advertisement

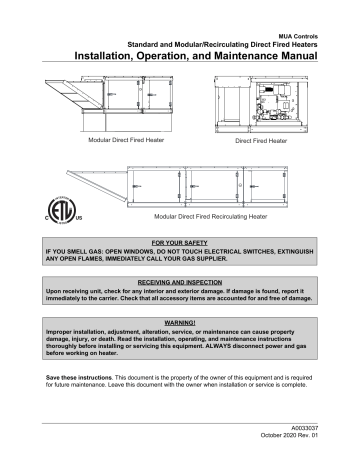

MUA Controls

Standard and Modular/Recirculating Direct Fired Heaters

Installation, Operation, and Maintenance Manual

Modular Direct Fired Heater

Direct Fired Heater

Modular Direct Fired Recirculating Heater

FOR YOUR SAFETY

IF YOU SMELL GAS: OPEN WINDOWS, DO NOT TOUCH ELECTRICAL SWITCHES, EXTINGUISH

ANY OPEN FLAMES, IMMEDIATELY CALL YOUR GAS SUPPLIER.

RECEIVING AND INSPECTION

Upon receiving unit, check for any interior and exterior damage. If damage is found, report it immediately to the carrier. Check that all accessory items are accounted for and free of damage.

WARNING!

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death. Read the installation, operating, and maintenance instructions thoroughly before installing or servicing this equipment. ALWAYS disconnect power and gas before working on heater.

Save these instructions . This document is the property of the owner of this equipment and is required for future maintenance. Leave this document with the owner when installation or service is complete.

A003303 7

October 2020 Rev. 01

Table of Contents

WARRANTY .......................................................... 3

Listings ................................................................ 3

Patents ................................................................ 3

INSTALLATION ..................................................... 4

Mechanical .......................................................... 4

Curb and Ductwork ............................................. 7

Roof Mount Installation ................................... 9

Installation with Exhaust Fan .......................... 9

Duct Mount Installation .................................. 10

Indoor (Inline) Installation .............................. 10

Roof Mount Installation - Recirculation Unit .. 11

Indoor (Inline) Installation Recirculation Unit . 11

Heat Module Add-On Installation .................. 12

Gas ................................................................... 13

HMI and Remote Room Sensor Installation ...... 15

Make-up Air (MUA) Board Connectors ............. 16

ELECTRICAL ...................................................... 26

Fan to Building Wiring Connection .................... 27

Temperature Control ......................................... 28

ECM Speed Control .......................................... 28

External PWM Signal ........................................ 28

OPERATION ....................................................... 29

Accessing Menu Configurations ....................... 29

Remote (HMI) Control Panel ......................... 29

HMI Notification Letters ................................. 29

HMI Configuration Menu ................................... 30

Communication ............................................. 30

Advanced Options ......................................... 30

Status ............................................................ 30

About ............................................................. 30

Scheduling ........................................................ 31

Fan Speed and Damper Position Presets ......... 31

Unit Options ...................................................... 32

Building Signal Damper Control .................... 32

Electric Cabinet Heater ................................. 32

Motorized Intake Damper .............................. 32

Mixing Box Control Unit Options ....................... 32

Menu Descriptions ............................................ 33

Menu Tree ......................................................... 41

Variable Frequency Drive (VFD) ....................... 49

VFD Installation ............................................. 50

Input AC Power ............................................. 50

VFD Output Power ........................................ 50

VFD Programming ........................................ 51

ACTECH SMV VFD ...................................... 52

START-UP OPERATION .................................... 53

Start-up Procedure ............................................ 53

Pulley Adjustment ............................................. 54

Pulley Alignment/Proper Belt Tension .............. 55

Pulley Combination Chart ................................. 56

Air Flow Sensor ................................................. 57

Modulating Gas System .................................... 58

High Temperature Limit .................................... 58

Pilot Adjustment ................................................ 58

Main Burner Adjustment ....................................59

Final Start-up Procedure ...................................60

Sequence of Operation .....................................61

Flame Safety Control .....................................61

Components ......................................................63

Network .............................................................64

BACnet ..........................................................64

LonWorks ......................................................65

Device Instance, MAC Address, Baud Rate ..66

Changing the IP Address ...............................67

DDC Control Points ...........................................68

DDC Fault List ...................................................72

Troubleshooting .................................................73

Burner Troubleshooting ................................74

HMI Fault Codes ...............................................75

VFD Fault List ....................................................78

Resetting Unit ................................................78

MAINTENANCE ...................................................79

General Maintenance ........................................79

2 Weeks After Start-up ......................................79

Every 3 Months .................................................79

Yearly ................................................................79

Burner Maintenance ......................................80

Unit Filters .........................................................80

Emergency Shutdown of Unit ........................81

Prolonged Shutdown of Unit ..........................81

Start-Up Documentation ....................................84

2

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and service, for a period of 2-years from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation instructions shipped with the product.

2. The equipment is not installed in accordance with Federal, State, and Local codes/regulations.

3. The equipment is misused or neglected, or not maintained per the MANUFACTURER’S maintenance instructions.

4. The equipment is not installed and operated within the limitations set forth in this manual.

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be defective in material or workmanship within the 2-year warranty period, upon examination by the MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall not be returned without

MANUFACTURER’S prior authorization, and all returned equipment shall be shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

NOTE: To receive warranty coverage for this product, copy and print out the “Start-Up

Documentation” on page 84. Fill in all required information. Fax the page to 1-919-516-8710 or call

1-866-784-6900 for email information.

Listings

This unit is ETL-listed to the American National Standard/CSA Standard for Gas Unit Heaters And Gas-

Fired Duct Furnaces ANSI Z83.4, CSA 3.7.

The Safety Control Board is ETL-listed to standard UL 60730-2-9, UL 60730-1, CSA E60730-1, CSA

E60730-2-9.

