROL

SENSOR

2. The ice machine senses water level by a probe located in the water reservoir. At least twice a year, the probe should be removed from the reservoir, and the tip wiped clean of mineral build-up.

BIN TOP

Clean the Probe's Tip with ice machine cleaner and a clean, soft cloth.

3. Air Cooled Models: Check the air cooled condenser for lint, dirt or grease build-up. Clean with vacuum or soft brush until light can be seen thru the fins.

March 2000

Page 18

BEARING MAINTENANCE

The bearing in the breaker should also be checked at least two times per year.

A. Check the bearing by:

· removing the ice chute cover

Chute Cover

NDE554 & NDE654

· unscrewing the auger stud

Auger Stud

Cap Screw

· unscrewing the ice sweep

Ice Sweep

Inspect the bearing. There should be plenty of grease in sight. If grease is needed the bearing and breaker should be removed to check the action of the bearing. It should rotate smoothly.

To remove the breaker remove the lower ice chute then take out all four allen head cap screws and pull the breaker off the auger and evaporator.

If the bearing only needs grease, inject grease into the bearing using Scotsman grease needle pn

02-3559-01 and Scotsman bearing grease cartridge, pn A36808-001. Be sure to inject grease evenly and thoroughly.

Bearing Needle, pn

02-3559-01

· removing the water shed & unscrewing the breaker cover (left hand threads).

Breaker

Cover

Off See Removal and Replacement section to replace bearing or seals.

Reverse to reassemble.

March 2000

Page 19

NDE554 & NDE654

AUGER MAINTENANCE

In some areas, the water supply to the ice maker will contain a high concentration of minerals, and that will result in an evaporator and auger becoming coated with these minerals, requiring a more frequent removal than twice per year. If in doubt about the condition of the evaporator and auger, the auger can be removed so the parts can be inspected.

Note: Water filters can filter out suspended solids, but not dissolved solids. “Soft” water may not be the complete answer. Check with a water treatment specialist regarding water treatment.

For more information on removal of these parts, see REMOVAL AND REPLACEMENT.

1. To remove the auger, remove the front and top panels.

2. Push bail clamp off of cover and remove cover.

3. Unscrew and remove ice sweep.

4. Remove ice chute from evaporator.

5. Remove 4 allen screws holding breaker to evaporator.

6. Pull up to remove auger.

After the auger has been removed, allow the auger to dry: if the auger is not bright and shiny, it must be cleaned.

Clean the auger and evaporator as required. DO

NOT HONE THE EVAPORATOR.

7. Replace the water seal.

8. Reverse to reassemble.

ALLEN

HEAD

SCREWS

BREAKER

AND AUGER

ASSEMBLY

March 2000

Page 20

NDE554 & NDE654

SERVICE DIAGNOSIS:

Symptom Possible Cause

No ice is made, nothing operates Unit off due to no power

Unit off due to master switch in OFF position.

No ice, auger motor is turning

Probable Correction

Restore Power

Switch master switch to ON.

Unit off due to low water level.

Unit off due to ice level sensors

(photo-electric eyes) blocked.

Unit off due to scale on water level sensor.

Unit off due to high pressure control open.

Auger motor hums but does not turn.

Unit is shut down

Check water supply, filter, strainer, float valve. Correct water supply.

Check/clean ice level sensors.

Clean water level sensor.

Check for water interruption (water cooled) or fan motor failure (air cooled).

Auger can’t turn. Circuit board has not yet shut unit down.

Circuit board has shut ice machine down due to high auger motor amp draw. Check for cause of high amp draw, including bearings, gearmotor condition and scale on auger and in evaporator.

Low pressure control open

Circuit board compressor relay will not close.

Auger not turning due to: motor failure; auger relay failure on circuit board; or gears stripped. Check drive train.

TXV restricted or not metering.

Check bulb temperature.

Lack of refrigerant. Check for leak.

Check for a restricted system

No power to circuit board.

Circuit Board gear motor relay will not close

Water level or ice level sensor failed.

Check harness

Low or hi pressure cut outs open

Check, replace board

Check, replace sensor

Compressor contactor coil is open Check/replace contactor

Compressor will not start Check start capacitor.

