advertisement

LEVERSETS

INSTALLATION INSTRUCTIONS

TOOLS NEEDED

CAUTION: Use of manual tools recommended. When using power tools, adjust to lowest torque setting.

Set Screw

Exterior Lever

Exterior Rose &

Lock Assembly

COMPONENTS

Latch

AA Mounting Screws (2)

BB Latch & Strike Plate Screws (4)

CC Allen Key (1)

DD Set Screws (2)

Lock Assembly

EE Keys for Entry Function (2)

Interior Rose

Back Plate

Face Plate

Strike Plate

Set Screw Interior Lever

PHILLIPS

SCREWDRIVER

FLAT HEAD

SCREWDRIVER

(OPTIONAL)

CHISEL

(OPTIONAL)

HAMMER

(OPTIONAL)

HAND DRILL

(OPTIONAL)

Allen Key

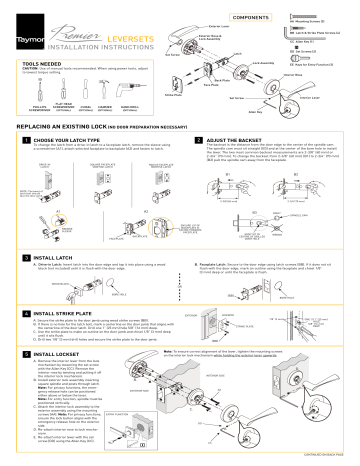

REPLACING AN EXISTING LOCK

(NO DOOR PREPARATION NECESSARY)

1

CHOOSE YOUR LATCH TYPE

To change the latch from a drive-in latch to a faceplate latch, remove the sleeve using a screwdriver (A1), attach selected faceplate to backplate (A2) and fasten to latch.

2

ADJUST THE BACKSET

The backset is the distance from the door edge to the center of the spindle cam.

The spindle cam must sit straight (B3) and at the center of the bore hole to install

the lever. The two most common backset measurements are 2-3/8” (60 mm) or

2-3/4” (70 mm). To change the backset from 2-3/8” (60 mm) (B1) to 2-3/4” (70 mm)

(B2) pull the spindle cam away from the faceplate.

DRIVE-IN

LATCH

SQUARE FACEPLATE

MORTISE LATCH

RADIUS FACEPLATE

MORTISE LATCH

B1 B2

NOTE: The bevel of latch bolt should face the door jamb

A1 A2

2-3/8 (60 mm)

B3

2-3/4 (70 mm)

RIGHT

SPINDLE CAM

REMOVE

SLEEVE

ENSURE LIP OF

BACKPLATE IS

FACING TOWARDS

FACEPLATE

FACEPLATE

BACKPLATE

MUST SIT IN

CENTRE OF DRILLED

DOOR HOLE

WRONG

3

INSTALL LATCH

A. Drive-in Latch: Insert latch into the door edge and tap it into place using a wood

block (not included) until it is flush with the door edge.

B. Faceplate Latch: Secure to the door edge using latch screws (BB). If it does not sit

flush with the door edge, mark an outline using the faceplate and chisel 1/8”

(3 mm) deep or until the faceplate is flush.

WOOD BLOCK

OR

BORE HOLE

(BB)

BORE HOLE

4

INSTALL STRIKE PLATE

A. Secure the strike plate to the door jamb using wood strike screws (BB).

B. If there is no hole for the latch bolt, mark a centerline on the door jamb that aligns with

the centerline of the door latch. Drill one 1” (25 mm) hole 5/8” (16 mm) deep.

C. Use the strike plate to make an outline on the door jamb and chisel 1/8” (3 mm) deep

until it sits flush.

D. Drill two 1/8” (3 mm) drill holes and secure the strike plate to the door jamb.

EXTERIOR INTERIOR

STRIKE PLATE

1/8” (3 mm)

(BB)

Note: To ensure correct alignment of the lever, tighten the mounting screws on the interior lock mechanism while holding the exterior lever upwards.

