advertisement

▼

Scroll to page 2

of 16

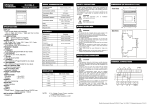

™ Digital Multi Function Meter Manual for Installation and Use Measurement of Energies Maximum Demand measurement Programmable features Separate models for Unidirectional and bidirectional measurement Suitable for 50Hz & 60Hz supply Class 1 and 0.5 meters available With RS485 MODBUS & without RS485 MODBUS communication With Relay & without Relay Freeze mode feature Navigation for ease of display parameter scroll L&T Electrical & Automation Doc. No. 4D060193 Rev. L 1 ™ Digital Multifunction Meter Table of Contents Sl. No. 1 2 3 4 5 6 Descriptions General Details Front Panel Details Mechanical Dimensions Installations Programming the meter Warranty & Disclaimer Appendix 1: Technical Specifications Appendix 2: Modbus communication details Appendix 3: Addressing in Modbus Appendix 4: Display Parameters Appendix 5: Catalogue Number Page No. 2 2 4 4 5 6 6 7 8 11 16 1. General Details: ™ is a digital panel meter for measuring electrical parameters with multiple displays in size 96 x 96 mm. The meter is designed with high performance processor to combine measurements of both instantaneous and cumulative values in an electrical system. The device is built with bright 7 segment displays and provides high-resolution value of various parameters. The parameters can be scrolled up & down by front panel push buttons. The parameters like CT / PT ratings, baud rates, port address, demand parameters etc, can set by push buttons on the front panel as well through as Modbus protocol (RS485). The programming parameters are password protected. Meter is provided with measurement energies, MDs with programmable integration period. The unique feature of Multi Function meters, it is provided with two relays which are used to trip circuits/isolate circuits in case of predefined fault/threshold conditions. Relays & RS485 are available for specific models only. 2. Front Panel Details: 2.1 Display & LED indications ™ Digital Multi Function Meter features with 7 segment display and LEDs for multipurpose indications. 1. Bright 7 segment Displays for displaying the Parameters. 2. LEDs for indicating units (kilo (k), Mega (M) & Giga (G) values.),LEDs indication for phase’s R,Y & B. 3. LEDs for indicating Reverse of individual phases. If any of the phases are reversed, the reversed phase is indicated through LEDs. 4. LEDs for indicating Lead, export and Communication. Figure 1: Front view of digital multifunction meter 2.2 Front panel push buttons: Three push buttons Up , Down & Mode to do following functions: 1. Navigation through display parameters 2. Programming of parameters 3. Increase /Decrease the numeric values during programming 2 2.3 Programming using push buttons Sl. No 1 2 3 4 5 6 7 8 9 Action with keys Press up key and down key simultaneously to enter to programming mode. Meter displays PASS & 0000 with first digit blinking. Enter the password for user authentication (Default password is 0000). Press mode key. Password can be changed in the programming mode once meter displays “PASS” (Password). If password is correct, meter displays ACPt followed by first programming parameter. If entered password is incorrect, meter displays PErr & meter will return to display parameters. Press up key to scroll the main menu programming pages. Press mode key to select the page. Parameter default / Previous value will display. Press up key to increment the cursor position value Press down key to shift cursor position to right i) Press mode key to update the values. “UUPd” will be displayed. ii) Press up key to accept the entered value/down key to skip the entered value. 10 Press up & down key to exit programming mode, meter will display ‘ESCP’ & ‘rSEt’ then followed by restart 11 For manual reset press up key and mode key simultaneously in default screen. Meter displays “rSt” and continued by display parameter. 12 In Freeze mode, ‘Desired parameter can be monitored continuously’. 1) To enter Freeze mode: Press DOWN & MODE key simultaneously for 3sec to Freeze the parameter. The meter displays “diSP StAY On” and then continues to show display parameter on which it has been freezed. 