Check start relay

Check compressor windings

Check, replace board

March 2000

Page 21

NDE554 & NDE654

SERVICE DIAGNOSIS

Symptom

Water Leak

Excessive water use

Excessive ice meltage

Machine makes too much noise

Does not dispense

Possible Cause

Drain plugged up

Tubing cracked

Condensation on drain tubing

Hose off

Reservoir cover off

Reservoir cracked

Evaporator water seal leaks

Probable Correction

Clean out drain

Replace tubing

Insulate tubing

Reattach hose

Return cover to reservoir

Replace reservoir

Check base of evaporator & drip pan. If the seal leaks, shut off the water, remove the auger, replace the water seal. Check gear motor for water infiltration.

Adjust to 245 PSIG discharge pressure

Water cooled model, water regulating valve not adjusted properly.

Reservoir float valve leaks thru

Water cooled model, overcharged with refrigerant

Water cooled model, condenser coated with minerals

Bin drain clogged

Improper installation of drains, they are connected.

Poor fit between bin door and door frame

Evaporator coated internally with minerals

Motor bearings dry

Vend switch does not close

No ice in bin

Ice not flowing out of bin

Replace float valve or seat

Recover and weigh refrigerant.

Weigh in correct charge.

Acid clean water cooled condenser.

Clean out bin drain.

Drains must be separate.

Adjust or replace

Clean with Scotsman Ice Machine

Cleaner

Oil or replace motor

Check / replace switch

Check bin, check ice machine section

Check vane for proper rotation

Check inner bin bottom

Bin walls have scale on them, remove scale

March 2000

Page 22

NDE554 & NDE654

CONTROL SYSTEM DIAGNOSTICS

The control system consists of:

· Control Board

· Water Sensor

· Ice Sensors

· High Pressure Cut Out

· Low Pressure Cut Out

If the unit is OFF, check the control board:

1. Is the Power OK light on? If not check power to the unit. If it has power, and the Power OK light is

NOT on, check the high pressure and low pressure cut outs. If they are both closed, replace the board.

If the Power OK light is ON, go to the next step.

2. Is the Water OK light on? If it is, go to the next step. If not, check the water level in the reservoir. If there is water in the reservoir, check that the water sensor is plugged in. To check the water sensor:

A. Unplug water sensor.

B. Pull water sensor from reservoir.

C. Place one ohmmeter lead on the sensor's plug and the other on the sensor's tip. The meter should show nearly zero resistance. If it reads infinite resistance, check the tip for corrosion. If it is clean and still reads open, replace the sensor.

OR connect a copper wire to the wire where the water sensor plugs into and place the other end in the water. The water OK light should go ON. If it does not, replace the control board.

3. Ice sensor check. Is the Bin Full light Off? If it is

OFF and the Service light is Off, and the unit is not running, replace the control board.

If it is OFF and the auger motor is running but the compressor is not, check the compressor contactor coil.

If it is on, the ice sensors may be blocked. Remove them and check for mineral scale. Scotsman's test box can also be used to determine if the ice sensors or board are defective.

Using the tester:

A. Disconnect the ice sensors at the connection by the ice chute. Connect the LED and PHOTO

TRANS wires to the control board's wires.

B. With the On - Off (mode) switch in either position, move the Bin Full switch on the tester to

Bin Full - the tester's light will blink and after a few seconds the bin full light on the control board will come on. If not, replace the board.

Move the Bin switch on the tester to Bin Empty.

The light on the tester will go out, and after a few seconds the Bin Full light on the board will go out.

If master switch is ON, the unit should start.

4. High pressure cut out check.

Disconnect electrical power.

Pull the wires off the high pressure cut out.

Use an ohmmeter to determine if the switch is

OPEN, If it is, check the discharge pressure. If the discharge pressure is less than 300 PSIG, replace the high pressure cut out.

If the high pressure cut out is open and the system has high discharge pressure, check for the cause.

5. Low pressure cut out check.

Disconnect electrical power.

Pull the wires off the low pressure cut out.

Use an ohmmeter to determine if the switch is

OPEN, If it is, check the suction pressure. If the suction pressure is greater than 35 PSIG, replace the low pressure cut out.

If the low pressure cut out is open and the system has low suction pressure, check for the cause.

