- Computers & electronics

- TVs & monitors

- Wall & ceiling mounts accessories

- Zebra

- Xi4 Rewind Option Series

- Installation Guide

Zebra Xi4 Rewind Option Series Installation Instructions Manual

Add to My manuals29 Pages

Zebra Xi4 Rewind Option Series is designed to enhance the functionality of your Xi4 printer by enabling the rewinding of printed labels for efficient label management and organization. With the rewind option, you can conveniently rewind printed labels onto a rewind spindle, keeping them organized and easily accessible. This feature is particularly useful for applications that require multiple labels to be printed and then rewound for further processing or storage.

advertisement

Rewind Option Kit

Installation Instructions

This kit includes the parts and documentation necessary to install the Media Rewind option into the Xi4™ printers.

Read these instructions thoroughly before attempting to install this option.

Prepare for Installation

Parts List

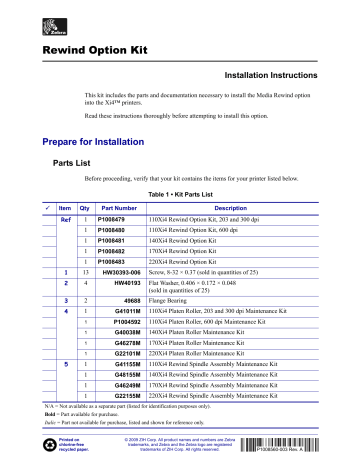

Before proceeding, verify that your kit contains the items for your printer listed below.

Table 1 • Kit Parts List

3 Item Qty

Ref

1

Part Number

P1008479

1 P1008480

1 P1008481

1 P1008482

110Xi4 Rewind Option Kit, 203 and 300 dpi

110Xi4 Rewind Option Kit, 600 dpi

140Xi4 Rewind Option Kit

170Xi4 Rewind Option Kit

Description

1

2

1 P1008483

13

4

HW30393-006

HW40193

220Xi4 Rewind Option Kit

Screw, 8-32 × 0.37 (sold in quantities of 25)

Flat Washer, 0.406 × 0.172 × 0.048

(sold in quantities of 25)

3

4

5

2

1

1

1

1

1

1

1

49688

G41011M

P1004592

G40038M

G46278M

G22101M

G41155M

G48155M

Flange Bearing

110Xi4 Platen Roller, 203 and 300 dpi Maintenance Kit

110Xi4 Platen Roller, 600 dpi Maintenance Kit

140Xi4 Platen Roller Maintenance Kit

170Xi4 Platen Roller Maintenance Kit

220Xi4 Platen Roller Maintenance Kit

110Xi4 Rewind Spindle Assembly Maintenance Kit

140Xi4 Rewind Spindle Assembly Maintenance Kit

1

1

G46249M

G22155M

170Xi4 Rewind Spindle Assembly Maintenance Kit

220Xi4 Rewind Spindle Assembly Maintenance Kit

N/A = Not available as a separate part (listed for identification purposes only).

Bold = Part available for purchase.

Italic = Part not available for purchase, listed and shown for reference only.

Printed on chlorine-free recycled paper.

© 2009 ZIH Corp. All product names and numbers are Zebra trademarks, and Zebra and the Zebra logo are registered trademarks of ZIH Corp. All rights reserved.

P1008560-003 Rev. A

2 Rewind Option Kit

Prepare for Installation

Table 1 • Kit Parts List

3 Item Qty

6

9

10

7

8

1

1

1

1

1

4

1

1

1

1

Part Number

P1006121

P1006122

P1006123

P1006124

P1006105

HW30392-004

HW33810

G41383M

G48383M

G46383M

Description

110Xi4 J-Hook Maintenance Kit

140Xi4 J-Hook Maintenance Kit

170Xi4 J-Hook Maintenance Kit

220Xi4 J-Hook Maintenance Kit

Rewind Roller Adjustment Plate Maintenance Kit

Screw, 6-32 × 0.25 (sold in quantities of 50)

Crescent Ring, 0.25 (sold in quantities of 100)

