- No category

advertisement

Robotics Course - Instructional Guide

CP5894

www.matrixtsl.com

Copyright © 2016 Matrix Technology Solutions Ltd.

FORMULA

II

ALLCODE

Contents

Page 2

Robotics Course

Instructional Guide

Introduction

Pseudo-code - A simple programming aid

Take the Tour - Check out my body parts

Language Neutral - Application Program Interface

Hardware setup

Controlling the Robot

Worksheets

Worksheet 1 - Robo makes its first move

Worksheet 2 - Watch out - those lights are animated

Worksheet 3 - Switch it on, switch it off

Worksheet 5 - How bright is that light?

Worksheet 6 - Searching for the light

Worksheet 8 - Push buttons do the work

Worksheet 10 - Tilt and turn (using a mobile device)

Worksheet 11 - Lefty can navigate through a maze

Taking it further - Challenges 16-20

Appendix

Microcontroller Pin Connections

Reloading the AllCode API Firmware

Trademarks

PIC, PICMicro and dsPIC are registered trademarks of Microchip Technology. Raspberry Pi is a registered trademark of the Raspberry Pi Foundation.

Other product names that appear in this document may be trademarks of their own respective owners.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Introduction

Getting started

Page 3

Robotics Course

Instructional Guide

Where do you start?

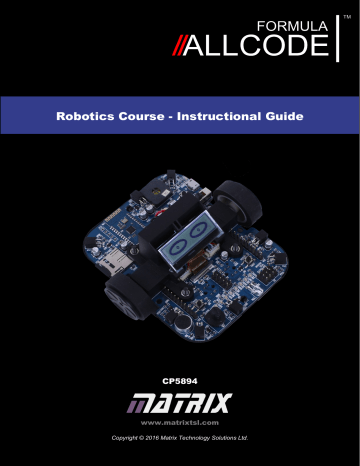

Congratulations. You now have a state-of-the-art Formula AllCode robot that can perform all sorts of interesting manoeuvres, navigate a maze, dance, make sounds, play music, record and playback audio. The list goes on and on. As there are so many things you can do with the robot, the first problem you might encounter is working out the best place to start.

This instructional guide has been prepared to help you get up the learning curve as quickly as possible so you can enjoy making the robot do the things you want it to do.

Fun

One of the key elements of this instructional guide is to make sure you have some fun.

Learning or acquiring a new skill is always much more rewarding when the task has a lot of fun associated with it. The worksheets in this guide book have been developed to give you hours of fun and enjoyment while you learn the basics of robotics. Getting the robot to make its first moves, then to utter its first sounds might start off as a challenge - but should end up as pure delight and personal satisfaction when you achieve it.

Creativity

Although you can use the robot on your own, it’s much more fun when you team up with one or more of your friends, as you will find that each of you have ideas and suggestions of things to try out. You will be surprised how a simple idea can be transformed by a little piece of collective creativity or imagination into something truly amazing!

Building Blocks

The worksheets in this guide are structured so they start off tackling the easy things like operating the LEDs or displaying a message on the LCD panel, then move on to more complicated tasks like navigating a maze or following a path. Each worksheet has a coloured bar that indicates the suggested “Skill Level” - easy, intermediate or advanced.

The exercises on some of the worksheets are “Standalone” which means you can dive in and try them out in any order you like. Others are “Linked” and use a building block approach that incorporates work you would have encountered in a previous activity. Again this is indicated by a coloured bar at the top of the worksheet.

Planning your work

It’s a good idea to start off by making a plan of what you want to achieve each time you use the robot. This will ensure that you are focused and productive with your time.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Take the Tour

Check out my body parts

Page 4

Robotics Course

Instructional Guide

This section explores the various parts of the robot and explains the basic operation of all the sensors and control systems.

Apart from the two motors that can be used to navigate the robot through a maze, there are light and distance sensors as well as sound recording equipment that will give you hours of fun.

You will probably want to revisit this page as you read this Guide.

Key parts of the robot

The block diagram below shows the important parts of the Formula AllCode robot.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Take the Tour

Check out my body parts

Page 5

Robotics Course

Instructional Guide

Digital Signal Controller

At the heart of the robot is a Digital Signal Controller (dsPIC

®

) manufactured by Microchip Technology Inc. This high performance device offers motor control (PWM), advanced analog features, a number of communication interfaces including audio capture, processing and playback as well as a considerable number of high speed counter/timers.

Motors

The robot has two powerful permanent magnet motors, coupled via reduction gearboxes

(used to increase the torque) that drive rubber wheels (to provide grip on smooth surfaces). A highly efficient electronic control system ensures the power drain on the battery is as small as possible. This means you can have a lot of fun with the robot before the lithium-ion battery needs to be recharged. The two motors can be driven independently to give the robot the ability to pivot on its own axis and escape from tight or tricky situations.

Feedback encoders in the motors allows the dsPIC

® to “know” exactly how far each one has turned - which allows the robot to move forward/backward a given distance or turn at a given angle.

LCD panel

Situated in the centre of the robot is a graphical LCD panel that can be used to show messages and/or simple graphical shapes.

LEDs

Across the front edge of the robot is a row of green

LEDs that can be driven by commands from your program.

Light sensor

Positioned along the front edge of the robot is a light sensor. It can be used to measure and report back to your program the amount of light falling on the robot.

If this is linked to controlling the motors it enables the robot to find or avoid a light source.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Take the Tour

Check out my body parts

Page 6

Robotics Course

Instructional Guide

Distance sensors

Around the four sides and four corners of the robot are mounted infrared (IR) transmitters and receivers that can measure and report back to your program the distance from the robot to a possible obstacle. Each of the eight IR transmitters can be instructed to send out a beam of infrared light. If the beam encounters an obstacle it is reflected back to the robot where it is detected by the IR receiver.

Microphone, microSD card slot and miniature speaker

These three items work together to enable sounds and voices to be captured (using the microphone), stored on the microSD card and played back using the robot’s on-board speaker.

Pre-recorded sounds and music, previously written onto the card, can also be played.

Notes generated by the robot can be played and linked together to make musical sounds.

Micro USB connector

This connector can perform two functions. It can be used to recharge the robot’s lithium battery by plugging in a charger like the one you probably use with your mobile phone. It can also be connected to a computer/laptop/tablet (with a USB socket) to download and execute programs you have written.

On-board Bluetooth module

This is a small daughter board mounted on the rear edge of the robot. It provides another method for you to download programs to the robot.

One of its main uses is to enable you to connect wirelessly to the robot and then interact with the on-board sensors, control the motors, write messages to the LCD, operate the LEDs, and playback sounds, etc.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Take the Tour

Check out my body parts

Push buttons

There are three push buttons on the robot labelled SW1, SW2 and SW3. The first two buttons can be sampled by your computer program to trigger a user-defined task. SW3 performs a hardware reset, to restart your program, when it is pressed.

Page 7

Robotics Course

Instructional Guide

Slider switch

This is labelled as SW4 and is the robot’s main On/Off switch.

Line detectors

If you turn the robot over you will see two line detectors. Each unit sends out a beam of light.

Depending on the colour and what sort of surface

(i.e. reflective or non-reflective) is underneath the robot determines how much of the beam returns.

