Midmark LED Dental Light Installation Manual

Add to my manuals

2 Pages

Midmark LED Dental Light offers exceptional illumination and versatility for dental procedures. Its high-intensity LED bulbs provide bright, shadow-free light, while the articulating arm allows for precise positioning. The light intensity is adjustable, letting you customize it to your preference. With its long lifespan and energy efficiency, the Midmark LED Dental Light is a reliable and sustainable choice for your dental practice.

advertisement

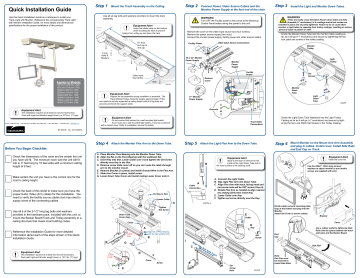

Quick Installation Guide

Use this Quick Installation Guide as a reference to install your

Track Light with Monitor. Reference the corresponding Track Light with Monitor Installation Guide, for more details and dimensional specifications for the proper installation of this product.

Applies to Models:

1531017 (-000 thru -008)

1531018 (-010 thru -018)

153963 (-000 thru -008)

153964 (-010 thru -018)

153829 (000 thru - 008)

153906 (-010 thru - 018)

153830 (-000 thru -008)

153907 (-010 thru -018)

Equipment Alert

This installation requires at at least two service technicians.

Track with Light and Monitor weight (max.) is 157 Lbs. (71 kgs).

© 2017 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-937-526-3662 | 1-800-643-6275 | midmark.com

003-10003-00 Rev. AA4 (6/25/2019)

Step 1

Mount the Track Assembly on the Ceiling.

Head

End

Use all six lag bolts and washers provided, to mount the track assembly.

Equipment Alert

Leave the plastic wrap on the trolleys while mounting the track to prevent trolleys from rolling up and down the track.

Right Side

91” from end cap to end cap

6 Lag

Bolts &

Washers

Left Side

Video Input

Source Box

Wall

Foot End

DA2255i

Equipment Alert

Support for the assembly during installation is essential. The

Track Monitor/Trolley Assembly weighs approximately 75 lbs. and needs to be fully supported at ceiling height until all 6 lag bolts are securely anchored into support studs.

Equipment Alert

Do not connect this product to a wall mounted light switch.

If you must use a wall mounted light switch, it must be contained with a locked cover. Refer to installation manual for details.

Before You Begin Checklist:

Check the dimensions of the room and be certain the unit you have will fit. The minimum room size the unit will fit into is 11 feet long by 10 feet wide with a minimum ceiling height of 8 feet.

Make certain the unit you have is the correct one for the room’s ceiling height.

Check the back of this sheet to make sure you have the proper Audio Video (A/V) cables for this installation. You need to verify the facility source cables and may need to supply some of the connecting cables.

Use all 6 of the 3-1/2” long lag bolts and washers provided in the hardware pack, included with this unit, to mount the Backer Board/Track and Trolley Assembly to a ceiling structure that meets local building codes.

Reference the Installation Guide for more detailed information about each of the steps shown in this Quick

Installation Guide.

Equipment Alert

This installation requires at at least two service technicians.

Track with Light and Monitor weight (max.) is 157 Lbs. (71 kgs).

Step 2

Connect Power, Video Source Cables and the

Monitor Power Supply at the foot end of the chair. wArning

Turn OFF the Facility power to this circuit at the Electrical

Control Panel before wiring the power to this unit.

Remove the cover on the video input source box (four screws).

Remove the power source supply (two nuts).

Connect the monitor power supply, facility power and video source cables.

Facility Power

Video input Source Connections

19 or 24" Monitor

Power Supply

Monitor

Power

Supply

Step 3

install the Light and Monitor Down Tubes.

wArning

These are easily cross-threaded. Ensure down tubes are fully threaded (≈7 revolutions) in to castings and all set screws are installed in place and securely tightened. Failure to do so could allow monitor or light tubes to separate from trolley castings, resulting in serious personal injury to patient or staff.

Screw the Monitor Down Tube into the monitor trolley casting as far as it will go (≈ 7 revolutions) and secure by tightening the two lock patch set screws in the trolley casting.