Patents

The Direct Gas Fired Make-Up Air Profile Plates is covered under the following patent: Heated Make-Up

Air System: United States Patent No. 6629523 B2.

3

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in accordance with this manual. If there are any questions about any items, please call the service department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE UNIT BY THE INTAKE HOOD, BLOWER, MOTOR SHAFT, OR

BEARINGS. USE ALL LIFTING LUGS PROVIDED WITH A SPREADER BAR OR SLING UNDER THE

UNIT.

Clearance

The top, back, and front surfaces of this heater may not be installed less than 6” from combustible materials. The heater base may be installed on combustible surfaces. Allow 24” minimum service clearance on both sides of this heater.

Site Preparation

Figure 1 - Spreader Bar

1. Provide clearance around installation site to safely rig and

lift equipment into its final position ( Figure 1 ). Supports

must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Locate unit close to the space it will serve to reduce long, twisted duct runs.

3. Consider general service and installation space when locating unit.

4. Do not allow air intake to face prevailing winds. Support unit above ground or at roof level high enough to prevent precipitation from being drawn into its inlet. The inlet must also be located at least 10 feet away from any exhaust vents. The fan inlet shall be located in accordance with the applicable building code provisions for ventilation air.

5. All air to the heater must be ducted from the outdoors.

Recirculation of room air is not permitted. If in doubt regarding the application, consult the manufacturer.

6. Recirculation of room air may be hazardous in the presence of:

• Flammable solids, liquids, and gases

• Explosive materials (e.g., grain dust, coal dust, gun powder, etc.)

• Substances which may become toxic when exposed to heat (e.g, refrigerants, aerosols, etc.)

7. Recirculation is not recommended in uninsulated buildings where outside temperatures fall below 32 ° F (0°C).

8. Excessive recirculation or insufficient ventilation air, which results in inadequate dilution of the combustion products generated by the heater, may create hazardous concentrations of carbon dioxide, carbon monoxide, nitrogen dioxide, and other combustion products in the heated space. Refer to Table 1 for ventilation requirements.

Spreader

Bar

Lifting Lugs

Lifting Lugs

4

9. If gas fork trucks or other fossil fuel powered equipment are utilized in the conditioned area, additional ventilation requirements for the facility must be addressed separately.

10. If the heater utilizes room sensors for limiting room CO

2

concentration:

• The CO

2 control set-point shall be no greater than the maximum allowable room concentration of

5000 ppm less the sensor’s published accuracy tolerance. The control shall prevent the CO

2 concentration in room air from exceeding 5000 ppm.

• A minimum of one sensor shall be installed per room served by the heater.

• When a room area, served by a single heater, does not exceed 10,000 ft 2 (929 m 2 ) and height does not exceed 20 ft. (6 m), a duct sensor may be installed in the return air opening of the heater.

• Sensors shall be calibrated per the sensor manufacturer’s recommended procedure and frequency or annually, whichever is more frequent.

• Each heater shall require CO

2

sensor(s).

• Sensors shall not be placed near sources of CO

2

.

%

Natural

Gas

Propane

Gas

Table 1 - Minimum Ventilation Requirements for Heaters that Recirculate

5

12.2

(6.8)

10.6

(5.9)

Minimum Ventilation Rate (as % of Total Air Throughput)

10 15 20 25 30 40

Maximum Equivalent Temp. Rise Through Heat for CO 2 °F (°C)

24.5

(13.6)

21.1

(11.7)

36.7

(20.4)

31.7

(17.6)

49.0

(27.2)

42.2

(23.5)

61.2

(34.0)

52.8

(29.3)

73.5

(40.8)

63.4

(35.2)

98.0

(54.4)

84.5

(46.9)

50

122.5

(68.0)

105.6

(58.7)

60

146.9

(81.6)

126.7

(70.4)

5

Intake Assembly

) are shipped on a separate skid. Upon unit arrival, perform the following steps to assemble the intake to the unit.

1. Apply silicone or weather-proof gasket on the backside of the flanges of the intake hood or V-bank intake.

2. Secure the flanges of the intake hood to the unit with the supplied sheet metal screws.

3. Use caulk on the outside of the screws to prevent water leaks.

4. If the unit is a modular unit with a V-bank or evaporative cooler section, the V-bank or evaporative cooler will bolt to the heater with the bolts provided.

5. Slide the filters down the filter track.

Figure 2 - Intake and Curb Assembly

Direct Fired

1

2

3

4

Direct Fired Recirc

1

2

3

1. Unit

2. Intake Housing

3. Intake Filter(s)

4

5

4. Curb

5. Mixing Box Curb

6

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will significantly affect airflow performance. When using rectangular ductwork, elbows must be radius throat, radius back with turning vanes. Flexible ductwork and square elbows should not be used. Any transitions and/or turns in the ductwork near the fan outlet will cause system effect. System effect will drastically increase the static pressure and reduce airflow.

•

fan performance. Table 2 displays recommended return ductwork sizes for recirculating units.

• Do not use the unit to support ductwork in any way. This may cause damage to the unit.

• Follow SMACNA guides and manufacturer's requirements for the remaining duct run. Fans designed for rooftop installation should be installed on a prefabricated or factory-built roof curb.

• Follow curb manufacturer’s instructions for proper curb installation.

• The unit should be installed on a curb and/or rail that meets local code height requirements.

• Make sure the duct connection and fan outlet are properly aligned and sealed.

• Secure fan to curb through vertical portion of the ventilator base assembly flange. Use a minimum of eight (8) lug screws, anchor bolts, or other suitable fasteners (not furnished). Shims may be required depending upon curb installation and roofing material.

• Verify all fasteners are secure.

through Figure 8 show different mechanical installations.

• Adequate building relief shall be provided so as not to over pressurize the building when the heating system is operating at its rated capacity. This can be accomplished by taking into account, through standard engineering methods, the structure’s designed infiltration rate; by providing properly-sized relief openings; or by interlocking a powered exhaust system; or by a combination of these methods.