The line detectors are primarily used to get the robot to follow a path drawn on a piece of paper or printed on a mat.

This is achieved by writing a program to detect when the robot strays off the edge of the path, adjusting the speed of the two motors to bring the robot back on track.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Language Neutral

Application Program Interface

Page 8

Robotics Course

Instructional Guide

Language independent, agnostic, language neutral, platform independent - what do these terms mean?

Basically it means you are not forced to use a certain programming language or platform to control the robot.

This is because Formula AllCode offers an Application

Program Interface (API) that enables you to interact with the robot using a set of simple routines or protocols.

If you have not heard of APIs then this section will help you understand how to make use of it with the robot.

One way to explain this is to think about how a TV remote controller works. Although modern televisions have touch buttons or soft-touch areas along the edges of the screen, most people find it more convenient to use a remote controller to turn the TV On/Off, change a channel, adjust the volume or brightness settings, etc.

When you think about it, a TV remote is a very simple device consisting of a keypad and an infrared light beam. When a button is pressed its value is encoded and used to send a binary pattern, via the infrared beam, to the TV. The TV decodes the received pattern and carries out the required function.

If for some reason the TV remote failed it would be an easy task to replace it with a new one, or even purchase a universal remote (if you had a number of devices to control).

There are Apps that can be used to turn smart phones into a TV remote controller and other hardware is available that can send out TV remote codes. The only critical part is to send the correct pattern (i.e. command) when it is required.

So you could say the TV has an API that allows a remote controller (whatever form it might take) to control the intelligence or electronic control systems within the television.

The API, as used on the Formula AllCode Robot, offers the same platform and language independence as the TV example described above. The difference is the transmission medium for the robot is Bluetooth rather than an infrared beam. This means providing you have a Bluetooth facility on your system, you have the freedom to use your favourite platform and programming language to interact with the robot.

As an example, you might choose to use a Bluetooth-enabled mobile phone to control the robot. Alternatively, you could Bluetooth-enable a PC/Mac/Raspberry Pi® or a Matrix

Multiprogrammer board by fitting a low-cost Bluetooth module to create a simple control system.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Language Neutral

Application Program Interface

Page 9

Robotics Course

Instructional Guide

As the API reacts to a simple text-based protocol (as shown below) it means you have the freedom to use formal programming languages like C, C#, C++ or Python, or graphical or icon-based languages like Flowcode, App Inventor or LabView.

The other thing to note about the API is that some commands are bi-directional. This means that a command sent to the robot could result in a value being returned. A good example of this are the infrared distance sensors fitted to the robot. An API command could be sent to a specified sensor (that effectively interrogates it) causing it to return a numerical value of the distance between the robot and an obstacle.

Shown below is the general format for the robot’s API.

API command

... Parameters …

Text string Numerical values and/or text string

Every command starts off with a text string that identifies what the robot should do. This may be followed by one or more parameters. Depending on what you are trying to do with the robot these parameters can be numerical or textual or a mixture of both.

For example to send a value to the eight LEDs on the front of the robot you would use:

LEDWrite <value>

As the LEDs are grouped together and form an 8-bit row, they can be driven by sending a binary number to them. So the parameter <value> can take a value between 0 and 255.

It should be noted that the API commands for a particular language might have some subtle differences. For example, Python will use something like "fa.LEDWrite(20)" whereas C# would look like "FA_DLL.FA_LEDWrite(20);" and for App Inventor,

Flowcode and LabView the appropriate icon would be selected.

Here’s another example that shows how to control the motors on the robot.

Forward <distance>

The parameter labelled <distance> can take a value between 1 to 1000 to define the distance the robot will travel (in millimetres) in a straight line.

If you wanted to independently control the two motors you could use this command.

Setmotors <left> <right>

The parameters <left> and <right> can take a value from -100 to 100 to define the speed and direction of each motor, allowing the robot to move in various directions.

The API is listed in the appendix and worksheets in this Guide will explain in more detail.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Pseudo-code

A simple programming aid

Page 10

Robotics Course

Instructional Guide

Most of the examples that appear in this Instructional Guide are written with pseudo-code.

You may question why we didn’t use flowcharts or one of the many programming languages that can be used with the Formula AllCode Robot.

The answer is twofold. Firstly, this Guide would be huge if all the examples were written in every language the robot supported, and only certain parts would be applicable to you.

Secondly, if you use flowcharts there is nothing to prevent you creating structures that do not easily map onto the three main control constructs (e.g. sequence, decision and iteration) that formal programming languages support. Here’s an example of a program, written in pseudo-code, using all three constructs for the robot.

Sequence light_threshold = 500 sound_threshold = 100

Iteration

Subroutine

Iteration

Decision

DO sound_level

= ReadMic

UNTIL sound_level >= sound_threshold

CALL play_some_dance_music

LOOP-FOREVER illumination =

ReadLight

IF illumination > light_threshold THEN

Forwards 100

ELSE

LEDWrite 255

END-IF

DELAY 200ms

END-LOOP

A sequence is a group of one or more statements that follow each other. There are two examples of iteration in this piece of pseudo-code: the first one repeats until a certain event occurs and the second one repeats forever. A decision, sometimes called a branch, can take one of two paths depending on the answer to a question.

Also shown in this example is a CALL that jumps to a subroutine. This is used to make the code easier to read by hiding some of the unnecessary detail.

The items highlighted in

dark blue

are API calls that allow you to interact with the robot.

The name of these calls will map across to the set of macros available in Flowcode, App

Inventor, Python and other languages supported by the Formula AllCode Robot.

Using pseudo-code allows you to take the first step of putting your ideas into practice in a structured way without getting tripped up by the syntax of a formal programming language.

Once you have expressed your ideas, using pseudo-code, you can move on and write the actual program using your chosen programming language, a fairly simple coding task.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Hardware setup

Windows PC

Page 11

Robotics Course

Instructional Guide

A lot of Windows devices, especially laptops and tablets, have inbuilt Bluetooth functionality. If your

PC does not, you will need to use a Bluetooth 2

USB dongle.

Different versions of the Windows operating system use slightly different ways of connecting Bluetooth devices, but they all follow the same steps.

You will need to perform this process just once as

Windows will remember which devices are paired.

1) Turn on Bluetooth

Often, Bluetooth is enabled by default and you can usually ignore this step. However if it is not, it can be enabled in the Windows settings and/or control panel. Very occasionally,

Bluetooth needs to be switched on using a special switch or function-key. Please consult your PC or Windows help for more information.

2) Pair the robot

First switch on the robot - its name will be displayed in the top-left of its screen.

Again, pairing works slightly differently on the various Windows versions and so it is difficult to give specific instructions here. The Windows help and website will have guides explain how.

When pairing, you will be presented with a screen or list of available Bluetooth devices.

Select the device with the name of your robot and click Next or Pair.

You will be asked to enter the pairing code. The Formula AllCode robot uses the default code of 1234, although this can be changed to another code if you want to ensure no-one else can pair with your robot.

Once the code has been entered, Windows will confirm that it has paired with the robot.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Hardware setup

Windows PC

Page 12

Robotics Course

Instructional Guide

3) Determine the COM port number

You should get a popup balloon on the task bar saying device is ready to use. If you click this before it fades away then you can find out the COM port assigned to the robot.

You use this COM port number when communicating with the Formula AllCode robot and this COM port number will stay the same as long as you do not remove or unpair the robot from Windows.

If you did not see the COM port when the robot was paired, you can find it in the Bluetooth

Settings window, as shown on the right.

There are two COM ports listed for each robot.

Make sure you always use the “outgoing” port number.

This window can be a bit hard to find on some versions of Windows. For example, on

Windows 10 you can find this via the “More

Bluetooth options” link on the Bluetooth settings screen.

Luckily, there is a guaranteed way of opening this window in all versions of Windows from version 7. Open the “Run…” window by holding the Windows key and pressing R, then type (or copy and paste) the following command into the box and press “OK”:

rundll32.exe shell32.dll,Control_RunDLL bthprops.cpl,,2

Now you have paired the robot and determined the COM port number, you can use any of the many programming languages available on Windows to control the Formula AllCode robot.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Hardware setup

Android tablet / phone

Page 13

Robotics Course

Instructional Guide

Android phones and tablets, when used with intuitive programming software such as App Inventor, provide a motivating platform for controlling the Formula AllCode robot.

These devices almost always include Bluetooth built-in.

As with other devices, the Formula AllCode robot must be paired with the phone or tablet before it can be used.

If your Phone or Tablet already has Bluetooth functionality built in then you may first have to enable it by clicking on Settings -> Connections.

Bluetooth Switched Off

Bluetooth Switched On

Once Bluetooth is enabled you need to pair the Formula AllCode robot to your phone to allow Apps to see the device.

Begin by clicking the Bluetooth option in Settings -> Connections

Next make sure your robot is switched on click the Scan button on your Android device to check for new Bluetooth devices. Note you may have to scroll down to see the results from the scan.

The name of the Formula AllCode appears on the top left of the LCD to let you know the

Bluetooth name of the robot you want to connect to.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Hardware setup

Android tablet / phone

When the device name has appeared click the device name and you will be asked to enter the pair key.

The default key is 1234.

Page 14

Robotics Course

Instructional Guide

Once the device is paired it will be listed along with any other paired Bluetooth devices you might have and is ready to be used with any Formula AllCode apps you download or create.

Please note: This may be subtly different on your Android device. For specifics on your

Phone or Tablet please look up how to pair Bluetooth devices for your specific device.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Hardware setup

Raspberry Pi and Linux

Page 15

Robotics Course

Instructional Guide

The Raspberry Pi is a popular single-board computer.

The most common operating system used on the

Raspberry Pi is a variety of Linux called

Raspbian.

The instructions here for pairing the Formula

AllCode robot are not limited to a Raspberry Pi and should apply to most Linux-based computers.

Setting up Bluetooth is relatively easy on a Raspberry Pi and can be done in a number of ways. The following steps are perhaps a more complex way of setting it up, but it should work in all situations. Note the Pi needs a Bluetooth USB dongle.

Step 1 – Get your Bluetooth settings

Open a command-line terminal and type the command “hciconfig”. This will bring up a list of Bluetooth devices available on your RPi. The important thing to note is the identifier of the Bluetooth module – in my case it is “hci0”:

Step 2 – Detect the Formula AllCode

Switch on the robot and then type “hcitool scan”. When I did this, it showed two devices.

Mine was the latter (“API_B”) and you will need to take note of the 6 pairs of hexadecimal numbers that are the MAC address, a unique identifier to the robot – in my case,

“00:BA:55:23:1C:20”.

Step 3 – Pair the robot with the RPi

To pair, you can use the “bluez-simple-agent” command using the “hci0” and MAC address found in the previous steps.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Hardware setup

Raspberry Pi and Linux

Page 16

Robotics Course

Instructional Guide

Step 4 – Making the change permanent

The final step is to make this pairing happen automatically when the RPi is next used.

This can be done by editing the “/etc/bluetooth/rfcomm.conf” file (e.g. using nano) and entering the following code. Again, you will need to ensure you use the correct MAC address that was found earlier.

You will need to add a section to this rfcomm.conf file similar to the following: rfcomm1 {

# Automatically bind the device at startup bind yes;

# Bluetooth address of the device device 00:BA:55:23:1C:20 ;

# RFCOMM channel for the connection channel 1;

# Description of the connection comment " Formula AllCode ";

}

The three red bits of text can be customised - you will use the MAC address found in step

2, and can use and name in the “comment” field.

If you have more than one robot, you can add multiple sections - just name each one

“rfcomm1”, “rfcomm2”, etc.

Step 5 – Testing the connection

Once you are paired, you can test the connection by using the following in the commandline terminal: echo "PlayNote 100,100\n" > /dev/rfcomm1

If all goes well, you should here a beep from the Formula AllCode.

If this does not work and you get “permission denied” message, you may need to add yourself to the “dialout” group. To see if this is the case, use the “id” command with your username as a parameter to check which groups you belong to. If the group “dialout” is not listed, you can add yourself to the group using the following command (remember to substitute your username in place of “username”!): sudo usermod -a -G dialout username

You will then need to logout and log back in to see this change, and the “PlayNote” command above should now work ok.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Flowcode

Page 17

Robotics Course

Instructional Guide

This section explains how to use Flowcode to control the robot.

As you probably know, Flowcode provides component macros for all complex devices like CAN bus, ZigBee, and the robot. This means you can start learning about robotics and how to control the Formula AllCode Robot very quickly and very easily.

There are programs on the Matrix website to inspire and help you.

This section assumes you are familiar with the basics of using Flowcode. There are two ways of using Flowcode to control the Formula AllCode robot. 1) re-programming the firmware on the robot and 2) using the in-built API functionality.

In Flowcode 6.1.3 and later there are two components available from the mechatronics menu to allow you to select the desired mode of operation, as shown on the right.

Downloading code to the robot

The Formula AllCode component allows us to create code which will run on the microcontroller on-board the Formula AllCode.

The component comes with a fully operational simulation allowing us to create programs to follow lines or solve mazes without having to keep compiling and downloading code to the robot.

To reduce the number of macro functions within the Formula AllCode component the code for driving the Servo motor outputs, SD card and Accelerometer have not been included.

There are separate components available which allow you to do this.

Note: Downloading code using this component will remove the API functionality from the

robot. Instructions on restoring the API to get the robot back to the original factory firmware are provided elsewhere.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Flowcode

Direct control from Flowcode using the API

The other component (“Formula AllCode API”) allows us to control a Formula AllCode robot from within Flowcode without downloading.

Note that the Component Macro functions appear in the Simulation tab rather than the usual components tab. This highlights the fact that the code is not downloadable onto

Formula AllCode.

Here we control the value on the LEDs by reading a value from a simulated analogue slide potentiometer. The console now provides a list of the API function calls, the parameters and the return values.

Page 18

Robotics Course

Instructional Guide

The selected communications port is automatically opened when you start the simulation.

The speed of the motors is automatically set to 0 before closing the port when you end the simulation.

By also dragging a Formula AllCode component onto the panel you can also control the simulated robot via the API component macros.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using App Inventor

Page 19

Robotics Course

Instructional Guide

Template

This section explains how to get started with the coding language called App Inventor that will enable you to use an Android device to control the robot.

