advertisement

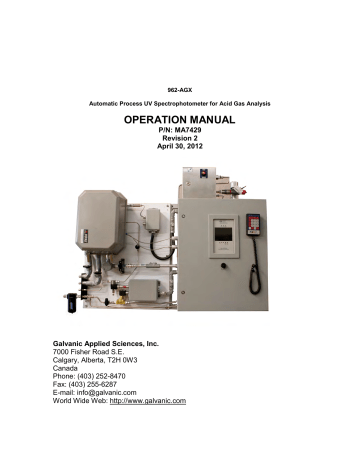

962-AGX

Automatic Process UV Spectrophotometer for Acid Gas Analysis

OPERATION MANUAL

P/N: MA7429

Revision 2

April 30, 2012

Galvanic Applied Sciences, Inc.

7000 Fisher Road S.E.

Calgary, Alberta, T2H 0W3

Canada

Phone: (403) 252-8470

Fax: (403) 255-6287

E-mail: [email protected]

World Wide Web: http://www.galvanic.com

NOTICES

This system is covered by a limited warranty. A copy of the warranty is included with this manual.

The operator is required to perform routine maintenance as described herein on a periodic basis to keep the warranty in effect. For routine maintenance procedures, refer to Section 6.

All information in this manual is subject to change without notice and does not represent a commitment on the part of Galvanic Applied Sciences, Inc.

No part of this manual may be reproduced or transmitted in any form or by any means without the written permission of Galvanic Applied Sciences, Inc.

Note: Changes or modifications not expressly approved by Galvanic Applied Sciences, Inc. could void the user's authority to operate the equipment.

© Copyright 2011, 2012 Galvanic Applied Sciences, Inc. All rights reserved.

Printed in Canada

Table of Contents

S ECTION 1 M ODEL 962-AGX A CID G AS A NALYZER S PECTROPHOTOMETER O VERVIEW ..................... 12

Sample Line and Sample Return Line Connections ............................................ 18

Connection of the Zero Gas Service (Nitrogen) ................................................... 20

Revision 1 3 9/10/2019

The Enron Modbus Protocol ..................................................................... 58

Modicon with Floating Point Protocol ........................................................ 58

Visual Inspection of Key Operating Parameters................................................... 62

Revision 1 4 9/10/2019

Calibrating and Testing the Analog Outputs ............................................. 97

Revision 1 5 9/10/2019

Tables

Revision 1 6 9/10/2019

Safety Symbols used in Manual

The Danger symbol indicates a hazardous situation that, if not avoided will result in death or serious injury.

The Warning symbol indicates a hazardous situation that, if not avoided could result in death or serious injury.

The Caution symbol with the safety alert symbol indicates a hazardous situation that, if not avoided could result in minor or moderate injury.

The Notice symbol is used to highlight information that will optimize the use and reliability of the system.

Revision 1 7 9/10/2019

Important Safety Guidelines for the 962-AGX

Acid Gas Analyzer System

Please read the following warnings and cautions carefully before using the 962-AGX Acid Gas

Analyzer System

This equipment must be used as specified by the manufacturer or overall safety will be impaired.

Access to this equipment should be limited to authorized, trained personnel ONLY.

Due to the thermal mass of the hardware, cooling of the items takes substantial time.

Observe all warning labels on the analyzer enclosures.

The analog outputs and alarm relay contacts may be powered by a source separate from the one (s) used to power the analyzer system. Disconnecting the AC Mains Source (s) may not remove power from the analog output signals or the alarm relay contacts .

Any safety recommendations or comments contained herein are suggested guidelines only.

Galvanic Applied Sciences Inc. bears no responsibility and assumes no liability for the use and/or implementation of these suggested procedures.

This system, when operating in its normal mode, and/or when it is being serviced, maintained, installed and commissioned contains items which may be hazardous to humans if handled or operated incorrectly or negligently. These hazards include, but are not limited to;

• High Voltage Electrical Energy

• Toxic and Explosive Gases

• Intense Ultraviolet Radiation

• High Temperature Surfaces

Access to this equipment should be limited to only to authorized, trained personnel.

Installation of the system requires the opening of the process access point (sample access) to allow for flow of the acid gas sample. To achieve this, stainless steel tubing and Swagelok ® fittings are used. When connections are made, toxic gases may be expelled to the atmosphere until the system sample probe and its associated flange are in place and securely fastened.

It is recommended that the personnel installing the sample and vent connections wear plant approved breathing air apparatus, and approved personal protective equipment (i.e. gloves, coveralls and protective eye wear) suitable for high temperature work. The user’s company safety procedures must be followed when installing the analyzer.

Revision 1 8 9/10/2019

During normal operation, toxic gases, (e.g. H

2

S, and CO

2

) are present in the tubing, measurement cell, and all other system components through which the gas sample flows. They should not be opened before the complete system is purged with zero gas (an inert gas such as nitrogen), and the system is blocked using the two valves identified as Sample Flow and Vent

Flow on/off valves.

Purging of the system should be performed with both valves in the open position and maintained for approximately five (5) minutes. Once purging is complete, and with the purge gas still flowing, the two valves should be switched to the ‘Off’ position. The purge gas can now be shut off and the tubing or associated apparatus opened.

The sampling system will be under positive pressure. Loosen a fitting and allow the pressure to be released before completely disconnecting the tubing.

The measurement cell assembly is enclosed in an oven cabinet that is heated and maintained at approximately 50ºC/120ºF to prevent the condensation of water. Maintenance performed before the cooling of the oven and hardware should be done while wearing suitable protective clothing, eye wear, and gloves to prevent burns to the hands and arms.

Due to the thermal mass of the hardware, cooling of the internal components of the system takes substantial time.

The system includes an ultraviolet spectrometer which employs a source that generates intense

UV radiation that is transmitted to the measurement cell and spectrometer through fibre optic cables.

This radiation is extremely harmful to the naked eye and skin, even in short duration exposures.

Always extinguish the UV radiation source (lamp) before removing a fibre optic cable or the lamp power supply cover by turning the AC power to the lamp power supply ‘Off’. Should the lamp be turned on for any reason while the cover is off, ensure that certified eye protection is worn and that the exposure is limited to the bare minimum.

Although the UV radiation is transmitted through a narrow diameter fibre, it should never be viewed directly. The beam is extremely intense and will cause permanent eye damage. Should visual inspection of the beam be required, point the end of the fibre at an inanimate object and view the illumination reflection. Never expose human skin to the radiation from the optical fibres.

The system is powered by AC Mains (120 or 240 volt) electrical power. Higher level voltages may be present in several system modules where transformers are present (i.e., the UV lamp power supply). Follow user company procedures regarding best practices and safety recommendations for any electrical work, repair, and maintenance.

The 962-AGX analyzer is designed to be safely operated in a Class I, Division 2, Groups C & D,

T3 (NEC and CEC) area by means of a Type Z purge system installed on the analyzer control cabinet. Follow the user company’s published practice and/or regulatory agency’s procedures for initial start-up, operation and shut down of this type of purged system.

Revision 1 9 9/10/2019

Manufacturer’s Warranty Statement

Galvanic Applied Sciences Inc. (“Seller”) warrants that its products will be free from defects in materials and workmanship under normal use and service in general process conditions for 12 months from the date of Product start-up or 18 months from the date of shipping from Seller’s production facility, whichever comes first (the “Warranty Period”). Products purchased by Seller from a third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by the original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable commercial effort to arrange for procurement and shipping of the Resale

Products. Buyer must give Seller notice of any warranty claim prior to the end of the Warranty

Period. Seller shall not be responsible for any defects (including latent defects) which are reported to

Seller after the end of the Warranty Period.

THIS WARRANTY AND ITS REMEDIES ARE IN LIEU OF ALL OTHER WARRANTIES OR

CONDITIONS EXPRESSED OR IMPLIED, ORAL OR WRITTEN, EITHER IN FACT OR BY

OPERATION OF LAW, STATUTORY OR OTHERWISE, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, WHICH SELLER SPECIFICALLY DISCLAIMS.

Seller’s obligation under this warranty shall not arise until Buyer notifies Seller of the defect.

