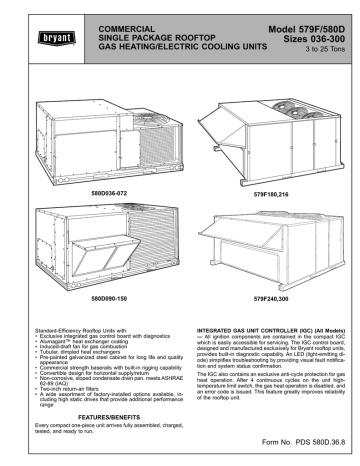

ARI Capacity Ratings. Bryant 579F, 580D

Add to My manualsadvertisement

ARI* CAPACITY RATINGS (cont)

HEATING CAPACITIES AND EFFICIENCIES — 580D036-150

UNIT 580D

036 074

036 115

048 074

048 115

048 150

060 074

060 115

060 150

072 074

072 115

072 150

090 125

090 180

090 224

102 125

102 184

102 224

120 180

120 224

120 250

150 224

150 250

HEATING INPUT

(Btuh)

Stage 2/Stage 1

—/ 72,000

115,000/ 82,000

—/ 72,000

—/115,000

150,000/120,000

—/ 72,000

—/115,000

150,000/120,000

—/ 72,000

—/115,000

150,000/120,000

—/125,000

180,000/120,000

224,000/180,000

—/125,000

180,000/120,000

224,000/180,000

180,000/120,000

224,000/180,000

250,000/200,000

224,000/180,000

250,000/200,000

OUTPUT CAPACITY

(Btuh)

59,200

92,000

59,200

92,000

120,000

59,200

92,000

120,000

59,200

92,000

120,000

100,000

144,000

179,200

100,000

144,000

179,200

144,000

179,200

200,000

179,200

200,000

TEMPERATURE

RISE

(F)

25-55

55-85

25-55

35-65

50-80

25-55

35-65

50-80

25-55

35-65

50-80

20-50

35-65

45-75

20-50

35-65

45-75

35-65

35-65

40-70

35-65

40-70

AFUE

(%)

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

LEGEND

AFUE — Annual Fuel Utilization Efficiency

NOTE: NOx levels are 40 nanograms/joule or less with the accessory NOx reduction kit (sizes 036-060).

STEADY-STATE

EFFICIENCY

(%)

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

80.0

CALIFORNIA

SEASONAL

EFFICIENCY

(%)

77.2

76.7

77.2

77.1

76.9

77.2

77.1

76.9

77.2

77.1

76.9

75.8

77.1

77.1

75.8

77.1

77.1

77.1

77.1

76.4

77.1

76.4

HEATING CAPACITIES AND EFFICIENCIES — 579F180-300

UNIT 579F

180 230

180 300

216 275

216 360

240 275

240 360

300 275

300 360

HEATING INPUT

(Btuh)

Stage 2/Stage 1*

230,000/172,000

300,000/225,000

275,000/206,000

360,000/270,000

275,000/206,000

360,000/270,000

275,000/206,000

360,000/270,000

OUTPUT CAPACITY

(Btuh)

186,000

243,000

223,000

292,000

223,000

292,000

223,000

292,000

TEMPERATURE

RISE

(F)

15-45

30-60

15-45

20-50

15-45

20-50

15-45

20-50

*All units are 2-stage heat.

NOTE: Minimum allowable temperature of mixed-air entering the heat exchanger during first-stage heating is 45 F. There is no minimum mixed-air temperature limitation during second-stage heating.

For entering-air temperatures below 45 F both stages of heat must be energized together to minimize condensation issues and to ensure proper unit operation.

STEADY-STATE

EFFICIENCY

(%)

81.0

81.0

81.0

81.0

81.0

81.0

81.0

81.0

MINIMUM

HEATING

CFM

3800

3800

4750

5450

4750

5450

4750

5450

7

PHYSICAL DATA — 580D036-072

UNIT SIZE 580D

NOMINAL CAPACITY (tons)

OPERATING WEIGHT (lb)

Unit

Al/Al*

Al/Cu*

Cu/Cu*

Economizer

Durablade

Parablade

Roof Curb†

COMPRESSOR

Quantity

No. Cylinders (per Circuit)

Oil (oz)

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb-oz)

Circuit 1

Circuit 2

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Quantity...Diameter (in.)

Motor Hp...Rpm

Watts Input (Total)

EVAPORATOR COIL

Rows...Fins/in.