5

INSTALL LOCKSET

A. Remove the interior lever from the lock mechanism by loosening the set screw with the Allen Key (CC). Remove the interior rose by twisting and pulling it off the interior lock mechanism.

B. Install exterior lock assembly inserting square spindle and posts through latch.

Note: For privacy functions, the emer-

gency release hole can be positioned either above or below the lever.

Note: For entry function, spindle must be positioned vertically.

C. Attach the interior lock assembly to the exterior assembly using the mounting screws (AA). Note: For privacy functions, ensure the lock button aligns with the emergency release hole on the exterior side.

D. Re-attach interior rose to lock mechanism.

E. Re-attach interior lever with the set screw (DD) using the Allen Key (CC).

ENTRY FUNCTION

B.

EXTERIOR SIDE

C.

DD

INTERIOR SIDE

CC

AA

A.

D.

E.

ONE (1) 1” (25 mm)

HOLE

5/8” (16 mm)

DEEP

CONTINUED ON BACK PAGE

LEVERSETS

INSTALLATION INSTRUCTIONS

CONTINUED FROM FRONT PAGE

DOOR PREPARATION TEMPLATE

IMPORTANT: Print template to scale if not factory supplied instructions.

1 INCH

Fold here.

Place on the door edge.

Drill a 1” (25 mm) diameter hole at the center of the door edge.

1-3/4”

(45 mm)

1-3/8”

(35 mm)

Backset - 2-3/8” (60 mm)

Backset - 2-3/4” (70 mm)

NOTE: For beveled doors, apply template to pull side of door.

ø

2-1/8” (54 mm)

NEW DOOR PREPARATION

1

USE TEMPLATE PROVIDED TO MARK CENTER HOLES ON THE DOOR

A. Stand so the door swings towards you. Fold the template over door edge approximately 36” (914 mm) from the floor.

B. Make a center mark for a 1” (25 mm) hole on the door edge and a center mark for a 2-1/8”

(54 mm) hole on the door surface.

C. Drill the 2-1/8” (54 mm) door surface hole. Drill the 1” (25 mm) hole to meet surface hole.

Note: Drill surface hole from both sides to reduce risk of wood splitting.

CENTERLINE

TEMPLATE

1” (25 mm)

”

2-1/8” (54 mm)

CENTERLINE

36” (914 mm) FROM FINISHED FLOOR

BACKSET 2-3/8” (60 mm) - 2-3/4” (70 mm) )

See other side for lock installation instructions.

✃

CHANGE LEVER HANDING

A. Remove the set screw on the side of the lever using the Allen Key.

B. Swap levers . Align the hole on the lever with the catch hole on the rose and press until secure.

Reinstall the set screw. Tighten using the long leg of the Allen Key.

EXTERIOR VIEW

LEFT HANDED RIGHT HANDED

SET SCREW & ALLEN KEY (CC & DD)

CARING FOR YOUR LOCK

Our locksets are polished and then protected with a coating to help prevent tarnishing. This protective coating has limitations and in time may deteriorate from handling, cleaning or exposure to atmospheric conditions such as extreme climate, pollution and proximity to salt water, humidity and ultraviolet rays.

Eventual tarnishing is, therefore, not a defect, but a normal process which is unavoidable. With proper care, these products will last a long time.

To care for your lock, wash and clean only with water and polish with a soft, clean cloth.

LIFETIME MECHANICAL AND FINISH WARRANTY

This product is warranted to be free from finish, mechanical and workmanship defects for the life of the product. Taymor Industries Ltd. will replace any Taymor Premier series lock which fails to meet this warranty. Any finish deterioration occurring from use of paints, solvents or other chemicals is not a defect and therefore is not covered by this warranty. Taymor Industries Ltd. is not liable for incidental or consequential damages.

If your Taymor lock does not meet the warranted quality, return the product with proof of purchase information to the Taymor dealer from which the product was purchased. Go to taymor.com for full warranty information.

CUSTOMER SERVICE

WESTERN CANADA

1-800-267-4774 |

EASTERN CANADA

1-800-387-7064 |

USA

1-800-388-9887 taymor.com

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

REV. MAY, 2016

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement