Yamaha BBS251 Installation Manual EN (image)

Add to my manuals2 Pages

Yamaha BBS251 is a versatile baton clamp speaker bracket designed to securely hold and position speakers weighing up to 66 lbs. Its sturdy construction and adjustable design make it ideal for a variety of applications, including live sound reinforcement, studio recording, and home theater setups. With a wide range of motion and precise angle adjustments, the BBS251 allows for optimal speaker placement to achieve the best possible sound quality.

advertisement

▼

Scroll to page 2

ENCINA

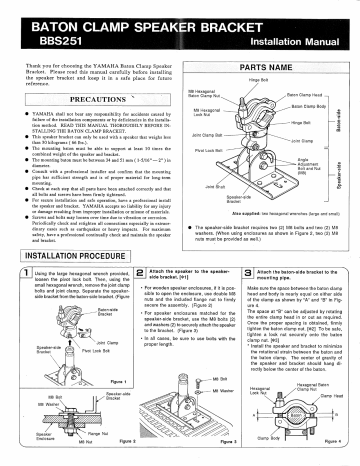

Thank you for choosing the YAMAHA Baton Clamp Speaker - E -. PARTS NAME 5 . € 2

Bracket. Please read this manual carefully before installing —_—

the speaker bracket and keep it in a safe place for future Hinge Bolt

reference.

M8 Hexagonal

| A KN a Baton Clamp Nut Baton Clamp Head —-

PRECAUTIONS *

Baton Clamp Body

- M8 Hexagonal

0 YAMAHA shall not bear any responsibility for accidents caused by Lock Nut

failure of the installation components or by deficiencies in the installa-

tion method. READ THIS MANUAL THOROUGHLY BEFORE IN-

STALLING THE BATON CLAMP BRACKET.

® This speaker bracket can only be used with a speaker that weighs less

than 30 kilograms ( 66 1bs.).

® The mounting baton must be able to support at least 10 times the Pivot Lock Bolt

combined weight of the speaker and bracket.

@ The mounting baton must be between 34 and 51 mm ( 1-5/16” — 2”) in

diameter,

e Consult with a professional installer and confirm that the mounting

pipe has sufficient strength and is of proper material for long-term

mounting.

e Check at each step that all parts have been attached correctly and that

all bolts and screws have been firmly tightened. Speaker-side

e For secure installation and safe operation, have a professional install Bracket —

the speaker and bracket. YAMAHA accepts no liability for any injury

or damage resulting from improper installation or misuse of materials. “ Also supplied: two hexagonal wrenches (large and small)

O Screws and bolts may loosen over time due to vibration or corrosion.

Periodically check and retighten all connections especially in extraor-

dinary cases such as earthquakes or heavy impacts. For maximum

safety, have a professional continually check and maintain the speaker

and bracket,

Hinge Bolt

Baton-side

Joint Clamp Bolt

—

Angie

Adjustment

Bolt and Nut

(M8)

Speaker-side

e The speaker-side bracket requires two (2) M8 bolts and two (2) M8

washers. (When using enclosures as shown in Figure 2, two (2) M8

nuts must be provided as well.)

INSTALLATION PROCEDURE

1 Using the large hexagona! wrench provided, | 2 ido bracken 1 to the speaker 3 Attach the baton-side bracket to the >)

— loosen the pivot lock bolt. Then, using the [| dois — mounting pipe.

mel hexagonal wrench, remove he joint clamp * For wooden speaker enclosures, if it is pos- Make sure the space between the baton clamp

ba on “he bat E deb X Fi er sible to open the enclosure, use double M8 head and body is nearly equal on either side

side bracket from the baton-side bracket. (Figure nuts and the included flange nut to firmly of the clamp as shown by “A” and “B” in Fig-

secure the assembly. (Figure 2) ure 4,

Baton-sid uma . ;

Bracket * For speaker enclosures matched for the The space at “B” can be adjusted by rotating

the entire clamp head in or out as required.

speaker-side bracket, use the M8 bolts (2

P 2) Once the proper spacing is obtained, firmly

and washers (2) to securely attach the speaker

- to the bracket. (Figure 3) tighten the baton clamp nut. [*2] To be safe,

tighten a lock nut securely onto the baton

* In all cases, be sure to use bolts with the clamp nut. [%3]

Speaker-side Joint Clamp proper length. * Install the speaker and bracket to minimize

Bracket Pivot Lock Bolt the rotational strain between the baton and

\

the baton clamp. The center of gravity of

the speaker and bracket should hang di-

rectly below the center of the baton.