Total Face Area (sq ft)

EVAPORATOR FAN

Quantity...Size (in.)

Type Drive

Nominal Cfm

Motor Hp

Maximum Continuous Bhp

Motor Frame Size

Nominal Rpm High/Low

Fan Rpm Range

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Diameter Min/Max (in.)

Nominal Motor Shaft Diameter (in.)

Fan Pulley Pitch Diameter (in.)

Nominal Fan Shaft Diameter (in.)

Belt, Quantity...Type...Length (in.)

Pulley Center Line Distance (in.)

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns

From Closed Position

Factory Setting

Factory Speed Setting (rpm)

Fan Shaft Diameter at Pulley (in.)

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

*Evaporator coil fin material/condenser coil fin material. Contact your local representative for details about coated fins.

†Weight of 14-in. roof curb.

036

3

460

465

468

34

42

115

1

2

50

048

4

470

476

482

34

42

115

Hermetic

060

5

490

497

505

34

42

115

1

2

50

1

2

50

R-22

Acutrol™ Feed Device

072

6

565

576

587

34

42

115

1

2

54

3-6

—

1...17

7.36

3500

1...22.0

1 ⁄

4

...1100

325

4-11

—

5-13

—

Enhanced Copper Tubes, Aluminum Lanced Fins

1...17

11.39

1...17

13.19

1

4000

325

Propeller Type

1...22.0

⁄

4

...1100

1

4000

1...22.0

⁄

4

...1100

325

7-8

—

2...17

10.42

4000

1...22.0

1 ⁄

4

...1100

325

1...10 x 10

1...10 x 10

Direct

Belt

1200

—

—

.34

1.00

48

48

860/800

—

—

760-1000

Ball

2100

—

1.9/2.9

1 ⁄

2

1 ⁄

2

—

4.5

—

—

1...A...34

—

10.0-12.4

—

48

—

5

—

3

—

856

1 ⁄

2

2...15

4.17

Enhanced Copper Tubes, Aluminum Double-Wavy Fins

2...15

5.5

3...15

5.5

4...15

5.5

Centrifugal Type

1...10 x 10

1...10 x 10

Direct

Belt

1600

—

—

.75

1.00

48

48

1075/970

—

—

835-1185

Ball

2100

—

1.9/2.9

1 ⁄

2

1 ⁄

2

—

4.0

—

—

1...A...34

—

10.0-12.4

—

70

—

5

—

3

—

975

1 ⁄

2

1...11 x 10

1...10 x 10

Direct

Belt

2000

—

—

1.20

1.80

48

48

1075/970

—

—

900-1300

Ball

2100

—

2.4/3.4

1 ⁄

2

1 ⁄

2

—

4.5

—

—

1...A...39

—

14.7-15.5

—

80

—

5

—

3

—

1060

1 ⁄

2

—

4.5

—

—

1...A...40

—

14.7-15.5

—

80

—

5

—

3

—

1225

—

1 ⁄

2

1...10 x 10

—

Belt

—

2400

—

—

2.40

—

56

—

—

—

1070-1460

—

Ball

2100

2.8/3.8

—

5 ⁄

8

**Rollout switch lockout is manually reset by interrupting power to unit or resetting thermostat.

††Requires an optional or accessory Controls Upgrade Kit.

NOTE: The 580D036-150 units have a loss-of-charge/low-pressure switch (accessory or option) located in the liquid line.

8

PHYSICAL DATA — 580D036-072 (cont)

UNIT SIZE 580D

036

MEDIUM/

HIGH HEAT

048

LOW/MEDIUM/

HIGH HEAT

060

LOW/MEDIUM/

HIGH HEAT

072

LOW/MEDIUM/

HIGH HEAT

FURNACE SECTION

Rollout Switch Cutout

Temp (F)**

Burner Orifice Diameter

(in. ...drill size)

Natural Gas

Liquid Propane

Pilot Orifice Diameter

(Quantity) in. ...drill size

Natural Gas

Liquid Propane

Thermostat Heat Anticipator

Setting (amps)

208/230 v and 575 v Stage 1

Stage 2

460 v Stage 1

Stage 2

Gas Input (Btuh) Stage 1

Stage 2

Efficiency (Steady

State) (%)

Temperature Rise Range

Manifold Pressure (in. wg)

Natural Gas

Liquid Propane

Gas Valve Quantity

Gas Valve Pressure Range

Psig in. wg

Field Gas Connection

Size (in.)