March 2000

Page 23

NDE554 & NDE654

REMOVAL AND REPLACEMENT

WATER RESERVOIR

1. Shut off the water supply to the icemaker.

2. Remove front panel and reservoir cover.

3. Disconnect inlet water line from valve.

4. To remove just the float, push the locking tab at the back of the valve mounting block in and lift the valve and block up and out of the reservoir tank.

Note: inside the valve, there is a plunger which may be replaced separately, if desired.

5. To remove reservoir, remove drain hose from reservoir.

6. Remove evaporator inlet hose from reservoir.

7. Remove mounting screws from reservoir bracket, and remove reservoir from icemaker.

8. Reverse to reassemble.

FLOAT

ASSEMBLY Water

Sensor

BIN CONTROLS

GROMMETS

BIN TOP

LOCKING

TABS

BIN CONTROLS (Ice Level Sensors)

1. Disconnect electrical power.

2. Remove front panel.

3. Remove control box cover.

4. Locate bin top, in front of and behind it are two rubber bin control grommets.

5. Pull each bin control out, and in the control box, disconnect the electrical leads connecting the bin control to the circuit board.

6. Reverse to reassemble, be certain that the bin controls are aligned so that the ice level sensors are visible (centered) through the holes in the ice chute.

March 2000

Page 24

NDE554 & NDE654

REMOVAL AND REPLACEMENT: Bearing And Breaker

Note: Removal of the auger, water seal, evaporator and gearmotor must begin at the top of the assembly.

Moving Parts Hazard.

Disconnect electrical power to the icemaker dispenser before beginning.

To Remove the Breaker Bearing Assembly:

1. Remove panels and disconnect electrical power.

2. Move bail clamp back and remove ice chute cover.

3. Unscrew and remove ice sweep.

4. Remove insulation halves from outside of ice chute, lift up and remove ice chute.

5. The breaker may be removed from the auger and evaporator without disturbing the auger.

a. Unscrew breaker cover from breaker (left hand threads) b. Unscrew auger stud from top of auger.

c. Unscrew 4 allen head cap screws holding breaker to evaporator.

Steps 3 - 5a Step 5 b d. Lift up, and remove breaker/bearing assembly from auger & evaporator.

6. Service the bearing. Check for rust, rough spots and damage.

a. The bearing is pressed into the breaker, to remove the bearing and replace it an arbor press is needed.

b. Replace lower seals before installing new bearing in breaker.

Note: seals must be pressed in with a tool pushing against the outer edge only, they will not install by hand.

Replace parts as required. Re-grease bearing with

Scotsman part number A36808-001 bearing grease. Replace top seal, and check the o-rings, replace if cut or torn.

7. Reverse to reassemble: specific tools and materials are required to install properly.

a. Add food grade grease such as Scotsman part number 19-0569-01 to the seal area before installing on the auger.

b. Check the seal to shaft areas for cuts, or rough spots: none are permitted.

Steps 5c - 6

BEARING

ICE

SWEEP

BREAKER

AUGER

STUD

BREAKER

March 2000

Page 25

NDE554 & NDE654

REMOVAL AND REPLACEMENT

To Remove the Auger:

Turn off the water to the machine, and unclip the evaporator drain hose, pull it down and drain the evaporator into the bin or a container.

Moving Parts Hazard.

Disconnect electrical power to the icemaker dispenser before beginning.

e. If the auger is stuck use a slide hammer type puller to pull on the auger at the threaded hole.

The size of that hole is 5/8"-18.

Inspect the auger, the critical areas of the auger are:

1. The auger body. It should be clean and shining. Sometimes an auger will appear clean when wet, but after it is dry it will be seen to be stained. Scrub the auger with ice machine cleaner and hot water.

Ice machine cleaner is an acid. Handle it with extreme care, keep out of the reach of children.

2. The water seal area. Because the auger has been removed, the water seal will have to be replaced. Remove the water seal top half from the auger, and inspect the auger for minerals clean as required.

1. The top panel must be removed.

2. Remove ice chute cover.

3. Unscrew ice sweep.

4. Remove ice chute body.

5. The auger and breaker/bearing may now be removed as an assembly.

a. Unscrew 4 allen head cap screws holding breaker to evaporator.

b. Lift up on breaker and remove auger from evaporator.

Note: If the auger is stuck, the breaker must be removed from the auger.

The breaker may be removed from the auger and evaporator without disturbing the auger.

a. Unscrew breaker cover from breaker (left hand threads) b. Unscrew auger stud from top of auger.

c. Unscrew 4 allen head cap screws holding breaker to evaporator.

d. Lift up & remove breaker from evaporator.

BREAKER

AND AUGER

ASSEMBLY

SLIDE HAMMER

PULLER

March 2000

Page 26

REMOVAL AND REPLACEMENT: Water Seal

NDE554 & NDE654

To Remove the Water Seal:

(Assuming all steps to remove the auger have been performed.)

1. The gearmotor/evaporator assembly will have to be exposed. (See illustration - next page)

2. Remove the 4 hex head cap screws holding the evaporator to the gearmotor assembly. Lift the evaporator up and off of the gearmotor.

3. Remove the snap ring or wire retainer from the grove under the water seal.

4. Pull or drive out the lower half of the water seal.

To Replace the Water Seal:

1. Lubricate the water seal with water, and push the water seal into the bottom of the evaporator slightly past the grove for the snap ring.

19-0529-01) on the area of the auger where the water seal is to be mounted.

5. Carefully push the water seal (rubber side against the auger shoulder and the silastic.)

Do not get any silastic onto the face of the seal.

6. Allow the auger and seal to air dry until the silastic is dry on the surface.

WATER

RETAINING

FOOD GRADE

SILASTIC

SEALANT

HERE

7. If the original water seal was leaking, it would be a good idea to inspect the interior of the gearmotor.

2. Replace the snap ring and pull the water seal down against it.

3. The part of the water seal that rotates with the auger must also be replaced. Remove the old part from the auger and clean the mounting area.

4. Place a small bead of food grade silastic sealant

(such as 732 RTV or Scotsman part number

March 2000

Page 27

NDE554 & NDE654

REMOVAL AND REPLACEMENT

To Replace the Evaporator:

(Assuming all the steps for removal of the thrust bearing, breaker, auger, and water seal have been performed.)

1. Discharge the refrigerant from the ice maker.

2. Unsweat the refrigerant connections: a) At the thermostatic expansion valve outlet.

Heat sink the TXV body when unsweating or resweating the adjacent tubing.

b) At the suction line at the joint about 3" from the evaporator.

3. Remove the evaporator.

4. Unsweat the drier from the liquid line.

5. After installing a new water seal in the new evaporator (see “To Replace the Water Seal”) sweat in the new evaporator at the old tubing connections.

6. Install an new drier in the liquid line.

7. Evacuate the system until dehydrated, then weigh in the nameplate charge. Check for leaks.

8. Install auger, breaker, breaker bearing assembly, and ice discharge chute in reverse order of disassembly.

To Reassemble the Evaporator and Auger

1. After the gearmotor has been inspected, fasten the evaporator to the gear motor, be sure that the number of shims indicated on the gear case cover is in place between the gearcase cover and the drip pan gasket. Torque the bolts to 110 inch pounds.

2. Lower the auger into the evaporator barrel, slightly turning it to match up with the drive end. Do

Not Drop Into the Evaporator.

3. Complete the reassembly by reversing the disassembly for the breaker & thrust bearing assembly.

MOVE THE

GEARMOTOR -

EVAPORATOR

For Access to the Evaporator to

Gearmotor bolts:

1. Remove upper front and top panels.

2. Remove screws holding control box assembly to the cabinet, move the control box out of the way, temporarily secure to cabinet.

3. Remove the upper half of the ice chute.

4. Remove the ice sweep.

5. Remove the lower half of the ice chute.

6. Remove the 2 screws securing the front portion of the gearmotor support to the cabinet

7. Move the the gearmotor - evaporator to the right: space is now available for removal of the evaporator and gearmotor bolts. When reassembling, reverse the above steps.

CONTROL

BOX

SCREWS

March 2000

Page 28

NDE554 & NDE654

TO REMOVE AND REPAIR THE GEARMOTOR ASSEMBLY

(Assuming that the procedures through removal of the water seal have been performed.)

If there is evidence of water in the oil (rusty bearings and gears; the oil having a creamy white appearance; oil level too high) carefully inspect the bearings and gears. If in doubt about the condition of a part, replace it. The oil quantity is 14 fluid ounces, do not overfill.

Electrical Shock Hazard.