Figure 1 Hexagonal Baton

Hexagonal Clamp Nut

Speaker-side ock Nut

M8 Bolt Bracket Clamp Head

M8 Washer

A A rer ¥ B

TT i

Speaker = Flange Nut

Enclosure Clamp Body

\_ M8 Nut Figure 2 Figure 3 Figure 4 |

(1) Insert the joint shaft of the speaker-side bracket

into the shaft hole of the baton-side bracket. While

holding the speaker in position, attach the joint

clamp and firmly tighten the joint clamp bolts. [4] In

this condition, the speaker-side bracket can be

horizontally rotated 360°,

Baton-side

(2) Pivot the speaker to the desired horizontal angle Bracket

and securely tighten the pivot lock bolt to set the

position. [#5] |

(3) Set the vertical angle of the speaker after loosen- Bolt

ing the angle adjustment bolts and nuts (M8). Firmly

Joint Shaft

retighten the bolts and nuts.

* Do not adjust the speaker position without loos-

ening the required bolts and nuts,

* It the vertical angle of the speaker is extreme,

the baton clamp may slip depending on the ma-

terial of the baton.

Speaker

(4) After adjustment, check again that the rotational

strain between the baton and the baton clamp is

minimized. The center of gravity of the speaker

and bracket should hang directly below the center

of the baton. [#7]

* Firmly tighten the hexagonal lock nut and baton

\_ clamp nut. [*%8]

Insert the joint shaft of the speaker-side bracket into the baton-side bracket.

Joint Clamp

Joint Cl

y

ZA

Ti 7 Tighten

Speaker-side

Bracket

J

e \

N

Lastly, recheck the entire

installation. Make sure of

the following:

[1 Bracket Attachment to

the Speaker [+1]

[} Bracket Attachment to

the Baton (Baton Clamp

Nut Tightening) [%2]

[] Hexagonal Lock Nut

Tightening [#3]

[] Joint Clamp Bolt

Tightening [#4]

[] Pivot Lock Bolt Tight-

ening [+5]

L] Angle Adjustment Bolt

Tightening [+6]

[] Baton-side Bracket

Angle Adjustment [7]

[ J] Hexagonal Lock Nut

and Baton Clamp Nut

Tightening [#8]

D,

= SPEAKER ANGLE ADJUSTMENT —

The speaker bracket can be adjusted for a wide range of listening

positions.

Pivot Lock Bolt [#5]

Using the large hexagonal

wrench supplied, loosen the

Maximum pivot lock bolt. Rotate the

adjustable speaker to the desired angle

angle: 360 and retighten the pivot bolt

securely.

Maximum adjustable

angle: 90°

Angle Adjustment Bolts

(2) and Nuts (2) [+6]

Using a wrench, slightly

loosen the angle adjust-

ment bolts and nuts. Ad-

just the speaker to the

desired angle and firmly

retighten the bolts and nuts.

46 (1-13/16"

Lu

©

+ 95 (3-3/4")

= Ms | #0 45

a - jet

= (1-15/167) | (1-3/4”)

[37]

(1-7/16”)

>

10

(3/8")

[135] (5-5/16™)

[175] (6-7/8")

[212] (B-3/8")

240 (9-7/16”)

+

_— = —

f---_ex Hu cs SET a own) À

==

{1-8/16")

o

e

)

(1/8

* [] dimensions for 40

mm (1-9/16") baton

diameter

Weight: 2.3 kg (5 Ibs.)

Units: mm (inch)

YAMAHA CORPORATION

Pro Audio Division, # 18/3

P.O.Box3,Hamamatsu,430-8651,Japan

YAMAHA

Printed in Japan

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project