• Heaters installed with intake ductwork must be purged to replace at least four air changes of the volume of the intake duct.

• If the failure or malfunction of this heater creates a hazard to other fuel-burning equipment in the building (e.g., when the heater is providing makeup air to a boiler room), the unit is to be interlocked to open inlet air dampers or other such devices.

• On outdoor installations, it is recommended that the discharge duct be insulated to prevent condensation during the “OFF” cycle in cold weather.

• Flexible connectors should be used on all ductwork connections. Vibration isolators are optional and can be supplied in the loose parts package.

• Units that are installed in airplane hangars should be installed in accordance with the Standard for

Aircraft Hangars, ANSI/NFPA 409. Units that are to be installed in public garages should be installed in accordance with the Standard for Parking Structures, ANSI/NFPA 88A, or the Standard for Repair

Garages, ANSI/NFPA 88B, and with CAN/CGA B149 Installation Codes.

Table 2 - Recommended Return Ductwork Sizes

Mixing Box

3

4

1

2

5

Duct Size (Inches)

19 x 15

25 x 24

31 x 29

37 x 34

44 x 44

7

Blower Size (Inches)

10

15D, 16Z, 18Z

12

15

20D, 20Z, 22Z

18

24D, 25Z

20

30D, 28Z

25

36D

Table 3 - Required Supply Ductwork

Discharge

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Duct Size

14” x 14”

20” x 20”

14” x 14”

16” x 16”

20” x 20”

26” x 26”

20” x 20”

24” x 24”

30” x 30”

24” x 24”

26” x 26”

32” x 32”

26” x 26”

32” x 32”

36” x 36”

32” x 32”

WARNING!

Failure to properly size ductwork may cause system effects and reduce the performance of the equipment.

Straight Duct Length

48”

72”

48”

54”

168”

108”

168”

189”

168”

72”

108”

72”

86”

108”

86”

108”

8

Roof Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 3 - Roof Mount Details

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit Located in Curb Area for Field

Wiring

1

4. Intake Housing

5. Lifting Lugs

6. Direct Fired Module

7. Service Disconnect Switch

8. Blower/Motor Access Door

9. Curb (20” High)

10. Control Drop

11. Motor Drop

12. Gas Connection

Max. Roof Opening 2” Smaller than Curb

Outside Dimension.

8

3

7

2

12

6

Installation with Exhaust Fan

Note: Refer to submittal drawings for specific unit dimensions.

Figure 4 - Exhaust Fan Details

2

1

11

AIRFLOW

10

9

AIRFLOW

5

4

8

3

7

6 5

4

9

10

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit Located in

Curb Area for Field Wiring

4. Intake Housing

5. Lifting Lugs

6. Direct Fired Module

7. Service Disconnect Switch

Max. Roof Opening 2” Smaller than Curb Outside Dimension.

8. Blower/Motor Access Door

9. Curb with Support Legs or

Rail (20” High)

10. Gas Connection

9

Duct Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 5 - Duct Mount Details

1. Control/Valve Access Door

2. Gas Connection

3. Optional Unistrut Base

4. Lifting Lugs

AIRFLOW

1

2

4

3

Indoor (Inline) Installation

Note: Refer to submittal drawings for specific unit dimensions.

1. Flex Conduit for Field Wiring

2. Optional Unistrut Base

3. Lifting Lugs

4. Control/Filter Access Door

5. Control/Valve Access Door

6. Gas Connection

7. Blower/Motor Access Door

8. Service Disconnect Switch

Figure 6 - Indoor Installation Details

8

1

AIRFLOW

2

3

7

6

5 4

10

Roof Mount Installation - Recirculation Unit

Note: Refer to submittal drawings for specific unit dimensions.

Figure 7 - Roof Mount Details

1. Discharge Opening

2. Curb Outer Wall

3. Curb

4. Return Damper

5. Intake Damper

6. Intake Filter

7. Direct Fired Module

8. Control Drop

9. Motor Drop

10. Blower/Motor Access

Door

11. Flex Conduit for Field

Wiring

12. Service Disconnect

Switch

13. Optional Filters

14. Lifting Lugs

1

9

10

11

8

2

12

13

7

AIRFLOW

3

4

4

AIRFLOW

5

6

14

Indoor (Inline) Installation Recirculation Unit

Note: Refer to submittal drawings for specific unit dimensions.

Figure 8 - Indoor Installation Details

1. Flex Conduit for Field

Wiring

2. Optional Filters

3. Return Damper

4. Intake Damper

5. Direct Fired Module

6. Blower/Motor Access

Door

7. Service Disconnect

Switch

8. Lifting Lugs

9. Optional Uni-Strut Base

AIRFLOW

7

1

2

AIRFLOW

6 5

3

3

4

8

9

11

Heat Module Add-On Installation

require field mechanical and wiring installation.

1. Remove existing intake housing and lifting lugs from the blower section intake side.

2. Attach heat module to blower intake using the provided sheet metal screws and bolts. Tighten screws and bolts to compress the gasket between the heat module and the blower module.

3. Support and level the end of the heat module (end opposite the blower) with the provided equipment legs/rails.

4. Attach the intake housing to the intake side of the heater module.

5. Drill a hole in the discharge of the blower large enough to insert the discharge control sensor (if provided). Install the sensor through the hole.

6. Wire the sensor and coil as indicated on the supplied wiring schematic. Route all wiring through metal conduit.

7. After the add-on installation is complete, refer to

“Start-up Procedure” on page 53 .

Figure 9 - Heat Module

4

1 2

3

1. Blower

2. Direct Fired Module

3. Intake Housing

4. Filters

7

6

5

5. Equipment Legs

6. Conduit

7. Curb

12

Gas

Installation of gas piping must conform with local building codes, or in the absence of local codes to the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, installation must be in accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane units.