These QR codes and hyperlinks will help speed-up your installation, so you can start having some fun coding.

App Inventor

App Inventor

App Inventor is a freely available graphical programming language hosted on one of the cloud-computing and storage systems at Massachusetts Institute of Technology (MIT) in the United States. All you need to get started developing apps for an Android mobile phone or tablet is a web browser and a Google account. App Inventor uses colour-coded icons, shaped like jigsaw-puzzle pieces, to create an app by joining the pieces together.

The system prevents you making mistakes by ensuring only certain shapes with the same colour scheme can be joined together. This technique encourages people of all ages to enjoy ‘coding’ and develop their confidence and ability in computer programming.

Setting up App Inventor

The key items you need are a desktop or laptop (running a modern browser like Chrome or Firefox) and a phone or tablet running the Android operating system. You will also need a QR reader so it would be a good idea at this stage to download one on to your mobile.

Just follow these simple steps to get yourself up and running really quickly.

1. Set up a Google account (if you haven’t already got one).

2. Go to the App Inventor website by scanning the QR code or clicking the hyperlink above and then login using your Google account.

3. Follow the online instructions, including installing the “MIT AI2 Companion App” onto your Android device.

4. You will need to link the web-based App Inventor with your phone or tablet. To do this, select ‘AI Companion’ from the ‘Connect’ menu in App Inventor.

5. Download the Formula AllCode template onto your computer by scanning the QR code or clicking the hyperlink. Remember where you saved them on your desktop/laptop.

6. Import the template (you just saved) using the ‘Projects’ menu in App Inventor. You will use this template as a starting point for every new project.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using App Inventor

Page 20

Robotics Course

Instructional Guide

Your first program

Each time you want to start a new project, follow these steps:

1. Load the template file by clicking ‘My Projects’ from the

App Inventor menu and selecting ‘FA_Template’ project.

2. Save this template as a new file by selecting ‘Save project as…’ from the ‘Projects’ menu and then entering an appropriate name for your project.

3. Click ‘Screen1’ from the ‘Components’ pane and set the ‘AppName’ and ‘Title’ in the

‘Properties’ pane to something suitable.

4. Drag a button from the User Interface panel onto the Viewer screen and alter its text to read “Spin”. Also rename the button so it reads “btnSpin”.

Do the same again to create another button called “Stop” with the name

“btnStop”.

5. Switch to ‘Blocks’ mode and click on the ‘btnSpin’ object - a list of icons will appear. Drag the “when btnSpin.Click” icon onto your program.

Do the same again but this time click on the ‘btnStop’ object.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using App Inventor

Page 21

Robotics Course

Instructional Guide

6. Click ‘Procedures’ from the ‘Built-in’ list and drag the “call SetMotors” icon into the middle of your “when btnSpin.Click” and “when btnStop.Click” icons. Add two literal values from ‘Math’ as the Left and Right parameters to the SetMotors code blocks.

Your two blocks should look like this:

7. Now you should build the project. Select “App (provide QR code for .apk)” from the

“Build’ menu. Once this is complete, run the “MIT AI2 Companion” app and then scan the

QR code into your Android device using the “Scan QR Code” button.

Note:

If you visit the App Inventor website you will find instructions about other methods that are available for transferring your program to your Android device.

8. You can now run your program on your Android device. Click “Connect to device” and select the Formula AllCode Robot from the list. Clicking the “Spin” button should make the robot spin, and “Stop” should make it stop.

You may have noticed a number of icons at the top of the screen in App Inventor. These define the procedures for communicating with the Formula AllCode Robot and some standard functions to allow the Bluetooth link to be set-up.

The tan coloured icons represent events such as when a button is clicked, when a timer triggers or when an error occurs.

The mauve coloured icons relate to a set of procedures or subroutines that have been designed to perform certain tasks for you. You should not alter these unless you are an experienced App Inventor user.

Some of the worksheets in this Instructional Guide show how events and procedures can be joined together to carry out tasks that interact with the user and the robot.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using C++ / C# / VB

Page 22

Robotics Course

Instructional Guide

A common programming tool is Visual Studio from Microsoft.

In this section we introduce various methods to communicate with the Formula AllCode robot using some of the more widely known programming languages such as C++, C# and

Visual Basic.

Using the Formula AllCode with Visual Studio via the Visual C++, Visual C# or Visual

Basic programming languages is fairly straightforward and consists of using a DLL library and associated files provided by MatrixTSL to communicate with the robot.

As will other languages, you need to use the COM port number that the robot is connected to. There are examples on the Formula AllCode pages of the Matrix TSL website here: http://www.matrixtsl.com/formula-allcode/

Using C#

The program on the right shows a basic program in C#.

using System;

You should use the namespace “FormulaAllCode” and place the FA_DLL library file in the same folder as your project. The DLL itself needs to be in the same folder as the

EXE you create.

namespace FormulaAllCode

{ class MyProgram

{ static void Main( string [] args)

{

//Assign the port number char iPort = ( char ) 9;

You will notice that the Formula

AllCode API commands are prefixed with the characters

“FA_” and also need to have the COM port sent to them each time as the first parameter.

//Open the COM port

FA_DLL.FA_ComOpen(iPort);

//Play a tune

FA_DLL.FA_PlayNote(iPort, 523, 400);

FA_DLL.FA_PlayNote(iPort, 659, 400);

FA_DLL.FA_PlayNote(iPort, 784, 800);

Remember to modify the API commands in the appendix when using them.

Also remember to close the

COM port at the end of your program!

FA_ComClose(iPort);

}

}

}

//Close the COM port

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using C++ / C# / VB

Page 23

Robotics Course

Instructional Guide

Using VB

Remember also to put the

“FASlave.DLL” file into the same folder as your created

EXE.

Module Module1

The same program is shown on the right, this time in Visual

Basic.

Sub Main()

'Assign the port number

Dim iPort As Byte

iPort = 9

You will see that the program is is very similar to the C# program, with only some minor differences in syntax. The calls to the Formula AllCode API are identical.

The FA_API.vb file should be added to your project.

'Open the COM port

FA_ComOpen(iPort)

'Play a tune

FA_PlayNote(iPort, 523, 400)

FA_PlayNote(iPort, 659, 400)

FA_PlayNote(iPort, 784, 800)

'Close the COM port

FA_ComClose(iPort)

End Sub

End Module

Using C++

A slightly different program is shown for C++, this time drawing an equilateral triangle.

#include "stdafx.h"

#include "FA_API.h"

To use the DLL with C++, you need to reference the functions by including the “FA_API.h” header file.

You also need to add the

“FASlave.lib” file to your Visual

Studio project.

int main ()

{

//Assign and open the COM port char iPort = 9;

FA_ComOpen(iPort);

Also put the DLL into the same folder as the EXE you create.

//Draw a triangle for ( int i=0; i<3; i++)

{

FA_Forwards(iPort, 500);

FA_Left(iPort, 120);

} As with the other languages, the calls to the Formula AllCode API are very similar, meaning it is very easy to use the robot with different languages - assuming you know the basics of that language anyway!

//Close the COM port

FA_ComClose(iPort); return 0;

}

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Python

Page 24

Robotics Course

Instructional Guide

Python is a widely-used computer programming language that is available on many systems. It is free, easy to learn and fun to use.

This section will show you how to set up Python for use with

Formula AllCode. It is assumed you have a basic working knowledge of Python itself. If not, there are many good resources on the internet if you wish to learn this language.

Set-up

The first thing you need is to make sure Python is installed on your computer. It is usually installed by default on a Raspberry Pi, but for Windows and other devices you will probably need to download and install it from http://www.python.org

.

There are two versions of Python, 2 and 3, and either can be used to control the Formula

AllCode robot, but you may wish to ensure you have the latest version installed.

In addition to Python itself, you will also need to install the PySerial library. This can be found on GitHub: https://github.com/pyserial/pyserial or can be downloaded on a Linuxbased device using the following command in a terminal window: sudo apt-get install python-serial

Now that Python and the PySerial library are installed, you should download the Formula

AllCode Python library from here: http://www.matrixtsl.com/formula-allcode/

You will find examples and other resources on this page that will help you control the robot in Python and many other languages.

My first Python program

This is best shown as an example: import FA # Import the Formula AllCode library fa = FA.Create() # Create an instance of the API fa.ComOpen(5) # Open the COM port fa.Forwards(100) # Move forward 100mm fa.ComClose() # Close the COM port

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Python

Page 25

Robotics Course

Instructional Guide

This very simple program drives the robot forward 10cm using the API command

Forwards

, but there are a number of other lines of code before and after that command that may need more explanation.

The first three lines of code import the library so you can use the API commands, then an instance of the API is created and a communication channel to it is opened. The number

“5” represents the COM port that was created when the robot was paired.

It is important to close the COM port and at the end of the program we should do that using a call to the

ComClose

API command.

Controlling multiple robots

By creating multiple instances of the API, we can actually control more than one at the same time. The program on the right shows how this can be done.

Just like the first program, we start by importing the FA library (note we are also importing the “time” library too). We then create 2 instances of the API and open their

COM ports.

# Import the libraries import FA import time

#Create and open 2 robots fa1 = FA.Create() fa2 = FA.Create() fa1.ComOpen(5) fa2.ComOpen(6)

The routine for drawing the square should be self-explanatory.

Finally, both COM ports are closed.

Theoretically many robots can be controlled simultaneously, but unfortunately there is a practical limit due to the capability of the computer’s Bluetooth device. I have found 3 or

4 is the realistic maximum.

#Draw a square loop = 0 while loop > 0:

fa1.Forwards(100)

fa2.Forwards(100)

time.sleep(1)

fa1.Right(90)

fa2.Right(90)

time.sleep(1)

loop = loop - 1

# Close the COM ports fa1.ComClose() fa2.ComClose()

Going further

We have shown only a few brief examples of how to control the Formula AllCode robot using Python. If you look at the API reference at the end of this document you will find many other commands that can be used.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Labview

Page 26

Robotics Course

Instructional Guide

LabVIEW is a development environment for creating custom applications that interact with real-world data or signals in fields such as science and engineering.

It can also be used to control the Formula AllCode robot.

This section explains how to get started

Using the robot with Labview is fairly easy and consists of using a library provided by

MatrixTSL. First, download the library (which consists of a DLL and a LabView library file) from the Matrix TSL website: http://www.matrixtsl.com/formula-allcode/

To begin, create a new blank VI and then open the “FASlave.lvlib” file that was downloaded earlier. This contains all of the function calls to the Formula AllCode API, as shown on the right.

A sample program is shown below, using two sliders to control the robot. Set the number in the “Port” box to the COM port number created for your robot when it was paired.

The program at the bottom of the page shows a flat sequence structure that ensures the various parts of the program are called in turn.

The left window executes first and opens the COM port.

The middle window loops until “stop” is pressed. It takes the value of the sliders and sends it to the SetMotors API command every 100ms.

The next window stops the motors when the loop has completed and the final right-most window closes the COM port.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Scratch

Page 27

Robotics Course

Instructional Guide

Scratch is a very popular programming tool for introducing coding techniques to school-aged children.

While predominantly used to create programs that control on-screen characters, you can also use it to control external hardware like the

Formula AllCode robot.

This section describes what you need to get started.

At the time of writing, there are many versions and derivatives of Scratch - both online and offline. The instructions here relate to the Scratch 2 Offline Editor.

Scratch does not natively support external hardware, so we have written an external

“helper” application that translates communication between Scratch and the Formula

AllCode robot. There is also a template file to get you started with using the robot. You can download this helper application and the template file from here: http://www.matrixtsl.com/formula-allcode/

Before starting Scratch, run the helper application and select the robot you wish to connect to from the list.

You can now open Scratch. First open the template file to begin your new project. This will load all of the API commands in the “More Blocks” area of

Scratch. It will also give you a Formula

AllCode sprite and a basic example program.

Creating your own programs should now be simple.

For example, to move the robot when the arrow keys are pressed, the icons below can be used.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Controlling the robot

Using Scratch

Page 28

Robotics Course

Instructional Guide

There are many other programs you can write in Scratch. For example, here are three pieces of code:

The first makes an interesting sound, the second does a little dance and the third plays a familiar tune!

Of course, you can also link with on-screen activities as shown on the right.

Here, the computer asks your name and then displays it on the LCD of the Formula AllCode robot.

After that, it flashes the LCD backlight to catch your attention.

More complex programs can also be written. The program on the left draws an interesting trigonometric equation.

You can also read sensor values back from the robot and create routines that react to them.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 1

Robo makes its first move

Page 29

Robotics Course

Instructional Guide

This worksheet explains how to make the robot move forwards and backwards, and turn through a specified angular position so it can trace out a geometrical shape, like a square, a triangle or a house.

It’s probably the very first thing you’ll want to do before investigating other exciting things the robot can do.

Skill Level

Easy

Activity

Standalone

Motor Controls

There are two ways to control the robot’s motors. The first method uses the API command

SetMotors

to set the speed and direction of rotation for each of the two motors. This particular command will be covered in detail in a later worksheet. The second method of control is based on Logo movements.

Logo movements

Logo is a language designed many years ago to teach computer programming to students, so they could control devices like a small robot or a turtle using a set of simple commands.

Forwards and Backwards

There are two API commands to control straight line movement.

Forwards <distance>

and

Backwards <distance>

The value for <distance> specifies the distance in millimetres the robot should travel and can vary from 0 to 1000. Here’s a very simple program to make it move forwards and backwards by 100 mm.

// An example program written in pseudo-code

LOOP-FOREVER

Forwards 100

DELAY 250ms

Backwards 100

DELAY 250ms

END-LOOP

//move forward 100 mm

//move backwards 100 mm

The important thing to note about these two commands is the robot will travel in a straight line because there is rotational feedback from each motor, to control and vary the power applied to the motors. Now let’s get the robot to move sideways.

Left and Right

These are the two API commands to control angular movement.

Left <angle>

and

Right <angle>

The value for <angle> specifies the angle in degrees the robot should rotate and can vary from 0 to 360.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 1

Robo makes its first move

Page 30

Robotics Course

Instructional Guide

Drawing the shape of a house

Let’s get a bit more adventurous and get the robot to mark out the front face of a house.