110Xi4 Rewind Plate Maintenance Kit, non-cutter version

140Xi4 Rewind Plate Maintenance Kit, non-cutter version

170Xi4 Rewind Plate Maintenance Kit, non-cutter version

1 G22383M 220Xi4 Rewind Plate Maintenance Kit, non-cutter version

11

12

1

1

N/A

P1006071

Bearing Housing Assembly, part of rewind spindle maintenance kit

Rewind Drive Pulley, part of rewind drive system maintenance kit

(includes rewind take-up pulley and drive belt)

13

14

1

1

HW33811

P1006072

E-Ring, 0.500 × 0.042 (sold in quantities of 25)

Rewind Drive Belt Maintenance Kit (203 and 300 dpi)

1 P1006073 Rewind Drive Belt Maintenance Kit (600 dpi)

15

16

17

1

1

HW33804

HW30115

Flat Washer, 0.76 × 0.51 × 0.03 (sold in quantities of 25)

Wave Washer, 0.74 × 0.52 × 0.080 (sold in quantities of 25)

1 N/A Rewind Platen Pulley, part of rewind drive system maintenance kit

(includes rewind take-up pulley and drive belt)

18

19

20

1

2

P1006136

HW45937

Take-Label Sensors Assembly Maintenance Kit

Screw, M4 × 10 (sold in quantities of 10)

1 N/A Idler Pulley, part of rewind drive system maintenance kit (includes rewind take-up pulley and drive belt)

21

1 N/A Spacer, part of rewind drive system maintenance kit (includes rewind take-up pulley and drive belt)

22

1 N/A Idler Shaft, part of rewind drive system maintenance kit (includes rewind take-up pulley and drive belt)

23

1 N/A Spacer, part of rewind drive system maintenance kit (includes rewind take-up pulley and drive belt)

24

25

1

1

N/A

N/A

Hex Key (Allen wrench), Long 7/64 in.

Grease

N/A = Not available as a separate part (listed for identification purposes only).

Bold = Part available for purchase.

Italic = Part not available for purchase, listed and shown for reference only.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Prepare for Installation

3

Figure 1 • Kit Contents

3

1 2

11

5

6

10

20

13 23

17

Grease

22

21

25

12

15

16

19

14

24

4

7 3 2

8

9

8

18

18

2

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

4 Rewind Option Kit

Remove the Electronics Cover

Manuals Required

• 110Xi4 User Guide

• 110Xi4 Maintenance Manual

Tools Required

Tools • You need these tools to complete this procedure:

Phillips Screwdriver Set

SAE Nutdriver Set

SAE Hex Key (Allen wrench) Set

Utility Knife

Utility Pliers

Safety Glasses

Metric/Inch Ruler

Spindle Torque Adjustment Kit, Zebra

Part Number 01773

Antistatic Mat and Wriststrap

Push/Pull Gauge 1000g, Zebra Part

Number 11302 or

Push/Pull Gauge 2250g, Zebra Part

Number 11303

Remove the Electronics Cover

Note • Retain all parts removed during disassembly, unless otherwise directed.

1.

Caution • Turn off ( O ) the printer and disconnect it from the power source before performing the following procedure.

Turn off ( O ) the printer and disconnect the AC power cord and all data cables.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Remove the Power Supply

5

2.

See Figure 3 . Remove the electronics cover by removing the three mounting screws securing it.

Figure 2 • Remove the Electronics Cover

Lift up at rear corner.

1

2

1

2

Electronics cover

Mounting screws (3)

3.

Lift up on the rear of the electronics cover and then lift the electronics cover off the printer.

Remove the Power Supply

1.

Which model of the Xi4 are you working on?

If you have… Then…

110Xi4

All others

Go to

Remove the DC Power Supply on page 10 .

.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

6 Rewind Option Kit

Remove the Power Supply

Remove the AC/DC Power Supply

1.

See

Figure 3 . Remove the AC power connector from the AC/DC power supply.

Figure 3 • Disconnect the AC Power Input Cable

1

2

1

2

AC input connector

White plastic beaded cable tie

2.

Open and remove the white plastic beaded cable tie going through the left corner of the

AC/DC shield and around the AC power input cable. Save this tie for reinstallation.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Remove the Power Supply

7

Caution • Certain components located under the insulation shield can store a residual charge for as long as ten minutes after power has been removed. Use extreme care when removing the power supply. Handle the board only by the outer edges.