Std

Alt

Std

Alt

Std

Alt

HIGH-PRESSURE SWITCH (psig)††

Standard Compressor

Internal Relief (Differential)

Cutout

Reset (Auto.)

LOW-PRESSURE SWITCH (psig)††

Cutout

Reset (Auto.)

FREEZE PROTECTION

THERMOSTAT (F)**

Opens

Closes

OUTDOOR-AIR INLET SCREENS

Quantity...Size (in.)

RETURN-AIR FILTERS

Quantity...Size (in.)

195

.113...33

.089...43

—

—

.14

.14

.14

.14

80

25-55/55-85

3.5

3.5

1

0.180-0.487

5.0-13.5

1 ⁄

2

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

*Evaporator coil fin material/condenser coil fin material. Contact your local representative for details about coated fins.

†Weight of 14-in. roof curb.

195

.113...33/.113...33/.129...30

72,000/82,000 72,000/115,000/120,000

—/115,000 —/—/150,000

80

25-55/35-65/50-80

3.5

3.5

1

0.180-0.487

5.0-13.5

1 ⁄

2

450 ± 50

428

320

30 ± 5

45 ± 5

Cleanable

Throwaway

195

.113...33/.113...33/.129...30

1...20 x 24 x 1

2...16 x 25 x 2

80

25-55/35-65/50-80

3.5

3.5

1

1

0.180-0.487

5.0-13.5

⁄

2

80

25-55/35-65/50-80

3.5

3.5

1

0.180-0.487

5.0-13.5

1 ⁄

2

500 ± 50

428

320

**Rollout switch lockout is manually reset by interrupting power to unit or resetting thermostat.

††Requires an optional or accessory Controls Upgrade Kit.

NOTE: The 580D036-150 units have a loss-of-charge/low-pressure switch (accessory or option) located in the liquid line.

195

.113...33/.113...33/.129...30

.089...43/.089...43/.102...38 .089...43/.089...43/.102...38 .089...43/.089...43/.102...38

—

—

.14

.14

.14

.14

7 ± 3

22 ± 7

—

—

.14

.14

.14

.14

72,000/115,000/120,000

—/—/150,000

—

—

.14

.14

.14

.14

72,000/115,000/120,000

—/—/150,000

9

PHYSICAL DATA — 580D090-150

UNIT SIZE 580D

NOMINAL CAPACITY (tons)

OPERATING WEIGHT (lb)

Unit

Al/Al*

Al/Cu*

Cu/Cu*

Economizer

Durablade

Parablade

Roof Curb†

COMPRESSOR

Quantity

No. Cylinders (per Circuit)

Oil (oz)

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb-oz)

Circuit 1

Circuit 2

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Quantity...Diameter (in.)

Motor Hp...Rpm

Watts Input (Total)

EVAPORATOR COIL

Rows...Fins/in.

Total Face Area (sq ft)

EVAPORATOR FAN

Quantity...Size (in.)

Type Drive

Nominal Cfm

Motor Hp

Maximum Continuous Bhp

Motor Frame Size

Nominal Rpm High/Low

Fan Rpm Range

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Diameter Min/Max (in.)

Nominal Motor Shaft Diameter (in.)

Fan Pulley Pitch Diameter (in.)

Nominal Fan Shaft Diameter (in.)

Belt, Quantity...Type...Length (in.)

Pulley Center Line Distance (in.)

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns

From Closed Position

Factory Setting

Factory Speed Setting (rpm)

Fan Shaft Diameter at Pulley (in.)

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

Std

Alt

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

*Evaporator coil fin material/condenser coil fin material. Contact your local representative for details about coated fins.

†Weight of 14-in. roof curb.

090

7 1

2

2

⁄

2

870

881

893

44

62

143

50 ea

102

8 1 ⁄

2

880

896

907

44

62

143

Hermetic

120

10

1035

1057

1080

44

62

143

2

2

50 ea

2

2

50 ea

R-22

Acutrol™ Feed Device

1050

1077

1100

44

62

143

**Rollout switch lockout is manually reset by interrupting power to unit or resetting thermostat.

††Requires an optional or accessory Controls Upgrade Kit.

NOTE: The 580D036-150 units have a loss-of-charge/low-pressure switch (accessory or option) located in the liquid line.