B C

The suggested length for sides A, D and E is 200 mm.

As shown below, the roof structure consists of two right-angled triangles that have a length of 100 mm for the base and perpendicular.

A

D

B

100

C

100

100

Start

E

Over to you

(a) Using Pythagoras theorem you can work out the length for sides B and C. You should also be able to deduce the angles.

Then, using the program shown below as a guide, enter your calculated values (where you see the question marks) and see if the robot draws the correct shape.

// An example program written in pseudo-code

Forwards 200

//Draw side A

Right ??

Forwards ???

//Draw apex B

Right 90

Forwards ???

//Draw apex C

Right ??

Forwards 200

//Draw side D

Right 90

Forwards 200

//Draw base of house, side E

(b) See if you can get the robot to draw these geometrical shapes: equilateral triangle, right-angled triangle, hexagon, parallelogram. What other shapes can you draw?

(c) Challenge one of your friends to draw a shape and get your robot to copy it.

Summary

This section has explained how to use the API commands to control the robot’s motors so they accurately move forwards or backwards, or turn left or right a specified angle.

The work covered in this worksheet will be really useful when you tackle other aspects of controlling the robot. For example, getting the robot to move towards the direction of a light source, reacting to a hand being placed in front of it, or navigating a maze.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 2

Watch out - those lights are animated

Page 31

Robotics Course

Instructional Guide

This worksheet explains how to use the eight green LEDs, located towards the front edge of the Formula AllCode Robot.

They can be used to produce interesting and creative visual effects that will enhance your enjoyment of using the robot.

Skill Level

Easy

Activity

Standalone

LEDs

At the front of the robot is a row of eight LEDs. Each one has a reference number (from

LED-7 down to LED-0) as shown below.

LED-0

LED-7

The following two API commands enable you to turn an individual LED on or off.

LEDOn <index>

and

LEDOff <index>

<Index> can take a value between 0 and 7 to define the LED you want to manipulate.

For example to turn LED-7 on you would use:

LEDOn 7

and to turn it off:

LEDOff 7

Note:

These two commands just affect a single LED.

The state of the other seven LEDs remain unchanged.

This program makes LED-7 blink 4 times a second.

// pseudo-code example

LOOP-FOREVER

LEDOn 7

DELAY 125ms

LEDOff 7

DELAY 125ms

END-LOOP

If you wanted to set the state of all the LEDs at the same time then you can use the API command

LEDWrite <value>

where <value> can take a value between 0 and 255.

Collectively the LEDs can be represented as an 8-bit binary number (i.e. a value between

0 and 255). LED-0 is the least significant bit and has a value of 1. While LED-7 is the most significant bit and has a value of 128.

So to set the state of all LEDs at the same time you just need to work out the overall value and then use

LEDWrite <overall value>

.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 2

Watch out - those lights are animated

Page 32

Robotics Course

Instructional Guide

For example, to light just LED-2, LED-1 and LED-0, you would need to send the value 7

(i.e. 4 + 2 + 1 = 7) as a parameter. To do this you would use the following API command.

LEDWrite 7

Over to you

You may have heard of Knight Rider, an American television series, that featured a car with a set of headlights that were used to create an animated sequence. The best known sequence had the lights move in towards the centre and then back out again.

You should be able to create the Knight Rider pattern using the robot’s eight LEDs. The first step is to work out the numerical values that need to be written to the LEDs.

The first pattern has LED-7 and LED-0 turned on together. You need to work out what value this represents. The next pattern has LED-6 and LED-1 on. Again you need to work out its value. Keeping on doing this until you have worked out all the values, then enter those values into your program as API commands.

You will probably find you need to add a delay between API commands to give a smooth transition and achieve the desired Knight Rider effect.

Other effects for you to try out

There are lots of other effects you can try out. Here are two suggestions:

The Snake pattern - this starts off with the first LED illuminated (value 1) then moves across one place to the left so that the second LED is illuminated (value 2). This sequence continues until the most significant LED is illuminated (value 128). Then the sequence retraces its steps back to the beginning. The resultant effect should look like a snake moving or weaving its head or body from side to side.

Another effect you might like to try is the Egg pattern. This pattern starts off like the Snake effect but upon reaching the top most digit (value 128) the LED remains illuminated whilst the pattern retraces its steps back to start. The effect is that of an ‘egg’ being laid at the far end. The sequence then repeats again until LED-6 is reached. This LED remains on (as well as LED-7) as the pattern retraces its steps.

Some patterns you might want to create may follow a mathematical sequence which means you could output a value from a named variable as shown below.

LEDWrite <named_variable>

Summary

This section has shown you how to use the API commamds to manipulate the row of LEDs on the robot by sending a value to control all eight LEDs together or individually.

The work covered in this worksheet will be really useful when you tackle other aspects of controlling the robot. For example, getting the robot to show the value of the light sensor.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 3

Switch it on, switch it off

Page 33

Robotics Course

Instructional Guide

This worksheet explains how the on-board push buttons and LEDs operate so that you can understand how inputs and outputs function in a simple digital system.

Activity

Standalone

Skill Level

Easy

Push Buttons

Towards the front of the robot, next to the fixings for the motors, are two push buttons labelled SW1 and SW2 that can be sensed by your program and used to trigger a task.

There is also another push button labelled SW3, adjacent to the micro-USB connector, that performs a reset function whenever it is pressed.

The API command to read the state of SW2 or SW1 is:

ReadSwitch <index>

The ReadSwitch API call uses a single "index" parameter (0 for the left button, 1 for the right button), and returns a value of 1 (pressed) or 0 (not pressed).

The way this call would be used is to assign the result to a named variable (e.g. SW_1).

SW_1 =

ReadSwitch 0

If you just wanted to perform an action or a simple task when a button is pressed, then all you need to do is test if the value in the named variable is greater than zero - then carry out that particular action if the answer is true. Here’s an example program.

// An example written in pseudo-code

LOOP-FOREVER

SW_1

=

ReadSwitch 0

IF SW_1 > 0 THEN

CALL SW_1_TASK

END-IF

SW_2

=

ReadSwitch 1

IF SW_2 > 0 THEN

CALL SW_2_TASK

END-IF

END-LOOP

// Detect if SW1 is pressed

// User routine

// Detect if SW2 is pressed

// User routine

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 3

Switch it on, switch it off

Page 34

Robotics Course

Instructional Guide

Over to you

Now that you know how to check buttons SW1 and SW2 you should try writing a program to perform a series of tasks one after another.

(a) When SW1 is pressed output the Knight Rider pattern to the robot’s LEDs, and when

SW_2 is pressed output the Snake pattern.

This means you will need to write some code to go inside the user routines labelled

SW_1_Task and SW_2_Task to output the desired patterns.

To keep things simple at this stage, you will find that your program will perform the above sequence once, unless the appropriate button is still pressed.

When you finally release the button, the current pattern will stop when it comes to the end of its sequence.

In a later worksheet you will find out how to write a program that remembers which button was pressed, so you don’t need to keep your finger on the button.

(b) Make the left button cause the robot to draw a square and the right button draw a circle.

(c) Have a look at the API commands in the appendix and see if you can make other things happen when you press a button.