WARNING: INLET GAS PRESSURE MUST NOT EXCEED PRESSURE INDICATED ON NAMEPLATE.

SEE UNIT NAMEPLATE FOR PROPER GAS SUPPLY PRESSURE AND GAS TYPE.

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect switch or breaker to prevent accidental power-up.

2. Piping to the unit should conform to local and national requirements for type and volume of gas handled, and pressure drop allowed in the line. Refer to the Gas Engineer’s Handbook for gas line capacities.

3. The incoming pipe near the heater should be sized to match the connection on the outside of the unit.

Unit inlet sizes are shown in

Table 4 . The unit requires a steady supply of gas at all times, avoid

multiple taps in the gas supply line.

4. Install a ground joint union with brass seat and a manual shut-off valve external to the unit casing.

Install shut-off valve adjacent to the unit for emergency shut-off and easy servicing of controls. Refer to

.

5. Provide a sediment trap, as shown in

Figure 10 on page 14 , before each unit and where low spots in

the pipeline cannot be avoided.

6. Clean out the gas line to remove debris before making connections. Purge gas line to remove air before attempting to start unit. Purging air from gas lines should be performed as described in ANSI

Z223.1-latest edition “National Fuel Gas Code,” or in Canada as described in CAN/CGA-B149.

7. All field gas piping must be pressure/leak tested before unit operation. Use a non-corrosive bubble forming solution or equivalent for leak testing. The heater and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psi.

8. This unit requires the gas pressure to be within the unit’s minimum and maximum gas pressure ratings. If the pressure is greater than the maximum, the internal valve components will be damaged. If the pressure is below the minimum, the heater will not perform to specifications. Refer to

Table 5 on page 14 for gas pressure ratings.

Unit Size

Size 1

Size 2

Size 3

Size 4

Size 5

Table 4 - Gas Connection Sizes

Gas Pipe Size (NPT)

3/4”

1”

1”

1-1/4”

1-1/2”

13

1

Figure 10 - Gas Connection Diagram

1

2

3

4

A

5

1. Gas Supply Line Connection

2. Manual Gas Shut-off Valve

3. Ground Joint Union with Brass Seat

4. Plugged 1/8” NPT Test Gauge Connection

5. Sediment Trap

A. Minimum Depth = 3”

Table 5 - Gas Pressure

Gas Pressure Type

Size 1-3 Inlet

Size 4-5 Inlet

Maximum Manifold Pressure - Natural Gas

Maximum Manifold Pressure - Propane

Gas Pressure

7 -14 Inches WC

7 Inches WC - 5 psi

5 Inches WC Maximum

2.5 Inches WC Maximum

NOTICE

Refer to the heater’s rating plate for determining gas supply pressures and requirements.

14

ELECTRICAL

WARNING!

Disconnect power before installing or servicing unit. High voltage electrical input is needed for this equipment. A qualified electrician should perform this work.

Before connecting power to the heater, read and understand the entire section of this document. As-built wiring diagrams are furnished with each unit by the factory. The diagrams are attached to the control module’s door or provided with paperwork packet.

National Electric Code, ANSI/NFPA 70. Verify the voltage and phase of the power supply, and the wire amperage capacity is in accordance with the unit nameplate. For additional safety information, refer to

AMCA publication 410-96, Recommended Safety Practices for Users and Installers of Industrial and

Commercial Fans.

1.

Always disconnect power before working on or near this equipment. Lock and tag the disconnect switch and/or breaker to prevent accidental power-up .

2. An electrical drop containing the line voltage power wiring is shipped with every unit. The electrical drop should be brought through one of the conduit openings located in the base of the unit (

Figure 3 on page 9 ), run through the curb, and connected to a junction box inside the building.

3. A dedicated branch circuit should supply the motor circuit with short circuit protection according to the

National Electric Code. This dedicated branch should run to the junction box.

4. Verify that the power source is compatible with the requirements of your equipment. The nameplate identifies the proper phase and voltage of the equipment.

5. Units shipped with a remote HMI will require a second drop through the base of the unit. It is important to route the motor wires in a separate conduit from the HMI wiring. Refer to

Figure 7 (Recirc) on page 11 .

6. Before connecting the unit to the building’s power source, verify that the power source wiring is deenergized. Refer to

“Fan to Building Wiring Connection” on page 16 .

7. Secure the power cable to prevent contact with sharp objects.

8. Do not kink power cable and never allow the cable to encounter oil, grease, hot surfaces, or chemicals.

9. Before powering up the unit, make sure that the fan rotates freely. Make sure that the interior of the unit is free of loose debris or shipping materials.

10. If any of the original wire supplied with the unit must be replaced, it must be replaced with type THHN wire or equivalent.

Table 6 - Copper Wire Ampacity

Wire Size AWG

3

2

6

4

1

14

12

10

8

Maximum Amps

65

85

100

115

130

15

20

30

50

15

Fan to Building Wiring Connection

Figure 11 - Wiring Connection Details

120V 1 PH.

1

Single Point Connection

208-240V 1 PH.

1

208-240/460/600V 3 PH.

1

2 2 2

3

4

BK WH GR

1. Disconnect Switch

2. Galflex Conduit (In Unit)

2

120V 1 PH.

1

3 3

4

BK

4

RD

WIRE COLOR

GR BK BK BK GR

BK - BLACK

RD - RED

WH - WHITE

GR - GREEN

3. Factory Wiring

4. Field Supplied Wiring - From building power or pre-wired control panel.

2

120V Optional

208-240V 1 PH.

1

208-240/460/600V 3 PH.