Monitor

Trolley

Light

Trolley

Facility

Power

Set

Screws remove

Cover

Monitor

Down

Tube

17" Monitor

Power Supply

Light

Down

Tube grounds

Track Video

Connections

Screw the Light Down Tube Weldment into the Light Trolley

Casting as far as it will go (≈ 7 revolutions) and secure by tight ening the two Lock Patch Set Screws in the Trolley Casting.

Step 4

Attach the Monitor Flex Arm to the Down Tube.

A. Place Monitor Pivot Bearing into the Monitor Down Tube.

B. Align the flat on the Pivot Bearing with the weldment flat.

C. insert Key into Slot, Lower Collar over it and tighten the Set Screw

directly over Key in the Slot.

D. Remove screw slide cover off so you can route the cable through

arm to the monitor mount.

E. remove Bracket (2 screws) and install ground wire in the Flex Arm.

F. Slide Arm Cover in place, install screw.

g. Lower Down Tube Cover and install mating Lower Cover onto it.

Cable

Path

Down Tube

Cover (top)

Collar

G

Cable

Path

E

OUT

OUT

Put Key in Slot

Lower Collar

C

Tighten

Set Screw

A

Align flat on Pivot Bearing with the right weldment flat

B

D

Cover

F

Screw

Step 5

Attach the Light Flex Arm to the Down Tube.

B

Equipment Alert

Apply a thin layer of lubricant to the inside of the Light Down Tube and to the outer surface of the bearing shaft.

Step 6

Mount Monitor on the Mount Arm Arm Assembly and plug in cables. install cover. install Side rails and End Cap on Track.

+

Equipment Alert

Verify the cover fits.

Use four M4x7, 12mm long screws/ washers to attach monitor to arm (metric screws are supplied with arm).

Cable

A

Connection

DA2252_a

A. Connect the Light Cable.

B. Slip Light Flex Arm into Down Tube.

C. Align Flex Arm with track, facing head end

(set screw hole will be 180° across from it).

D. rotate Flex Arm as needed to align nearest

two mating Slots then insert Key,

E. Lower Collar over Key.

F. Tighten set screw directly over the Key.

C

Align Flex

Arm with T rack

Set

Screw

Hole

E

Collar

D

Key

F

Set

Screw

DA2258i

OUT

Divide cables around mounting plate, loop at the bottom and plug into the

Monitor.

Attach the Cover to secure cables.

End

Cap

Bracket

Cover

Use a rubber mallet to lightly tap Side rails into the space between the track extrusion and the Backer Board.

Side rail note:

End Cap must be removed to install Side rails.

DA2259

Audio / Video Connections

Basic Setup - Antenna/Cable COAX / DVD Player / Desktop PC

note

Use only single cables that fit the total installation lengths required. Combining smaller cables will result in poor picture quality.

Digital Receiver Setup - Digital Receiver / DVD Player / Desktop PC HD Receiver Setup - HD Receiver / DVD Player / Desktop PC

Cables routed from video source to ceiling

Cables routed from video source to ceiling

Cables routed from video source to ceiling

Desktop or laptop computer

VGA and 3.5mm Audio Cable

DA2109c

VGA Cable

• HD15 male-to-male UXGA cable

• Maximum Length 50 feet

• Double shielded cable construction

• 3 internal coax lines for red, green, and blue

• Ferrites to protect against EMI/RFI on each end

3.5mm Audio Cable (PC audio)

• Maximum length 50 feet

• Single shielded cable construction

Coax Cable

DA2109a

Coax Cable

• RG6 - male-to-male cable

• Triple shielded cable construction

Cable or Satellite receiver

Desktop PC

Desktop or laptop computer

Minimum Cable Specifications for Optimal Output

Cable or Satellite receiver

Monitor Connections

HDMI Cable

DA2109e

HDMI Cable

• HDMI Type A male-to-male cable

• HDMI 1.2 or 1.3 compatible

• Maximum length 50 feet

• Gold plated contacts (shell and pins)

• Triple shielded cable construction

• 24 AWG wire used for twisted pairs

• Ferrites to protect against EMI/RFI on each end

Monitor Connections

17" Monitor Power Supply

Equipment Alert

Always connect as shown. Do not leave any visible cables disconnected.

19 or 24" Monitor Power Supply

Equipment Alert

This document addresses the Midmark monitor.

For non-Midmark monitors, refer to that product’s manual to ensure equipment functions safely including proper input voltage and is in proper working condition before use.

003-10003-00

Page 2

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement