advertisement

TB7220U COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

YES

NO

6. Insert the mounting screws into the wall anchors and tighten.

DRILLED

HOLES (2)

WALL

ANCHORS (2)

NO

NO 5 FEET

[1.5 METERS]

WALLPLATE

M22258

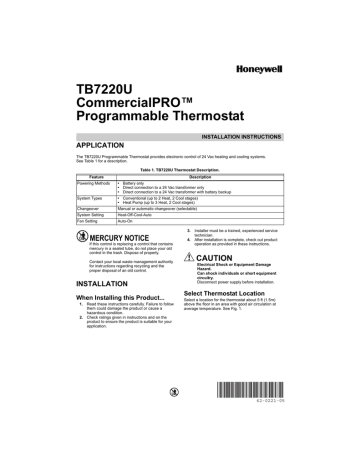

Fig. 1. Select thermostat location.

Do not install the thermostat where it can be affected by:

— Drafts or dead spots behind doors and in corners.

— Hot or cold air from ducts.

— Radiant heat from sun or appliances.

— Concealed pipes and chimneys.

— Unheated (uncooled) areas such as an outside wall behind the thermostat.

Separate Wallplate from

Thermostat

1. Separate the wallplate from the thermostat. See

Fig. 2.

WALLPLATE

WIRE HOLE

THERMOSTAT

M22267

Fig. 2. Separate wallplate from thermostat.

Install Wallplate (See Fig. 3)

Mount the thermostat horizontally on the wall:

1. Pull the wires through the wire hole on the wallplate.

2. Position the wallplate on the wall with the arrow pointing up. Level the wallplate for appearance only.

3. Use a pencil to mark the mounting holes.

4. Remove the wallplate from the wall and drill two

3/16 in. holes in the wall (if drywall) as marked. For firmer material such as plaster, drill two 7/32 in. holes. Tap the wall anchors (provided) into the drilled holes until flush with the wall.

5. Pull the wires through the wire hole on the wallplate and position the wallplate over the wall anchors.

M22268

MOUNTING

SCREWS (2)

Fig. 3. Install wallplate.

WIRING

IMPORTANT

— All wiring must agree with applicable codes, ordinances and regulations.

— Use 18 gauge thermostat wire. Shielded cable is not required.

NOTES:

— Sensor wires must have a cable separate from the thermostat control cable.

— Refer to Table 2 for terminal designation descriptions.

— See Fig. 6 through 16 for wiring diagrams for specific equipment applications.

1. Select set of terminal identifications that correspond to your system type (conventional or heat pump).

(See Fig. 4).

C

G

Y

O/B

RC

R

SCREW

TERMINALS

C

G

Y

W

RC

R

W2

Y2

A

S1

S2

W1

Y2

A

S1

S2

CONVENTIONAL

HEAT PUMP

M23010

Fig. 4. Terminal identifications for system type.

2. Loosen screw terminals used for the application.

3. Insert the wires into the terminal block and tighten each screw terminal.

4. Push excess wire back into the wall opening and restrict wires to the shaded area. See Fig. 5.

5. Plug the wall opening with nonflammable insulation to prevent drafts from affecting the thermostat.

62-0221—05 2

WIRE WALLPLATE

TB7220U COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

WALL OPENING

SHADED AREA

M22266

Fig. 5. Restrict wires to shaded area of wire hole.

Terminal Designation

RC (see Note 1)

R (see Note 1)

Y

C (see Note 2)

W

G

W2

Y2

O/B (see Note 3)

A (see Note 4)

S1 (See Note 5)

S2 (See Note 5)

W1

Table 2. Terminal Designation Descriptions.

Description

Power for cooling—connect to secondary side of cooling system transformer.

Power for heating—connect to secondary side of heating system transformer.

Compressor output.

Common wire from secondary side of cooling system transformer.

Heat relay.

Fan relay.

Second stage heat relay.

Second stage cooling.

Changeover valve for heat pumps.

Economizer/Time-Of-Day (TOD) output—powered via RC terminal.

Optional outdoor or indoor remote sensor.

Optional outdoor or indoor remote sensor.

Auxiliary Heat Relay Output (Head Pump Mode 2H/1C, 3H/2C)

NOTES:

1.

2.

3.

4.

5.

When used in a single-transformer system, leave metal jumper wire in place between RC and R. If used on a two-transformer system, remove metal jumper wire between RC and R.