Summary

This section has shown you how to read the state of buttons SW1 and SW2 and perform a certain task.

Another possible use for SW1 or SW2 is to act as a trigger, so that when a button is pressed it sends a signal to another program telling it to commence operation.

For example, you could arrange for audio (previously recorded on the micro SD card) to be played and the robot perform a dance when a button is pressed.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 4

Hello world

Page 35

Robotics Course

Instructional Guide

This worksheet explains how to send a text message to the LCD panel located in the central area of the robot.

The second part of this exercise covers sending a series of multi-line messages that change after a certain period of time.

Activity

Standalone

Skill Level

Easy

The graphical LCD (gLCD) panel, situated in the centre of the robot, is capable of drawing graphical elements like lines and rectangles, and manipulating individual pixels.

Note: These aspects will be covered in greater detail in another worksheet.

Using the panel in its non-graphical mode allows messages (text and numbers) to be displayed, for example the numerical values obtained from the light or distance sensors, or just a plain message to send “visual” feedback to the user. You can of course mix the two modes by placing dividing lines, shaped blocks or user-created graphical symbols (near pieces of text) to draw the user’s attention to certain parts of the panel.

The brightness of the panel’s back-light can also be varied under program control.

However it should be noted that having the back-light on fully will drain the battery quicker.

LCD panel layout

The diagram below shows how the X and Y coordinates of the panel are laid out. The X coordinate runs across the top of the panel (from left to right) and can take a value from 0 to 127 to define a column on the display. The Y coordinate goes from the top to the bottom of the panel and can take a value from 0 to 31 to define a row on the display.

Whenever you work in a graphical environment, it is normal practice to specify the X and then the Y coordinate (i.e. the column and then the row), so the top-left position would be known as 0,0 and bottom-right position as 127,31. A common mistake is to mix up the coordinates which means your program will display characters in the wrong place.

X coordinate

0,0

127,0

Y coordinate

127,31

0,31

Characters are formed on a 6 by 8 pixel-matrix, so it is possible to display 21 characters across the width of the panel, and 4 rows deep.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 4

Hello world

Page 36

Robotics Course

Instructional Guide

Now you know how the panel is laid out, you can write a message using the API call.

LCDPrint <x> <y> <text>

Hello World

Here’s an example of the message you see in most books about programming.

// An example written in pseudo-code

LCDPrint 0 0 “Hello World”

Here’s an example of a multi-line message centred on the LCD panel.

// An example written in pseudo-code

LCDPrint 0 0 “ Hello and welcome ”

LCDPrint 0 8 “ to the ”

LCDPrint 0 16 “ Robotics ”

LCDPrint 0 24 “ Instructional Guide ”

Each line of the message is centred by padding either side of the text string with spaces.

The number of spaces needed is calculated by subtracting the length of each message from 21 (the character width of the LCD panel) and dividing the result by two. Sometimes the result is an odd number which means one side of the message has an extra space.

Over to you

Turn the above program into a macro or sub-routine by gathering the pseudo-code together and giving it a suitable name like MESSAGE_1. Once you have done that create other multi-line messages, give them suitable macro names and combine them together to make announcements in a timed sequence (as shown below).

// An example written in pseudo-code

LOOP-FOREVER

LCDClear

CALL MESSAGE_1

DELAY 5s

LCDClear

CALL MESSAGE_2

DELAY 5s

END-LOOP

Any information currently on the screen can be erased, with the API command

LCDClear

before sending a new message to the LCD panel.

Displaying numerical values

If you need to display the numerical value of a named variable, then this can be achieved using the API command.

LCDNumber <x> <y> <number>

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 4

Hello world

Page 37

Robotics Course

Instructional Guide

Here’s an example of how the value of the named variable ‘distance’ could be displayed.

LCDNumber 0 0 distance

To make the layout more user friendly, a piece of text could be used to label the numerical value so you know what it represents.

// An example written in pseudo-code

LCDClear

LCDPrint 0 0 “Distance = ”

LCDNumber 66 0 distance

Back-light brightness

As mentioned on the previous page, the brightness of the panel’s back-light can be altered to suit the viewing conditions. The API command to do this is:

LCDBacklight <value>

where <value> can vary from 0 (back-light off) to 100 (full brightness).

LCDOptions in non-graphical mode

The following API call can be used to control the way text is shown on the LCD screen.

LCDOptions <foreground> <background> <transparent>

The first two parameters can take a value of 0 or 1 to define white or black respectively.

This means you can display white text on a black background, or black text on a white background. The third parameter can also take a value of 0 (display text on foreground and background) or 1 (display text on foreground only).

Related LCD commands

The following API commands affect the graphical aspect of the LCD panel and are covered in a later worksheet.

LCDLine, LCDRect and LCDPixel

Things to remember

- the layout of the LCD panel is just like a piece of graph paper

- the X axis runs across the top and the Y axis goes down the side

- the X and Y axes are numbered starting from zero (not one)

Over to you (again)

This section has shown you how to use the various API commands to display and format information (text and numerical values) on the LCD panel.

(a) Get the robot to display the lines of a joke. You will need to pause before displaying the punch line!

(b) Display the results of your favourite football team. Perhaps pause between results until a button is pressed.

In later worksheets you will display useful information such as the sensor readings.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 5

How bright is that light?

Page 38

Robotics Course

Instructional Guide

Linked

This worksheet explains how to use the light sensor located at the front edge of the robot.

The first exercise measures the light level and displays it on the LCD panel.

The second exercise involves adjusting the illumination of the LEDs depending on the ambient light level.

Skill Level

Easy

Activity

Situated at the centre of the front edge of the robot is a light sensor. Although it looks just like a plain LED it is in fact a photo transistor that reacts to the amount of light falling on it.

The amount of current that can pass through the device increases as the light increases.

So, by placing the device in a simple potential divider circuit will cause a voltage to vary as the light changes. The robot can sense this and convert it into a value.

The API command to read the light level is:

ReadLight

and the way it would be used is to assign the result to a named variable (e.g. illumination).

illumination =

ReadLight

The first thing you should do is find out the range of numerical values produced by the photo transistor under different lighting conditions. This simple exercise shows how to measure the light level and display the value on the LCD panel.

// An example written in pseudo-code

LCDClear

LCDPrint 0 0 “Light value = ”

LOOP-FOREVER

illumination = ReadLight

LCDNumber 84 0 illumination

DELAY 100ms

END-LOOP

Although the photo transistor can theoretically produce values from 0 to 4095, you may not be able achieve them without placing the robot in a pitch black enclosure or holding it next to a bright electric light bulb.

Write down some of the results you obtain when you place the robot in different parts of a room or take it outdoors. Make a note as to whether it is a sunny or an overcast day.

You could also try shining a hand-held torch towards the light sensor and see what readings you get as you move closer to or further away from the robot.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 5

How bright is that light?

Page 39

Robotics Course

Instructional Guide

The next exercise is a very simple control or feedback system. The objective is to measure the ambient light level and then use this value to adjust how many of the LEDs on the front of the robot are turned on. The idea is to turn more LEDs on as the light level reduces, and turn more off as the light increases.

If this idea was applied to a practical situation (using more powerful lights) then it should be possible to maintain a room’s illumination at a constant level regardless of light levels.

