- Computers & electronics

- TVs & monitors

- Greenheck

- 476811 Network Interface BMS v1.10 April 2013

- Manual

advertisement

®

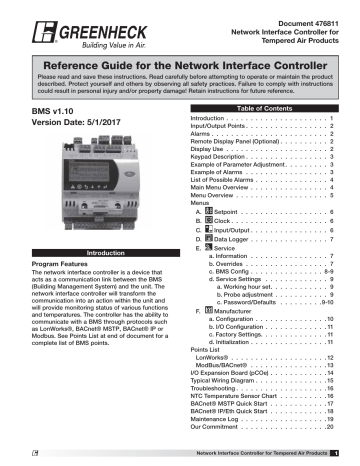

Document 476811

Network Interface Controller for

Tempered Air Products

Reference Guide for the Network Interface Controller

Please read and save these instructions. Read carefully before attempting to operate or maintain the product described. Protect yourself and others by observing all safety practices. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

BMS v1.10

Version Date: 5/1/2017

Introduction

Program Features

The network interface controller is a device that acts as a communication link between the BMS

(Building Management System) and the unit. The network interface controller will transform the communication into an action within the unit and will provide monitoring status of various functions and temperatures. The controller has the ability to communicate with a BMS through protocols such as LonWorks®, BACnet® MSTP, BACnet® IP or

Modbus. See Points List at end of document for a complete list of BMS points.

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . 1

Input/Output Points . . . . . . . . . . . . . . . . . 2

Alarms . . . . . . . . . . . . . . . . . . . . . . . . 2

Remote Display Panel (Optional) . . . . . . . . . . 2

Display Use . . . . . . . . . . . . . . . . . . . . . 2

Keypad Description . . . . . . . . . . . . . . . . . 3

Example of Parameter Adjustment . . . . . . . . . 3

Example of Alarms . . . . . . . . . . . . . . . . . 3

List of Possible Alarms . . . . . . . . . . . . . . . 4

Main Menu Overview . . . . . . . . . . . . . . . . 4

Menu Overview . . . . . . . . . . . . . . . . . . . 5

Menus

A. Setpoint . . . . . . . . . . . . . . . . . . 6

B. Clock . . . . . . . . . . . . . . . . . . . . 6

C. Input/Output . . . . . . . . . . . . . . . . 6

D. Data Logger . . . . . . . . . . . . . . . . 7

E. Service a. Information . . . . . . . . . . . . . . . . 7 b. Overrides . . . . . . . . . . . . . . . . . 7 c. BMS Config . . . . . . . . . . . . . . . 8-9 d. Service Settings . . . . . . . . . . . . . 9 a. Working hour set. . . . . . . . . . . . 9 b. Probe adjustment . . . . . . . . . . . 9 c. Password/Defaults . . . . . . . . .9-10

F. Manufacturer a. Configuration . . . . . . . . . . . . . . . 10 b. I/O Configuration . . . . . . . . . . . . . 11 c. Factory Settings. . . . . . . . . . . . . . 11 d. Initialization . . . . . . . . . . . . . . . . 11

Points List

LonWorks® . . . . . . . . . . . . . . . . . . . . 12

ModBus/BACnet® . . . . . . . . . . . . . . . . 13

I/O Expansion Board (pCOe) . . . . . . . . . . . . 14

Typical Wiring Diagram . . . . . . . . . . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . 16

NTC Temperature Sensor Chart . . . . . . . . . . 16

BACnet® MSTP Quick Start . . . . . . . . . . . . 17

BACnet® IP/Eth Quick Start . . . . . . . . . . . . 18

Maintenance Log . . . . . . . . . . . . . . . . . . 19

Our Commitment . . . . . . . . . . . . . . . . . . 20

Network Interface Controller for Tempered Air Products 1

®

Input/Output Points

Standard Input/Output points are Supply Air Temp, Outside Air Temp and Fan Proving Status. The following are optional I/O points. See Network Interface unit diagram to see job specific I/O.

Input Points (Max 5)

Cold Coil Temp

Return Air Temp

Exhaust Discharge Temp

Outdoor Air After Wheel Temp

Dirty Filter Status

Rotation Status

CO

2

Sensor

Supply VFD Monitor Signal

Exhaust VFD Monitor Signal

User Defined

Room Temp

Frost Status

Econ Status

Output Points Digital (Max 5)

Call for Heat Stage 1

Call for Cool Stage 1

Call for Cool Stage 2

Occupied Unoccupied

Remote Exhaust Fan

Call for HGRH

Alarm

User Defined

Output Points Analog (Max 3)

Heat Output

Cool Output

Supply VFD

Exhaust VFD

Energy Wheel VFD

Return Air Damper

User Defined

Alarms

The network interface controller will monitor the unit conditions for alarm conditions. Upon detecting an alarm, the controller will record the alarm description, time, date and available temperatures for user review.

An optional digital output is available for remote alarm indication. Alarms are also communicated via

BMS.

• Network interface controller will send an alarm in the case of a failed air temperature sensor.

• If the supply air temperature drops below the supply air low limit (35°F), the network interface controller can do one of the following based on user setup.

Display Use

The network interface controller is located in the unit control panel. The face of the controller has six keys, allowing the user to view unit conditions and alter parameters. The network interface controller is preprogrammed with easy-to-use menus.

- Alarm and Open NO3: Sends an alarm and turns the unit run command off, even if BMS run command is active.

- Disable: Disables the supply air low limit function.

Remote Display Panel (Optional)

A display panel allows for remote monitoring and adjustment of parameters, allowing ease of control access without going outdoors .

A remote mounted display is also available, which connects via the J4 port. A six-wire patch cable is needed.

2 Network Interface Controller for Tempered Air Products

®

or

!

Alarm

Down

Arrow

Up

Arrow

Esc or

Keypad Description

Button will blink red, indicating an alarm condition. Press to review current alarms. To review previous alarms, access the DATA LOGGER through the main menu.

The arrow keys allow the user to scroll through different screens and adjust parameters.

Enter

A. In screens with adjustable parameters, pressing the Enter key moves the cursor from the upper left corner of the screen to the parameter. The arrow keys can then be used to adjust the parameter.

B. To move to the next parameter on the same screen, press the Enter button.

C. To save the change, press the Enter button until the cursor moves back to the upper left corner of the screen.

Escape Allows the user to exit the current menu, jumping to the Main Menu.

Prg or Program

Pressing the Prg (Program) button allows the user to enter the Main Program Menu.

See below for Main Program Menu description.

Supply air low limit

Alarm when supply is

F

Alarm delay: 300s

Example of Parameter Adjustment

The cursor always begins in the upper left corner of the display and will be blinking. Press the

key to move the cursor down for parameter adjustment.

Supply air low limit

Alarm when supply is

F

Alarm delay: 300s

Once the cursor has reached the desired parameter, press the

keys to adjust the value.