150

12

2

2

1 ⁄

2

54 ea

4-13

4-14

1...17

20.50

6500

2...22

1 ⁄

4

...1100

600

6-14

6- 3

5-13

5-14

Enhanced Copper Tubes, Aluminum Lanced Fins

2...17

18.00

2...17

17.42

1

6500

2...22

600

Propeller Type

⁄

4

...1100

1

7000

2...22

⁄

4

...1100

600

8-10

8- 8

2...17

25.00

7000

2...22

1 ⁄

4

...1100

600

1...15 x 15

1...15 x 15

Belt

Belt

3000

—

—

2.40

—

56

—

—

590-840

685-935

Ball

2100

2.4/3.4

2.8/3.8

5 ⁄

8

—

7.0

7.0

—

1...A...49

1...A...49

16.75-19.25

16.75-19.25

50

50

5

5

5

5

590

685

1

3...15

8.0

Enhanced Copper Tubes, Aluminum Double-Wavy Fins

3...15

8.0

3...15

10.0

4...15

11.1

Centrifugal Type

1...15 x 15

—

Belt

—

3400

—

—

2.40

—

56

—

—

685-935

—

Ball

2100

2.8/3.8

—

5 ⁄

8

—

7.0

—

—

1...A...49

—

16.75-19.25

—

50

—

5

—

5

—

685

—

1

1...15 x 15

1...15 x 15

Belt

Belt

4000

—

—

2.40

2.90

56

56

—

685-935

835-1085

Ball

2100

2.8/3.8

3.4/4.4

5 ⁄

8

7 ⁄

8

7.0

7.0

—

1...A...49

1...A...49

15.85-17.50

15.85-17.50

50

50

5

5

5

5

685

835

1

1...15 x 15

1...15 x 15

Belt

Belt

5000

—

—

4.20

5.25

56

56

—

860-1080

900-1260

Ball

2100

4.0/5.0

3.1/4.1

7 ⁄

8

7 ⁄

8

8.0

5.9

—

1...A...52

1...BX...46

15.85-17.50

15.85-17.50

44

50

5

6

5

5

860

960

1

10

PHYSICAL DATA — 580D090-150 (cont)

UNIT SIZE 580D

FURNACE SECTION

Rollout Switch Cutout

Temp (F)††

Burner Orifice Diameter

(in. ...drill size)

Natural Gas

Liquid Propane

Pilot Orifice Diameter

(Quantity) in. ...drill size

Std

Alt

Natural Gas

Liquid Propane

Thermostat Heat Anticipator

Setting (amps)

208/230 v and 575 v Stage 1

Stage 2

460 v Stage 1

Stage 2

Std

Alt

Gas Input (Btuh) Stage 1

Stage 2

Efficiency (Steady

State) (%)

Temperature Rise Range

Manifold Pressure (in. wg)

Natural Gas

Liquid Propane

Gas Valve Quantity

Gas Valve Pressure Range

Psig in. wg

Field Gas Connection

Size (in.)

Std

Alt

HIGH-PRESSURE SWITCH (psig)††

Standard Compressor

Internal Relief (Differential)

Cutout

Reset (Auto.)

LOW-PRESSURE SWITCH (psig)††

Cutout

Reset (Auto.)

FREEZE PROTECTION

THERMOSTAT (F)**

Opens

Closes

OUTDOOR-AIR INLET SCREENS

Quantity...Size (in.)

090

LOW/MEDIUM/

HIGH HEAT

195

.120...31

.096...41

—

—

120

LOW/MEDIUM/

HIGH HEAT

195

.120...31/.120...31/.129...30 .120...31/.129...30

.096...41/.096...41/.102...38 .096...41/.102...38

—

—

150

LOW/

MEDIUM HEAT

195

—

—

.14

.20

.14

.20

.14

.20

.14

.20

.14

.20

.14

.20

.14

.20

.14

.20

125,000/120,000/180,000 125,000/120,000/180,000 120,000/180,000/200,000 180,000/200,000

—/180,000/224,000 —/180,000/224,000 180,000/224,000/250,000 224,000/250,000

80

20-50/35-65/45-75

3.5

3.5

1

0.180-0.487

5.0-13.5

1 ⁄

2

/ 3 ⁄

4

/ 3 ⁄

4

20-50/35-65/45-75

0.180-0.487

5.0-13.5

1

80

3.5

3.5

1

⁄

2

/ 3 ⁄

4

/ 3 ⁄

4

3

80

35-65/35-65/40-70

3.5

3.5

1

0.180-0.487

5.0-13.5

⁄

4

/ 3 ⁄

4

/ 3 ⁄

4

80

35-65/40-70

3.5

3.5

1

0.180-0.487

5.0-13.5

3 ⁄

4

/ 3 ⁄

4

RETURN-AIR FILTERS

Quantity...Size (in.) 4...16 x 20 x 2

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

*Evaporator coil fin material/condenser coil fin material. Contact your local representative for details about coated fins.