2) To exit Freeze mode (To Unfreeze): Press DOWN & MODE key for 3sec, the meter displays “diSP StAY OFF” and continues to display scroll mode. 3) In case of power fail and resume: If the freeze mode is activated, on power resume, Meter Displays “diSP StAY On” and then continue to show display parameter on which it was freezed. 13 Press Mode key to display parameters block wise 14 Press UP or Down key to scroll within blocks 15 Once block display comes, press Mode key again to display the parameters under that block 16 Press Mode key to go back to display parameters block wise Display Status Pages scrolling 0/1/2/3/4/5/6/7/8/9 ---Step i step ii “Inst” ( sequence:- “InSt”, “Pwr”, “Md”, Engy”, “rst”, Othr”) Time out for programming mode is 1minute.After time out, meter exits programming mode & restarts. 3 3. Mechanical Dimensions Figure 2. Mechanical Dimensions Figure 3. Panel cut out dimension ( 92 x 92 mm) 4. Installations 1. Dimensions of panel cut-out (92mm x 92mm) for mounting Multi Function is shown in Figure 3. Care to be taken for proper connection. 2. Auxiliary voltage:Multi Function meter will power ON with auxiliary voltage(Range from 80V to 300VAC). 3. ™ Multi Function meter is suitable for operating in Star connected system and Delta connected system. For connection refer Figure 4. The meter should be programmed appropriately for the type of system. The default setting is for 3P4W system. To change the settings to 3P3W configuration mode, change “cnfg” setting from “0000” to “0001” in programming mode. Refer section 5.2 for details. 4. The rating of input measurement current is 5A (maximum current rating is 6A).In case of higher current measurement, external Current Transformers (CT) to be used. The CT ratios need to be programmed appropriately. Refer section 5.2 for programming details. The ‘terminal S1’->’terminal S2’ is forward direction and ‘terminal S2’->’terminal S1’ is reverse direction. In case of reverse connection the meter is capable of detecting the reverse connection & will indicate through reverse LEDs. In case of Model C the forward direction is based on majority current lines. The reverse current detection logic is applicable for 3P4W connection only. 5. Maximum measuring input voltage is 300V phase to neutral. External potential transformers are to be used for high voltage measurement (HV/MV systems). The PT ratios need to be programmed in the meter suitably. Refer section 5.2 for programming details. 6. The meter is provided with two relays, to trip circuits in case of fault\threshold conditions. The setting for fault conditions can be decided by the customer. The default factory settings are available in section 5.1. Relay terminals for relay 1 is RL1C, RL1N and for relay 2 is RL2C, RL2N. Refer section A.1.2(Applicable for specific models only). 7. The parameters on display can be monitored remotely using RS485 communication. The terminal connections of RS485 are D+ & D-. Modbus protocol is implemented with RS485 communication. The communication parameters need to be programmed appropriately. For connections details, settings & memory map refer section 5.1 and Appendix 2. 4.1 Installations Model A meters: Terminal connection 17 & 18 not applicable 3P3W connection: Neutral wire (Terminal 1) & Y Current (Terminal 13 & 14) not to be connected. Figure 4 3P4W connection Check these programming parameters during installation: CTPT ratios, System configuration (3P3W or 3P4W) mode, MD integration period, Relay operation setting if applicable & RS485 communication setting if applicable. 4 5. Programming the meter 5.1 List of relay programming parameters Meter is programmed with default factory settings. These parameters can be changed by authenticated user/customer. Relay features are available for specific models only. Refer page 16 for the same. Sl. No. # 1 # 2 Parameter Lower Voltage cut off Limit Min / Max Value Upper Voltage cut off Limit 264.0V Display Factory setting 9.6V 9.600V 264.0V π 3 Lower Current cut off Limit 0.1A/0.02A 4 Upper Current cut off Limit 5.867A/1.1734A 5 Lower Frequency cut off Limit 40.0Hz 40.00Hz 6 Upper Frequency cut off Limit 70.0Hz 70.00Hz 7 Relay cut-off occurrence persistence time 1 – 9999 s 15 seconds 0.100A/0.02A π π 5.867A/1.1734A π Relay cut off restoration persistence time 8 1 – 9999 s 15 seconds ‘π’ indicates applicable for -/1A meter(otherwise -/5A meter) # Relay cut-off limits is not applicable for 3P3W system, the immediate below table is