Supply air low limit

Alarm when supply is

F

Alarm delay: 300s

When satisfied with the adjustment, press the key to save the parameter.

When finished, make certain the cursor is in the upper left corner. If the cursor is not in the upper left corner, the changes will not be saved. The cursor must be in the upper left corner to enable screen advancement.

Examples of Alarms

If an alarm occurs, the status line will state !PRESS ALARM BUTTON! and the or the controller and the remote display (if installed).

Alarms

Press DOWN to review current alarm(s).

Press ESC to exit.

Press ALARM to reset.

!

button will glow red on

To view alarm, press the or recent alarm. Press the

or

!

button once. This will display the most

!

button again to reset the alarm. If the alarm cannot be cleared, the cause of the alarm has not been fixed. Press the buttons to view any additional occurring alarms.

This is an example of an outdoor air sensor failure.

B3-Outdoor Temp

Sensor B03 Failure

Alarms

No active alarm

This screen appears if there are no active alarms.

To view all saved alarms, press the button to enter the DATA LOGGER. For more information, see the Data Logger menu.

Network Interface Controller for Tempered Air Products 3

®

Temperature Sensor

Failure

System has exceeded the set number of run hours

Supply temperature low limit alarm pCOe Offline pCOe - Analog input probe on channel # disconnected or broken

List of Possible Alarms

Failure of temperature sensor.

The unit has been operating for a period longer than the maintenance set point.

Indicates a supply air temperature lower than the supply low limit set point.

Indicates communication with pCOe auxiliary I/O has failed.

Indicates an analog probe failure on the pCOe.

Check integrity of auxiliary I/O analog probes.

Alarm only

Alarm only

Alarm & Open NO3 or Alarm Only

Alarm only

Alarm only

Main Menu Overview

The remote interface controller will revert to a default main menu loop. This loop includes several screens to view the operating conditions of the unit. Scroll through the menu screens by using the keys. Screens with a dashed line border are dependent upon an optional accessory and may not always appear.

TIME DATE UNIT##

T HE INITIAL MENU SCREEN DISPLAYS THE PROGRAM VERSION , UNIT CODE AND S TATUS

L

INE

. T

HE

S

TATUS

L

INE WILL DISPLAY

“!M

ANUAL

O

VERRIDE

!”

IF THE OVERRIDE

SCREEN IS ACTIVE OR “!P

RESS A LARM B UTTON !” IF THERE IS AN ALARM CONDITION .

® v1.10 GXXXXX00XX100b

STATUS LINE

TIME DATE UNIT##

Inputs

B1-

B2-

B3-OutsideAir: 80.0ºF

B4-SupplyAir: 65.0ºF

B5-

B6-

I

NPUTS

This screen displays real-time conditions from the input sensors located in the unit.

TIME DATE UNIT##

Digital Inputs

ID1-Fan Proving: Open

ID2-DirtyFilter: Open

D

IGITAL

I

NPUTS

This screen displays real-time digital input open/closed status from the selected components.

TIME DATE UNIT##

Analog Ouput

Y2-VFD Supply: 100%

Y3-

Y4-

A

NALOG

O

UTPUTS

This screen displays real-time analog output signals to the selected components .

TIME DATE UNIT##

Digital Output

NO1-

NO2-

NO3- Unit OnOff: Open

NO4-

NO5-

NO6-

D

IGITAL

O

UPUTS

This screen displays real-time digital output open/closed status.

4 Network Interface Controller for Tempered Air Products

®

Press Prg or to enter menus.

Main Menu

¬

¬

Main Status

Inputs

¬

Digital Inputs

¬

Analog Output

¬

Digital Output Status

Setpoint

¬

Supply Air Low Limit

¬

CO2 Sensor Setup

Clock

¬

Clock

¬

Daylight Savings Time

Input/Output

¬

Analog Input

¬

Digital Input

¬

Relay Output

¬

Analog Output

Data Logger

¬

Alarm Description

Service

¬

Information

Overrides

¬

Service Password

¬

Testing Overrides

BMS Config

¬

Service Password

¬

BMS Configuration

¬

Modbus Setup

¬

MSTP Setup

¬

TCP/IP Setup

¬

BACnet ReadWrite

Service Setting

¬

Service Password

Working hour set

¬

Maintenance Hours

Probe Adjustment

¬

Analog Inputs

¬

Probe Adjust

Password/Defaults

¬

User Default

¬

User Default settings

Manufacturer

Configuration

¬

¬

Expansion I/O

¬

Controller pLAN Setup

I/O Configuration

¬

Analog Input

¬

Digital Input

¬

Relay Output

¬

Analog Output Config

Factory Setting

¬

Factory Setup

¬

Temperature Scale

¬

Display Buzzer

Initialization

¬

Factory Settings

¬

New Password

¬

Initialization

Network Interface Controller for Tempered Air Products 5

®

Menus

The controller is equipped with several menus to help guide users with altering program parameters. The following menus can be accessed by pressing the Prg or key. To enter the desired menu, press the key.

The Setpoint menu allows the user to view and adjust temperature related

A. Setpoint

Supply air low limit

Alarm when supply is below

Alarm delay:

Alarm Function:

35.0°F

300s

CO2 Sensor Setup

CO2 Output

Scaling:

2-10VDC

T

HIS SCREEN DISPLAYS THE LOW SUPPLY AIR TEMPERATURE LIMIT

.

If the unit supply air temperature falls below Supply Air Low Limit for a period of

Alarm Delay, the unit will do one of the following based on the Alarm Function.

• Alarm Only: Sends alarm via BMS.

• Alarm and Open NO3: Sends an alarm and opens NO3 (Unit Start/Stop command) even if the BMS start/stop command is active.

• Disable: Disables the supply air low limit function.

The purpose of the supply low limit is to protect the building and contents from cold supply air. It is NOT designed to protect the air handling unit.

If the unit does not have cold or hot water coils, it should not need additional protection from freezing. If the unit does have cold or hot water coils, field provided coil freeze protection may be necessary.

T

HIS SCREEN DISPLAYS

CO2

SENSOR SETUP

.

This screen only appears if the unit is equipped with a CO

2

sensor.

This screen is used to match the settings of the CO

2

sensor to the network interface controller.

B. Clock

Set Date & Time

Day: Monday

Date: 01/31/10

Hour: 15:30

The Clock/Scheduler menu allows the user to view and alter the time and date.

The Clock screen allows the user to adjust the time and date.

Clock

Daylight Savings Time

DST: ENABLE

Transition Time: 60min

Start: SECOND SUNDAY in

2:00

End: FIRST SUNDAY in

2:00

T

HIS SCREEN ALLOWS THE USER TO MODIFY THE

D

AYLIGHT

S

AVINGS

T

IME FUNCTION

.

This internal clock is set by default to adjust for daylight savings time. On this screen the user can enable, disable, or change when the unit compensates for daylight savings time.

