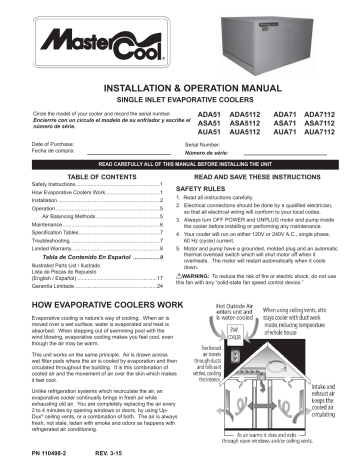

Installation. MasterCool ADA71, AUA71, ASA71, ADA5112, AUA51, AUA5112, AUA7112, ASA51, ASA7112, ASA5112

Add to my manuals

24 Pages

advertisement

INSTALLATION

CAUTIONS:

Before installing the cooler, note the following items:

• Before installation, ensure your existing electrical system is rated for the additional amperage draw from unit.

• Installation inside attic areas is NOT recommended.

• If installing unit on ground, ensure surface area is level, well packed and will not erode or become unstable with water erosion.

• If installing on brace, or existing construction, ensure structure will hold the operating weight of the cooler. (See specifi cation table for operating weight.)

• Ensure entire unit is suffi ciently supported. If supporting the unit with legs at each corner, the middle of the unit where the two sections join must be supported as well.

• We strongly recommend consulting a professional contractor if installation will require cutting through existing structure such as walls or roof.

• Do not screw or drill within 5 inches of the bottom of the wet section as you could puncture the reservoir.

• Ensure all electrical work is accomplished to local standards. An electrician may be needed for correct and safe wiring.

WARNING: Disconnect all electrical service that will be used for this unit before beginning the installation and DO NOT reconnect until installation is complete.

PARTS AND TOOLS NEEDED:

• Motor with Motor Pulley (purchased separately)

• 5/32 Allen Wrench (for pulley installation)

• 7/16 Wrench or Crescent Wrench

• Sill cock or water valve and tubing

• Multimeter (for amp reading)

SEPARATING SECTIONS

Follow the steps below to separate the sections of the unit, if desired for ease of installation.

1. Remove four bolts (two on each side) from the inside center post of the unit connecting the wet section to the blower section.

2. On a few models, two bolts on the interior of the unit attaching the bottom pans of the two sections will need to be removed as well.

MOTOR INSTALLATION

Note: Motor must be purchased separately. See Motor Specifi cation Table for motors that can be used.

1. For typical 120V installation, install motor cord (provided) to motor

(purchased separately). Follow motor electrical diagram using the following color code:

BLACK - HIGH; RED - LOW; WHITE- COMMON; GREEN - GROUND

2. When installing a 1 hp motor, reverse the adjustable yolk to accommodate the larger motor. Adjust the cradle spacing as needed for size of motor.

Mount the blower motor onto the yokes of the motor mount. Fasten with provided motor clips.

3. Leave motor cord unplugged until electrical portion of installation is complete.

PULLEY INSTALLATION

1. Open adjustable pulley about 5 full turns to the least diameter.

2. Install the motor pulley onto the motor shaft so that it aligns with the blower drive pulley and tighten with Allen wrench.

3. Loosen adjustment screw on motor mount.

4. Install belt onto pulleys.

5. Rotate motor mount until belt is tight, then tighten adjustment screw to secure belt. Check belt tension per instructions on page 5.

Note:

Further adjustment to belt and pulley may be required after installation is complete.

Remove

Two Bolts

(Each Side)

Connecting

Wet And

Blower

Sections

Remove Two Bolts

Connecting Bottom Pans

Motor

Pulley

Adjustable

Motor Mount

ALIGN PULLEYS

Motor

Motor

Pulley

Belt

Adjustment Screw

Motor

Motor

Clips

Adjustable

Yoke

Blower

Pulley

2

110498-2

ELECTRICAL CONNECTION

WARNING: Electrical connections should be accomplished by a qualifi ed electrician to ensure all electrical wiring conforms to local standards.

WARNING: Follow all safety precautions when working with electrical power.

WARNING: Before proceeding with installation, ensure electrical power is disconnected until installation is complete.

Note:

This unit can be controlled with a manual 6 position switch found at a local hardware store, or with a thermostat such as

Champion’s Masterstat ® Wall Control Thermostat model #110423-2. For thermostat installation refer to its operating manual.

Follow the steps below for manual switch installation:

1. Determine location on internal wall for 6 position switch.

2. Supply 120V or 240V power to switch, depending on motor and pump voltages.

3. Remove screws securing junction box to cooler cabinet.

Junction Box

Remove Screws to Access

Wiring Connections

4. Bring four conductors plus a ground from switch to cooler junction box

(such as two 2-wire Romex ® wire)

CAUTION: Make sure to use correctly sized wire and follow all local electrical codes.

Motor And Pump

Receptacles

5. Connect the four conductor wires to the leads of the motor and pump receptacles located in the junction box. Follow the connection diagrams below for 120V or 240V installations.