1

2

5

3

5

3

6

5

3

7

4 4

4

RD WH BK WH GR RD WH BK

1. Disconnect Switch

2. Galflex Conduit (In Unit)

3. Factory Wiring

4. Field Supplied Wiring - From building power or pre-wired control panel.

RD

WIRE COLOR

GR RD WH BK BK BK GR

BK - BLACK

RD - RED

WH - WHITE

GR - GREEN

5. 120V Single Phase Standing Power

6. 208-240 Single Phase

7. Three Phase

16

SL

SL

LLT

LLT

ICT

ICT

OCT

OCT

CDT

CDT

RT

OT

OT

DT

DT

ST

ST

IT

IT

RT

Make-up Air (MUA) Board Connectors

The Make-up Air (MUA) Board (

) is located in the main control cabinet.

Figure 12 - Make-up Air Board

J20 J21

Power Vent

Neutral

J19 J17

Power

Vent

Hot

Power

Vent

Hot

24V

DC

0-10

VIN

COM

COM

24V

DC

0-10

VIN

COM

COM

24V

AC

24V

AC

IN

COM

24V

AC

0-10

VIN

COM

COM

24V

AC

0-10

VIN

COM

COM

24V

AC

24V

AC

IN

COM

J39

PS1

1

CASLink BMS Slave

Pilot

Gas

Spark

Alarm

Blower

Burn

Hi

Temp

Aux

1 J11 8 1 J16 8 1 J25 3

R C DDC

C

HMI VFD Master

Y G BAS/STAT

17

Note: Some connections may not be used dependent on system configurations

RJ45 connectors.

Connector J1 and J2 are associated with BMS.

Connector J3 through J6 are interchangeable and may be used to connect to an HMI or VFD.

J1 - CASLink/Slave

J2 - CASLink/Slave

J3 - HMI/VFD/Master

J6

J4 - HMI/VFD/Master

J5 - HMI/VFD/Master

J6 - HMI/VFD/Master

J2

J5

J1

J4 J3

Connector J7 contains inputs and outputs for the

Flame Safety Controller (FSC)

9

18

Pin 1 - N/A

Pin 2 - 24VAC Pilot Valve

Pin 3 through Pin 8 - N/A

Pin 9 - 24VAC Common to Main/Pilot Gas Valve

Pin 10 through Pin 18 - N/A

1

10

Connector J8 contains inputs and outputs for the

Flame Safety Controller (FSC)