C. Input/Output

Analog Input

B4-Supply Air Temp

Input B04: 70.0°F

The Input/Output menu allows the user to quickly view the status of the controller inputs and outputs.

To manually control I/O values, go to the Service menu > Overrides .

Similar screens appear for all controller inputs and outputs.

6 Network Interface Controller for Tempered Air Products

®

13:21:04 10/05/10

OA Sensor

Outside Air T:

Supply Air T:

-623.3

70.0

The Data Logger menu allows the user to view past alarms.

T HIS SCREEN IS AN EXAMPLE OF A RECORDED ALARM .

The unit conditions are displayed for past alarm events. The date, time, temperatures and unit status are recorded.

To clear recorded alarms, press Prg or and Esc or simultaneously.

E. Service

The Service menu allows the user to access several sub-menus regarding controller information, controller overrides, operating hours, BMS configuration,

I/O manual management and Probe Adjustment. The user can also change the default Service Password (Default=1000) by accessing the Service Settings sub-menu. By accessing the BMS Config sub-menu, the user can adjust BMS protocol settings (BACnet, LonWorks, Modbus).

E. Service

a. Information

E

NTERING THE

I

NFORMATION SUB

-

MENU WILL DISPLAY INFORMATION ABOUT THE

CONTROLLER AND THE PROGRAM LOADED ON THE CONTROLLER .

Information Code: Controller setup code determines functionality of program. When contacting the factory, please reference this code.

Greenheck Fan Corp.

Code:GXXXXX00XX100b Manual: Reference this Installation and Operation Manual, available at

Ver.: 1.10 05/1/17 www.greenheck.com

Manual: 476811

Bios:

Boot:

5.18 11/17/10

4.07 12/18/11

E. Service

b. Overrides

The Overrides menu is for start-up, commissioning and troubleshooting.

This menu allows the user to override the control loops. If further control is required, the user can also manually control the controller inputs and outputs.

To access the Overrides sub-menu, enter the service password (Default=1000).

Testing Overrides

To resume normal operation, cycle unit power.

Testing Overrides

Override: No Position

NO1-

NO2-

NO3- Unit On/Off: Open

NO4-

NO5-

NO6-

To manually override an output, in each respective screen, change the override from No to Yes, then change the Position to open or closed or adjust the vdc output setting.

To resume normal operation after overriding the controller, simply cycle power to the unit.

This menu allows the user to manually control the outputs of the controller. The user can manually control the analog outputs and digital outputs. EXTREME

CAUTION should be used when manually controlling the outputs and should only be used as a troubleshooting feature. If the controller is powered down, overrides are reset to off. Therefore, if using this troubleshooting feature, the best way to clear manually input values is to power down the controller.

T

HIS SCREEN ALLOWS THE USER TO OVERRIDE THE DIGITAL OUTPUTS

.

This screen only appears if the unit is equipped with a digital output option.

Testing Overrides

Override: No

Y2- VFD Supply: 10.0vdc

Y3-

Y4-

T

HIS SCREEN ALLOWS THE USER TO OVERRIDE THE ANALOG OUTPUTS

.

This screen only appears if the unit is equipped with an analog output option.

Network Interface Controller for Tempered Air Products 7

®

E. Service

c. BMS Config

BMS Configuration

BACnet Plugin? YES

The BMS Config menu allows the user to view and alter BMS protocol settings. If the BMS protocol is BACnet or Modbus, additional screens allow further configuration. See below for details. To access the BMS Config sub-menu, enter the service password (Default=1000).

T HIS SCREEN ALLOWS THE USER TO SELECT THE BMS PROTOCOL . A LL BMS

PROTOCOLS REQUIRE A COMMUNICATIONS CARD INSTALLED IN THE

SERIAL CARD

PORT , LOCATED ON THE FACE OF THE CONTROLLER .

If the protocol is BACnet MSTP or BACnet IP/Eth, the user can change common BACnet parameters via the controller. The BACnet Plugin must be set to YES.

MODBUS SETUP

Address: 1

Baudrate 9600

T HIS SCREEN ALLOWS THE USER TO ADJUST M ODBUS PARAMETERS .

This screen only appears if the selected BMS protocol is set to Modbus .

The address is the Modbus address of the card installed in the SERIAL CARD port located on the face of the controller. (Factory Default Address = 1). The

Baud Rate should be set to the BMS baud rate. (Factory Default Baud Rate is

9600).

MSTP SETUP

Instance: 77000

MAC Addr: 0

MaxInfoFrames: 20

BACnet Read/Write

Function: Read

Update? Yes

*Cycle unit power to confirm write command.

T

HIS SCREEN ALLOWS THE USER TO ADJUST

BAC

NET

MSTP

PARAMETERS

.

This screen only appears if the selected BMS protocol is set to BACnet MSTP and changed via the controller display. Factory settings are shown in the screen to the left.

To view current parameters:

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Config menu and view BACnet Read/Write screen.

3. Change Function to Read and Update?

to YES .

Current BACnet MSTP parameters should now be displayed in the BACnet

MSTP SETUP screen. If all values appear to be zeros, consult the factory.

(Make sure you have allowed several minutes for the controller to initialize).

*Values may appear to be zero prior to setting the Function to READ.

To change BACnet MSTP parameters:

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Config menu and view MSTP SETUP screen.

3. Move cursor to desired parameter by pressing the

to select the parameter to change. Press the

buttons. Press

buttons to adjust the parameter. Press to save adjusted value.

4. Once desired parameters have been entered, go to BACnet Read/Write screen. Change Function to Write and Update?

to YES .

5. Reboot the controller by cycling power to the unit. Allow several minutes for the controller to initialize.

6. View MSTP parameters. If changed values did not save, contact the factory.

8 Network Interface Controller for Tempered Air Products

®

TCP/IP SETUP

Instance: 77000

IP set by: DHCP

T

HIS SCREEN ALLOWS THE USER TO ADJUST

BAC

NET

IP

PARAMETERS

.

This screen only appears if the selected BMS protocol is set to BACnet IP/Eth and

BACnet Plugin = YES.

Subnet: 255.255.000.000

Gatewy: 128.2.0.12

DNS 1:

DNS 2:

Type: IP

Function: Read

Update? Yes

*Cycle unit power to confirm write command.

E.

TCP/IP SETUP

193.168.001.001

193.168.001.001

BACnet Read/Write

Service

d. Service Settings a. Working hour set b. Probe adjustment c. Password/Defaults via the controller display. The card is in DHCP mode from the factory.

Once communication is established, the user can enter static IP parameters.

To view current parameters:

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Config menu and view BACnet Read/Write screen.

3. Change Function to Read and Update?

to YES .

Current BACnet IP parameters should now be displayed in the BACnet TCP/IP

SETUP screen. If all values appear to be zeros, consult the factory. (Make sure you have allowed several minutes for the controller to initialize).