Seller’s sole responsibility and Buyer’s sole and exclusive remedy under this warranty is, at

Seller’s option, to replace or repair any defective component part of the product upon receipt of the Product at Seller’s production facility, transportation charges prepaid or accept the return of the defective Product and refund the purchase price paid by Buyer for that Product. If requested by Buyer, Seller will use its best efforts to perform warranty services at Buyer’s facility, as soon as reasonably practicable after notification by the Buyer of a possible defect provided that Buyer agrees to pay for travel time, mileage from the Seller’s facility or travel costs to the airport / train station closest to Buyer’s facility plus all other travel fees, hotel expenses and subsistence.

Except in the case of an authorized distributor or seller, authorized in writing by Seller to extend this warranty to the distributor’s customers, the warranty herein applies only to the original purchaser from Seller (“Buyer”) and may not be assigned, sold, or otherwise transferred to a third party. No warranty is made with respect to used, reconstructed, refurbished, or previously owned

Products, which will be so marked on the sales order and will be sold “As Is”.

Limitations

These warranties do not cover:

• Consumable items such as lamps.

• Analyzer components which may be damaged by exposure to contamination or fouling from the process fluid due to a process upset, improper sample extraction techniques or improper sample preparation, fluid pressures in excess of the analyzer’s maximum rated pressure or fluid temperatures in excess of the analyzer’s maximum rated temperature. These include but are not limited to sample filters, pressure regulators, transfer tubing, sample cells, optical components, pumps, measuring electrodes, switching solenoids, pressure sensors or any other sample wetted components.

• Loss, damage, or defects resulting from transportation to Buyer’s facility, improper or inadequate maintenance by Buyer, software or interfaces supplied by Buyer, operation

Revision 1 10 9/10/2019

outside the environmental specifications for the instrument, use by unauthorized or untrained personnel or improper site maintenance or preparation.

• Products that have been altered or repaired by individuals other than Seller personnel or its duly authorized representatives, unless the alteration or repair has been performed by an authorized factory trained service technician in accordance with written procedures supplied by Seller.

• Products that have been subject to misuse, neglect, accident, or improper installation.

• The sole and exclusive warranty applicable to software and firmware products provided by Seller for use with a processor internal or external to the Product will be as follows:

Seller warrants that such software and firmware will conform to Seller’s program manuals or other publicly available documentation made available by Seller current at the time of shipment to Buyer when properly installed on that processor, provided however that

Seller does not warrant the operation of the processor or software or firmware will be uninterrupted or error-free.

The warranty herein applies only to Products within the agreed country of original end destination.

Products transferred outside the country of original end destination, either by the Seller at the direction of the Buyer or by Buyer’s actions subsequent to delivery, may be subject to additional charges prior to warranty repair or replacement of such Products based on the actual location of such Products and Seller’s warranty and/or service surcharges for such location(s).

Repaired Products

Repaired products are warranted for 90 days with the above exceptions.

Limitation of Remedy and Liability

IN NO EVENT SHALL SELLER BE LIABLE TO BUYER FOR ANY INDIRECT,

CONSEQUENTIAL, INCIDENTAL, SPECIAL OR PUNITIVE DAMAGES, OR FOR ANY LOSS OF

USE OR PRODUCTION, OR ANY LOSS OF DATA, PROFITS OR REVENUES, OR ANY

CLAIMS RAISED BY CUSTOMERS OF BUYER OR ANY ENVIRONMENTAL DAMAGE OR ANY

FINES IMPOSED ON BUYER BY ANY GOVERNMENTAL OR REGULATORY AUTHORITIES,

WHETHER SUCH DAMAGES ARE DIRECT OR INDIRECT, AND REGARDLESS OF THE

FORM OF ACTION (WHETHER FOR BREACH OF CONTRACT OR WARRANTY OR IN TORT

OR STRICT LIABILITY) AND WHETHER ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES OR NOT.

Revision 1 11 9/10/2019

Section 1 Model 962-AGX Acid Gas Analyzer

Spectrophotometer Overview

The use of an Acid Gas Analyzer to provide a continuous measurement of the H

2

S concentration in the Acid Gas feed stream in Claus sulfur recovery plants is a standard procedure in industry. If a single sulfur plant vents into an incinerator stack equipped with an

SO

2

CEM system or if the sulfur plant is equipped with a Tail Gas analyzer system that can provide an accurate total sulfur number, it is possible to achieve a sulfur balance by knowing the total sulfur into the plant via an Acid Gas analyzer. The acid gas stream is analyzed using ultraviolet spectroscopy and a corresponding output signal is determined.

1.1 Analytical Method

The Model 962-AGX analyzer system measures the broadband absorption of H

2

S in the ultraviolet (UV) region of the electromagnetic spectrum. The UV radiation is supplied from a highly stable deuterium broadband source and is transmitted to and from the measurement cell via UV fibre optic cables. The measurement cell has a specific optical path length through which a sample of the acid gas flows. Light from the source is transmitted to the measurement cell via a fibre optic cable. After passing through the gas space in the measurement cell, it is transmitted to the spectrometer by a second fibre optic cable. The

CCD array converts the light into electrical signals which represent the intensity of the spectral distribution within the band of interest. The spectral data is acquired from the spectrometer by the system controller which calculates the concentration of the H

2

S.

The system includes a spectrometer with the grating efficiency optimized in the spectral region where the species of interest absorb (200-400nm). A detection system is coupled to the grating which is well suited for the desired analysis in terms of sensitivity and resolution while minimizing dark current and stray light noise. To achieve this, a 2048 element CCD detector is employed.

This system design provides for high analytical accuracy beyond that of a conventional photometer (using narrow band optical filters measuring only a few discrete wavelengths) and spectrometers having lower resolution and fewer elements in the detector.

1.2 Analyzer Design

The 962-AGX analyzer system consists of a sample handling panel and a control cabinet mounted to a supporting framework. The oven cabinet, pressure transmitter and all the necessary plumbing, fittings and valving associated with transporting the sample and calibration (zeroing) of the analyzer are mounted to the sample handling panel.

The oven cabinet contains the measurement cell. The interior of the oven cabinet maintains the area classification of the installed location, which is generally Class I, Division 2, Groups

C & D.

Revision 1 12 9/10/2019

The control cabinet contains the electrical hardware necessary for the operation of the analyzer. Under normal operating circumstances, the interior of the control cabinet maintains a general purpose area classification through a Type Z purge system. Both visual and electrical (contact closure) indications are provided for monitoring the status of the control cabinet purge.

1.3 Sample System

The 962-AGX analyzer system utilizes a straight-through flow pattern from the ‘sample in’ to the ‘sample out’ port. A pressure differential is required between the sample probe location and the sample return point. The analyzer plumbing incorporates an adjustable metering valve to control the sample flow rate.

Incoming sample gas is filtered to 60 microns. The measurement cell contains a fixed quantity of sample that is monitored by UV radiation for spectroscopic analysis.

Analyzer zeroing is accomplished by introducing higher pressure zero gas upstream of the measurement cell. The zero gas flushes the entire sample system (probe to vent) and allows readings to be taken through the measurement cell when no absorbing species are present.

To the sample system, zeroing and back purging are identical.

A temperature-controlled oven maintains all components exposed to the gas sample at higher than dew point values and the measurement cell is electrically heated. The typical cell temperature is 50 o C.

1.4 System Operating Control

The analyzer system operation is controlled by a dedicated data acquisition system which provides supervisory control, performs all calculations and provides the user interface.

The system includes a graphic display which provides full screen display of key system control parameters and their status, a digital display of the instantaneous value of the H

2

S, and historical graphic displays of the H

2

S. The display monitor is mounted on the door of the control cabinet. Cabinet access is not required for viewing or operation.

The H

2

S output can be configured as a loop powered 4 – 20 mA signal and the system status is available via relay contacts. An RS485 serial port is also provided which can be used for

Modbus communication.

A hand held key pad is provided for user interface with the analyzer. Operation of the system with the keypad is described in Section 4. As an alternative, a web based graphical user interface (GUI) can be used to view and enter information on a remote basis (Section 5).