NOTE: Connector J8 only for Compact Models

9

18

Pin 1 - N/A

Pin 2 - 24VAC Pilot Valve

Pin 3 through Pin 8 - N/A

Pin 9 - 24VAC Common to Main/Pilot Gas Valve

Pin 10 through Pin 18 - N/A

1

10

Connector J9 contains 120V AC connections 1 8

Pin 1 - 120VAC Main Input

Pin 2 - 120VAC Input from Discharge Damper End

Switch

Pin 3 - 120VAC Input from Fire Micro-Switch

Pin 4 - 120VAC Output to Intake/Discharge Damper

Actuator

Pin 5 - 120VAC Input from Intake Damper End

Switch

Pin 6 - N/A

Pin 7 - 120VAC Output to Cabinet Heater

Pin 8 - 120VAC Neutral

18

Connector J10 contains 120V AC connections 1 8

Pin 1 - 120VAC Input from Evap Cooler Pressure

Switch

Pin 2 - 120VAC Input from Evap Cooler Float

Switch

Pin 3 - 120VAC Output to Evap Cooler Water

Solenoid

Pin 4 - 120VAC Output to Evap Cooler 3-way Drain

Valve

Pin 5 - 120VAC Input from Supply Overload

Pin 6 - 120VAC Output to Supply Starter Coil

Pin 7 - 120VAC Output to Exhaust Starter Coil

Pin 8 - 120VAC Input from Exhaust Overload

1 8

Connector J11 contains low voltage screw terminal connections

Pin 1

Pin 2

Pin 3

Pin 4

- 24VAC Auxiliary Input

- 24VAC Auxiliary Input

- 24VAC Auxiliary Input

- 24VAC Call for Heat Input

W Y G BAS/STAT

Pin 5 - 24VAC Call for Cooling Input

Pin 6 - 24VAC Call for Blower Input

Pin 7 - 24VAC Occupied Override Input

Pin 8 - 24VAC Isolated Common

1 8

Connector J12 contains low voltage screw terminal connections

Pin 1

Pin 2

Pin 3

Pin 4

- 24VAC Output to Smoke Detector

- 24VAC Output to Smoke Detector

- 24VAC Digital Input from Smoke Detector

- 24VAC Common to Smoke Detector

24V AC 24V AC

DI-1

24V AC

AI-1

Pin 5 - 24VAC Output to Air Quality Sensor

Pin 6 - 0-10V Analog Input from Air Quality Sensor

Pin 7 - 24VAC Common to Air Quality Sensor

Pin 8 - 24VAC Common to Air Quality Sensor

19

Connector J13 contains low voltage connections

7

14

1

10

Pin 1 - N/A

Pin 2 - PWM + Output for Supply ECM

Pin 3 - 24VAC Output for Low Gas Pressure Switch

Pin 4 - 24VAC Output for High Gas Pressure Switch

Pin 5 - 24VAC Output for Clogged Filter Switch

Pin 6 - 24VAC Output for Low Airflow

Pin 7 - 24VAC Input for Board Power

Pin 8 - N/A

Pin 9 - PWM Output for Supply ECM

Pin 10 - 24VAC Input from Low Gas Pressure

Switch

Pin 11 - 24VAC Input from High Gas Pressure

Switch

Pin 12 - 24VAC Input from Clogged Filter Switch

Pin 13 - 24VAC Input from Low Air Pressure Switch

Pin 14 - 24VAC for Board Power

1 8

Connector J14 contains screw terminal connections

24V DC

AI-2

24V DC

AI-3

Pin 1 - 24VAC Output to Humidity Sensor

Pin 2 - 0-10VDC Analog Input from Humidity Sensor

Pin 3 - 24VAC Common to Humidity Sensor

Pin 4 - 24VAC Common to Humidity Sensor

Pin 5 - 24VAC Output to Humidity Sensor

Pin 6 - 0-10VDC Analog Input VFD/Humidity Sensor

Pin 7 - 24VAC Common VFD/Humidity Sensor

Pin 8 - 24VAC Common to Humidity Sensor

1 10

Connector J15 contains low voltage connections

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

- Intake Temperature Thermistor Input

- Intake Temperature Thermistor Input

- Return Temperature Thermistor Input

- Return Temperature Thermistor Input

- Outdoor Temperature Thermistor Input

THERMISTORS

Pin 6 - Outdoor Temperature Thermistor Input

Pin 7 - Discharge Temperature Thermistor Input

Pin 8 - Discharge Temperature Thermistor Input

Pin 9 - Space Temperature Thermistor Input

Pin 10 - Space Temperature Thermistor Input

20

1 8

Connector J16 contains low voltage screw terminal connections

BAS/STAT

Pin 1 - 0-10VDC Analog Input for Heat Modulation

Pin 2 - 4-20 mA Analog Input for Heat Modulation

Pin 3 - 24VAC Common

Pin 4 - 24VAC Common

Pin 5

Pin 6

Pin 7

Pin 8

- 24VAC Unit Interlock Input

- 24VAC Output (Stat)

- 24VAC Output (R)

- 24VAC Common

NOTE: Connector J17 is grouped with connectors J-19 through J-21

R C

Connector J18 contains low voltage connections

7

14

1

10

Pin 1 - 24VDC + Output

Pin 2 - 0-10VDC Analog Output for Mixing Box

Actuator

Pin 3 - 0-10VDC Analog Output for Bypass Damper

Pin 4 - 24VAC Output for DX Float Switch

Pin 5 - 24VAC Output for Door Interlock

Pin 6 - 24VAC Warm Liquid Bypass Output

Pin 7 - 24VAC for Damper Actuator

Pin 8 - 24VDC - Common

Pin 9 - Common for Mixing Box Actuator

Pin 10 - Common for Bypass Damper

Pin 11 - 24VAC Input from DX Float Switch

Pin 12 - 24VAC Input from Door Interlock

Pin 13 - 24VAC Warm Liquid Bypass Output

Common

Pin 14 - 24VAC for Damper Actuator

J20 J21

Connector J17 - N/A

Connector J19 - N/A

Connector J20 - N/A

Connector J21 - N/A

J19 J17

21

Connector J22 (Y1) Condenser 1

Connector J23 (Y2) Condenser 2

Connector J24 (Y3) Condenser 3

2 1

2 1

2 1

J22

J23

J24

J22 Pin 1 - 24VAC Output to Condenser 1

J22 Pin 2 - 24VAC Common to Condenser 1

J23 Pin 1 - 24VAC Output to Condenser 2

J23 Pin 2 - 24VAC Common to Condenser 2

J24 Pin 1 - 24VAC Output to Condenser 3

J24 Pin 2 - 24VAC Common to Condenser 3

1

Connector J25 contains low voltage screw terminal connections for DDC Communications Isolated

Pin 1 RS-485 +

Pin 2 RS-485 -

+ -

DDC

C

Pin 3 RS-485 Common

3

Connector J26 Programming Port

1

2

USB

Connector J27 USB Programming Port

1 8

Connector J28 contains low voltage screw terminal connections

Pin 1

Pin 2

Pin 3

Pin 4

- 24VAC Start Command for 3rd-Party VFD

- 24VAC Output

- 24VAC Trouble Input

- 24VAC Common for 3rd-Party VFD

24V AC 24V AC

DI-2

24V AC

AI-4

Pin 5 - 24VAC Constant Output

Pin 6 - 0-10VDC Analog Input VFD Speed

Reference

Pin 7 - 24VAC Common

Pin 8 - 24VAC Common

22

Connector J29 contains 120V AC connections

Pin 1 - 120VAC Blower Service Switch Input

Pin 2 - 120VAC Burner Service Switch Input

Pin 3 - 120VAC High Temp Limit Input

Pin 4 - 120VAC Output to FSC (6)

1

Pin 5 - 120VAC Output to FSC (7)

Pin 6 - N/A

Pin 7 - N/A

Pin 8 - 120VAC Neutral

8

Connector J30 contains 120V AC connections 1 8

Pin 1 - 120VAC Input from Pilot Gas FSC (3)

Pin 2 - 120VAC Pilot Gas Output - Connected to

J30-1

Pin 3 - 120VAC Input from Spark FSC (4)

Pin 4 - 120VAC Spark Output

Pin 5 - 120VAC Input from Main Gas FSC (5)

Pin 6 - 120VAC Main Gas Output - Connected to

J30-5

Pin 7 - 120VAC Alarm Input from FSC (A)