*Values may appear to be zero prior to setting the Function to READ.

To change BACnet TCP/IP parameters:

1. Power on the controller and allow several minutes to initialize.

2. Go to BMS Config menu and view TCP/IP SETUP screen.

3. Move cursor to desired parameter by pressing the buttons. Press

to select the parameter to change. Press the the parameter. Press to save adjusted value.

buttons to adjust

4. Once desired parameters have been entered, go to BACnet Read/Write screen. Change Function to Write and Update?

to YES .

5. Reboot the controller by cycling power to the unit. Allow several minutes for the controller to initialize.

6. View TCP/IP parameters. If changed values did not save, contact the factory.

The Service Settings menu allows the user to change the default Service

Password (1000), save and restore default parameters, and adjust probe values.

MAINTENANCE HOURS

SYSTEM

Run hours:

Set Point:

Reset to Zero?

0000h

0000h

No

T HIS SCREEN ALLOWS THE USER TO VIEW UNIT RUN HOURS , AND ALTER SET POINTS

FOR MAINTENANCE

.

Run hours: The amount of time in hours that the unit has been powered.

Set Point: The amount of running time in hours before a maintenance alarm should occur.

Reset to Zero: Reset the measured amount of run time.

Analog Input

Outside Temperature

Input B3

Offset: 0.0°F

Value: 70.5°F

T HE P ROBE A DJUSTMENT MENU ALLOWS THE USER TO CALIBRATE SENSOR PROBES

WITH AN OFFSET VALUE

.

Similar screens are available for remaining sensor probes.

User Default T HIS SCREEN ALLOWS THE USER TO CHANGE THE S ERVICE L EVEL PASSWORD (PW1)

Insert new service password

(PW1): 1000

Network Interface Controller for Tempered Air Products 9

®

User Default Settings

Save? No

Restore? No

T HIS SCREEN ALLOWS THE USER TO SAVE AND RESTORE THE DEFAULT

PARAMETERS STORED IN MEMORY

.

If the user would like to save their settings, move the cursor to the SAVE position and change to YES. This will save all of the current parameters into memory as Service Settings. If the user would like to restore to these values at some point in the future, moving the cursor to the RESTORE position, and selecting YES will restore the controller to the user saved defaults.

F. Manufacturer

a. Configuration

Unit Code

Select DDC configuration code here.

Code: GXXXXX000XX101b

Configuration menu allows the user to change the setup code for the unit, enable

Scheduling, Holidays, expansion I/O and change Field Card settings. Users are welcomed to enable Scheduling and Holidays. However, code changes and expansion I/O enabling are to be done under factory advice only!

T

HIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE

U

NIT

C

ODE

.

This code is set from the factory to operate the components selected with the unit. When troubleshooting, refer to the wiring diagram sent with the unit

(located on the control center door) to verify the Unit Code is correct. The code will be listed on the wiring diagram.

Configuration

Modbus settings

Stop bit:

Parity mode:

2

None

Timeout: 300ms

T

HIS SCREEN ALLOWS THE USER TO ALTER THE

FIELD CARD M

ODBUS SETTINGS

.

The FIELD CARD is used for peripheral device control (pCOe Expansion

The Modbus settings should only be changed with factory guidance.

Unit Expansion I/O

Enable Expansion: No

Controller pLAN Setup

Current pLAN Addr:

New pLAN Addr:

1

1

T

HIS SCREEN ALLOWS THE USER TO ENABLE ADDITIONAL

I/O

POINTS

.

Unit I/O expansion requires the installation of a pCOe and Field Card. Please contact the factory for more information.

Enabling the I/O expansion allows the user to add the following points for monitoring:

• Four analog inputs (0/1vdc, 0/5vdc, 0/20mA, 4/20mA, NTC Temp)

• One analog output (0/10vdc)

• Four digital inputs

• Four digital outputs

The additional I/O points available on the pCOe expansion module allow the user to monitor and control the additional points over the BMS and user display.

T

HIS SCREEN ALLOWS THE USER TO VIEW AND CHANGE THE CONTROLLER P

LAN

ADDRESS

.

A pLAN (pCO Local Area Network) is a Carel proprietary local area network, allowing the user to connect multiple controllers to one remote display panel.

Each controller on a pLAN must have a unique address.

This address is only applicable for units connected on a pLAN. For BACnet,

LonWorks or Modbus parameters, go to Service > BMS Config .

10 Network Interface Controller for Tempered Air Products

®

F. Manufacturer

b. I/O Configuration

The I/O Configuration menu allows adjustment of all controller inputs and outputs. This menu is similar to the Probe Adjustment menu, except that it additionally allows adjustment of the factory default ‘normal’ states of the digital inputs and the direction of the analog outputs. Additionally, it allows adjustment of the physical location of each I/O. ADJUSTMENT OF I/O

PHYSICAL LOCATION MUST ONLY BE DONE UNDER FACTORY GUIDANCE!

IMPROPER ADJUSTMENT MAY RESULT IN SYSTEM DAMAGE!

Analog Input

Outside Temperature

Type: NTC

This is an example of an analog input configuration screen.

type of each point.

Value: 70.5°F

Alarm Time Delay

Outside Temperature

Input B03: 72.0°F

Out of Range Alarm

Power Delay:

Run Delay:

30s

30s

Digital Input

ID1- Fan Proving

Channel: ID1

Action: CLOSED

Delay 0s

CLOSED

Relay Output

NO3- Unit ON

Channel: 3

Status: OFF

Analog Output Config

Y2-Heat Output

Channel: Y2

Action: DIRECT

Minimum: 0.0vdc

Maximum: 10.0vdc

F.

c. Factory Settings

Temperature Scale

Select: Fahrenheit

Display Buzzer

Select: Disable

F.

Manufacturer

Manufacturer

d. Initialization

Factory Settings

Save? No

Restore? No

New Password

The Factory Settings menu allows adjustment of parameters that are critical for proper unit operation. Adjustment of these parameters is only recommended with factory guidance. To access the Factory Settings menu, enter the manufacturer password (Default=1000).

T

HIS SCREEN ALLOWS THE USER TO ADJUST WHAT TEMPERATURE UNITS THE

CONTROLLER SHOULD DISPLAY AND WHETHER THE DISPLAY BUZZER SHOULD BE

ENABLED OR DISABLED

.

The temperature unit of measurement can either be Fahrenheit or Celsius.

If using Celsius, the user will need to manually convert the factory default parameters in the Factory Settings menu.

The display buzzer is only applicable when a remote interface panel is attached to the controller. If an alarm were to occur, the remote display panel would begin buzzing loudly (if the buzzer was enabled) and would show the alarm status.

The Initialization Menu allows the user to save and restore the controllers default parameters. The controller can be restored with either the

Manufacturer’s default parameters from shipment, or an unconfigured factory default.