The pseudo-code below shows how this is achieved.

// An example written in pseudo-code

LOOP-FOREVER

illumination = ReadLight

illumination = Round(illumination / 16)

LEDs = 255 - illumination

LEDWrite = LEDs

DELAY 100ms

END-LOOP

The program begins by reading the value of the light sensor into the named variable

‘illumination’ and then divides this value by 16. This will scale the light reading to fall within the range 0 to 255 rather than 0 to 4091.

To make sure the result is an integer we use the Round() function. Your chosen programming language will have this function, but it might be called something else and might require an extra parameter to specify the level of rounding.

The next part of the program creates the inverse proportional lighting effect by subtracting the illumination value from 255. So what happen is, as the illumination value increases the value in the named variable ‘LEDs’ decreases.

The last part of the program writes the value in the named variable ‘LEDs’ to the LEDs on the front of the robot, then after a short delay the whole sequence is repeated.

Over to you

This section has shown you how to use the API call to read the value of the light sensor.

Try out the two exercises described here to gain experience of using the light sensor and to reinforce your knowledge of operating the LCD panel and LEDs.

The second exercise will not work as expected - if the value of the variable “LEDs” is 127,

7 LEDs will light, yet if it is 128 then only one will light. Try to change the program so the number of LEDs that light increased when the light level falls.

The work covered in this worksheet will be really useful when you tackle other aspects of the robot. For example, getting the robot to move towards the direction of a light source.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 6

Searching for the light

Page 40

Robotics Course

Instructional Guide

This worksheet brings together the work covered during a couple of previous exercises to solve a real-life problem.

The problem that needs to be solved is for the robot to follow a light source from a hand-held torch. It sounds simpler than you think!

Skill Level

Intermediate

Activity

Linked

Strategy

The first thing you need to do, to solve the problem outlined above, is to work out a strategy for dealing with the possible situations that could occur. For example, if the robot detects the light-beam from the torch, then move forward a certain distance and check again. Pretty obvious, but what should the robot do if it loses sight of the beam? It needs to stop and try to find the light source.

One way to work out what the robot should do is to put yourself in the same situation and think what you would do. Using your eyes you could probably see the light-beam. You might have to move your eyes slightly to the left or right in order to ‘see’ the beam again. If the beam has dramatically changed its position, then you might have to move your head left or right because the amount of travel your eyes can make is physically limited.

The anatomy of the robot is a little bit different from ours. It might only have a single eye

(i.e. light sensor) in a fixed position (on the front edge of the robot), but it is able to move its head through a full 360 degree rotation. Something we can’t do!

This is the strategy to try to find the light-beam. Currently the robot is stationary, so make it rotate left by a certain angle, say 5 degrees, and check for the beam. If it manages to find the beam then it starts moving forward. If it is unsuccessful, then it moves its head to the right by the same angle, and checks again. If these two manoeuvres were unsuccessful, then the angle is increased, to say 10 degrees, and the procedure repeated.

Here’s a sequence diagram to show pictorially how the strategy could be implemented.

A

Point A is the robot pointing straight ahead. The arrow from

A to B indicates an angular movement to the left. B to C represents the robot returning to point forward again. The arrow from C to D indicates an angular movement to the right, while D to A is the return movement to point ahead.

B

C

D

The existence of the light-beam is checked at all four points.

The transition from D to A is the place where the detection angle is increased before the sequence is repeated.

If detection angle reaches 180 degrees this will indicate the light-beam failed to be located.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 6

Searching for the light

Page 41

Robotics Course

Instructional Guide

Here’s an example of the structure for the light searching program. To assist you in reading through the program the API commands have been highlighted in blue .

// An example program written in pseudo-code threshold = 2000 pos = “A” movement = 5

LOOP-FOREVER

//Experimental value

//Initial 5 degrees illumination =

ReadLight

IF illumination > threshold THEN pos = “A” movement = 5

Forwards

100

ELSE

IF pos == “A” THEN pos = “B”

Left

movement

ELSE-IF pos == “B” THEN pos = “C”

Right

movement

ELSE-IF pos == “C” THEN pos = “D”

Right

movement

ELSE pos = “A”

//Must be at point D

Left

movement

IF movement < 180 THEN movement = movement + 5

ELSE movement = 5

END-IF

END-IF

END-IF

DELAY 50ms

END-LOOP

//Short delay (see text)

Although the structure closely matches the textual description, given on the previous page, there are a few things that you should note. The threshold value was obtained by experimenting with a small hand-held torch in a room with subdued lighting. You need to aim for the situation where the amount of available light plus the light from the torch does not exceed the upper limit of the light sensor (e.g. 4095).

The main loop includes a short delay to smooth out the timing of the left/right movements.

You could try changing the value of the named variable movement and see how this affects the behaviour of the robot and its ability to locate the light-beam.

Over to you

This section has shown how to combine the API calls for the light sensor with Logo-style movements to solve a real problem. See if you can program your robot to do the same.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 7

Follow my line

Page 42

Robotics Course

Instructional Guide

This worksheet brings together some tasks covered in previous sections, to solve a real-world problem.

The problem that needs to be solved is for the robot to use the on-board sensors to follow a black line on a white background. It sounds simpler than you think!

Skill Level

Intermediate

Activity

Linked

If you’ve not looked underneath the robot now is the time to do so. You should be able to spot the two sensors that detect the amount of light reflected off of a surface. Each sensor includes an infrared emitter and a photo transistor, that can identify the difference between white and black surfaces based on the contrast and reflective properties of an object.

The API command to read the line sensor is:

ReadLine <index>

and the way it would be used is to assign the result to a named variable (e.g. line_reading).

The parameter

<index>

can take a value of 0 or 1 to select the appropriate sensor.

Here’s an example of reading line sensor-0 which is the left-hand sensor when viewed from the upper side of the robot with the face of the gLCD panel pointing away from you.

left =

ReadLine 0

As an exercise you could write a simple program to read the line sensors and display their values on the LCD panel. This will enable you to experiment and see what sort of values are returned from different coloured surfaces.

// An example written in pseudo-code

LCDClear

LCDPrint 0 0 “ Left Right ”

LOOP-FOREVER

left = ReadLine 0

right = ReadLine 1

LCDNumber 24 0 left

LCDNumber 72 0 right

END-LOOP

The above program should produce a clearly formatted screen with the line sensor values displayed under the headings Left and Right. This will enable you to record the reflection values for different types of surfaces. Note the readings for a black and a white surface.

The sort of readings you should get are probably 0 for black and 200 for white.

Copyright © 2016 Matrix Technology Solutions Limited http://www.matrixtsl.com

FORMULA

II

ALLCODE

Worksheet 7

Follow my line

Page 43

Robotics Course

Instructional Guide

Setting up a test track and solving the problem

If you have the mat that came with your robot you can make use of that, or you can make your own track using a roll of 25 mm wide black tape stuck onto a piece of stiff white card.

An oval or figure-of-eight track are good shapes to start off with. Make sure the bends are not too sharp or tight otherwise the robot will have a hard time navigating them.

When you use Logo movements the robot should travel in a straight, however there are factors like skidding or grease marks on the surface that could cause the robot to gradually veer off the track.

B