Pin 8 - 120VAC Alarm Output

Connector J31 - Contains inputs and outputs for components

9

18

1

10

Pin 1 - 24VDC + Output to Profile / Main Air Flow

Pressure Sensor

Pin 2 - 0-10VDC Analog Input from Profile / Main Air

Flow Pressure Sensor

Pin 3 - 24VDC/0-10VDC Common from Profile /

Main Air Flow Pressure Sensor

Pin 4 - N/A

Pin 5 - N/A

Pin 6 - N/A

Pin 7 - 24VDC + Output to Manifold Gas Pressure 1

Sensor

Pin 8 - 0-10VDC Analog Input from Manifold Gas

Pressure 1 Sensor

Pin 9 - 24VDC/0-10VDC Common from Manifold

Gas Pressure 1 Sensor

Pin 10 - 24VDC + output to Manifold Gas Pressure

2 Sensor

Pin 11 - 0-10VDC Analog Input from Manifold Gas

Pressure 2 Sensor

Pin 12 - 24VDC/0-10VDC Common from Manifold

Gas Pressure 2 Sensor

Pin 13 - 24VDC + output to Clogged Filter Pressure

Sensor

Pin 14 - 0-10VDC Analog Input from Clogged Filter

Pressure Sensor

Pin 15 - 24VDC/0-10VDC Common from Clogged

Filter Pressure Sensor

Pin 16 - 24VDC + Output for Analog or Static

Pressure Control for Blower/Damper

Pin 17 - 0-10VDC Analog Input for Analog or Static

Pressure Control for Blower/Damper

Pin 18 - 24VDC/0-10VDC Common for Analog or

Static Pressure Control for Blower/Damper

23

Connector J32 contains inputs and outputs for components

9

18

1

10

Pin 1 - N/A

Pin 2 - N/A

Pin 3 - 24VAC Output for Proof Of Closure

Pin 4 - N/A

Pin 5 - 24VAC Output To CO Alarm

Pin 6 - 0-24VDC + Analog Input from Flame Sensor

Pin 7 - 24VDC Powered PWM to Modulating Gas

Valve, Full Wave, 16 kHz

Pin 8 - 0-10VDC Out for VFD

Pin 9 - N/A

Pin 10 - N/A

Pin 11 - N/A

Pin 12 - 24VAC Input from Proof of Closure

Pin 13 - N/A

Pin 14 - 24VAC From CO Alarm

Pin 15 - 24VDC Common From Flame Sensor

Pin 16 - 24VDC Powered PWM to Modulating Gas

Valve, Full Wave, 16 kHz

Pin 17 - 0-10VDC Common for VFD

Pin 18 - N/A

Connector J33 contains inputs and outputs for components

Pin 1 through 8 - N/A

Pin 9 - 0-10VDC Analog Input for CFM

9

18

Pin 10 through 17 - N/A

Pin 18 - 0-10VDC Common for CFM

1

10

Connector J34 - N/A

2 1

4 3

1 10

Connector J35 N/A

THERMISTORS

24

Connector J36 N/A

9

18

Connector J37 N/A

2 1

4 3

MODBUS

C B A

Connector J38 Modbus

3

Pin 3 (C) Modbus Ground

1

Pin 1 (A) Modbus (-)

Pin 2 (B) Modbus (+)

ON

Dip Switch S1

1 2 3 4

Switch 1, 2, 3 always OFF. Switch 4 Always ON. If Switch 4 is OFF, BAS terminals disabled.

1

10

25

Dip Switch S2

Programming - Service Only

Dip Switch S3

End of line termination

Dip Switch S4

Programming - Service Only

ON

26

HMI and Remote Room Sensor Installation

Remote HMI faceplates (

, remote room sensors (

), and smart controls may be ordered and shipped separately. These components measure temperature and assist in controlling the unit. These components should be installed in a safe location, free of influence from external heat sources.

Install sensors in areas indicative of the average room temperature, and away from heat-producing appliances. HMIs and remote room sensors can be installed directly to industry-standard junction boxes, either surface mounted or recessed mounted. HMIs have a built-in temperature/relative humidity (RH) sensor, which is typically used to help control the automatic function of the unit.

The HMI can also be configured to control the unit from a remote location manually. They can be configured not to use the internal temperature/relative humidity sensor. In this configuration, the sensor in the HMI is ignored in automatic operation. Multiple HMIs can be connected to one unit for temperature and

R/H averaging. All combination temperature/humidity HMIs will use a vented standoff. Mount the static pressure tube close to the HMI to obtain proper room conditions.

A max of 4 additional HMIs can be daisy-chained together. Place an End-of-Line (EOL) device in the last

HMI connected.

Figure 13 - HMI with Standoff

HMI Standoff

J-Box

Route static pressure tube close to the HMI in the space.

Static Pressure Tube

Connected to the High Pressure

Port on Pressure Sensor

5-1/2”

Cat 5 Connection

J1 on HMI-1 to J2 on HMI-2

HMI with Built-in

Temperature/Humidity

Sensor

5-1/2”

The room temperature sensor is a 10K ohm thermistor. The sensor provides constant room temperature to the controller.

It should be installed on a wall somewhere in the room, but not directly in the HVAC diffuser’s path or close to heatproducing appliances so that the reading is not affected by heat.

Room sensors are not required for proper control operation, but still can be configured as remote sensors or averaging sensors.

Do not install the room sensor on the ceiling .

Figure 14 - Remote Room Sensor

27

Temperature Control

Discharge Control : When used in discharge control, the MUA board receives a call to heat from the intake sensor. The MUA board will modulate the discharge temperature until the desired setpoint is reached. The user can choose whether discharge heating/cooling is activated based on intake temperature, space temperature, either, or both.

Space Control : When selected, an HMI with an internal temperature sensor or a temperature sensor wired to ST terminals on the MUA board can be used to sense space temperature. The user can choose whether the space heating/cooling is activated based on intake temperature, space temperature, either, or both.

Analog Control : If Analog Control is utilized, DIP switch #4 on the MUA board should be set On. Blower/

Heating/Cooling will be controlled by a 0-10V DC or 0-20mA signal based on input source.

Direct Digital Control (DDC) : A 0-10V DC or 0-20mA signal is sent to the MUA board from the building control system to regulate the blower/heating output of the unit.

In all cases, the MUA board controls the amount of gas to the burner based on the signal from the temperature control components.

The operation of the modulating gas valve with regard to voltage is as follows: from 0 volts to approximately 5 volts, the modulating gas valve should be on bypass flow with the heater operating on low or minimum fire. From approximately 5 volts to 15 volts DC, the valve should be performing its modulating function, and the heater should be firing at a modulated flow rate between low and high fire, depending upon the voltage. Above approximately 15 volts DC, the valve should be delivering full flow to the heater and the unit should be on high fire.

control board.

Figure 15 - Temperature Sensor

ECM (Electronically Commutated Motor) Speed Control

EC motors with control allow accurate adjustment of fan speed. The benefit of EC motors is exceptional efficiency, performance, and motor life.

External PWM Signal

The fan unit will be shipped with power wiring and communication wiring fed to an internal junction box.