T

HIS SCREEN ALLOWS THE USER TO

SAVE

AND

RESTORE

THE FACTORY DEFAULT

PARAMETERS STORED IN MEMORY .

The Factory Settings include the Factory default parameters and the unit setup code. If the user would like to restore to these parameters, move the cursor to the Restore position and change to YES.

T HIS SCREEN ALLOWS THE USER TO CHANGE THE M ANUFACTURER P ASSWORD (PW2)

Insert new manufacturer password (PW2): 0000

Initialization

DEFAULT INSTALLATION

Erase user settings and install global default values: No

T HIS SCREEN ALLOWS THE USER TO RESTORE BACK TO THE ORIGINAL F ACTORY

DEFAULT PARAMETERS

.

Restoring to the original default parameters will result in a non-customized controller. The user should not restore to these settings unless instructed by the factory.

Network Interface Controller for Tempered Air Products 11

®

Type

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Integer pCOe Analog Variables

Analog

Analog

Analog

Analog

Analog

NV_Index

8

30

31

32

4

5

6

7

27

28

29

3

23

24

25

26

33

34

35

36

10

41

37

38

39

40

9

Name NV nvoOutsideTemp nvoSupplyAirTemp nvoColdCoilDisch nvoReturnTemp nvoExhDishTemp nvoOAAWTemp nvoRoomTemp nviHeatOutput nviCoolOutput nviVFDSupply nviVFDExhaust nviVFDWheel nviRADamperOut nvoOutdoorRH nvoVFDSupSignal nvoVFDExhSignal nvoB1User nvoB2User nvoB5UserAI nvoB6UserAI nviY4UserOut nvoCO2Output nvoAux_AI1 nvoAux_AI2 nvoAux_AI3 nvoAux_AI4 nviAux_AO1

Points List • LonWorks®

Type NV

105

81

81

44

44

81

81

81

81

105

105

105

105

105

105

81

9

9

9

9

81

29

9

9

9

9

81

Read (Unit to BMS)

Write (BMS to Unit)

Read

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital pCOe Digital Variables

Digital

Digital

Digital

Digital

Digital

Digital bit8

49

50

19

20

51 bit4 bit5 bit6 bit7 bit0 bit1 bit2 bit3

45

46

47

48

18

42

43

44

11

12

13

14

15

16

17

52

53

54

55

21

22 nviUnitOnOff nviResetAlarms nviStg1Cooling nviStg2Cooling nviStg1Heat nviOccUnocc nviRemoteExhFan nviHGRH nvoGlobalAlarm nvoFrostStatus nvoEconStatus nvoFanStatus nvoFilterStatus nvoWheelStatus nvoAlarm nvoSupplyTempAlm nvoB1Alarm nvoB2Alarm nvoB3Alarm nvoB4Alarm nvoB5Alarm nvoB6Alarm nvoB5UserAlarm nvoB6UserAlarm nvoB5UserDI nvoB6UserDI nviNO1UserDO nviNO2UserDO nvoID2UserDI nvoAux_DI1 nvoAux_DI2 nvoAux_DI3 nvoAux_DI4 nviAux_DO1 nviAux_DO2

95

95

95

83

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

95

12 Network Interface Controller for Tempered Air Products

Read

Read

Read

Write

Write

Read

Read

Read

Read

Read

Read

Read

Read

Read

Write

Read

Read

Read

Read

Read

Read

Write

Write

Write

Write

Write

Write

Write

Read

Read

Read

Read

Read/Write

Read/Write

Write

Write

Write

Write

Write

Read

Read

Read

Read

Read

Read

Read

Read

Read

Write

Read

Read

Read

Read

Write

Read

Read

Read

Read

Read

Write

Description

Outdoor Air Temp (###.#°F)

Supply Air Temp (###.#°F)

Cold Coil Temp (###.#°F)

Return AirTemp (###.#°F)

Exhaust Discharge Temp (###.#°F)

Outdoor Air After Wheel Temp (###.#°F)

Room Temp (###.#°F)

Heater output (0-100%)

Cooling output (0-100%)

VFD Supply Fan Output (0-100%)

VFD Exhaust Fan Output (0-100%)

VFD Wheel Output (0-100%)

RA Damper Output (0-100%)

Outdoor RH

Supply VFD Monitor Signal (Vdc)

Exhaust VFD Monitor Signal (Vdc)

User Define B1 Analog Input

User Define B2 Analog Input

User Define B5 Analog Input

User Define B6 Analog Input

User Define Y4 Analog Output

CO2 Levels (ppm) pCOe Analog Input Probe Value 1 pCOe Analog Input Probe Value 2 pCOe Analog Input Probe Value 3 pCOe Analog Input Probe Value 4 pCOe Auxillary Analog Out (0-10V)

Unit start/stop command

Reset alarms command

Cooling Stage 1 Command

Cooling Stage 2 Command

Heating Stage 1 Command

Occupied/unoccupied Command

Remote Exhaust Fan Command

Hot Gas Reheat Command

Global alarm indication (active when there is at least one alarm)

Frost Status

Econ Status

Fan Proving status

Dirty filter status

Wheel status-Not Ok=Wheel not running when commanded on

Supply air temperature low limit alarm

Sensor B1 out of range

Sensor B2 out of range

Sensor B3 out of range

Sensor B4 out of range

Sensor B5 out of range

Sensor B6 out of range

B5 User Input Alarm

B6 User Input Alarm

User Define B5 Digital Input

User Define B6 Digital Input

User Define NO1 Digital Output

User Define NO2 Digital Output

User Define ID2 Digital Input pCOe Auxillary Digital Input1 pCOe Auxillary Digital Input2 pCOe Auxillary Digital Input3 pCOe Auxillary Digital Input4 pCOe Auxillary Digital Output1 pCOe Auxillary Digital Output2

®

Type

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Type

Digital

Digital

Digital

Digital

Digital

Digital

Analog

Analog

Analog

Analog

Analog

Analog

Analog

Integer 40216 pCOe Analog Variables

Analog

Analog

40022

40023

Analog

Analog

Analog

40024

40025

40026

40018

40019

40027

40028

40029

40030

40031

10019

10020

10021

10022

10023

10024

10026

10027

Address

10011

10012

10015

10016

10017

10018

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital 10043 pCOe Analog Variables

Digital

Digital

10052

10053

Digital

Digital

Digital

Digital

Digital

Digital

10054

10055

10056

10057

10058

10059

10028

10029

10030

10031

10032

10033

10034

10035

10036

10039

10040

10041

10042

Modbus-RTU/TCP/IP

Network Address: 1

Address

40002

40003

40004

40005

40006

40007

40008

40011

40012

40013

40014

40015

40016

40017

Points List • Modbus / BACnet®

BACnet IP/Ethernet BACnet MSTP

Device Instance: 77000(default)