Revision 1 13 9/10/2019

1.5 Contents of this Manual

This manual contains the following information:

• Section 1: Model 962-AGX Tail Gas Analyzer Spectrophotometer Overview presents introductory information about spectrophotometry and the system.

• Section 2: Installation describes unpacking the system, installing it in the facility and interfacing with other devices.

• Section 3: Operation of the System explains how the operator interacts with the system

• Section 4: System Control- Hand Held Keypad describes how the user enters data and views system parameters using the hand held keypad.

• Section 5: System Control - Web Based Operation describes how the user controls the system and views system parameters using a remote computer via the Internet

• Section 6: Maintenance describes a series of activities which should be performed on a routine basis to optimize system performance.

• Section 7: Service contains a description of actions to be taken to remedy faults in the system.

• Section 8: Quality Assurance describes the testing performed during manufacturing and provides test results.

• Section 9: Drawings includes mechanical engineering drawings and wiring diagrams that assist in location of items in the system.

• Section 10: Specifications presents the principal specifications of the analyzer.

• Section 11: Spare Parts lists the suggested spare to support operation of the system.

Revision 1 14 9/10/2019

Section 2 Installation

2.1 Receiving the System

When the system arrives, inspect the packaging for external signs of damage. If there is any obvious physical damage, immediately contact the shipping agent and Galvanic Applied

Sciences to report the damage and request that the carrier's agent be present when the unit is unpacked. It is recommended that you retain the shipping container so that it may be used for future shipment of the unit, if necessary.

2.2 Environmental Requirements

2.2.1 Electrical Requirements

The power input is 110/220 V, 1 phase, 50/60 Hz, 15 A. The operating voltage is specified on the serial number name plate.

2.2.2 Temperature

The system is designed to be operated at ambient temperatures (10 – 50 o C) .

Galvanic offers complete analyzer shelters from sun shades to complete building, please contact Galvanic

Applied Sciences, Inc. (or your local representative) for additional information.

2.2.3 Space Requirements

The system is mounted on a frame with the outside dimensions of 57” (145 cm) W x 41” (104 cm) H x 16” 41 cm) D. The control cabinet has dimensions of 30” (76 cm) x 24” (61 cm) W x

12” (30 cm) D.

2.2.4 Instrument Air

The system requires < 15 SCFM at 80 psi.

2.2.5 Nitrogen (Zero Gas)

Bottled, Regulated

2.2.6 Area Classification

Class 1, Division 2, Groups C and D. (Type Z pressurized)

Revision 1 15 9/10/2019

2.3 Unpacking

The 962-AGX analyzer system is packed for shipment in a wooden crate.

To unpack the system: a) Remove the lid by undoing the marked lag bolts. b) Once the lid is off, remove the excess packing material and boxes from the shipping crate. c) Visually inspect the small packages to ensure that no major damage has occurred. If damage has occurred, contact the shipping company and Galvanic Applied Sciences.

Place the small packages aside in a safe, secure storage area as they are not needed at this stage of the system installation.

The analyzer weighs approximately 250 lb/113 kg. Use suitable precautions when removing it from the crate and placing it in the facility. d) Locate and remove the four (4) bolts that secure the analyzer framework to the 2' x 4' boards at the bottom of the shipping crate. e) Once the bolts are removed, the analyzer system can be lifted from the crate. f) Lay the analyzer system frame onto a structurally strong and level surface and inspect for any visual damage. g) Remove the plastic wrap from the analyzer system to gain access to the doors of the cabinets. h) Open the cabinet doors and carefully remove the packing material from inside the cabinet.

Care should be taken while removing the cabinet packing material so that no hardware or wiring is damaged. i) Inspect the internal equipment to ensure that no damage has occurred and that no components have become loose during transport.

If any damage is visible contact Galvanic Applied Sciences Inc. immediately and do not proceed with the system installation. Do not attempt to facilitate repairs yourself as this will negate and/or invalidate any possible insurance claim or equipment warranty. j) If no damage is apparent, the analyzer system is ready for transport to the installation

(sample point) site. The analyzer system framework has two (2) lifting rings located at the top. Installation of proper clevises is recommended. The lifting rings are rated for approximately 227 kg / 500 lbs per ring.

Revision 1 16 9/10/2019

2.4 Installation Steps

Installation of the 962-AGX analyzer system consists of the following steps

• • Mounting of the Analyzer System (Section 2.4.1)

• • Sample Line and Sample Return Line Connections (Section 2.4.2)

• • Connection of the AC Power Service (Section 2.4.3)

• • Connection of the Analog Signal Cables (Section 2.4.4)

• • Connection of the Digital Signal Cables (Section 2.4.5)

• • Connection of the Instrument Air Services (Section 2.4.6)

• • Connection of the Zero Gas Service (Section 2.4.7)

• • Connection of the ‘Loss of Purge Signal’ (Section 2.4.8)

The user should read each step and make certain that it is fully understood before proceeding to installing the analyzer.

2.4.1 Mounting of the Analyzer System

The framework that is used in the analyzer system must be securely attached to a support structure provided by the end user.

The analyzer should be tightly bolted in place. The analyzer system frame has four (4) 3/4" diameter holes to accommodate the mounting to the plant support structure. The plant support structure should be suitable for mounting the analyzer frame as shown in Figure 2-1.

Figure 2-1: Customer Connections

Figure 2-1 indicates the location of the various connections that have to be made.

Revision 1 17 9/10/2019

2.4.2 Sample Line and Sample Return Line

Connections

Follow all plant/company safety procedures for wotk on toxic gases (e.g.

H

2

S) during the sample and vent connection line procedures.

The analyzer is designed to analyze the H

2

S in the acid gas stream at line pressures. A sample line (316 stainless steel, 1/4" tubing) should be connected from the block valve at the process sample point probe to the 1/4" tube connector labeled ‘Sample Gas Inlet’. Ensure that the analyzer sample system block valve is in the Off position before connecting the sample line. The block valve is labeled Sample Inlet Shut Off Valve . Refer to the Service

Connections drawing (Figure 2-2) for the connection location.

The vent line (316 stainless steel, 1/4" tubing) should be connected to the block valve at the process low pressure sample return point. Connect the analyzer end of the vent line to the

1/4" tube connector labeled Sample Gas Outlet . Ensure that the analyzer vent system block valve is in the Off position before connecting the vent line. The block valve is labeled ‘ Sample

Outlet Shut Off Valve’ . Refer to the Customer Connections drawing (Figure 2-1) for the connection location.

Once both the sample and vent lines are installed, leave the block valves at both ends of each line closed (Off). Pressure checking for leaks will be done at the time of analyzer commissioning by Galvanic Applied Sciences,

Inc. personnel.

2.4.3 Connection of the AC Power Service

A conduit connection is provided on the control cabinet for the AC power connection (s) as shown in the Mounting and Service Connections drawing (Section 9). The AC power is connected to the terminals inside the cabinet as shown in the AC Power Distribution drawing

(Figure 9-4).

Open all of the fused terminals by lifting up on the tab.

Installation of the conduit, wiring and disconnect devices must comply with all applicable national, local and user electrical codes.

DO NOT energize the AC service to the analyzer system. This will be done at time of commissioning by Galvanic Applied Sciences Inc. personnel .

Revision 1 18 9/10/2019

2.4.4 Connection of the Analog Signal Cables

One conduit connector labeled ‘Analog Signals’ is provided on the bottom of the control cabinet for the signal cable connection as shown in Mounting and Service Connections drawing,. The analog output signals are available at the terminals shown in the Customer

Signal Outputs drawing (Section 9). The user may connect to any of all of the available signals. The shields from the signal cable pair should be connected to the ‘shld’ terminals.

Installation of the conduit, wiring and disconnect devices must comply with all applicable national, local and user electrical codes.

2.4.5 Connection of the Digital Signal Cables

One conduit connector labeled ‘Digital Signals’ is provided on the bottom of the control cabinet for the signal cable connections as shown in the Mounting and Service connections drawing,

The alarm relay contacts are available at the terminals shown in the Inputs/Outputs drawing

(Figure 9-3). The relays are shown in the ‘alarm’ state. The user may connect to any or all of the available signals. The signal cable pair shields should be connected to the ground terminals provided.