†Weight of 14-in. roof curb.

102

LOW/MEDIUM/

HIHG HEAT

195

.120...31

.096...41

—

—

450 ± 50

428

320

4...16 x 20 x 2

7 ± 3

22 ± 7

30 ± 5

45 ± 5

Cleanable

1...20 x 25 x 1

1...16 x 25 x 1

Throwaway

4...20 x 20 x 2

500 ± 50

428

320

4...20 x 20 x 2

**Rollout switch lockout is manually reset by interrupting power to unit or resetting thermostat.

††Requires an optional or accessory Controls Upgrade Kit.

NOTE: The 580D036-150 units have a loss-of-charge/low-pressure switch (accessory or option) located in the liquid line.

11

PHYSICAL DATA — 579F180-300

UNIT SIZE 579F

NOMINAL CAPACITY (tons)

OPERATING WEIGHT (lb)

Unit

Al/Al*

Economizer

Roof Curb†

COMPRESSOR

Model No. ...Quantity

(Number of Cylinders)

Oil (oz)

No. of Cylinders (per circuit)

Cooling Capacity Stages (%)

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb-oz)

Circuit 1**

Circuit 2

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Quantity...Diameter (in.)

Motor Hp...Rpm

Watts Input (Total)

EVAPORATOR COIL

Rows...Fins/in.

Total Face Area (sq ft)

EVAPORATOR FAN

Quantity...Size (in.)

Type Drive

Nominal Cfm

Motor Hp

Motor Nominal rpm

Maximum Continuous Bhp

Motor Frame Size

Nominal Rpm High/Low

Fan Rpm Range

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Diameter

Min/Max (in.)

Nominal Motor Shaft Diameter (in.)

Fan Pulley Pitch Diameter (in.)

Nominal Fan Shaft Diameter (in.)

Belt, Quantity...Type...Length (in.)

Pulley Center Line Distance (in.)

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns

From Closed Position

Factory Setting

Factory Speed Setting (rpm)

Fan Shaft Diameter at Pulley (in.)

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

TXV — Thermostatic Expansion Valve

*Evaporator coil fin material/condenser coil fin material.

†Weight of 14-in. roof curb.

**On 579F180-300 units, Circuit 1 consists of lower portion of condenser coil and lower portion of evaporator coil, and Circuit 2 is the upper portion of both coils.

180

15

216

18

240

20

300

25

1650

110

200

06D-537...1 (6)

115

6

0, 66, 100

TXV

2150

110

200

2200

110

200

2250

110

200

Semi-Hermetic

06D-824...1 (6)

06D-818...1 (4)

88,115

6

0, 57, 100

06D-824...2 (6)

115 ea

6

0, 50, 100

06D-328...2 (6)

R-22

Acutrol™ Refrigerant Metering Device

128 ea

6

0, 50, 100

19-4

—

13-4

11-0

12-13

12-13

16-12

15-12

3 ⁄

8

-in. Enhanced Copper Tubes, Aluminum Lanced or Copper Fins

2...17

22.2

3...15

22.2

3...15

22.2

4...15

22.2

10,500

1

3...22

⁄

2

...1050

1100

1

10,500

3...22

⁄

2

...1050

1100

Propeller Type

14,200

2...30

1...1075

3400

14,200

2...30

1...1075

3400

56H

—

891-1179

1227-1550

Ball

1550

3.1-4.1

3.7-4.7

7 ⁄

8

6.0

5.2

1 3 ⁄

16

1...BX...42

1...BX...42

13.5-15.5

48

55

3 ⁄

8

-in. Enhanced Copper Tubes, Aluminum or Copper Plate Fins, Face Split

2...17

17.9

3...17

17.9

4...15

17.9

4...15

17.9

2...10 x 10

Belt

6000

3.7

1725

4.25

184T

—

817-1038

994-1197

Ball

1550

3.7-4.7

4.9-5.9

1 1 ⁄

8

7.9

8.6

1 7 ⁄

16

1...BX...46

1...BX...50

13.3-14.8

37

34

5.90

Centrifugal Type

2...12 x 12

Belt

7200

5

1745

2...12 x 12

Belt

8000

7 1 ⁄

2

1745

8.7 [208/230 v]