applicable. Sl. No. 1 2 Parameter Min / Max Value Lower Voltage cut off Limit Upper Voltage cut off Limit Display 16.62V 457.2V Factory setting 16.62V 457.2V To disable the condition/parameter specific relay trip, set that specific parameter(s) to zero. 5.2. List of programming parameters Sl. No. 1 Min / Max Value Display Factory setting 1 Slave ID 1- 247 Baud rate 9600 & 19200 9600 Parity Odd/Even/None Even 3 CT Primary Max up to 9999 1 4 CT Secondary 1A or 5A 1 5 PT Primary Max up to 9999 1 6 PT Secondary Max up to 9999 1 7 Meter wiring configuration 0000 for 3P4W,0001 for 3P3W 0000 8 Programming Password 0000 to 9999 0000 9 Number of poles MD Active Integration period (Model B/Model C) 2,4,6,8,10,12,14,16 2 10α ‘α’ Parameter 2 30 Minutes 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 11α MD Apparent Integration Period (Model B/Model C) 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 30 Minutes 12α MD Current (I) Integration Period (Model B/Model C) 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, 60 30 Minutes 13 Command to clear the Power fails count (rest Intr). Step 1: Press mode key meter displays “CnFn reSt”. Step 2: Press mode key meter displays “UUPd”. Step 3: Press up key meter displays ACPt. Applicable for Model B &C only Note :- Ct Pr X Pt Pr ≤ 10000000 CtSE PtSE 5 Step 1: Step 2: Step 3: 6. Warranty and Disclaimer 6.1 Warranty Larsen & Toubro warrants that Digital Multi Function meter is free from defects in workmanship and material. Larsen & Toubro’s obligation under this warranty shall be for a period of 18 months from the date of sale subject to the following terms and conditions provided the notice of defects and satisfactory proof thereof is given to Larsen & Toubro by its Customer within the warranty period. 1. Larsen & Toubro shall provide only repairs for the sold item. 2. Defective parts shall be serviced or replaced by Larsen & Toubro. This warranty does not cover any defect in the product caused by accident, misuse, mishandling (includes improper electrical, mechanical installation), tamper, neglect, alteration/modification or substitution of any of the components or parts, or any attempt of internal adjustment by unauthorized service personnel. For applicability of warranty Larsen & Toubro shall be the sole judge. Under no circumstance shall Larsen & Toubro be liable for any consequential or resulting injury or for loss, damage or expense directly or indirectly from the use of this product. The foregoing warranty is in lieu of all other warranties, expressed or implied, and is the sole and exclusive remedy for any claim arising from any defect in the product. 6.2 Disclaimer Sufficient care is taken to provide all information regarding the product but Larsen & Toubro does not claim any responsibility for the damage caused by using the product directly or indirectly. Appendix 1: Technical Specifications A.1.1 Specifications Auxiliary supply Auxiliary burden Class of accuracy Input current measurement range Current range for accuracy class -/5A -/1A -/5A -/1A Class 1 Auxiliary circuit Measurement circuit Class 0.5 Class of accuracy Input current measurement range Current range for accuracy class -/5A -/1A -/5A -/1A Line frequency measurement range Measurement circuit burden Input voltage measurement range Voltage range for class of accuracy Insulation properties Electrical requirements Impulse voltage test AC voltage Test Insulation resistance Test of power consumption Voltage dips and interrupts Short time over current Protection 6 80 to 300VAC < 4VA 1.0$ as per IEC 62053-21 40mA to 6A 40mA to 1.2A 250mA to 6A 50mA to 1.2A Active Energy 0.5$ as per IEC 62053-22 Reactive Energy 1.0 as per IS14697:2004 40mA to 6A 40mA to 1.2A 250mA to 6A 50mA to 1.2A 50Hz ± 10% & 60Hz ± 10% (Suitable for both 50Hz & 60Hz supply) < 0.2VA per phase 10V to 300V(P-N) 17.32V (P-P) to 520V (P-P) 57.7V (P-N) to 277V (P-N) 100V (P-P) to 480V (P-P) ±4kV as per IEC 62053-21 4kV double insulation as per IEC 62053-21 500V DC Voltage as per IS 13779 As per IEC 62053-21 As per IEC 61326-1 20 times of Imax for half a second as per IEC 62053-21 ElectroMagnetic Compatibility (EMC) Operating Conditions Mechanical testing ‘$’ Electrical fast transient/burst immunity test ±4kV as per IEC 61000-4-4 Electrostatic discharge immunity test ±8kV air discharge , ±6kV