Address

1

Name

Outside_Air_Temp

Units

°F

Read

Write

R

11

12

13

14

15

7

10

5

6

2

3

4

16

28

29

30

17

18

26

27

1007

Supply_Air_Temp

Cold_Coil_Leaving_Temp

Return_Air_Temp

Exhaust_Discharge_Temp

OA_After_Wheel_Temp

Room_Temp

Heat_Output

Cool_Output

VFD_Supply_Output

VFD_Exhaust_Output

VFD_Wheel_Output

RA_Damper_Output

Outdoor RH

Supply_VFD_Mointor

Exhaust_VFD_Monitor

User_Define_B1_Analog_Input

User_Define_B2_Analog_Input

User_Define_B5_Analog_Input

User_Define_B6_Analog_Input

User_Define_Y4_Analog_Output

CO2_Level

°F

°F

°F

°F

°F

°F percent percent percent percent percent percent percent relative humidity volts volts no-units no-units no-units no-units no-units ppm

R

R

R/W

R

R

R

R

R

R/W

R/W

R/W

R/W

R/W

R

R

R

R/W

R

R

R

R

Description

Outdoor Air Temp (###.#°F)

Supply Air Temp (###.#°F)

Cold Coil Temp (###.#°F)

Return AirTemp (###.#°F)

Exhaust Discharge Temp (###.#°F)

Outdoor Air After Wheel Temp (###.#°F)

Room Temp (###.#°F)

Heater output (0-100%)

Cooling output (0-100%)

VFD Supply Fan Output (0-100%)

VFD Exhaust Fan Output (0-100%)

VFD Wheel Output (0-100%)

Return Air Damper Output (0-100%)

Outdoor RH

Supply VFD Monitor Signal (Vdc)

Exhaust VFD Monitor Signal (Vdc)

User Define B1 Analog Input

User Define B2 Analog Input

User Define B5 Analog Input

User Define B6 Analog Input

User Define Y4 Analog Output

CO2 Levels (ppm)

30

31

32

33

27

28

29

22

23

25

26

18

19

20

21

39

40

41

34

35

38

42

21

22

23

24

25

Address

10

11

14

15

16

17

51

52

53

54

55

56

57

58 pCOe_Analog_Input_Probe_Value_1 pCOe_Analog_Input_Probe_Value_2 pCOe_Analog_Input_Probe_Value_3 pCOe_Analog_Input_Probe_Value_4 pCOe_Analog_Out

Name

Unit_Start_Stop

Reset_Alarms

Cooling_Stg1_Command

Cooling_Stg2_Command

Heat_Stg1_Command

Occ_Unocc_Command

Inactive_Text

Stop

Don't Reset

Off

Off

Off

Off

°F or Percent

°F or Percent

°F or Percent

°F or Percent percent

Active_Text

Start

Reset Alarms

On

On

On

On

R

R

R

R

R/W

Read Write

R/W

R/W

R/W

R/W

R/W

R/W pCOe Analog Input Probe Value 1 pCOe Analog Input Probe Value 2 pCOe Analog Input Probe Value 3 pCOe Analog Input Probe Value 4 pCOe Auxillary Analog Out (0-10V)

Description

Unit start/stop command

Reset alarms command

Cooling Stage 1 Command

Cooling Stage 2 Command

Heating Stage 1 Command

Occupied/unoccupied Command

Exh_Fan_Command

HGRH_Command

Global_Alarm

Frost_Status

Econ_Status

Fan_Proving_Status

Dirty_filter_Status

Wheel_Status

Supply_air_low_limit

Sensor_B1_out_of_range

Sensor_B2_out_of_range

Sensor_B3_out_of_range

Sensor_B4_out_of_range

Sensor_B5_out_of_range

Sensor_B6_out_of_range

B5 _User_Alarm

B6_User_Alarm

User_Define_B5_DI

User_Define_B6_DI

User_Define_NO1_DO

User_Define_NO2_DO

User_Define_ID2_DI

Off

Off

Off

Off

Off

Off

Clean

Ok

Off

Off

Off

Off

Off

Off

Off

No Alarm

No Alarm

Open

Open

Off

Off

Open

On

On

Alarm

On

On

On

Dirty

Not Ok

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Alarm

Closed

Closed

On

On

Closed

R/W

R/W

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R/W

R/W

R

Exhaust Fan Command

Hot Gas Reheat Command

Global alarm indication (active when there is at least one alarm)

Frost Status

Econ Status

Fan Proving status

Dirty filter status

Wheel status-Not Ok=Wheel not running when commanded on

Supply air temperature low limit alarm

Sensor B1 out of range

Sensor B2 out of range

Sensor B3 out of range

Sensor B4 out of range

Sensor B5 out of range

Sensor B6 out of range

B5 User Input Alarm

B6 User Input Alarm

User Define B5 Digital Input

User Define B6 Digital Input

User Define NO1 Digital Output

User Define NO2 Digital Output

User Define ID2 Digital Input pCOe_Auxiliary_Digital_Input_1 pCOe_Auxiliary_Digital_Input_2 pCOe_Auxiliary_Digital_Input_3 pCOe_Auxiliary_Digital_Input_4 pCOe Auxillary Digital Output1 pCOe Auxillary Digital Output2 pCOe Auxillary Digital Output3 pCOe Auxillary Digital Output4

Off

Off

Off

Off

Off

Off

Off

Off

On

On

On

On

On

On

On

On

R

R

R

R

R/W

R/W

R/W

R/W pCOe Auxillary Digital Input1 pCOe Auxillary Digital Input2 pCOe Auxillary Digital Input3 pCOe Auxillary Digital Input4 pCOe Auxillary Digital Output1 pCOe Auxillary Digital Output2 pCOe Auxillary Digital Output3 pCOe Auxillary Digital Output4

Network Interface Controller for Tempered Air Products 13

®

I/O Expansion Board (pCOe)

The pCOe expansion board is an I/O module that can be used to monitor additional statuses within the unit or provide commands. The pCOe allows the user to view and control:

• 4 Digital Inputs

• 4 Digital Outputs

• 4 Analog Inputs

• 1 Analog Output

The inputs and outputs can be monitored and manually controlled either via the controller display or Building Management System.

See Points List for detailed point information.

24 VAC Power

0/10 VDC

Analog Output

Digital Inputs Linked Analog Inputs

(NTC, 0/1VDC, 0/20mA, 4/20mA, 0/5VDC)

Digital

Outputs

Linked Analog Inputs

(NTC, 0/1VDC, 0/20mA, 4/20mA, 0/5VDC)

Setup

In order for the controller to communicate with the pCOe, several parameters must be adjusted. If you have a pCOe installed from the factory, the controller is already set up for communication with the main controller.

Unit Expansion I/O

Enable Expansion Yes

Enabling the pCOe in the Main Controller: To enable the pCOe expansion

I/O module, go to Manufacturer > Configuration . You will have to enter the

Manufacturer password (Default = 1000). Enabling the pCOe expansion module allows additional screens to appear in other menus (see below).

Analog Inputs pCOe1

Aux AI Pair 1

Channels: B1 & B2

Configuring the pCOe Analog Inputs: The analog inputs are grouped in pairs

(Channels B1-B2 and Channels B3-B4). Each pair must be configured as the same analog input type (Carel NTC, 0/1 VDC, 0/20 mA, 4/20 mA or 0/5 VDC).

To setup the analog inputs:

1. Go to Manufacturer > I/O Configuration > Analog Inputs .

2. Find the pCOe Analog input screens.

3. Select desired channels and input type. If only one channel is to be used, select the desired channel to prevent nuisance sensor alarms.

If using a non-Carel NTC type, scale the input to match the probe range.

Analog Input pCOe1

Aux AI Pair 2

Channels: B3 & B4

Type:

B3 Min:

4 . . 20 mA

0.0

B3 Max:

B4 Min:

B4 Max:

10.0

0.0

10.0

Digital Inputs pCOe1

Channel ID1:

Channel ID2:

Channel ID3:

Channel ID4:

Closed

Closed

Closed

Closed

Viewing pCOe I/O Values: To view input values, go to the Input/Output menu.

The pCOe I/O values can be viewed on the BMS. The digital and analog outputs can be changed through the BMS. See Points List for more details.

Analog Inputs pCOe1

Input B1:

Input B2:

Input B3:

Input B4:

32.0ºF

32.0ºF

0.0°F

0.0°F

Digital Outputs pCOe1 Analog Outputs pCOe1

Output Y1: 0.0vdc

Output NO1:

Output NO2:

Output NO3:

Output NO4:

OFF

OFF

OFF

OFF

14 Network Interface Controller for Tempered Air Products

®

®

Typical Wiring Diagram

NETWORK INTERFACE CONTROLLER TO UNIT CONNECTION WIRING DIAGRAM

UNIT ELECTRICAL BOARD TERMINALS/COMPONENTS NETWORK INTERFACE CONTROLLER/COMPONENTS pCO5 INTERFACE

CONTROLLER

G BLUE

J1

GO

WHITE

TO TERMINAL "R"

TO TERMINAL "C"

R

C

24 VAC

C1

J3 NO1

NC1

B4

J2 GND

B2

B3

B5

B6

ID1 PINK

GND

YELLOW

ID2 LT. BLUE

GND

RED

J13

Y3

(0/10V)

Y4

(0/10V)

Y1

(PWM)

J9 Y2

(0/10V)

GND

J10

NO2

C2

NO3

PINK

J11 C3

NO4

NO5

J12 C5

NO6

BROWN

B1

TO TERMINAL "G"

TO TERMINAL "W1"

TO ST1-AUX

TO ST1-AUX

TO "C" ON PS2

TO "NO" ON PS2

OAI

OAD

G

UNIT START/STOP

REPLACES S1 FAN SWITCH

FACTORY WIRED

W1

HEATING STAGE 1

REPLACES S4 CALL FOR HEAT SWITCH

FACTORY WIRED

NO

C

ST1-AUX FAN PROVING STATUS

C

NO

PS2

DIRTY FILTER STATUS

REPLACES FIELD INTERFACE

CONNECTION TO PS2

FACTORY WIRED

®

Wiring Diagram Code:

GEXXXXD000XX101BL01

CAUTION

UNIT SHALL BE GROUNDED IN ACCORDANCE WITH N.E.C.

POWER MUST BE OFF WHILE SERVICING.

NOTES

USE COPPER CONDUTORS ONLY

60° C FOR TERMINALS RATED LESS THAN 100 AMPS.

75° C FOR TERMINALS RATED 100 AMPS OR MORE.

FIELD CONTROL WIRING RESISTANCE SHOULD

NOT EXCEED 0.75 OHM.

FIELD WIRED

FACTORY SUPPLIED AND WIRED

BK BLACK BL BLUE

GY GRAY LT BL

PK PINK PR PURPLE

W WHITE Y YELLOW

WIRE COLOR CODE

BR BROWN

LIGHT BLUE

R RED

LEGEND

OAD OUTDOOR AIR DISCHARGE TEMP SENSOR

OAI OUTDOOR AIR INLET TEMP SENSOR

O ORANGE

FOR MANUAL GO TO WWW.GREENHECK.COM

AND SEARCH "476811".

TYPE

Analog

Analog

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

Digital

ADDRESS

1

2

10

11

16

20

23

25

27

30

31

POINTS LIST

NAME

Outside_Air_Temp

Supply_Air_Temp

Unit_Start_Stop

Reset_Alarms

Heat_Stg1_Command

Global_Alarm

Fan_Proving_Status

Dirty_Filter_Status

Supply_Air_Low_Limit

Sensor_B3_Out_Of_Range

Sensor_B4_Out_Of_Range

DDC Code: Verison - BMS v 1.10

G X X X X D 0 0 0 X X 1 0 1 b

Wiring Template: L01

Network Interface Controller for Tempered Air Products 15

Troubleshooting

Display is hard to read.

Unit Controller Display: Hold Esc

or while pressing

DOWN or

ESC and

ENTER at the same time,

UP to adjust display contrast.

Remote Display: Hold

or same time, while pressing

!

ALARM, Prg

or PRG, and

Esc

or

ESC at the

DOWN or UP to adjust display contrast.

Remote display panel displays “NO LINK” or is blank.

Red alarm button is flashing.

Hold

DOWN, UP and ENTER for 4 seconds. Set the display address to 32. The display requires a standard 24 AWG six conductor phone cable connected to the unit controller.

Press the

or

!

ALARM button to review and clear unit alarms. Enter the

DATA LOGGER menu to view previous alarms.

Controller resets itself or is not on.

Menus are locked with a password.

Temperature sensor failure.

Check the supply voltage to the controller at terminals G-G0. The board requires

24VAC. Check the 24VAC transformer in the unit control center.

The factory default Manufacturer Password = 1000.

The factory default Service Password = 1000.

Check the analog input terminal block (labeled terminals B1, B2, B3, etc) for loose wires. Disconnect temperature sensors to check sensor resistance.

NTC Temperature Sensor Chart

90

80

70

120

110

100

60

50

40

30

20

10

0

4 6 8 10 12 14 16 18 20 22 24 26 28

Resistance (k

:

)

16 Network Interface Controller for Tempered Air Products

®

The card is loaded with the following default BACnet

MSTP parameters.

Parameter

Device Instance

Station Address

Max Master

Max Info Frames

Baudrate

Factory

77000

0

127

20

38400

Minimum Maximum

0

0

0

4194303

127

127

0 255

9600-19200-38400-76800

G. Service

c. BMS Config

BMS Configuration

BACnet Plugin? YES

BACnet® MSTP Quick Start

To view the current parameters, go the BMS

Config menu within the controller by pressing the Prg or

key.