Installation of the conduit, wiring and disconnect devices must comply with all applicable national, local and user electrical codes. The connection (s) must be ‘sealed’.

2.4.6 Connection of Instrument Air Services

The installation of the 962-AGX analyzer system requires the connection of instrument air service to the control cabinet air purge/cooler valve. Instrument air service should be 80 to

100 psig of clean, dry instrument air (ANSI/ISA Standard 57.3-1975 R (1981)). Service to the analyzer must be capable of a sustained flow of 900 SCFH at 80 to 100 psig.

It is recommended that a particulate filter be installed in the instrument air line before final connection to the analyzer system valve. Blow down the air lines to remove any possible debris such as dirt, scale, water, oil, etc., before connection to the analyzer system.

Purging of the control cabinet is required in respect of the hazardous area classification and to mitigate corrosive element exposure on the system electrical equipment. As soon as practical, initiate cabinet purge until the analyzer is commissioned by Galvanic Applied

Sciences, Inc.

Revision 1 19 9/10/2019

2.4.7 Connection of the Zero Gas Service

(Nitrogen)

A supply of oxygen free, high purity nitrogen (N

2

) in tank, complete with a two stage regulator and shut-off valve is required.

The 962-AGX analyzer system is analyzing a stream containing a high H

2 concentration. Oxygen (O

2

) should be used.

) can NOT be used as a zero gas and Nitrogen

S

(N

2

Connect the N

2

supply to the analyzer, system at the 1/4" tube fitting labeled ‘Zero Gas Inlet’ using 1/4" 316 stainless steel tubing as shown in figure 2-1.

Leave the main valve of N

2

tank closed as the complete N

2

zero gas system will be pressure leak checked at the time of analyzer commissioning.

2.4.8 Connection of Loss of Purge Signal

There is a pressure switch to indicate loss of sufficient control cabinet protective purge air flow as shown in the Figure 2-1.

The user must connect the Loss of Purge Signal to a plant alarm system in a constantly attended area in order to maintain a Class I, Division 2 area approval of the analyzer.

Purging of the control cabinet is required in respect of the hazardous area classification and to mitigate corrosive element exposure on the system electrical equipment. As soon as practical, initiate cabinet purge until the analyzer is commissioned by Galvanic Applied

Sciences Inc.

The control cabinet purge flow control valve is located inside the purge control box mounted on top of the analyzer. To open the purge control box use the supplied purge system access key. As soon as system air is available, initiate a small purge air flow rate through the control cabinet. Normal purge flow rates can not be adjusted until all conduit connections are sealed, and the control cabinet door is latched closed.

Revision 1 20 9/10/2019

Section 3 Operation

3.1 Overview

The 962-AGX analyzer system is designed to operate automatically with a minimum need for human intervention. Once installed, commissioned and the initial start-up procedures have been completed, the only human intervention required is when the system indicates a problem or when routine preventative maintenance is scheduled.

The user interaction program is described in Chapter 4 and web based operation is discussed in Chapter 5.

The analyzer system computer automatically performs all of the normal operational procedures including delete sample flow initiation, analysis, on-line calibration, range sensitivity selection, fault detection, and oven temperature control. Operators are alerted to an abnormal state or fault occurrence through indicators on the display on the front panel and the output alarm contact closures.

The only manual adjustments to system controls (not through the computer) are the zero gas, sample and enclosure purge/cooling air flows.

All valves are clearly labeled according to their title and function.

3.2 Flow Control Settings

There are three flow control settings which govern system operation. Once the system has been commissioned and the flow rates have been set, only occasional adjustments should be required. Flow settings will be checked and verified when doing the recommended routine preventative maintenance procedure.

Revision 1 21 9/10/2019

3.2.1 Cabinet Purge Air Flow Adjust Valve

The Cabinet Purge Air Flow Adjust Valve controls the rate of purge air entering the control cabinet. The Cabinet Purge Air Flow Adjust Valve is located inside the purge control box mounted on top of the analyzer. (The access key is required to open the purge control box.)

As a minimum, this valve is adjusted (with the control cabinet closed) until the control cabinet purge pressure indicator goes from Red to Green plus ½ a turn. If the control cabinet overpressure relief valve (mounted on the exterior upper right-hand side) opens, reduce the cabinet purge flow rate until the valve is midway between the safe purge indication flag (Red to Green transition) and the over-pressure release point (audible ‘flapping’ of the relief valve).

The safe purge indication (Red to Green flag) occurs at a control cabinet pressure of 1" water column (with respect to barometric pressure). The over-pressure relief valve opens at a cabinet pressure of 4" water column. The normal control cabinet purge flow rate is 1.3 scfm, as governed by selected orifices mounted in the cabinet purge vents.

Purging of the control cabinet is required in respect of the hazardous area classification and to mitigate corrosive element exposure on the system electrical equipment. This adjustment must be performed with the ‘Cabinet Cooler Air Valve’ closed.

Seventeen (17) minutes of normal purge air flow is required before the interior of the control cabinet may be considered safe (i.e. power applied).

3.2.2 Cabinet Cooler Air Valve

The system provides on/off control of the air to the cabinet cooler via a solenoid operated valve with respect to a configuration set-point. The Cabinet Cooler Air Valve is located on the top of the analyzer behind the purge box. The Cabinet Cooler Air Valve is a coarse flow rate adjustment of air to the vortex tube cabinet cooler (typically on or off with minor throttling possible). The temperature is displayed on the front panel as Control Cabinet Temperature .

When control cabinet cooling air is on, the additional purging flow will cause the overpressure relief valve to open.

3.2.3 Sample Flow Adjust Valve

The Sample Flow Adjust Valve controls the rate of process sample gas through the analyzer.

In practice, the sample flow adjustment is made to obtain a nominal five (5) second stabilized sample response time from a zeroing state. This adjustment is made by monitoring the time required for the analyzer display outputs of gas concentration to return to a stable process level after the zero state has been released .

The length of the sample inlet line impacts the flow rate required to obtain the desired response time.

Revision 1 22 9/10/2019

3.3 Analyzer Outputs

The 962-AGX analyzer generates both analog and digital output signals for connection to the users’ plant control system. The analog signals include the measured concentrations of H

2

S.

The provided digital signals (relay contacts) represent indications of the current analyzer and enclosure purge state.

3.3.1 Analog Outputs

The 962-AGX has one loop powered 4-20 mA signal for H

2

S concentration. The full scale output for this signal is configurable.

3.3.2 Digital Outputs

There are four (4) digital outputs available from the analyzer. The digital outputs are present in the form of zero potential form C relay contacts. The digital outputs are isolated to 250

V rms

. The digital outputs are provided to indicate analyzer operational status. The operational status outputs are:

• Status (Fault / Normal)

• Service (Warning / Normal)

• Mode (Calibrate / Run)

• Control (Manual / Auto). a) Status (Fault / Normal) Indicator

The Status (Fault / Normal) output provides analyzer system readiness information.

Before ‘Normal’ status indication is given, the analyzer temperature zones and the spectrometer signal must be within the specific set point ranges. This indicator will be in the ‘Normal’ state only when ALL of the following are true:

• The analyzer is receiving mains power.

• The cell temperature is between the cell ‘Low Alarm’ temperature and ‘High Alarm’ temperature set points.

• The last spectrometer ‘Measure’ scan was within range.

• The last spectrometer ‘Reference’ scan was within range.

• The last spectrometer ‘Dark’ scan was within range.

The purpose of this indicator is to signify an analyzer problem. When this indicator is in the ‘Fault’ state, the analyzer will continue to flow sample gas but the reading is considered to be invalid. Should the fault causing criterion clear, the analyzer will automatically return to ‘Normal’ status .

b) Service (Warning / Normal) Indicator

The Service (Warning / Normal) output indicates when service is requested. This indicator will be in the ‘Normal’ state unless one or more of the following is true:

• The control cabinet temperature is below 15ºC or over 40ºC.

• The spectrometer integration period is greater than 500 ms.

• The peak value of the absorbance vector is greater than 2.0.

• The peak value of the raw scan during last zero is less than16000 counts .

Revision 1 23 9/10/2019

The purpose of this indicator is to signify the analyzer is approaching the extremes of optimum levels. When this indicator is in the Warning state, the analyzer will continue to function normally, producing useable outputs. The analyzer will self-clear the ‘Warning’ condition and automatically return to Normal status once the offending parameter is found to be within range. c) Mode (Calibrate / Run) Indicator

The Mode (Calibrate / Run) output indicates when a zero calibration or a manually requested forced zero purge is in progress. This indicator will be in the ‘Run’ state unless one of the following is true:

• A clock triggered (auto) zero calibration sequence is in progress.

• A manually requested zero calibration sequence is in progress.

• The analyzer has been placed in the ‘Force Zero’ mode (manually).

• The analyzer is not receiving mains power.

When this indicator is in the Calibrate state, the analyzer is not measuring the process acid gas. When, during a calibration sequence, the zero calibration adjustment is complete, this indicator is held in the Calibrate state for a period of time specified by the

Zero Hold Interval configuration parameter. This buffer period allows the analyzer to draw process gas and commence measurement before clearing the Calibrate i ndicator. At the expiration of the Zero Hold Interval, this indicator returns to the Run state. d) Control (Manual / Auto) Indicator

The Control (Manual / Auto) output indicates the validity of the analog output signals.

When this indication is in the Auto state, the analyzer believes that output data are real and current measurements of the tail gas process stream. Under conditions where the validity of the output data is suspect, the analyzer places the Control flag in the Manua l state. This indicator will be in the Auto state only when ALL of the following are true:

• The Status indicator is in the Normal state ( i.e. no instrument fault).

• The Mode indicator is in the Run state ( i.e. not in calibration).

• The computer’s front panel On Line / Off Line switch in is the On Line position ( i.e. not being serviced).

• The analyzer is receiving mains power.

The purpose of this indicator is to signify when the analyzer outputs are suitable for use as closed loop control inputs. When this indicator is in the ‘Manual’ state, no control action should be taken on the basis of the analyzer output signals. This indicator is generated on the basis of the other analyzer indicators, as well as the condition of the manual On Line / Off Line selection on the display. The Control flag state is automatically returned to Auto once the offending condition (s) has cleared. When in Manual , the Track and Hold outputs are held. e) Typical Usage of the Digital Indicators

For most applications, connection of the Control indicator to the plant control room is all that is required. From an operations perspective, it is only important to know that analyzer data are valid or not. It is insignificant to an operator what the actual cause of invalid data is, but it is important that the data be known to be invalid. It is desirable to enunciate the state change of this indicator from Auto to Manual . Although the 962-AGX software

Revision 1 24 9/10/2019

automatically holds the last valid H

2

S concentration signal analog output going to the control room, operations personnel benefit from the knowledge of when a change in status occurs. f) The Control Cabinet Safe Purge Indication employs a contact switch indicating the status of the control cabinet purge. This connection is independent of the other analyzer outputs. A visual indication of purge status is provided on the purge control box (Red =

Unsafe, Green = Safe).

Revision 1 25 9/10/2019

Section 4 System Control - Hand Held Keypad

4.1 The User Interaction Program – Overview

The system includes an onboard computer, display panel and a hand held keypad that is local to the analyzer. As an alternative, a web based graphical user interface (GUI) can be used to view and enter information on a remote basis.

4.2 Using the Onboard Display and Hand Held Keypad

4.2.1 The Onboard Display

The main screen of the onboard display is presented in Figure 4-1. There are six panels which are accessed via pressing the Panel Prev or Panel Next buttons on the keypad (Figure

4-2). The various panels are described in Section 4.3-4.8. The main panel presents the current H

2

S concentration, a trend of the historical H

2

S concentration, status of the relays and access to the Manual Zero and Back Purge function.

Figure 4-1: Main Screen of the Onboard Display (Analysis 1 Panel)

Revision 1 26 9/10/2019

The dot in the upper right corner indicates that the system is monitoring a sample. If the system is monitoring samples it will be green. If the Back Purge function is selected (see

Section 4.3.5), the system is performing a Manual Zero operation (Section 4.3.4) or if the system is offline, the dot will be red. This dot is common to all panels.

4.2.2 The Hand Held Keypad

The hand held keypad (Figure 4-2) is used to navigate between the various panels and enter information.

Figure 4-2: Hand Held Keypad

The buttons on the keypad provide the following:

• Panel Prev - Changes the active panel to the previous panel.

• Panel Next - Changes the active panel to the next panel.

• Field Prev - Moves the cursor to the previous entry on the active panel for editing.

• Field Next - Moves the cursor to the next entry on the active panel for editing.

• Home - Returns the Analysis 1 panel.

• Purge - Toggles from Back Purge to Sample.

• Del Deletes the last numerical value.

• Exit - Erases the current input.

• Enter - Used to enter numerical information on various tabs.

Revision 1 27 9/10/2019

4.3 The Analysis 1 Tab

The Analysis 1 tab (Figure 4-1) presents a summary of the present status of the system

4.3.1 Online/Offline Button

Clicking the Online / Off Line button changes the status from On Line (green) to Off Line (red) and vice-versa. When the analyzer is changed to Off Line, the relay indication for Control is forced to the Manual state (amber).

The state of the On Line / Off Line button does not affect the operation of the analyzer. The ability to remotely signal plant operations using the relay output of the Control (in conjunction with the On Line / Off Line button) has been incorporated as a convenience to the user. The

On Line / Off Line function essentially provides a method of signaling that the analyzer data is invalid (undergoing maintenance or servicing).

When returning the analyzer to Online status, the relay indication for Control will return to the

Auto state only if no fault or calibration conditions exist.

The plot displays the H

2

S concentration as a function of time. The range for the x and y axes can be edited as described in Section 4.8.

4.3.2 H

2

S Field

The H

2

S, field indicates the present value of the concentration and cannot be edited. The analyzer physical scaling is optimized for the measurement of the typical H

2

S concentration in the acid gas.

Revision 1 28 9/10/2019

4.3.3 Relay Indicator Fields

The relay indicators show the state of the analyzer outputs: a) Status

Normal (Green) status indicates that the system is working properly

Fault (Red) status indicates that the computer has detected an error in one of the critical analyzer functions. The Status indicator and alarm relay are placed in a fault state. The analyzer will continue to flow sample although the reading is considered to be invalid. An occurrence of a fault status automatically forces the ‘Control’ to Manual. b) Service

Normal (Green) status indicates that service is not required

Warning (yellow) indicates that the computer has detected that one of the parameters for a warning condition is out of range. This indicates that service is requested but not required immediately. The analyzer continues to function normally, producing usable outputs. c) Mode

Run (Green) status indicates that the system is in Run mode

Calibrate (Amber) indicates that a zero calibrate sequence is in progress. At the end of the calibration sequence the Mode indicator returns to Run . A manually initiated Force

Zero condition also causes a Calibrate mode. The mode alarm relay contacts are changed in conjunction with the indicator. An occurrence of the Calibrate mode automatically forces the Control to Manual. d) Control

Auto (Green) indicates that the analyzer output signals are deemed to be a valid measurement of the process gas stream and may be used for control purposes if desired.

Manual (amber) indicates that the analyzer output signals should be assumed to be invalid (with respect to process stream measurement) and should not be used for control purposes. The analyzer automatically forces the Control indicator to Manual in case of any analyzer fault, a calibration sequence in progress (either manual or auto), or a user initiated Off Line request

Revision 1 29 9/10/2019

4.3.4 Manual Zero

The Manual Zero button starts the zero calibration sequence of the analyzer which incorporates the checking and adjusting of the instrument zero (baseline). No span correction is required under normal circumstances on an installed analyzer. The calibration sequence is identical whether trigger manually or automatically.

When triggered, the calibration sequence proceeds in the following order: a) The Mode relay outputs changes to Calibrate and the Control relay changes to Manual. b) The zero gas solenoid is energized and zero gas is introduced into the measurement cell and is allowed to purge the measurement cell for the number of seconds specified by the

Zero Purge Interval configuration parameter (Section 4.8.xx). c) At the conclusion of the Zero Purge Interval , the computer averages the last ten (10) spectrometer scans and determines a new reference scan vector (captures the new zero value). At this time the zero gas solenoid is de-energized to allow sample gas to flood the cell. d) The analyzer waits for the number of seconds specified by the Zero Hold Interval parameter of the configuration data (Section 4.8) e) During this period, process sample gas is drawn into the measurement cell and the displayed concentration values will rise from zero to the measured values. The Zero Hold

Interval allows the analyzer concentration outputs to stabilize at on-line values before the outputs are updated. f) Mode and Control relay outputs signal change to Normal at the expiration of the Zero

Hold Interval (barring a pre-existing fault condition).

4.3.5 Back Purge

The default condition of the analyzer is to have sample gas flowing through the sample cell.

When Back Purge is selected, the analyzer sampling system is continuously back purged with zero gas. This is useful as a precursor to maintenance activities or when long term purging is required.

4.3.6 Graphic Display

The Graphic display of the H

2

S concentration is updated once per second. The time and intensity scales can be set on the Config panel (Section 4.8).

Revision 1 30 9/10/2019

4.4 Analysis 2 Panel

The Analysis 2 panel (Figure 4-3) presents the present and historical H

2

S concentration in a single graphic window. The Cell Pressure and Temperatures fields indicate the instantaneous readings for these parameters, updated every second.

Figure 4-3: Analysis 2 Panel

The default full scale values and the time scale can be set on the Config panel (Section 4.8). using a range between 0% and the configured full scale analog output concentration. The default full scale values are determined at software restart to a range between ± the configured full scale analog output value for the H

2

S signal.

Revision 1 31 9/10/2019

4.5 Indicators Panel

The Indicators panel (Figure 4-4) is used to present details of the last 25 fault and warning events. The current status of each of the items is indicated on the right side and the last 25 events are indicated on the grid. A discussion of the causes and remedies for the faults is presented in Section 8.

Green - System is functioning within the accepted range

Yellow - System requires service

Red - System is not functioning properly

To clear the present display, use the Field Next or Field Previous buttons to activate the

Clear Fault/Warning History button and press Enter.

Revision 1

Figure 4-4: Indicators Panel

32 9/10/2019

4.6 Spectrum Panel

The Spectrum Panel (Figure 4-5) displays the present spectrum and allows the operator to change the integration time. The Peak Height , First Vector Pixel and Dark Level refer to the instantaneous readings for those parameters.

Figure 4-5: Spectrum Tab

The Integration time refers to the period of time for which the data is collected to provide a data point and is a compromise to optimize the resolution while minimizing the noise in the spectrum. A short integration time will optimize the resolution; however the noise may be relatively high. If a long integration period is employed, the resolution may be compromised and small features in the spectrum may be lost, however the noise in the spectrum is reduced.

The optimum integration time for the present set of conditions can be obtained by pressing the Optimize Integ. Time button. Note that the backpurge must be on to introduce zero gas to the cell before the integration time can be adjusted.

If desired, the operator can select the integration time by selecting the Set Integ. Tim e button which will present the Integration Period dialog box (Figure 4-6). To change the time, enter the desired value and press Okay .

Revision 1 33 9/10/2019

Figure 4-6: Integration Period Dialog Box

The Factory Reference spectrum refers to a spectrum of zero gas this was saved at the time of analyzer calibration at the factory. If the Show Factory Reference check box is selected, the spectrum will be superimposed on the same set of axes as the active spectrum (Figure

4-7).

Figure 4-7: Factory Reference Spectrum Superimposed on Spectrum

Revision 1 34 9/10/2019

New Reference - saves the scan to be used as a reference for calculation without turning solenoids and related activities, like the ZERO button would do (this button is used predominantly for troubleshooting purposes)

Peak Height - Height of the highest point in the spectrum

First Vector Pixel - The instantaneous reading at the pixel corresponding to the starting wavelength.

Dark Level - the signal from dark current

4.7 Absorbance Panel

The Absorbance panel (Figure 4-8) presents the Absorbance spectrum and reports the concentration of H

2

S.

The range can be edited on the Config panel (Section 4.8).

Revision 1

Figure 4-8: Absorbance Tab

35 9/10/2019

4.8 Config Panel

The Config panel is used to set a broad range of operating parameters and includes 8 subpanels. The Configuration Panel should be accessed only by qualified personnel.

4.8.1 Config Outputs Sub-Panel

The Outputs sub-panel (Figure 4-9) is used to define the H

2

S analog output. The Analog

Output Full Scale field can be used to set the full scale range for the H

2

S output level. If the field is selected, a dialog box similar to that shown in Figure 4-6 is presented to enter the desired value.

Figure 4-9: Outputs Sub-Panel

Revision 1 36 9/10/2019

4.8.2 Calculation Sub-Panel

The Calculation sub-panel (Figure 4-10) is used to set several calibration parameters.

Figure 4-10: Calculation Sub-Panel

To edit a parameter, use the Field Prev or Field Next button to access the field and press

Enter. A dialog box similar to Figure 4-6 will be presented. Enter the desired value, select the

Okay button and press Enter .

Revision 1 37 9/10/2019

When all desired changes have been made, select Save . Selecting Revert will keep the parameter values that were used before the start of the editing process. a) H2S Span - This parameter specifies the span factor utilized for the H

2

S concentration display and output. This value should always be close to 1.0.

Any deviation of the H

2 of the analyzer.

S span parameter will impact the output calibration b) Cell Length - Indicates the cell length of the measuring cell. c) Fixed Temperature - To select Fixed Temperature, navigate to the Fixed Temperature on/off field using the Field Next button on the keypad. Use the Enter key to toggle the x on and off in this field. If the x is present, the analyzer will use the temperature indicated here when calculating the concentration of the H

2

S. If the x is not present, the analyzer will use the live value for cell temperature when calculating the concentration of the H

2

S. d) Fixed Pressure - To select Fixed Pressure navigate to the Fixed Pressure on/off field using the Field Next button on the keypad. Use the Enter key to toggle the x on and off in this field. If the x is present, the analyzer will use the pressure indicated here when calculating the concentration of the H

2

S. If the x is not present, the analyzer will use the live value for cell pressure when calculating the concentration of the H

2

S.

4.8.3 Display

The Display sub-panel (Figure 4-11) is used to set the X and Y range for the display on the

Analysis 1 and Analysis 2 panels.

Revision 1 38 9/10/2019

Figure 4-11: Display Sub-Panel

To edit a parameter, use the Field Prev or Field Next button to access the field, enter the desired value for the parameter via the keypad and press Enter .

The X range is from 1-15 min and the Y range is from 0.1 to 1000.

When all desired changes have been made, select Save . Selecting Revert will keep the parameter values that were used before the start of the editing process.

Revision 1 39 9/10/2019

4.8.4 Timers/Alarms

The Timers/Alarm panel is presented in Figure 4-12.

Figure 4-12: Timers/Alarms Sub-panel

To edit a parameter, use the Field Prev or Field Next button to access the field. A dialog box similar to Figure 4-6 will be presented. Enter the desired value for the parameter via the keypad and press Enter .

When all desired changes have been made, select Save . Selecting Revert will keep the parameter values that were used before the start of the editing process.

Revision 1 40 9/10/2019

a) Timers

Auto Cal Interval - The time period between automatic calibrations. The range is 0 -

16,666 minutes. This parameter defines the integer time interval, in minutes, between autocalibration cycles. A value of zero (0) disables the auto-calibration function. An autocalibration is simply an automated Manual Zero sequence. Typical values are between

60 (once every hour) and 1440 (once every day). The auto-calibration will not run if the analyzer is in a fault condition.

Zero Purge Interval - The length of time (integer number of seconds) that zero gas is allowed to flush the measurement cell during the purging part of the calibration sequence, before a new Reference value is computed. The interval must be at least ten (10) seconds longer than the time typically required to flush the measurement cell of the sample. During the last ten (10) seconds of this interval, data is accumulated for the computation of the new ‘Reference’ value. The interval is typically greater than fifteen

(15) seconds.

The Auto Cal Interval is timed from the completion of the last zero sequence, whether manually or automatically initiated.

Zero Hold Interval - The length of time (integer number of seconds) that the relay outputs and indicators are held in a calibration state after a new zero has been established.

During this time interval, process sample gas flows into the measurement cell and the concentration outputs climb to actual readings. At the expiration of this interval, relay outputs and indicators are returned to a valid data state. This value is typically fifteen (15) seconds. b) Temperature Control

Cell Setpoint -This parameter specifies the temperature control setpoint of the measurement cell in degrees C (ºC). This set point is typically 50 – 80 C.

Cell Prop Band -This parameter specifies the proportional term (in percent) used in the

PID temperature control algorithm for the measurement cell heater. This value is typically

1.0%.

Cabinet Set Point (ºC) - This parameter specifies the set point temperature, in degrees C

(ºC), of the control cabinet. This value is typically 35ºC. If the cabinet set point temperature is exceeded, the cabinet cooling air solenoid is energized to deliver air to the cabinet Vortec cooler.

Cabinet Deadband (ºC) - This parameter specifies the control cabinet set point deadband in degrees C (ºC). This parameter is typically set to 5 or more to reduce the number of solenoid cycles .

Aux Set Point (ºC) - The 962-AGX is equipped with a spare on/off temperature control output. This parameter specifies the set point temperature, in degrees C (ºC) at which the auxiliary temperature control device is turned on.

Aux Deadband (ºC) - This parameter specifies the auxiliary device set point deadband, in degrees C (ºC).

Revision 1 41 9/10/2019

c) Alarms

Low Cell (ºC) - This parameter specifies the set point temperature, in degrees C (ºC), which will cause a Low Cell Temperature fault. When the measured cell temperature falls below this value, the analyzer is placed in a Fault condition. The relay outputs and Status indicator are forced to ‘Fault’, and the Control indicator is forced to ‘Manual’.

There is a three (3) degree deadband imposed on this alarm. The alarm will clear when the measured cell temperature rises to more than 3ºC above the set point. If at the time of clearing, no other fault conditions exist, the analyzer will return to a normal operating condition. The relay outputs and Status indicator will return to Normal and the Control indicator will return to Auto. This value is typically 40 o C.

Low Aux - This parameter specifies the set point temperature, in degrees C (ºC), which will cause a Low Auxiliary Device Temperature fault. When the measured auxiliary device temperature falls below this value, the analyzer is placed in a Fault Delay condition. The relay outputs and Status indicator are forced to Fault , and the Control indicator is forced to Manual .

4.8.5 Network Sub Panel

The Network sub-panel is presented in Figure 4-13. The parameters on this sub-panel are set during manufacturing and are not editable by the user.

The information under the Network column shows the connection data for the web GUI.

The information under the Direct Connect column shows the connection data for the laptop

Ethernet port.

Revision 1 42 9/10/2019

Figure 4-13: Network Sub-Panel

Revision 1 43 9/10/2019

Section 5 Web Based Operation

5.1 Overview

The Acid Gas Analyzer can be monitored, configured and controlled by use of a Web GUI on a personal computer. The Web GUI can be used to interface to the analyzer in two ways: through a local area network or by direct connection. The analyzer will have a different IP address for the network connection and for the direct connection.

The IP addresses of the analyzer for the network connection and for the local connection are shown on the local display of the analyzer by using the keypad to navigate to the

Config/Network panel (Figure 4-13).

To establish a connection to the analyzer with the Web GUI, simply type the IP address of the analyzer into the address line of any web browser.

Changes that are made via the Web GUI and saved to the analyzer will be shown on the local display.

When communication between the remote computer and the analyzer is established, the

Analysis page is presented. The left side of the page contains a menu which is used to access the various pages of the program and the right side presents information about the status of the system and plots showing the most recent data as described in Section 5.2.

The various pages in the program can be accessed by expanding the list with the + sign and clicking on the desired page. As an example, Figure 5-1 shows the expanded Analysis section, which has five pages.

Figure 5-1: Program Menu

When you access a page, the bottom of the left column will present a short explanation of the items on the page and provide information about entering parameter values.

Revision 1 44 9/10/2019

The web based program is divided into four major sections, each of which has one or more pages. The major sections are listed on the left side of the window and the pages in a given section can be accessed by expanding the list with the + sign and clicking on the desired page. As an example, the Analysis section has five pages.

When you access a page, the left column will present a short explanation of the items on the page and provide information about entering parameter values.

5.2 Analysis Section

5.2.1 Analysis Page

The Analysis page includes a display (Figure 5-2) containing the present concentration value, pressure and temperature information, an indication of the present system status, the

Sample/Back Purge status, the manual Zero controls and the status of various relays.

Figure 5-2: Analysis Page Information Display

5.2.1.1 Value Display

• H2S - The present value of the concentration of H

2

S. The physical scaling of the analyzer is optimized for the measurement of the typical H

2

S concentration in the acid gas.

• Cell Pressure - The pressure inside the measuring cell.

• Cell Temperature - The present temperature of the measuring cell in degrees C (ºC).

• Aux Temperature - The present temperature of the auxiliary device in degrees C (ºC).

• Cabinet Temperature - The present temperature of the cabinet in degrees C (ºC).

The reported values are live and cannot be edited on this page. The temperature and pressure setpoints and alarm setpoints for the temperature and pressure can be edited on the Configuration page (Section 5.3).

Revision 1 45 9/10/2019

5.2.1.2 Status and Control

• Online Status - A green indicator and the word Online is presented if the instrument is online. A flashing red indicator and the word Offline is presented if the unit is offline.

The state of the Online/Offline button does not affect the operation of the analyzer. The ability to remotely signal plant operations using the relay output of the Control indicator (in conjunction with the Online/Offline button) has been incorporated as a convenience to the user. The Online/Offline function essentially provides a method of signaling to the operator that the analyzer data is invalid (i.e. the system is undergoing maintenance or servicing).

When returning the analyzer to Online status), the relay indicator for Control (see below) will return to the Auto state only if no fault or calibration conditions exist.

• Sample/Backpurge - A green indicator and the word Sample is presented if sample is being monitored. A flashing red indicator and the words Back Purge is presented if zero gas is being monitored. The option of sample or back purge is effected by the buttons directly below the Sample/Backpurge line. The default condition of the analyzer is to have sample gas flowing through the sample cell.

• Manual Zero - The Manual Zero button starts the zero calibration sequence of the analyzer which incorporates the checking and adjusting of the instrument zero (baseline). No span correction is required under normal circumstances on an installed analyzer. The calibration sequence is identical whether trigger manually or automatically.

When triggered, the calibration sequence proceeds in the following order: a) The Mode relay outputs changes to Calibrate and the Control relay changes to Manual . b) The zero gas solenoid is energized and zero gas is introduced into the measurement cell.

The zero gas is allowed to purge the measurement cell for the number of seconds specified by the Zero Purge Time parameter on the Parameters page (Section 5.3.1). c) At the conclusion of the zero purge interval, the computer averages the last ten (10) spectrometer scans and determines a new reference scan vector (captures the new zero value). At this time the zero gas solenoid is de-energized to allow sample gas to flood the cell. d) The analyzer waits for the number of seconds specified by the Zero Hold Interval parameter on the Parameters page (Section 5.3.1). e) During this period, process sample gas flows into the measurement cell and the displayed concentration values will rise from zero to the measured values. The Zero Hold

Interval allows the analyzer concentration outputs to stabilize at on-line values before the outputs are updated. f) Mode and Control relay outputs signal change to Normal at the expiration of the Zero

Hold Interval (barring a pre-existing fault condition).

• Sample - The Sample button is used to indicate that the sample gas should be allowed to flow through the system. The Sample/Purge indicator will be green and the word

Sample will be indicated when sample is flowing through the system.

Revision 1 46 9/10/2019

• Back Purge The Back Purge button is used to indicate that zero gas (purge gas) should be allowed to flow through the system. The Sample/Purge indicator will be flashing red and the words Back Purge Sample will be indicated when zero gas is flowing through the system. When Back Purge is selected, the analyzer sampling system is continuously back purged with zero gas. This is useful as a precursor to maintenance activities or when long term purging is required.

• Manual Zero - The Manual Zero button is used to initiate a zero sequence.

5.2.1.3 R

elay Indicator

Fields

The Relay Indicators show the state of the analyzer outputs: a) Status

Normal (Green) status indicates that the system is working properly.

Fault (Red) status indicates that the computer has detected an error in one of the critical analyzer functions. The Status indicator and alarm relay are placed in a fault state. The analyzer will continue to flow sample although the reading is considered to be invalid. An occurrence of a fault status automatically forces the Control to Manual . b) Service

Normal (Green) status indicates that service is not required

Warning (Red) indicates that the computer has detected that one of the parameters for a warning condition is out of range. This indicates that service is requested but not required immediately. The analyzer continues to function normally, producing usable outputs. c) Mode

Run (Green) status indicates that the system is in Run mode

Calibrate (Amber) indicates that a zero calibrate sequence is in progress. At the end of the calibration sequence the Mode indicator returns to Run . A manually initiated Zero operation also causes a Calibrate mode. The mode alarm relay contacts are changed in conjunction with the indicator. An occurrence of the Calibrate mode automatically forces the ‘Control’ to Manual. d) Control

Auto (Green) indicates that the analyzer output signals are deemed to be a valid measurement of the process gas stream and may be used for control purposes if desired.

Manual (Amber) indicates that the analyzer output signals should be assumed to be invalid (with respect to process stream measurement) and should not be used for control purposes. The analyzer automatically forces the Control indicator to Manual in case of any analyzer fault, a calibration sequence in progress (either manual or auto), or a user initiated ‘Off Line’ request

Revision 1 47 9/10/2019

5.2.1.4 Graphic Display

The graphic display of the H

2

S Trend is updated once per second (Figure 5-3). The latest reading is at the extreme right of the plot.

Figure 5-3: H

2

S Trend Plot

If desired, the Y axis scaling can be changed. Right click on the plot to present a dialog box

(Figure 5-4) in which the desired Ymin and Ymax can be entered.

The graphic display of the H2S concentration is updated once per second. The latest reading is at the extreme right of the plot.

If desired, the Y axis scaling can be changed. Right click on the plot to present a dialog box in which the desired Ymin and Ymax can be entered.

Revision 1

Figure 5-4: Y-Axis Range Dialog Box

48 9/10/2019

5.2.2 Calibration Matrix Page

The Calibration Matrix page (Figure 5-5) allows for viewing of the calibration matrix used by the spectrometer for the analysis of the gas.

Click on the page to present the calibration matrix used by the spectrometer (Figure 5-3 in the determination of the H

2

S concentrations. The calibration matrix is uniquely determined for a particular spectrometer.

Figure 5-5: Calibration Matrix

If a spectrometer is replaced, a new calibration matrix must be loaded onto the system computer. Consult Galvanic Applied Sciences for the procedure.

The calibration matrix is a 9 x 530 element array used in conjunction with the computed absorbance vector to determine the concentration of the H2S present in the measurement cell. Galvanic Applied Sciences, Inc. determines the calibration matrix by incorporating H2S molar absorptivity data with the specific spectral resolution and sensitivity characteristics of a particular spectrometer. The purpose of displaying the contents of the calibration matrix is to provide a means of matrix identification, should the need arise.

Revision 1 49 9/10/2019

5.2.3 Indicators Page

The Indicators page (Figure 5-6) is used to present details of the last 25 fault and warning events. The last 25 events are indicated on the grid and the most recent report is on the right side. A discussion of the causes and remedies for the faults is presented in Section 7.2.

Figure 5-6: Indicators Page

The colours used on the Indicator page are:

• Green - System is functioning within the accepted range

• Red - System is not functioning properly

Revision 1 50 9/10/2019

5.2.4 Spectrum Curve Page

The Spectrum Curve page (Figure 5-7) displays the present spectrum and lets the operator change the integration time. The spectrum data is updated every second.

Figure 5-7: Spectrum Curve

Revision 1 51 9/10/2019

The X and Y coordinates of a data point on the curve can be determined by moving the mouse over the desired point on the spectrum.

The Display Factory Reference check box is used to indicate that the factory reference spectrum should be superimposed on the collected spectrum. This feature is useful in checking the system

The Peak Height, First Vector Pixel and Dark Level refer to the instantaneous readings for those parameters.

The Integration time refers to the period of time for which the data is collected to provide a data point and is a compromise to optimize the resolution while minimizing the noise in the spectrum. A short integration time will optimize the resolution; however the noise may be relatively high. If a long integration period is employed, the resolution may be compromised and small features in the spectrum may be lost, however the noise in the spectrum is reduced.

The optimum integration time for the present set of conditions can be obtained by pressing the Optimize Integ. Time button. The analyzer must be in Backpurge mode before the spectrometer’s integration time can be optimized.

If desired, the operator can select the integration time by selecting the Set Integ. Tim e button; this will present the Integration Period dialog box to set the time.

The Panorama field can be used to select a sub-section of the spectrum for viewing. To zoom in on a section of the spectrum, click the Stop Polling check box and then use the mouse to draw a box around the area of interest.

The Save Spectrum button accesses a dialog box to save the present spectrum in CSV format.

5.2.5 Absorbance

The Absorbance page (Figure 5-8) presents the Absorbance spectrum and reports the concentration of H

2

S .

The range can be edited on the Config panel (Section 4.8).

Revision 1 52 9/10/2019

Figure 5-8: Absorbance Curve

The Panorama field can be used to select a section of the spectrum for viewing. Use the mouse to define the region of the spectrum that is to be viewed.

If desired, the operator can edit the Y by selecting the Change Absorbance Curve Display Y

Axis button. This will present a dialog box to enter the desired upper and lower limits similar to Figure 5-2.

Revision 1 53 9/10/2019

5.3 Parameters Section

5.3.1 Parameters

The Parameter s page (Figure 5-9) lists a number of system parameters which can be viewed or edited.

Figure 5-9: Parameters Page

When the page is opened, the Read Only mode is active .

• The pink background color groups all temperature related parameters.

• The blue background color groups all concentration related parameters.

• The gray background color groups all timer/zero operation related parameters.

• The green background color groups all other parameters.

Revision 1 54 9/10/2019

To change a parameter: a) Click on the “ Change to Update Mode ” field. A prompt for the password entry will appear.

The default password is 2222. b) Click on the parameter that requires editing. The field for that parameter will change to a white background. c) Edit the parameter by typing in a new value. Some parameters such as Fixed

Temperature Enable can be edited by using the pull down selection menu. d) Press Enter on the keyboard. e) Press the Save to Unit button. This will cause the changed parameters to be implemented in the analyzer.

Pressing the Revert button before pressing the Save to Unit button will undo the edit .

5.3.2 Modbus

5.3.2.1 Overview

The Modbus page (Figure 5-10) allows the user to set up the acid gas analyzer to output data in 3 varieties of MODBUS communication protocol - Enron , Modicon 16 , and Modicon

Floating Point . As there are a large number of possible configurations for Modbus, and every user may desire a slightly different configuration, this manual will only cover the basics of

Modbus configuration. If the user requires assistance in setting up a Modbus configuration, the Service Department at Galvanic Applied Sciences Inc. will be pleased to assist in configuring the unit as desired.

Revision 1 55 9/10/2019

Figure 5-10: MODCON - MODCON32 Format

To set up a new Modbus list, press Change to Update Mode to present a dialog box for the password. After the password is entered, the New Load and Save buttons will be activated.

To select a different Modbus type, press New to present the Modbus Type dialog box (Figure

5-11).

Revision 1

Figure 5-11: Modbus Type Dialog Box

56 9/10/2019

Select the desired Modbus type and press OK. As an example, if the ENRON selection is made, the presentation appears as shown in Figure 5-12,

Figure 5-12: MODBUS-ENRON Format