contact discharge as per IEC 61000-4-2 Radiated, radio-frequency, electromagnetic field immunity test Immunity to conducted disturbances, induced by radio-frequency fields Surge immunity test Rated power frequency magnetic fields Emission Operating Temperature Storage Temperature Humidity Shock Vibration Casing Weight Available in separate Models 10 V/m as per IEC 61000-4-3 3V as per IEC 61000-4-6 ±4kV as per IEC 61000-4-5 1A/m as per IEC 61000-4-8 Class B as per CISPR 22 0 º C to +55 º C -20 º C to +70 º C 0 to 95% relative humidity non-condensing 40g in 3 planes 10 to 55Hz,0.15mm peak amplitude Plastic mould protected to IP51 from front side 400gms(approximately) A.1.2 Relay specifications: Multi Function meter is provided with two normally closed (NC) relays which can be programmed to trip in abnormal system conditions. There will be continuity between the contacts RL1C & RL1N and continuity between the contacts RL2C & RL2N in system healthy condition. The relay trip option can be disabled for one or all of the parameters by setting the corresponding parameter(s) to zero. The relay setting can be programmed for the following fault condition. 1. Abnormal voltage 2. Abnormal current 3. Abnormal frequency The abnormal voltage, current & frequency can be decided by the customer. The upper & lower limit can be programmed appropriately. Refer section 5.1 for details. Relay specifications Continuous Contact Rating 5A Maximum Switching Voltage 277V Maximum Switching Current 5A Maximum Switching Power Figure 6 Relay Contacts 1250VA Note: Relay option is applicable to selected models only. Note: Relay option applicablecommunication to selected models only. Appendix 2: isModbus details A.2.1 Introduction: The Default slave ID is 1, baud rate is 9600 & parity is EVEN. In Case of multiple meters connected in a network, the slave IDs to be unique to network. RS485 Modbus protocol allows up to 247 meters to be connected in a network. But the driver of RS485 allows only 32 meters to be connected in a network. Repeaters shall be connected to improve the signals strength for longer distance network. Figure 7 shows the typical network connection for RS485 communication. Repeaters are not shown in figure7 for simplicity. The value of the termination resistor should be equal to the cable impedance. The cable impedance can be obtained from the cable manufacturer. 7 In case value of cable impedance is not known, usually 120Ω, 0.5W resistor will work fine. The function of the termination resistor is to reduce the reflection of signals at the ends. Figure 7. Typical connection diagram of RS485 A.2.2 Modbus Address Map for Data read /write: 1. Maximum bytes that can be collected in single query - 180 Bytes 2. Recommended no response timeout – 400 milli Second 3. Updating rate for each parameter is 3 Second, so recommended polling frequency anything above 3 Second is preferred. Appendix 3: Addressing in Modbus For changing any programming parameter through Modbus, first password has to be entered then followed by the address of the parameters. Once password is entered the password is enabled for an idle time of 2 minutes. Address 40513 40337 40338 42305 41025 41026 41027 42561 41281 41283 41285 41287 Parameters Password (PRIDES) for programming Words 3 MF -- Data Type ASCII Value Address Parameters Words H-REGS Function code 0x06 is used for writing for following parameters 1.Relay Occurrence / Persistence Time Relay Occurrence time (in Seconds)(0001 to 9999) 1 Relay Persistence time (in Seconds)(0001 to 9999) 1 2.Meter Configuration (3W/4W) 0000 for 3-Phase 4-Wire Configuration 1 0001 for 3-Phase 3-Wire Configuration Function code 0x06 or 0x10 is used for writing for following parameters 3.Communication Parameters (password not required) Meter Address (1 to 247) 1 Baud Rate (Only following values are possible 1 Write 6 for 9600, 7 for 19200) Baud parity 0-none, 1- odd, 2 – even. 1 (Only following values are possible while writing) 4.No of Poles No of Poles (2 to 16)(only even values) 1 Function code 0x10 is used for writing for following parameters 1.External CT/PT Values CT Primary (1 to 9999) 2 CT Secondary (1A or 5A) 2 PT Primary (1 to 9999) 2 PT Secondary (1 to 9999) 2 MF Data type 1 1 integer integer 1 1 1 integer integer integer integer 1 1 integer 1 1 1 1 integer integer integer integer Ct Pr Pt Pr Note:- max. CtSE X PtSE ≤ 10000000 40769* 40770* 40849* 2. MD Information MD1(Apparent MD) - Integration Period 1 1 integer MD2(Active MD) - Integration Period 1 1 integer MD Current-Function code 0x06 is used for writing for following parameter MD3(Current MD)- Integration Period 1 1 integer (While programming, MD1& MD2 integration periods have to be programmed together. Individual programming is not supported.MD3 can be programmed separately.) 