To access the BMS

Config sub-menu, enter the service-password

(Default=1000).

Protocol must be

BACnet MSTP and

BACnet Plugin must be

MSTP SETUP

YES .

Instance: 77000

MAC Addr: 0

Press the button

Baudrate 38400 arrow to view next

MaxInfoFrames: 20

BACnet Read/Write

Function: Read

Update? Yes

*Cycle unit power to confirm write command.

Current BACnet MSTP parameters should be displayed. If values appear to be zero, follow the procedure below.

To read current settings:

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Config menu and view BACnet Read/

Write screen.

3. Change Function to Read and Update ? to YES .

Current BACnet MSTP parameters should now be displayed in the BACnet MSTP SETUP screen. If all values appear to be zeros, consult the factory.

(Make sure you have allowed several minutes for the controller to initialize). *Values may appear to be zero prior to setting the Function to READ.

To change BACnet MSTP parameters:

1. Power on the controller and allow several minutes to initialize.

2. Go to BMS Config menu and view MSTP SETUP screen.

3. Move cursor to desired parameter by pressing the

buttons. Press to change. Press the

to select the parameter

buttons to adjust the parameter. Press to save adjusted value.

4. Once desired parameters have been entered, go to BACnet Read/Write screen. Change Function to

Write and Update?

to YES .

5. Reboot the controller by cycling power to the unit.

Allow several minutes for the controller to initialize.

6. View MSTP parameters. If changed values did not save, contact the factory.

The communication card is located in the Serial

Card port on the face of the controller. The card includes two sets of LED lights for communication troubleshooting.

Status LED

Push Button

RS485 LED

Status LED: Indicates the status of communication between the card and controller.

• Quick green-off-green if communication with controller is ok.

• Slow red-off-red if communication is not established.

RS485 LED: Indicates the status of communication with the BACnet MSTP network. Wait for 40 seconds to determine status of communication.

• Green with occasional red, communication is OK.

• Green and red both on, communications is not established.

Communication Troubleshooting

See Carel Data sheet for more info.

If attempting to communicate with the controller over

BACnet MSTP, refer to the card LEDs for system information.

Status LED slow red blink

• Confirm card is firmly plugged in.

• Confirm BMS Protocol is set to BACnet MSTP.

RS485 LED green and red both on

• Confirm system and card baudrate are the same.

• Confirm card Max Master is equal to or greater than the Station (MAC) Address of the Master with the highest address.

Recalling Factory Parameters

Follow this procedure to revert to factory parameters for one power cycle. When restarted, the card will resume using the previous user parameters.

1. With controller off, hold the push button located on the BACnet MSTP card, while powering the controller back on.

2. Continue to hold the button, while watching the

Status LEDs . Wait for the Status LEDs to blink red slowly, and release before the third slow flash.

3. Wait for about one minute for the factory parameters to be loaded.

Network Interface Controller for Tempered Air Products 17

®

*The BACnet IP/Eth card is configured for DHCP from the factory.

To view the current parameters, go the BMS Config menu within the controller by pressing the Prg or key.

G. Service

To access the BMS c. BMS Config

Config sub-menu, enter

BMS Configuration the service password

(Default=1000) .

BACnet Plugin? YES

Protocol must be

BACnet IP/Eth and

BACnet Plugin must be

YES .

TCP/IP SETUP

Press arrow button to view next screen.

Instance: 77000

Current BACnet IP

IP set by: DHCP parameters should be

IP: 128.1.104.134 displayed. If values

Subnet: 255.255.000.000

Gatewy: 128.1.0.12

appear to be zero, follow the procedure below.

TCP/IP Setup To read current parameters:

DNS 1:

DNS 2:

Type: IP

193.168.001.001

193.168.001.001

1. Power on controller and allow several minutes to initialize.

BACnet Read/Write

Function: Read

Update? Yes

*Cycle unit power to confirm write command.

2. Go to BMS Config menu and view

BACnet Read/Write screen.

3. Change Function to

Read and Update ? to

YES .

Current BACnet IP parameters should now be displayed in the BACnet TCP/IP SETUP screen. If all values appear to be zeros, consult the factory.

(Make sure you have allowed several minutes for the controller to initialize). *Values may appear to be zero prior to setting the Function to READ.

To change BACnet TCP/IP parameters:

1. Power on the controller and allow several minutes to initialize.

2. Go to BMS Config menu and view TCP/IP

SETUP screen.

3. Move cursor to desired parameter by pressing the buttons. Press to select the parameter to change. Press the buttons to adjust the parameter. Press to save adjusted value.

4. Once desired parameters have been entered, go to BACnet Read/Write screen. Change Function to Write and Update?

to YES .

5. Reboot the controller by cycling power to the unit. Allow several minutes for the controller to initialize.

BACnet® IP/Eth Quick Start

6. View TCP/IP parameters. If changed values did not save, contact the factory.

The communication card is located in the Serial

Card port on the face of the controller. The card includes two sets of LED lights for communication troubleshooting.

MAC address

Status

LED

Push Button

Ethernet

LED

Status LED: Indicates the status of communication between the card and controller.

• Quick green-off-green if communication with controller is ok.

• Slow red-off-red if communication is not established.

Ethernet LED: Indicates the status of communication with the network. Wait for 40 seconds to determine status of communication.

• Flashing green, communication is OK.

• Steady red, communications is not established.

Communication Troubleshooting

See Carel Data sheet for more info.

If attempting to communicate with the controller over

BACnet IP/Eth, refer to the card LEDs for system information.

Status LED slow red blink

• Confirm card is firmly plugged in.

• Confirm BMS Protocol is set to BACnet IP/Eth.

Ethernet LED red on

• Confirm card is connected to the network.

Recalling Factory Parameters

Follow this procedure to revert to factory parameters for one power cycle. When restarted, the card will resume using the previous user parameters.

Factory Default IP address: 172.016.000.001

1. With controller off, hold the push button located on the BACnet IP/Eth card, while powering the controller back on.

2. Continue to hold the button, while watching the

Status LED . Wait for the Status LED to blink red slowly, and release before the third slow flash.

3. Wait for about one minute for the factory parameters to be loaded.

4. Follow the procedure to read the current parameters to confirm factory defaults have been loaded.

18 Network Interface Controller for Tempered Air Products

®

Maintenance Log

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Network Interface Controller for Tempered Air Products 19

®

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the

Library under Warranties.

AMCA Publication 410-96, Safety Practices for Users and Installers of Industrial and Commercial Fans, provides additional safety information. This publication can be obtained from AMCA International, Inc. at www.amca.org.

®

Phone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: [email protected] • Website: www.greenheck.com

20 476811 • Network Interface Controller, Rev. 2, May 2017 Copyright 2017 © Greenheck Fan Corporation

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement