advertisement

▼

Scroll to page 2

of 10

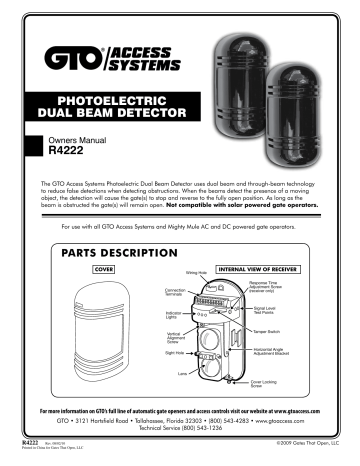

PHOTOELECTRIC DUAL BEAM DETECTOR Owners Manual R4222 The GTO Access Systems Photoelectric Dual Beam Detector uses dual beam and through-beam technology to reduce false detections when detecting obstructions. When the beams detect the presence of a moving object, the detection will cause the gate(s) to stop and reverse to the fully open position. As long as the beam is obstructed the gate(s) will remain open. Not compatible with solar powered gate operators. For use with all GTO Access Systems and Mighty Mule AC and DC powered gate operators. PARTS DESCRIPTION COVER Wiring Hole Connection Terminals Indicator Lights Vertical Alignment Screw Sight Hole INTERNAL VIEW OF RECEIVER Response Time Adjustment Screw (receiver only) Signal Level Test Points Tamper Switch Horizontal Angle Adjustment Bracket Lens Cover Locking Screw For more information on GTO’s full line of automatic gate openers and access controls visit our website at www.gtoaccess.com GTO • 3121 Hartsfield Road • Tallahassee, Florida 32303 • (800) 543-4283 • www.gtoaccess.com Technical Service (800) 543-1236 R4222 Rev. 08/02/10 Printed in China for Gates That Open, LLC ©2009 Gates That Open, LLC Installation Overview Diagram illustrates correct placement of photo beams in relation to the gate. Exterior placement of Photo Beams (placed outside of path of gate) Vehicular Gate Interior placement of Photo Beams (placed outside of path of gate) Mounting Cautions Be sure that the optical axis is never obstructed. (The optical axis is both the vertical and horizontal range of detection, or beam, between the transmitter and receiver) Do not mount the detector in the following conditions: Where the mounting surface is unstable. Spread of Beam Mounting Height Where obstructions (plants, fences, etc.) are between the receiver and the sender. Where sunlight and headlights shine directly into the front of the receiver. Beam Alignment Up/Down Direction Range 20° (±10° ) Horizontally 180° The optical axis can be fine tune adjusted in horizontal and vertical direction. Sensing Area 2 Transmitter Receiver Receiver Transmitter When using more than one set make sure to alternate the transmitters and detectors as above. Transmitter Receiver Transmitter Receiver Wall Mounting 1. Remove Photo Beam cover by loosening the cover holding screw, but DO NOT REMOVE THE SCREW ALL THE WAY. 3. Remove the rubber knockout and use the screw holes to mount the unit. 2. Pull the wire through the wiring hole at the top of the unit, from back to front. 4. Mount the Photo Beam on the wall while running the wire into the wiring location in the wall. SCREW HOLE RECEIVER GOOD LEVEL ALARM SCREW HOLE Pole Mounting 1. Remove the Photo Beam cover (as shown in step 1 above). 2. Feed the wire through the mounting pole. 3. Using the Mounting Plate and Bracket secure the Photo Beam to the mounting pole. Feed Wire Through Pole Mounting Bracket Base Plate Back to Back Installation (Refer to the figure above) 3 Connecting Photo Beams to GTO Access Systems and Mighty Mule Control Boards IMPORTANT: DO NOT use Photo Beams on systems charged with solar panels. Make sure the power switch to the opener is turned off before connecting safety device wiring to the terminal blocks. Unplugging the transformer does not turn power to the opener OFF. Wiring Precautions • Wire with 16awg minimum (RB509) • 300 ft (91.4m) max length • Be sure to capture the wire ends under the wire clamp plates. • Avoid frayed ends on wires that might produce a short circuit. • Be careful not to overtighten the screws as this may strip the threads in the plastic Wire Terminal Block Correct Wire Terminal Block Wire Wrong Terminal Block Wrong Terminal Strip Identification The diagrams below represent the terminal strips on the receiver and transmitter and can be used for reference for connections. RECEIVER Wiring Terminals 1 2 + – 3 4 5 POWER TRANSMITTER Wiring Terminals 6 7 1 2 6 7 TAMPER POWER TAMPER + ALARM 4 – Wiring the Photo Beams to GTO Access Systems and Mighty Mule Gen 3 (blue) or green Gate Opener Control Boards. (models listed below) To + Pos Terminal of Battery Connections for GTO Access Systems 2000XL, 3000XL, 4000XL; Mighty Mule FM500 and FM600 Control Boards To - Neg Terminal of Battery INTERIOR TOP OF INTERIOR TOP OF TRANSMITTER 1 2 + RECEIVER 6 7 – 1 2 + – 3 4 5 6 7 POWER POWER ALARM 6 6 7 TAMPER 7 TAMPER 12 Volt Battery or 12Vdc source Transmitter/Receiver Connections 1. Connect 1 and 2 power terminals of the transmitter to the 1 and 2 power terminals of the receiver. 2. Connect 1 and 2 power terminals of the Receiver OR Transmitter to the battery. RECEIVER CONTROL INPUTS 3. Connect 3 and 5 terminals of the receiver to the COM and SAFETY terminals on the control board. RED BLK GRN CLOSE EDGE OPEN EDGE SHADOW EXIT SAFETY CYCLE COM COM ALM GTO RCVR. Wires from Photo Beams 5 To + Pos Terminal of Battery To - Neg Terminal of Battery INTERIOR TOP OF INTERIOR TOP OF TRANSMITTER 1 2 + RECEIVER 6 7 – 1 2 + – 3 4 5 6 7 POWER POWER ALARM 6 6 7 TAMPER 7 TAMPER 12 Volt Battery or 12Vdc source Transmitter/Receiver Connections 1. Connect 1 and 2 power terminals of the transmitter to the 1 and 2 power terminals of the receiver. Connections for FM350 and FM352 Control Boards 2. Connect 1 and 2 power terminals of the Receiver OR Transmitter to the battery. CHARGING POWER 3. Connect 3 and 5 terminals of the receiver to the COM and SAFETY terminals on the control board. RED BLK GRN COMMON CYCLE EDGE 18VAC SOLAR PANEL SAFETY LINK EXIT X OUT Wiring the Photo Beams to Mighty Mule FM350 Gate Opener Control Board. RECR Wires from Photo Beams 6 Wiring the Photo Beams to GTO Access Systems GP-SL050, GP-SW050, GP-SL100 and GP-SW100 Gate Opener Control Boards. To + Pos Terminal of Battery To - Neg Terminal of Battery INTERIOR TOP OF INTERIOR TOP OF TRANSMITTER 1 2 + RECEIVER 6 7 – 1 2 + – 3 4 5 6 7 POWER POWER ALARM 6 6 7 TAMPER 2. Connect 1 and 2 power terminals of the Receiver OR Transmitter to the battery. COM W1 CUT TO USE 3 BUTTON STATION COM STOP CLOSE OPEN CLOSE EDGE OPEN EDGE SHADOW SAFETY CYCLE COM STOP CLOSE OPEN CLOSE EDGE OPEN EDGE SHADOW SAFETY CYCLE LED09 12Vdc source 1. Connect 1 and 2 power terminals of the transmitter to the 1 and 2 power terminals of the receiver. CLOSED LED10 Transmitter/Receiver Connections RUNNING 7 TAMPER COM COM COM Wires from Photo Beams 7 3. Connect 3 and 5 terminals of the receiver to the COM and SAFETY terminals on the control board. Wiring the Photo Beams to Mighty Mule 200 Gate Opener Control Board. To + Pos Terminal of Battery To - Neg Terminal of Battery INTERIOR TOP OF INTERIOR TOP OF TRANSMITTER 1 2 + RECEIVER 6 7 – 1 2 + – 3 4 5 6 7 POWER POWER ALARM 6 6 7 TAMPER TAMPER 2. Connect 1 and 2 power terminals of the Receiver OR Transmitter to the battery. GTO Inc. Tal l a hassee, FL LOCK - LOCK+ COM EDGE PGOK200 Rev. XC M_BLK M_RED GRN VAR3 VAR6 VAR5 VAR4 CYCLE EXIT SAFETY COM CHGR CHGR 12 Volt Battery or 12Vdc source 1. Connect 1 and 2 power terminals of the transmitter to the 1 and 2 power terminals of the receiver. POWER VAR1 VAR3 Transmitter/Receiver Connections LED3 7 3. Connect 3 and 5 terminals of the receiver to the COM and SAFETY terminals on the control board. Wires from Photo Beams 8 Beam Alignment Adjusting Optical Axis with the Viewfinder 1. With the POWER connected and the RECEIVER and TRANSMITTER covers removed adjust the horizontal pivot, and the vertical adjustment screw using the built-in viewer. Look through the viewfinder on either side and adjust to put the opposite sensor in the middle of the cross-hairs in the view finder. The GOOD LED should be on. (Adjust the light axis until the indication lamp is on.) Vertical Adjustment Screw RAISE The brighter the LEVEL (green) LED the more precise the alignment of the beams. TRANSMITTER INDICATOR LOWER GOOD LEVEL ALARM POWER POWER LED (green) • ON when when light beam is transmitting. Close-up of viewfinder with reflection centered. TRANSMITTER POWER RECEIVER INDICATORS RECEIVER GOOD LEVEL ALARM Horizontal Adjustment Bracket GOOD LED (green) • Use when adjusting bean alignment. ON when beams are aligned. LEVEL LED (green) • ON indicates receiving signal. Brightness varies, depending on beam alignment. ALARM LED (red) • ON indicates beam blocked. Use when setting response time. Adjusting Optical Axis with a Voltmeter If you have a voltmeter, the best method of adjusting the optical axis is to measure the signal level at the test probe points. 