8 40257 40258 40259 40260 40261 40262 30001 30003 30005 30007 30009 30011 30013 30015 30016 30018 30019 30021 30022 30024 30025 30027 30028 30030 30031 30033 30034 30036 30037 30039 30040 30042 30044 30046 30048 30049 30051 30052 30054 30055 30057 30059 30061 30063 30065 30067 30069 30071 30073 30075 30077 30079 30081* 30083* 30085* 30087* 30089* 30091* 30093* 3.Relay Cut off Limits Voltage Lower Limit(VL) (9.6<VL<VU) 1 0.01 integer Voltage Upper Limit(VU) (VL<VU<264) 1 0.01 integer Current Lower Limit(CL) (0.1<CL<CU) 1 0.01 integer Current Upper Limit(CU) (CL<CU<5.867) 1 0.01 integer Frequency Lower Limit(FL) (40<FL<FU) 1 0.01 integer Frequency Upper Limit(FU) (FL<FU<70) 1 0.01 integer For all the above relay cut off limits, if value is programmed to zero then that parameter won’t be considered for relay operations. (ZERO is a valid input value).All programming to be done together. I-REGS Read Only Registers (Function Code: 0x04) 1.Instantaneous Values R Phase Voltage 2 0.01 integer Y Phase Voltage 2 0.01 integer B Phase Voltage 2 0.01 integer R Phase Current 2 0.001 integer Y Phase Current 2 0.001 integer B Phase Current 2 0.001 integer Active Power R Phase 2 0.0001 integer Active Power R Phase(unit) 1 1 integer Active Power Y Phase 2 0.0001 integer Active Power Y Phase(unit) 1 1 integer Active Power B Phase 2 0.0001 integer Active Power B Phase(unit) 1 1 integer Reactive Power R Phase 2 0.0001 integer Reactive Power R Phase(unit) 1 1 integer Reactive Power Y Phase 2 0.0001 integer Reactive Power Y Phase(unit) 1 1 integer Reactive Power B Phase 2 0.0001 integer Reactive Power B Phase (unit) 1 1 integer Apparent Power R Phase 2 0.0001 integer Apparent Power R Phase(unit) 1 1 integer Apparent Power Y Phase 2 0.0001 integer Apparent Power Y Phase(unit) 1 1 integer Apparent Power B Phase 2 0.0001 integer Apparent Power B Phase(unit) 1 1 integer Power Factor R Phase 2 0.001 integer Power Factor Y Phase 2 0.001 integer Power Factor B Phase 2 0.001 integer Total Active Power 2 0.0001 integer Total Active Power(unit) 1 1 integer Total Reactive Power 2 0.0001 integer Total Reactive Power(unit) 1 1 integer Total Apparent Power 2 0.0001 integer Total Apparent Power(unit) 1 1 integer Total Power Factor 2 0.001 integer Line Frequency 2 0.01 integer RY-Line Voltage 2 0.01 integer YB-Line Voltage 2 0.01 integer BR-Line Voltage 2 0.01 integer Average Phase Voltage 2 0.01 integer Average Phase Current 2 0.001 integer R Phase Voltage Harmonic 2 0.01 integer Y Phase Voltage Harmonic 2 0.01 integer B Phase Voltage Harmonic 2 0.01 integer R Phase Current Harmonic 2 0.001 integer Y Phase Current Harmonic 2 0.001 integer B Phase Current Harmonic 2 0.001 integer Phase Difference-R Voltage & Current 2 0.01 integer Phase Difference-Y Voltage & Current 2 0.01 integer Phase Difference-B Voltage & Current 2 0.01 integer Voltage Unbalance R Phase 2 0.001 integer Voltage Unbalance Y Phase 2 0.001 integer Voltage Unbalance B Phase 2 0.001 integer Current Unbalance R Phase 2 0.001 integer 9 30095* 30097* 30099* 30101* 30103* 30105* 30107* 30109 30112 30115 30118 30121** 30124** 30127** 30130** 30133* 30135* 30136* 30138* 30139** 30141** 30142** 30144** 30145* 30147* 30148* 30150* 30151** 30153** 30154** 30156** 30157 30160 30163 30166 30169** 30172** 30175** 30178** 30181* 30183* 30184* 30186* 30187** 30189** 30190** 30192** 30193 30194 30196 30198** 30200 30202** 30204 30205* 30206* 30207* Current Unbalance Y Phase 2 0.001 Current Unbalance B Phase 2 0.001 Percentage Load R Phase 2 0.01 Percentage Load Y Phase 2 0.01 Percentage Load B Phase 2 0.01 RPM 2 1 Neutral Current 2 0.001 2.Read Cumulative Energies. ( 5 Bytes for value + 1 byte for unit) ref page 11 Note 3 Import Apparent energy + unit 3 0.01 Import Active energy+ unit 3 0.01 Import Reactive Lag energy +unit 3 0.01 Import Reactive Lead energy +unit 3 0.01 Export Apparent energy + unit 3 0.01 Export Active energy +unit 3 0.01 Export Reactive Lag energy +unit 3 0.01 Export Reactive Lead energy +unit 3 0.01 3.Read MD MD Import Apparent 2 0.0001 MD Import Apparent (unit) 1 1 MD Import Active 2 0.0001 MD Import Active(unit) 1 1 MD Export Apparent 2 0.0001 MD Export Apparent (unit) 1 1 MD Export Active 2 0.0001 MD Export Active(unit) 1 1 4.Read Rising Demand Import Apparent Rising Demand 2 0.0001 Import Apparent Rising Demand(unit) 1 1 Import Active Rising Demand 2 0.0001 Import Active Rising Demand(unit) 1 1 Export Apparent Rising Demand 2 0.0001 Export Apparent Rising Demand(unit) 1 1 Export Active Rising Demand 2 0.0001 Export Active Rising Demand(unit) 1 1 5.Cumulative Energy Backups ( 5 Bytes for value + 1 byte for unit) ref page 11 Note 3 Import Apparent Energy +unit 3 0.01 Import Active Energy +unit 3 0.01 Import Reactive Energy – lag +unit 3 0.01 Import Reactive Energy – lead +unit 3 0.01 Export Apparent Energy +unit 3 0.01 Export Active Energy+unit 3 0.01 Export Reactive Energy – lag +unit 3 0.01 Export Reactive Energy – lead +unit 3 0.01 6.Read MD Backup MD Import Apparent Backup 2 0.0001 MD Import Apparent Backup(unit) 1 1 MD Import Active Backup 2 0.0001 MD Import Active Backup(unit) 1 1 MD Export Apparent Backup 2 0.0001 MD Export Apparent Backup(unit) 1 1 MD Export Active Backup 2 0.0001 MD Export Active Backup(unit) 1 1 7.Other Parameters No. of Resets 1 1 Total Forward Load Time (Days(1) + hr(1)) 2 1 Total Power On Time (Days(1) + hr(1) 2 1 Total Reverse Load Time (Days(1) + hr(1) 2 1 Total Forward Load Time Backup (Days(1) + hr(1) 2 1 Total Reverse Load Time Backup (Days(1) + hr(1) 2 1 Total Power Fail Count 1 1 8.Time Remaining Time Remaining KVA MD (Import and Export) 1 1 Time Remaining KW MD (Import and Export) 1 1 Time Remaining Current MD 1 1 10 integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer integer 30208* 30209* 30211* 30212* 30214** 30215** 30217** 30218** 30220* 30221* 30223* 30225* 30226* 30228* 30229* 30231* 30232 30236 30240 30244 9.Hour MD Occurred Hour Import KVA MD Occurred (days) 1 1 integer Hour Import KVA MD Occurred(1st word hour+2nd word minute) 2 1 integer Hour Import KW MD Occurred(days) 1 1 integer Hour Import KW MD Occurred(1st word hour+2nd word minute) 2 1 integer Hour Export KVA MD Occurred (days) 1 1 integer Hour Export KVA MD Occurred(1st word hour+2nd word minute) 2 1 integer Hour Export KW MD Occurred(Days) 1 1 integer Hour Export KW MD Occurred(1st word hour+2nd word minute) 2 1 integer Hour Current MD Occurred(Days) 1 1 integer Hour Current MD Occurred(1st word hour+2nd word minute) 2 1 integer 10.Current MD Read Current MD 2 0.0001 integer Read Current MD(unit) 1 1 integer Read Current Average Demand 2 0.0001 integer Read Current Average Demand(unit) 1 1 integer Read Current MD Backup 2 0.0001 integer Read Current MD Backup(unit) 1 1 integer 11. Energy values with high precisions (without multiplying CTPT value) ref page 11 Note 4 Import Apparent energy double 4 Import Active energy double 4 Import Reactive Lag energy double 4 Import Reactive Lead energy double 4 - * Applicable for model B & C only. ** Applicable for model C only. Note 1: 0- No Scale(x10^0), Unit 1-KILO(x10^3), Unit 2-MEGA(x10^6), Unit3-GIGA(x10^9). When no value (empty register) is to be displayed in Modbus, then not applicable value will be displayed A410 (-23536).Then multiplication factor is not applicable. Note 2: Response for addresses 30007 to 30028, 30040 to 30049 & 30055 1st Word 2nd Word 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 x 1 Represents the Modbus data Value If X is 0, then Modbus data value is positive. If X is 1, then Modbus data value is negative and it is in 2’s Complement form. Note3: Cumulative Energy and its Backups - Address = 30109 to 30130 and 30157 to 30178 Ex: For import apparent energy (30109 to 30111), 3 word length. Each word is of 2 bytes. 30109 – 1st Byte (Most Significant Byte of value), 2nd Byte 30110 – 3rd Byte, 4th Byte 30111 - 5th Byte (Least Significant Byte of value), 6th Byte is unit Not applicable parameters: Export energies are not applicable for model A and model B, not applicable value will be displayed (00 00 00 A4 10 00).It is recommended to check unit value. If unit value is 00, then that parameter is not applicable. Note 4: Energy values with high precisions (30232 to 30244) These parameters should be read as double value of 8 byte size, without MF factor. This value shall be multiplied by CTPT ratio to get actual value. Appendix 4: Display Parameters 4 Display Features: On Power ON, following will be displayed sequentially: 1) All the segments of 7 segment display and all the LEDs will glow 2) The firmware version 3) Display parameters The meter has a provision to scroll the display parameters automatically after ~3 seconds. The meter enters into the manual mode by up/down key press. In manual mode, display shall scroll up & down by every up & down key press respectively. If key is not pressed for ~1 minute, it returns to auto scroll mode. Any display parameter can be monitored continuously using ‘freeze mode’ feature. The display parameters are divided into 6 blocks: 11 (a) Instantaneous Parameters(InSt) (b) Power(PYr) (c) MD (Md) (d) Energy(EngY) (e) Backup(rSt) (f) Others(Othr) . Meters shall be in normal mode (Auto/manual) as existing. On pressing mode key, the display will show Inst, which corresponds to instantaneous parameters. On pressing the mode key the display will start from 1 (Starts in manual mode, with standard time out of 1 min). On time out, the meter goes to auto scroll starting from the last display. To move to different block, up and down arrow will be used for scrolling. Example (Model C): Move from Frequency (Parameter 6) to Apparent Energy (parameter 39) • • • • Press Press Press Press mode key. Display will show INST the down key 3 times to get ENGY mode key. Display screen will now show active energy(parameter 38) down key to move to parameter 39. Meter will now be in this screen until a key is pressed for scrolling or manual scroll time out occurs (1min). In case of latter, meter resorts to auto scroll mode of the entire display list. Energy display format: Unit Min Display SL MF (CTxPT) Display Format Maximum value Range Resolution 999999.99 KWh 1 < 10 XXXXXX.XX 0.01 kWh k 9999999.9 KWh 2 < 100 XXXXXXX.X 0.1 kWh 99999999 KWh 3 ≤1000 XXXXXXXX 1 kWh 999999.99 MWh 4 < 10,000 XXXXXX.XX 0.01 MWh M 9999999.9 MWh 5 < 1,00,000 XXXXXXX.X 0.1 MWh 99999999 MWh 6 < 10,00,000 XXXXXXXX 1 MWh G 999999.99 GWh 7 ≤ 1,00,00,000 XXXXXX.XX 0.01 GWh When any energy value exceeds the maximum value for selected CTPT ratio, then that particular energy rolls over and starts accumulating fresh from 0. All Power, MD and Rising Demand are displayed in same format as energy (Display format and unit are fixed depending on the CTPT ratio). Parameter Phase voltage (V) Line to line voltage (V) Instantaneous Parameters Phase Current(A) Average Voltage(V) Average current(A) Neutral Current(A) Line Frequency(Hz) Percentage Load Voltage Unbalance(V) Current Unbalance(A) RPM Display Line1 Display Line2 U1 U1 Value U12 U12 Value A1 A1 Value AU AU Value An U2 U2 Value U23 U23 Value A2 A2 Value AA AA Value An Value U3 U3 Value U31 U31 Value A3 A3 Value F PLd1 PLd1 Value Uub1 Uub1 Value Iub1 Iub1 Value F Value Blank PLd2 PLd2 Value PLd3 PLd3 Value Uub2 Uub2 Value rPM Display Line3 Display LED Indication Display sequence § A B C R,Y,B 1 1 1 R,Y,B 2 2 2 R,Y,B 3 3 3 R,Y,B 4 4 4 5 5 6 6 R,Y,B 7 7 Uub3 Uub3 Value R,Y,B 8 8 Iub2 Iub2 Value Iub3 Iub3 Value R,Y,B 9 9 rPM Value Blank 10 10 12 Blank Blank 5 6 Power factor R ,Y,B phase System Power factor Power Phase Angle Active Power R ,Y,B phase PF-2 PF-2 Value PF-3 PF-3 Value 7 11 11 PF-t PF-t Value Blank 8 12 12 PA1 PA1 Value W1 W1 Value PA2 PA2 Value W2 W2 Value W-t (MSB) UA2 UA2 Value UA-t Value (MSB) UAr2 Value UArt Value (MSB) PA3 PA3 Value W3 W3 Value W-t (LSB) UA3 UA3 Value UA-t Value (LSB) UAr3 Value UArt Value (LSB) 13 13 9 14 14 10 15 15 11 16 16 12 17 17 13 18 18 14 19 19 20 20 21 21 Total active power W-t Apparent Power R ,Y, B phase Total apparent power Reactive Power R,Y,B phase Total reactive power UA1 UA1 Value UA-t UAr1 Value UArt R,Y,B R,Y,B kilo R kilo R,Y,B kilo R kilo R,Y,B kilo R kilo MD Import Active MD Value W Value Blank Occurrence Time of MD Import Active MD Days W Hours TIME Minutes MD Value W Value Blank Exp, R kilo 22 Occurrence Time of MD Export Active MD Days W Hours TIME Minutes Exp 23 MD Apparent MD Value VA Value Blank R kilo Occurrence Time of MD Import Apparent MD Days VA Hours TIME Minutes MD Export Apparent MD Value VA Value Blank Exp, R kilo 26 Occurrence Time of MD Export Apparent MD Days VA Hours TIME Minutes Exp 27 MD I Value 24 28 Occurrence Time of MD Current MD Days I Hours TIME Minutes 25 29 Rising MD Import Active RD W Value R kilo 26 30 Rising MD Export Active RD W Value Exp, R kilo MD Export Active MD PF-1 PF-1 Value MD Current (I) 13 R kilo 22 24 23 25 31 Remaining Time of MD Active (Import and Export) RT W n.xx Minutes Rising MD Import Apparent RD UA Value R kilo RD UA Value Exp, R kilo Remaining Time of MD Apparent (Import and export) RT UA n.xx Minutes 29 35 Rising current(I) MD RD I Value 30 36 Remaining Time of MD Current RT I n.xx Minutes 31 37 Import Active Energy Wh Value <MSB> Value <LSB> R kilo 15 32 38 Import Apparent Energy UAh Value <MSB> Value <LSB> R kilo 16 33 39 Import reactive lag Energy UArh Value <MSB> Value <LSB> R kilo 17 34 40 Import reactive lead Energy UArh Value <MSB> Value <LSB> 18 35 41 Export Active Energy Wh Value <MSB> Value <LSB> Lead, R kilo Exp, R kilo Export apparent Energy UAh Value <MSB> Value <LSB> Exp, R kilo 43 Export reactive lag Energy UArh Value <MSB> Value <LSB> Exp ,R kilo 44 Export reactive lead Energy UArh Value <MSB> Value <LSB> Lead, Exp, R kilo 45 Total Import load run hour Mains rnh d.xxx h.xx 19 36 46 Total Power on time tPot d.xxx h.xx 20 37 47 Total Power fail count Pr FAIL Value 21 38 48 Total Export load run hour Mains rnh d.xxx h.xx Energy MD Rising MD Export Apparent 14 Exp 27 32 28 33 34 42 49 Backup values Import Active Energy backup rSt Value Wh Value Blank R kilo 22 39 50 Import Apparent Energy backup rSt Value UAh Value Blank R kilo 23 40 51 Import Reactive Lag Energy backup rSt Value UArh Value Blank R kilo 24 41 52 Import Reactive Lead Energy backup rSt Value UArh Value Blank Lead, R kilo 25 42 53 Export Active Energy backup rSt Value Wh Value Blank Exp, R kilo 54 Export Apparent Energy backup rSt Value UAh Value Blank Exp, R kilo 55 Export Reactive Lag Energy backup rSt Value UArh Value Blank Exp, R kilo 56 Export Reactive Lead Energy backup rSt Value UArh Value Blank Exp, Lead, R kilo 57 MD Import Active backup rSt Value MD Value W R kilo MD Export Active backup rSt Value MD Value W Exp, R kilo MD Import Apparent backup rSt Value MD Value UA R kilo MD Export Apparent backup rSt Value MD Value UA Exp, R kilo MD Current backup rSt Value MD I Total load run hour Backup rSt d.xxx rnh h.xx Blank Total Export load run hour Backup rSt d.xxx rnh h.xx Blank 15 43 59 44 60 61 26 Exp 58 45 62 46 63 64 Others Phase Distortionvoltage UH1 Value UH2 Value UH3 Value Distortion-phase Current AH1 Value AH2 Value AH3 Value Modbus Slave ID Sl.Id Value Blank Modbus comm. Baud rate and parity Baud Value Parity No. of resets n.rSt Value Blank R,Y,B 27 47 65 R,Y,B 28 48 66 29 49 67 30 50 68 31 51 69 R kilo MSB: Most Significant Bit, LSB: Least Significant Bit, § Blank cells denote feature not applicable for that model. In LED indication column -Unit led will change to k/M/G depending on the value, the unit of energy is fixed depending on the CTPT ratio. Model A & Model B are unidirectional meters and Model C is bi-directional meter. Second letter from right in Catalogue number represents the model. For example WDM303FDWA0 represents Model A. Sl. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Note: All Variant MF model A with relay -/1A MF Model B with relay -/1A MF Model C with relay -/1A MF model A with relay -/5A MF Model B with relay -/5A MF Model C with relay -/5A MF model A without relay -/1A & -/5A MF Model B without relay -/1A & -/5A MF Model C without relay -/1A & -/5A MF model A without relay -/1A & -/5A (without RS485) MF Model B without relay -/1A & -/5A (without RS485) MF Model C without relay -/1A & -/5A (without RS485) MF model A without relay -/1A & -/5A MF Model B without relay -/1A & -/5A MF Model C without relay -/1A & -/5A the Models are with RS 485 except (10, 11&12) Class 1 0.5 Catalogue Number WDM303ODWA0 WDM303ODNB0 WDM303ODNC0 WDM303FDWA0 WDM303FDNB0 WDM303FDNC0 WDM303FDWA1 WDM303FDNB1 WDM303FDNC1 WDM303FDWAX WDM303FDNBX WDM303FDNCX WDM313CDWA1 WDM313CDNB1 WDM313CDNC1 L&T Electrical & Automation Manufactured by: L&T Electrical & Automation Larsen & Toubro KIADB Industrial Area Hebbal, Hootagalli Mysore 570018 Karnataka, INDIA 2015 L&T Electrical & Automation 16

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project