Common wire is optional when thermostat is used with batteries. When using separate transformers for heating and cooling, the common must come from the cooling transformer.

If thermostat is configured for a heat pump in the Installer Setup, configure changeover valve for cool (O-factory setting) or heat (B).

Reference economizer literature for wiring details. When set for economizer operation, the A terminal provides the occupancy signal.

(Power indicates occupied.)

Sensor wires must have a cable separate from the thermostat control cable.

Terminal “A” Wiring Details for

Economizers

— Wire the A terminal to the W7212 “N” terminal, or the

W7459 “TR” terminal.

— When using dual transformers at the thermostat, the cooling transformer must power the economizer.

— The A signal is powered from the RC terminal and energizes the economizer to signal occupied status and drive the damper to the set minimum position.

Table 3. Wiring Diagrams.

System Type

Standard Heat/Cool

Heat Only

Heat Only with Fan

Cool only

Standard Multistage up to 2 Heat/2 Cool

Heat Pump

(No Auxiliary Heat)

Wallplate

Terminal

Identifications

Conventional

Conventional

Conventional

Conventional

Conventional

Heat Pump

Heat Pump

(with Auxiliary Heat)

Heat Pump

Multiple TR21 Sensors

Multiple C7189U Sensors —

3

—

Wiring

Diagram

Figure

6, 7

8

9

10

11, 12

13, 14

15, 16

17, 18, 19

20

62-0221—05

TB7220U COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Conventional System Wiring

1

L1

1

(HOT)

L2

24 VAC

2

HEAT RELAY

COMPRESSOR CONTACTOR

FAN RELAY

C

G

Y

W

RC

R

3

W2

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

1

2

3

ECONOMIZER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

M23011

Fig. 6. Typical wiring of single transformer

1H/1C system.

L2 24 VAC

2

C

G

Y

W

RC

R

3

W2

Y2

A

S1

S2

HEAT RELAY

ECONOMIZER

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

1

2

3

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS

OPTIONAL.

M23013

Fig. 8. Typical hookup of heat-only system.

1

L1

(HOT)

L2

24 VAC

2

C

G

Y

W

RC

R

3

W2

Y2

A

S1

S2

L1

1

(HOT)

24 VAC

L2

COOLING

TRANSFORMER

2

C

G

Y

W

RC

R

3 W2

Y2

A

S1

S2

1

L1

(HOT)

24 VAC

L2

HEATING

TRANSFORMER

FAN RELAY

COMPRESSOR CONTACTOR

HEAT RELAY

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

ECONOMIZER

1

2

3

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

REMOVE FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. WHEN USED, THE COMMON MUST CONNECT

TO THE COOLING TRANSFORMER SECONDARY.

M23012

Fig. 7. Typical hookup of dual transformer

1H/1C system.

HEAT RELAY

FAN RELAY

ECONOMIZER

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2 FACTORY INSTALLED JUMPER.

3 WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

M23014

Fig. 9. Typical hookup of heat-only system with fan.

1

L1

(HOT)

L2

24 VAC

2

C

G

Y

W

RC

R

3

W2

Y2

A

S1

S2

COMPRESSOR CONTACTOR

FAN RELAY

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

1

2

3

ECONOMIZER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

M23015

Fig. 10. Typical hookup of cool-only system.

62-0221—05 4

TB7220U COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

L2

1

24 VAC

2

C

G

Y

W

RC

R

3 W2

Y2

A

S1

S2

COOL RELAY 1 COOL RELAY 2

FAN RELAY

HEAT RELAY 1

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

HEAT RELAY 2

ECONOMIZER

1

2

3

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

M23016

Fig. 11. Typical hookup of single transformer multistage system (up to 2H/2C).

1

L1

(HOT)

L2

24 VAC

2

C

G

Y

W

RC

R

3

W2

Y2

A

S1

S2

1

FAN RELAY

COOL RELAY 1 COOL RELAY 2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

2

3

HEAT RELAY 1

HEAT RELAY 2

ECONOMIZER

24 VAC

L2

HEATING

TRANSFORMER

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

REMOVE FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. WHEN USED, THE COMMON MUST CONNECT

TO THE COOLING TRANSFORMER SECONDARY.

M23017

Fig. 12. Typical hookup of dual transformer multistage system (up to 2H/2C).

5 62-0221—05

TB7220U COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Heat Pump System Wiring

L1

(HOT)

L2

1

24 VAC

3

W1

Y2

A

S1

S2

CHANGEOVER VALVE

COMPRESSOR CONTACTOR

FAN RELAY

2 FACTORY INSTALLED JUMPER.

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

1

ECONOMIZER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

5

3 WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

4 "O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

5 OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

M23018

Fig. 13. Typical hookup of single-stage heat pump with no auxiliary heat (1H/1C).

L1

(HOT)

4 O/B

RC

R

C

G

Y

2

3

L2

1

24 VAC

4

C

G

Y

O/B

RC

R

2

W1

Y2

A

S1

S2

FAN RELAY

CHANGEOVER VALVE

COMPRESSOR 1 COMPRESSOR 2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

5

ECONOMIZER

2

3

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

4 "O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

5 OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

M23019

Fig. 14. Typical hookup of multistage heat pump with no auxiliary heat (2H/2C).

L1

(HOT)

L2

1

24 VAC

4

C

G

Y

O/B

RC

R

2

CHANGEOVER VALVE

COMPRESSOR CONTACTOR

FAN RELAY

ECONOMIZER

3

W1

Y2

A

S1

S2

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

5

AUXILIARY HEAT RELAY

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

3

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

4 "O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

5 OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

M23020

Fig. 15. Typical hookup of single-stage heat pump with auxiliary heat (2H/1C).

L2

1

24 VAC

4

C

G

Y

O/B

RC

R

2

3

W1

Y2

A

S1

S2

CHANGEOVER VALVE

COMPRESSOR 1

FAN RELAY

OUTDOOR/INDOOR

TEMPERATURE

SENSOR

5

AUXILIARY HEAT RELAY

COMPRESSOR 2

ECONOMIZER

2

3

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FACTORY INSTALLED JUMPER.

WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL.

4

5

"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B"

IN THE INSTALLER SETUP.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR.

WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE.

M23021

Fig. 16. Typical hookup of multistage heat pump with auxiliary heat (3H/2C).

62-0221—05 6

TB7220U COMMERCIALPRO™ PROGRAMMABLE THERMOSTAT

Sensor Wiring for Temperature

Averaging

S1

SUBBASE

S2

TR21

SUBBASE

S1 S2

TR21

T T T T

TR21

T T T4

1

TR21-A

T3

TR21

T T

TR21 TR21

T T T T

M27481

Fig. 17. Wiring four T7770A1006 (20K ohm) Sensors.

S1

SUBBASE

S2

1 THE TR21-A IS A 10K OHM SENSOR.

M27483

Fig. 19. Wiring two TR21 (20K ohm) Sensors and one

TR21-A (10K ohm) sensor to provide a temperature averaging network

S1

SUBBASE

S2

1

C7189 C7189

T4 T3 T4 T3

C7189 C7189

1

TR21-A

1

TR21-A

1 THE TR21-A IS A 10K OHM SENSOR.

M27482

Fig. 18. Wiring two TR21-A (10K ohm) Sensors to provide a temperature averaging network.

1 WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

M23027

Fig. 20. Wiring four C7189U (10K ohm) Sensors to provide a temperature averaging network.

7 62-0221—05

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement

Table of contents

- 1 Application

- 1 Installation

- 1 When Installing this Product...

- 1 Select Thermostat Location

- 2 Separate Wallplate from Thermostat

- 2 Install Wallplate (See Fig. 3)

- 2 Wiring

- 4 Conventional System Wiring

- 6 Heat Pump System Wiring

- 7 Sensor Wiring for Temperature Averaging

- 8 Power the Thermostat

- 8 Wiring 24 Vac Common

- 8 Installing Batteries

- 8 Mount Thermostat to Wallplate

- 9 Setting Calendar and Time

- 9 Advanced Settings

- 10 Installer Setup Numbers, Settings, and Tests (Table 4)

- 10 Configure Installer Setup

- 10 Installer System Tests

- 13 Operation

- 13 System Settings

- 13 Fan Settings

- 13 Minimum-Off Timer (Compressor Protection)

- 13 Outdoor or Indoor Temperature Sensor

- 13 Economizer/TOD Logic (Table 6)

- 13 Heat Pump Temperature Lockouts

- 14 Troubleshooting (Table 7)

- 16 Specifications