6. Reinstall junction box to cooler cabinet.

7. Plug motor and pump plugs into receptacles.

8. Follow switch electrical instructions for connecting the four conductors and power leads to switch.

Warning: Pump cord must be secured in retaining clip to prevent contact with water.

120 VOLT

PUMP

MOTOR

HIGH

LOW

COMMON

GROUND

Black

Red

White

Green

BLOWER MOTOR

240 VOLT

PUMP

MOTOR

HIGH

LOW

COMMON

GROUND

Black

Red

Orange

Green

BLOWER MOTOR

Blue/Black

White

Brown

Orange

Green

Black

Red

White

Orange

Green

PUMP

HIGH

LOW

COMMON

GROUND

TO SWITCH

= WIRE NUT

NOTE:

If single speed motor is used, do not use the RED electrical leads from the motor or receptacle. Tape off both

RED leads.

CAUTION:

Receptacles in junction box are only for Motor and pump.

Do not plug anything else into receptacle.

Blue/Black

White

Brown

Orange

Green

Black

Red

White

Orange

Green

PUMP

HIGH

LOW

COMMON

GROUND

= WIRE NUT

TO SWITCH

WARNING:

Ensure cooler cabinet is properly grounded to a suitable ground connection for maximum safety and protection of equipment.

110498-2

3

WATER CONNECTION

Note:

Do not connect the water supply to any soft water applications.

SILLCOCK INSTALLATION

A steady water supply is required for the operation of this cooler. If water source comes from an external water faucet, a sillcock and shutoff valve will need to be purchased and installed.

Faucet

Water Shut

Off Valve

Ferrule

Nut

Copper Or

Plastic Line

To Cooler

1. Install sillcock and water valve on faucet.

2. Run ¼” plastic or copper tubing from the faucet to the unit.

3. Install one end of tubing to water valve by placing nut and ferrule on tubing and tightening the nut until water tight.

FLOAT VALVE INSTALLATION (Refer to illustration)

1. Remove items 1, 2, 3, and 4 from fl oat. shown.

3. Install washer (1) and nut (2). Tighten to keep fl oat from turning. Place nut (4) and ferrule (3) on water supply line. Connect to fl oat fi tting and tighten until water tight.

Sillcock With Std.

Hose Connection

Float

Shield

Back Post

Panel

1

2

3

4

Note:

After installation is complete and water is turned on, the fl oat level will need to be adjusted.

5. Bend rod to adjust fl oat. Water level should be about 1 inch below the top opening of the overfl ow pipe.

OVERFLOW INSTALLATION

1. Remove nut and place nipple through the hole in the pan with the rubber washer between the pan and the head of the drain nipple.

2. Screw nut onto nipple and draw up tight against bottom pan.

when necessary.

Note:

A garden hose may be screwed onto the drain nipple to drain water away from the unit.

SCALE BUILDUP PREVENTION

As water evaporates, minerals that were in the water will remain. Over time this accumulation of minerals will cause scaling on the pads and in the reservoir. We recommend the installation of either a bleed-off kit (included in unit) or a purge pump

(purchased separately) to help prevent scale build up and increase the life of the unit. A purge pump will drain the pan every few hours of pump operation, to keep fresh water in the unit. A bleed-off kit will continually bleed off a small portion of water while the pump is running allowing fresh water to continually replace the old stagnate water. Follow the instructions below for installing the bleed-off kit.

1. Cut the pump hose and insert the barbed ends of the bleeder tee into each cut end.

2. Insert one end of the bleeder tubing onto the bleeder tee and run the other end out of the cooler through the overfl ow pipe.

Note:

A restrictor clamp is provided which, if desired, may be installed onto the bleeder tubing to restrict the amount of water being bleed off. The amount of water to bleed off depends on the quality of the water in your area. Start with 1-2 gal/hr and increase if needed.

Float

Overfl ow Pipe

Nipple

Rubber Washer

Reservoir

Nut

BLEED-OFF KIT

Pump Hose

Bleeder Tee

Bleed Tube

Restrictor

Overfl ow Pipe

AMPERAGE DRAW AND BELT TENSION

CAUTION: No attempt should be made to completely install this unit without the aid of an electrician or someone familiar with testing amperage draw. Failure to comply with these instructions may void your warranty.

This unit is equipped with an adjustable motor drive pulley for adjusting the blower wheel speed to the proper loading for different duct systems. It is important that the motor drive pulley is adjusted to correct size to ensure maximum air delivery without damage to the motor. Be sure to follow these instructions carefully.

4

110498-2

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement

Table of contents

- 1 Safety Instructions

- 1 How Evaporative Coolers Work

- 2 Installation

- 5 Operation

- 5 Air Balancing Methods

- 6 Maintenance

- 7 Specifi cation Tables

- 8 Limited Warranty

- 17 (English / Español)

- 24 Garantía Limitada

- 9 Reglas De Seguridad

- 9 Cómo Funciona Los Enfriadores Evaporativos

- 10 Instalación

- 13 Operación

- 13 Método de Equilibrar el Aire

- 14 Mantenimiento

- 15 Tablas De Especifi caciones

- 17 Lista De Piezas De Repuesto

- 24 Garantía Limitada