1. Insert the voltmeter probes into the test points on the side of the receiver. 2. Adjust the horizontal angle and vertical angle until the voltage is at maximum. 3. If a voltage of 1.2v or above cannot be reached, the transmitter and/or receiver should be readjusted. Voltmeter Voltmeter test points + – LEVEL Beam Interruption Time Adjustment Adjusts the amount of time between the beam being broken and the normally open relay closing. Adjust time adjustment dial from (1) detecting fast moving objects to (5) detecting slow moving objects depending on your type of application and environment. The factory setting is set to 1 to detect fast moving objects. Slow Moving Objects Fast Moving Objects 9 4 2 3 T RE SPONSE E 5 IM 1 5 1 VERIFY CORRECT OPERATION After installation, confirm correct operation by suitable walking tests. Refer to the appropriate LED indicators during the walking test and ensure the gate opener operates in the correct manner. Condition Indication Transmitting POWER LED is ON Beam Not Blocked GOOD and LEVEL LEDs are ON Beam Blocked ALARM LED is ON Transmitter Receiver TROUBLESHOOTING Symptom Possible Cause Remedy Transmitter LED does not light. Improper voltage supplied. Check the power supply and wiring. Receiver LEDs do not light. Improper voltage supplied. Check the power supply and wiring. 1. Beams reflect to the receiver by other objects. 2. Both beams are not blocked simultaneously. 3. Beam interruption time is too short. Alarm LED does not light, even when beams are blocked. 1. Remove the reflecting object or change optical axis direction. 2. Block both beams. 3. Increase beam interruption time adjustment. When beams are blocked, receiver LED lights are ON, but not alarm. 1. Wiring is short circuited. 2. Wiring connection is not good. Check wiring and connection spot. The alarm indication lamp of receiver is always on. 1. Optical axis is not properly adjusted. 2. There are obstructions between the transmitter and the receiver. 3. The outer covers are dirty. 1. Adjust the optical axis. 2. Remove the obstructions. 3. Clean with window cleaner and a soft cloth. 1. Bad wiring. 2. Fluctuating power supply / voltage. 3. Intermittent blockage between the *If you’re experiencing false detections transmitter and the receiver. then increase the time adjustment by 1 increment at a time until the photo beam 4. The receiver or transmitter is unstable. 5. Blocked by other moving objects. functions as desired. 6. Beam interruption time out of adjustment. Intermittent Alarm (detection) 1. Check wiring. 2. Check the power supply. 3. Remove the obstruction or relocate. 4. Fix the mounting. 5. Adjust the optical axis. 6. Adjust interruption time or change installation position. For online Technical Support visit the Online Troubleshooter Wizard 24 hrs/day 7 days/week at http://support.gtoinc.com/support/troubleshooter.aspx and open a Tech Ticket Technical Support Hours: MON - FRI 8:00AM - 7:00PM (ET) (800) 543-1236 SPECIFICATIONS For optimal efficiency, wipe the outer cover frequently with a soft, damp cloth. Not compatible with Solar Panels. Detection Method Range MODEL R4222 Infrared photoelectric Outdoor 98.4 ft (30m) Indoor 295.2 ft (90m) Beam Characteristics Pulsed infrared dual beams Response Time 50~700msec (selectable) Power Input DC12.5~24V / AC11~18V Current Consumption 40mA max Output Pulse Duration 2Sec (±1)nominal Alarm Output Form B relay (AC/DC 30V 0.5A max) Tamper Switch N.O. contact is open when cover is removed (transmitter and reciever) Operating Temperature -13˚F (-25˚C)~131˚F (55˚C) Environment Humidity Alignment Angle Mounting Weight Appearance 95% max 20˚±10˚ vertical, ±90˚ horizontal Wall or pole .66lbs (300g) Both transmitter and receiver PC Resin (Black)

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project