Disconnect electrical power to the icemaker dispenser before beginning.

Note: The gears and bearings are available only as pressed together sets.

D) After replacing parts as required, (if any) reassemble the gearcase. The two smaller gears and the oil should be in the lower case, the output gear will be with the cover. As you lower the cover onto the lower case, cover will have to be moved closer to the second gear after the output gear has cleared the second gear top bearing.

E) After the case is together, and the locating pins are secure in both ends, replace all cap screws.

4. Bench test the gearmotor, check for oil leaks, noise, and amp draw.

To Check the Motor:

1. Remove wires from terminals 1 and 2.

2. Use an ohmmeter to check for continuity. If there is none, replace the motor only. If there is continuity but the motor will not start, check the motor's start switch.

3. Remove motor end bell or motor stator.

With ohmmeter wires attached to 1 and 2 move centrifugal switch actuator up and down to simulate motor rotation. If the ohmmeter does not show any change, replace the switch or motor. If the ohmmeter shows an open circuit, replace the switch or motor.

GEARCASE

COVER To Replace:

1. Remove the electrical wires from the gear drive motor.

2. Unscrew the 4 cap screws holding the gearmotor to the gearmotor plate.

3. Remove the gearmotor from the icemaker.

To Inspect the gearmotor.

A) Remove the cap screws holding the gearmotor case halves together and pry the two cases apart.

B) To lift off the cover, lift up until you can feel internal contact, then pull the cover towards the output gear end, and then lift the cover (with drive motor attached) up and away from the gear motor case.

FIRST GEAR &

BEARINGS

GASKET

ROTOR

BEARING

Note: The case cover output gear, bearings, and shaft are one pressed together assembly. Replace as a unit.

C) Inspect the oil, gears, and bearings. If the oil level and condition is acceptable, quickly check the gears and bearings. They are likely to be fine if the oil is.

March 2000

Page 29

NDE554 & NDE654

REFRIGERATION SERVICE

General: This ice machine uses R-404A refrigerant and polyolester oil. Do NOT use mineral oil in this refrigeration system.

·

·

·

·

·

When the system is serviced, a special liquid line drier is required. It is included with replacement compressors.

R-404A is not compatible with mineral oil so these ice machines use Polyolester oil.

Polyolester oil absorbs water very easily. A system opened for service must be re-sealed as soon as possible (15 minutes maximum).

Special leak detection equipment is required to locate small refrigerant leaks. Usually a leak detector capable of detecting a Halongenated refrigerant or HFC-134a will work. Check with the leak detector manufacturer if in doubt.

Evacuate to 300 microns.

Liquid charge the system

Access Valves: To use the access valves:

·

·

Remove the cap from the stem, use a 3/16" allen wrench to check that the valve is CLOSED. The remove the core cap.

Close the valve and replace the caps hen done.

The valve

Sight Glass w

Torque stem to 6-8 ft.-lb., caps to 7-12 ft.-lb.

R-404A

Tank Must

Be in Liquid

Dispensing

Position -

Check Tank!

Instructions for Liquid Charging R-404A

In preparation for charging, the low side hose should have a sight glass, and/or a restricting device (such as a “Charge Faster”) installed in it for metering liquid into the low side of the system.

1. After a thorough evacuation shut off the manifold valves and switch off the vacuum pump.

2. Place a drum of R-404A onto an electronic scale.

3. Attach the charging hose to the drum.

4. Open the valve on the drum and purge the charging hose.

5. Zero out the scale.

6. Shut the low side access valve at the ice machine.

7. Open the discharge manifold valve full open.

8. Watch the scale, when the correct charge is shown, shut the manifold valve.

Note: If all of the charge will not “go in” the discharge side:

A. Shut the discharge access valve at the ice machine.

B. Switch the machine on.

C. Open the low side access valve at the ice machine.

D. Open the low side manifold valve and observe the sight glass to be certain that only gas is flowing into the system.

E. When the proper charge is indicated on the scale, shut off the manifold valve(s).

9. Shut off the valve on the refrigerant drum.

10. Re-open the manifold valves until all liquid has flowed out of the hoses.

11. Shut the low side access valve on the ice machine.

12. Remove hoses from ice machine and replace all caps.

SCALE

Hose Connection Schematic for Liquid Charging

March 2000

Page 30

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project