3.

. Remove the two mounting screws securing the AC/DC power supply shield.

Pull the shield flaps out from behind the AC/DC power supply and remove the shield.

Figure 4 • Remove the AC/DC Power Supply Shield

1

2

1

2

AC/DC power supply shield

Shield mounting screws (2)

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

8 Rewind Option Kit

Remove the Power Supply

4.

Caution • Observe proper electrostatic safety precautions when handling static-sensitive components such as circuit boards and printheads.

Connect yourself to an antistatic device.

5.

See

Figure 5 . Make note of all cables connected to the AC/DC power supply and then

remove them.

Figure 5 • Remove All Cables

J4

J3

J1 J5

J6

J7

J2

J1

J2

J3

J4

J5

J6

J7

Control connector to P26 on the Main Logic

Board

Stepper motor

Head voltage

AC power input

DC output

DC output

DC output

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Remove the Power Supply

9

6.

See

Figure 6 . Remove the mounting two screws and nuts securing the AC/DC power

supply assembly.

Figure 6 • Remove the AC/DC Power Supply

1

2

1

2

3

AC/DC power supply

Mounting nuts (2)

Mounting screws (2)

7.

See

Figure 7 . Lift the AC/DC power supply assembly out of the printer.

Figure 7 • Remove the AC/DC Power Supply

3

AC/DC Power

Supply

12/21/2009

Mounting

Studs

8.

Go to Install the Rewind Option Kit on page 12 .

Xi4 Installation Instruction P1008560-003 Rev. A

10 Rewind Option Kit

Remove the Power Supply

Remove the DC Power Supply

1.

Caution • Observe proper electrostatic safety precautions when handling static-sensitive components such as circuit boards and printheads.

Connect yourself to an antistatic device.

2.

See

. Make note of all cables connected to the DC power supply and then remove them.

1

Figure 8 • Remove all Cables

2

3

6 5

3

4

1

2

5

6

4

J11 data cable from main logic board

J5—J10 DC output to options

J4 stepper motor

J1 AC input from AC power supply

J2 printhead power

J3 printhead power

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Remove the Power Supply

11

3.

See

Figure 9 . Remove the mounting screw and then remove the two mounting nuts.

Figure 9 • Remove the DC Power Supply

2

1

1

2

Mounting screw

Mounting nuts (2)

4.

Lift the DC power supply out of the printer.

5.

Continue with

.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

12 Rewind Option Kit

Install the Rewind Option Kit

Install the Rewind Option Kit

See

for part references.

Install the Idler Pulley

1.

See

. Remove the plastic plug in the lower access hole near the bottom of the side plate.

Figure 10 • Remove the Plastic Plug

1

1

Lower access hole cover

1

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Install the Rewind Option Kit

13

2.

See

Figure 11 . Place a flat washer on the mounting screw. Place the mounting screw and

washer through the lower access hole and idler pulley mounting hole in the main frame.

On the electronics side, install the idler shaft onto the mounting screw.

Figure 11 • Install the Idler Pulley Shaft

4

1

2

3

3

4

1

2

Flat washer

Mounting screw

Idler shaft

Idler pulley

3.

Position the idler shaft in the middle of the mounting hole and tighten. Apply a small amount of grease to the idler shaft, ensuring no grease is on other components.

4.

Slide the idler pulley, flat side facing out, onto the idler shaft.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

14 Rewind Option Kit

Install the Rewind Option Kit

Install the Media Rewind Spindle

1.

Remove and discard the cover plate and screws of the media rewind spindle mounting hole in the lower center portion of the main frame.

Figure 12 • Remove the Front and Cover Plates

1

2 3 4

3

4

1

2

Front cover

Front cover thumbscrews

Rewind platen mounting hole cover

Rewind spindle mounting hole cover

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Install the Rewind Option Kit

15

2.

Install the bearing housing assembly using three screws and three flat washers. Do not tighten the screws at this time.

1

2

Figure 13 • Install the Rewind Bearing Housing

4

2

3

Media Side

3

4

1

2

5

Rewind bearing housing

Mounting holes (3)

Access hole

Flat washers (3)

Mounting screws (3)

5

5

Electronics Side

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

16 Rewind Option Kit

Install the Rewind Option Kit

3.

Caution • Wear protective eyewear when installing or removing E-rings, C-clips, snap rings, springs, and mounting buttons. These are under tension and could fly off.

See

. From the media side, slide the shaft of the media rewind spindle through the bearing housing assembly.

1

Figure 14 • Install the Rewind Spindle

2

3 4

5 6

7 1

5

6

7

3

4

1

2

Rewind spindle shaft

Rewind spindle bearing housing

E-ring

Spacer

Rewind spindle pulley

Flat washer

Wave washer

4.

Caution • Wear protective eye wear when installing or removing E-rings, C-clips, snap rings, springs, and mounting buttons. These are under tension and could fly off.

Place the wave washer, flat washer, and pulley, counter-sunk side facing out, onto the media rewind spindle shaft, then the spacer, and secure with the E-ring.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Install the Rewind Option Kit

17

Install the Rewind Platen Roller

1.

See

. Install the rewind platen support bracket to the side plate using two washers and two screws. Do not tighten the screws at this time.

Figure 15 • Install the Rewind Platen Roller Support Bracket

1

2

4

3

3

4

1

2

Rewind platen roller support bracket

Flat washers (2)

Mounting screws (2)

Rewind platen roller access hole

2.

From the media side, insert the long end of the platen roller shaft into the access hole.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

18 Rewind Option Kit

Install the Rewind Option Kit

3.

See Figure 16 . While holding the rewind platen roller, slide a flange bearing, flange facing

out, onto the platen roller shaft and then into the support bracket.

Figure 16 • Install the Rewind Platen Roller, Media Side

2

3 4 5

2

1

5

3

4

1

2

5

Rewind platen roller access hole

Rewind platen roller shaft

Rewind platen roller support bracket

Flange bearing

C-clip

4.

Caution • Wear protective eyewear when installing or removing E-rings, C-clips, snap rings, springs, and mounting buttons. These are under tension and could fly off.

Slide the short end of the platen roller shaft through the flange bearing and the install the

E-ring to secure it.

5.

Tighten the mounting screws securing the platen support bracket. The bracket may need adjustment later.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Install the Rewind Option Kit

19

6.

From the electronics side slide the flange bearing, flange facing out, onto the rewind platen roller shaft and then into the mounting hole.

Figure 17 • Install the Rewind Platen Pulley

1

2 3

4

12/21/2009

3

4

1

2

Rewind platen roller shaft

Flange bearing

Spacer

Rewind platen roller pulley

7.

Slide the spacer and the platen roller pulley onto the rewind platen shaft.

8.

Align the two pulley set screws with the flat surfaces of the rewind platen shaft and tighten.

The pulley should be positioned with approximately 5 mm (0.20 in.) between the E-ring and the platen support bracket on the media side.

Figure 18 • Platen Pulley and Set Screws

2

1

3

1

2

3

Platen roller flats

Setscrews (2)

Platen roller pulley

Xi4 Installation Instruction P1008560-003 Rev. A

20 Rewind Option Kit

Install the Rewind Option Kit

Install and Adjust the Rewind Drive Belt

1.

See

. Remove the main drive belt by walking it off the ribbon take-up. Pull out on the drive belt while turning the ribbon take-up pulley.

Figure 19 • Remove the Main Drive Belt

1

2

1

2

Main drive belt

Ribbon take-up

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Install the Rewind Option Kit

21

Install the Rewind Drive Belt

1.

See

. Route the media rewind belt around the inner most stepper motor pulley, media rewind pulley, rewind platen pulley, and idler pulley.

Figure 20 • Install the Rewind Drive Belt

1

2

5

3

4

3

4

1

2

5

Rewind drive belt

Stepper motor pulley

Idler pulley

Rewind platen pulley

Rewind spindle pulley

2.

See

. Grasp the idler pulley and shaft assembly while loosening the mounting screw. Slide the assembly toward the rear of the printer until the belt tension is tight, and then retighten the idler pulley mounting screw.

3.

See

. Reinstall the main drive belt on the outer most pulley of the stepper motor and around the platen roller pulley.

4.

Walk the main drive belt onto the ribbon take-up pulley by pushing it onto the pulley while turning the pulley.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

22 Rewind Option Kit

Install the Rewind Option Kit

Adjust the Belt Tensions

1.

See

. Check the belt tension by hooking a spring scale at the midpoint of the lower section of the belt and pull down. The belt should deflect 6.35 mm (0.25 in.) with a tension of 2000 grams (4.5 in. lbs).

Figure 21 • Ribbon Take-Up Pulley

More

Tension

Less

Tension

1

2

3

1

INCHE

S

2

3

4

14

00

16

00

18

00

20

00

22

00

3

4

1

2

Take-up pulley mounting screw access holes (3)

Ribbon take-up pulley

Main drive belt

Stepper motor pulley

2.

Access the three ribbon take-up mounting screws through the three holes in the ribbon take-up pulley. Loosen but do not remove the three ribbon take-up mounting screws.

3.

Slide the media rewind assembly toward the rear of the printer until the belt tension is correct. Tighten the rewind spindle mounting screws.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Install the Rewind Option Kit

23

4.

See

. Check the belt tension by hooking a spring scale at the midpoint of the lower section of the belt and pull up. The belt should deflect 6.35 mm (0.25 in.) with a tension of 2000 grams (4.5 in. lbs).

5

Figure 22 • Adjust the Rewind Drive Belt

1

6

2

3

4

3

4

1

2

5

6

Rewind drive belt

Stepper motor pulley

Idler pulley

Rewind platen pulley

Rewind spindle mounting screw access holes (3)

Rewind spindle pulley

5.

Grasp the idler pulley and shaft assembly while loosening the mounting screw. Slide the assembly toward the rear of the printer until the belt tension is correct, and then retighten the mounting screw.

6.

When adjustment is completed, reinstall the plastic plug in the lower access hole in the print mechanism side plate.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

24 Rewind Option Kit

Install the Rewind Option Kit

Install the Take-Label Sensors

Important • Do not install the take-label sensors on cutter units. The take-label sensors are required in the peel-off mode of operation.

1.

See

. Remove the upper and lower take-label cover plates by removing the screws and pushing cover plate out of the mounting holes.

1

Figure 23 • Install the Take-Label Sensors

4

2

3

1

5

3

4

1

2

5

Cover plate mounting screws (2)

Upper take-label mounting hole

Lower take-label mounting hole

Upper take-label sensor

Lower take-label sensor

2.

Feed the upper sensor cable through the upper mounting hole.

3.

Position the sensor with the window facing down, and secure with the mounting screw.

4.

Feed the lower sensor cable through the lower mounting hole.

5.

Position the sensor with the window facing up, and secure it with the mounting screw.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Rewind Option Kit

Reinstall the Electronics Cover

25

6.

. Connect the upper sensor cable to J2 on the control panel and then connect the lower sensor cable to J3 on the control panel.

Figure 24 • Connect the Take Label Sensor Cables

J2

J3

Reinstall the Electronics Cover

1.

See Figure 2 on page 5 . Reinstall the electronics cover by aligning the cover so that it slips

over the main frame.

2.

Reinstall the mounting screws to secure the electronics cover.

3.

Reconnect the AC power cord and data cable.

4.

Caution • When you are loading media or ribbon, remove all jewelry that could come into contact with the printhead or other printer parts.

Reinstall the media and ribbon.

Configure the Printer

See the User Guide to configure the printer to the Rewind Mode. Rewind Mode rewinds a printed roll of continuous media or a printed roll with liner and labels.

To use this option to dispense individual labels and rewind the media backing only, see the

User Guide to set the printer to the Peel-Off Mode.

The rewind option kit usually requires some adjustments to prevent printing problems such as ribbon wrinkle, non-centered labels, and tearing media. Print a number of test labels to check for problems. Use the following procedures to correct any problems.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

26 Rewind Option Kit

Configure the Printer

Adjust the Tracking

If the media walks from side to side or tears or wrinkles against the backing plate of the media rewind spindle, it may be necessary to adjust the position of the rewind spindle assembly.

1.

See

. If the media cannot be made to track correctly after making this adjustment, check the distance from the backing plate to the main frame. The factory set dimension is 14 mm (0.550 in.) ±0.5 mm (0.020 in.).

Figure 25 • Adjust Rewind Spindle Position

1

2

5

4

3

3

4

1

2

5

Hex key, 7/64 in.

Setscrews (2), located inside spindle

Rewind spindle

Collar, located inside the spindle

Tracking plate

2.

Loosen the two set screws in the collar located inside the rewind spindle assembly near the backing plate. The set screws are accessible through a single hole in the rewind spindle assembly. Reposition the backing plate as required and retighten the set screws in the collar.

P1008560-003 Rev. A Xi4 Installation Instruction 12/21/2009

Adjust Tension

Media that is rewound too tightly can cause mis-registration of labels, tearing, or poor print quality due to smudging. Media rewound too loosely can jam up the printer before completing a roll or make it impossible to separate labels from liner in Peel-Off Mode.

See

to adjust the tension.

1.

Loosen the set screw in the adjusting nut at the end of the rewind spindle assembly.

Figure 26 • Adjust the Spindle Tension

Rewind Option Kit

Configure the Printer

27

1

5

2

4 3

12/21/2009

3

4

1

2

5

Spring gauge

Polyester strip

Adjusting nut

Setscrews (2)

Reinforced hole

2.

Insert a hex key through the access hole at the rear of the rewind spindle assembly into one of the set screws in the collar to prevent the rewind spindle shaft from turning while adjusting the tension.

3.

Position the adjusting nut with fingers or pliers as required.

• in for more tension

• out for less tension

Xi4 Installation Instruction P1008560-003 Rev. A

28 Rewind Option Kit

Configure the Printer

4.

Measure the spindle tension using a spring scale gauge. Place a media core on the spindle and attach a 51 mm (2 in.) wide by 7.6 m (30 in.) long strip of polyester film to the core

with adhesive tape. Wind the film in the direction shown in Figure 26

.

5.

Insert the spring scale tip through the reinforced hole in the end of the strip and pull slowly and evenly, 2 in. (51 mm) per second, in the direction shown. Make this measurement several times to ensure an accurate reading. This tension should be approximately 1400–

1500 grams (1.22–1.3 in. lb.).

6.

Readjust tension as required and recheck the tension setting. Retighten the adjusting nut set screw.

7.

Recheck the tension after running a full roll of labels.

Note • Depending on your application, it may be necessary to deviate slightly from the recommended tension setting shown above.

Adjust the Lower Roller

The lower roller alignment has much the same effect on media tracking as the rewind spindle does in Rewind Mode.

1.

. Loosen the mounting screws securing the platen support bracket to the side plate.

Figure 27 • Adjust Platen Support Bracket

P1008560-003 Rev. A

1

3

4

3

3

4

1

2

Mounting screws (2)

Platen support bracket

Bearing (2)

Lower platen roller

Xi4 Installation Instruction

2

12/21/2009

Rewind Option Kit

Configure the Printer

29

2.

Adjust the bracket as required and tighten the mounting screws.

• Moving the bracket toward the rear of the printer forces the media to wind closer to the large backing plate on the rewind spindle.

• Moving the bracket toward the front of the machine moves the media away from the backing plate.

3.

Perform this adjustment until the required results are achieved.

Adjust Tension

For liner and label combinations that are particularly difficult, it may be necessary to increase the rewind tension in Peel-Off Mode. Follow the same procedure used for the Rewind Mode.

12/21/2009 Xi4 Installation Instruction P1008560-003 Rev. A

advertisement

Key Features

- Media Rewind Capability

- Versatile Roll Management

- Reduced Media Waste

- Enhanced Print Run Efficiency

- Supports Label and Continuous Media

Related manuals

Frequently Answers and Questions

What is the Zebra Xi4 Rewind Option Series?

What types of media are supported by the Rewind Option Series?

How do I adjust the tension of the rewound media?

What are the recommended tension settings for the rewind spindle?

What if the media is not tracking correctly?

advertisement