9.5 [460 v]

213T

—

1002-1225

1193-1458

Ball

1550

5.4-6.6

5.4-6.6

1 3 ⁄

8

9.4

7.9

1 7 ⁄

16

1...BX...53

1...BX...50

14.6-15.4

37

44

2...12 x 12

Belt

10,000

10

1740

10.2 [208/230 v]

11.8 [460 v]

215T

—

1066-1283

1332-1550

Ball

1550

4.9-5.9

4.9-5.9

1 3 ⁄

8

8.0

6.4

1 7 ⁄

16

2...BX...50

2...BX...47

14.6-15.4

36

45

5

3.5

1035

1389

1 3 ⁄

16

5

3.5

934

1104

1 7 ⁄

16

5

3.5

1120

1328

1 7 ⁄

16

5

3.5

1182

1470

1 7 ⁄

16

††Rollout switch lockout is manually reset by interrupting power to unit or resetting thermostat.

\

The 579F300 unit requires 2-in. industrial-grade filters capable of handling face velocities of up to 625 ft/min (such as American Air Filter no. 5700 or equivalent).

NOTE: The 579F180-300 units have a low-pressure switch (standard) located on the suction side.

12

PHYSICAL DATA — 579F180-300 (cont)

UNIT SIZE 579F

FURNACE SECTION

Rollout Switch Cutout

Temp (F)††

Burner Orifice Diameter

(in. ...drill size)

Natural Gas

Thermostat Heat Anticipator Setting (amps)

208/230 v Stage 1

Stage 2

460 v Stage 1

Stage 2

Gas Input (Btuh) Stage 1

Stage 2

Efficiency (Steady State) (%)

Temperature Rise Range

Manifold Pressure (in. wg)

Natural Gas

Gas Valve Pressure Range in. wg psig

Gas Valve Quantity

Field Gas Connection Size (in.)

HIGH-PRESSURE SWITCH (psig)

Standard Compressor Internal Relief

(Differential)

Cutout

Reset (Auto.)

LOW-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

FREEZE PROTECTION THERMOSTAT (F)

Opens

Closes

OUTDOOR-AIR INLET SCREENS

Quantity...Size (in.)

RETURN-AIR FILTERS

Quantity...Size (in.)

POWER EXHAUST

180

LOW/HIGH HEAT

190

0.98

0.44

0.80

0.44

172,000/225,000

230,000/300,000

81

15-45/30-60

3.3

5.5-13.5

0.235-0.487

3

1

⁄

4

216

LOW/HIGH HEAT

190 190 190

0.1405...28/0.136...29

0.1405...28/0.136...29

0.1405...28/0.136...29

0.1405...28/0.136...29

0.98

0.44

0.80

0.44

206,000/270,000

275,000/360,000

81

15-45/20-50

3.3

5.5-13.5

0.235-0.487

3

1

⁄

4

—

426

320

7

22

30 ± 5

45 ± 5

240

LOW/HIGH HEAT

0.98

0.44

0.80

0.44

206,000/270,000

275,000/360,000

81

15-45/20-50

3.3

5.5-13.5

0.235-0.487

3

1

⁄

4

300

LOW/HIGH HEAT

0.98

0.44

0.80

0.44

206,000/270,000

275,000/360,000

81

15-45/20-50

3.3

5.5-13.5

0.235-0.487

3

1

⁄

4

Cleanable

2...20 x 25 x 1

1...20 x 20 x 1

Throwaway

\

4...20 x 20 x 2

4...16 x 20 x 2

1 ⁄

2

Hp 208/230-460 v Motor Direct Drive, Prop-Fan (Factory-wired for 460 v)

LEGEND

Al — Aluminum

Bhp — Brake Horsepower

Cu — Copper

TXV — Thermostatic Expansion Valve

*Evaporator coil fin material/condenser coil fin material.

†Weight of 14-in. roof curb.

**On 579F180-300 units, Circuit 1 consists of lower portion of condenser coil and lower portion of evaporator coil, and Circuit 2 is the upper portion of both coils.

††Rollout switch lockout is manually reset by interrupting power to unit or resetting thermostat.

\ The 579F300 unit requires 2-in. industrial-grade filters capable of handling face velocities of up to 625 ft/min (such as American Air Filter no. 5700 or equivalent).

NOTE: The 579F180-300 units have a low-pressure switch (standard) located on the suction side.

13

advertisement

Related manuals

advertisement