The fan is shipped with Shielded Twisted Pair (STP) wire, which is used for wiring to a remote PWM signal.

Red wire is used to go to the positive PWM signal, and black wire is used to go to the negative PWM signal.

Reference schematics for all wiring connections. STP is connected to the communication wiring of the motor using wire nuts in the junction box. If a preset length of STP is provided, it will be connected to the junction box from the factory. Run the STP through any available knockout in the fan base.

28

OPERATION

Accessing Menu Configurations

General Overview

The HMI allows the user to change parameters and options. The user may use the HMI to view operating information regarding sensors, temperatures, pressures, and fault history on the HMI screen

(

There are four buttons to navigate through the HMI screens.

NOTE: Buttons change functions during certain options and tests.

Verify the screen and buttons throughout the menu display.

Figure 16 - HMI Screen

OCCUPIED

SPACE

70°F

IDLE

The user can access the Top Menu HMI configurations by pressing the top two buttons simultaneously. To exit this screen, simply press the

‘BACK’ button. When setting certain options or functions, pressing the

‘BACK’ button multiple times will bring up the save screen (

The user may select ‘YES’ to save the changes, select ‘NO’ to return to factory settings or select ‘CANCEL.’ When selecting ‘CANCEL,’ any changes made will not be saved, and the screen will return to the top menu.

The HMI menu system allows full access to every configurable parameter in the HMI. The parameters are factory configured to the specific application. Parameters may need to be modified to fine-tune automatic operation after the original setup.

Figure 17 - Save Screen

UP

SAVE CHANGES?

CONFIRM YES

BACK

DOWN ENTER

Remote (HMI) Control Panel

On units shipped with a space HMI, a Cat 5 cable will need to be run from J4, J5, or J6 (refer to schematics) on the main MUA Board to J2 on the HMI. If additional space HMIs have been added, they can be daisy-chained from the first HMI. In the event there is a slave MUA board, HMIs can also be powered from J1 or J2 of the slave board. An end of line resistor should be added to the last HMI in the chain.

HMI Notification Letters

The HMI will display notification letters (

Figure 18 ) when the unit is in a

specific status.

• B = Blower Start or Blower Stop Delay Active

• C = Condenser Min On or Min Off Timer Active. Displayed when any of the condensers are in a Min On/Off Time.

• D = Min or Max Discharge Temp Reached

• M = Max Temp Rise Reached

• R = OA Reset

• Δ = Dynamic SP Applied

Figure 18 - Notification Letters

B

OFF

01/01

FRI

B

OFF

HEAT

TEMP +

09:49

AM

SPACE

70°F

TEMP -

Notification

Letter Location

29

HMI Configuration Menu

To enter the configuration menu (

), press the bottom two buttons simultaneously on the HMI faceplate. In this menu screen, you may adjust Communication and Advanced Options, check Status, and

About information.

Figure 19 - Configuration Menu

UP MENU

Configuration

Communication

Advanced Options

Status

DOWN ENTER

Communication

Under the communication menu, the user may adjust the following settings:

• Modbus Address - Default is 55 for the first HMI. For every additional HMI, increase the address by one. For example, if a second HMI is used, the Modbus Address should be 56. For a third HMI, the

Modbus Address should be 57.

• Baud - The baud rate address is 115200.

• Parity - Do not adjust this setting. The default setting should always be set to ‘EVEN.’

Advanced Options

Under advanced options, the user may adjust the following settings:

• Contrast - The user may adjust the setting from 0 to 10. Setting the contrast to 0 is the lowest setting available, and 10 is the highest contrast setting available. The factory default contrast setting is 5.

• Audio Enable - User may set the audio to off.

• Dimming Enable - Default is set to Off. If set to On, the ‘HMI Dimming Timer’ option will be available.

• Set Time - The user may adjust dimming setting from 10-60 seconds. The default time is 30 seconds.

Status

User may monitor board temperature status, Uptime (how long the board has been active since last restart), HW RH (HMI hardware humidity sensor), HW Temp (HMI hardware temperature sensor).

About

User may view SCADA HMI Software Version, Modbus Address (assigned to HMI), Baud (115200).

30

Scheduling

To set a schedule on the HMI (

Figure 20 ), you must first enable scheduling:

Factory Settings >

Occupied Scheduling > On

Set your sensor temperature setpoints for occupied and unoccupied schedules: User Settings > Temp

Set Points > (Varies)

Once scheduling is enabled, and the temperature setpoints are configured, you may enter your scheduled days and times: User Settings > Scheduling

Schedule A Default

• Monday - Friday

8:00AM to 6:00PM

• Saturday and Sunday

Unocc

Schedule B Default

• Monday - Friday

Unocc

• Saturday and Sunday

Unocc

Figure 20 - Scheduling Screen

Schedule C Default

• Monday - Friday

Unocc

• Saturday and Sunday

Unocc

UP BACK

A

B

OCCUPIED SCHEDULING

MONDAY

8:00AM TO 6:00PM

6:00PM TO 6:00PM

DOWN ENTER

To adjust the settings, highlight the parameter and press ENTER .

• The first parameter to be highlighted will be the day. Press UP or DOWN to select the day an occupied time schedule is required.

• Press ENTER to continue to set a start time. Press UP or DOWN to set start time.

• Press ENTER to set an end time. Press UP or DOWN to set end time.

The system will run between these days, time, and desired temperature settings. When in the

UNOCCUPIED setting, the system will run at the unoccupied temperature setting.

Fan Speed and Damper Position Presets

outlines the aux pins on Connector J11 for preset settings associated with fan speed and damper position found in Factory Settings > Unit Options .

Table 7 - Aux Presets

Presets

Normal Operation (Selected Blower Mode)

Fan Speed/Damper Position 1

Fan Speed/Damper Position 2

Fan Speed/Damper Position 3

Fan Speed/Damper Position 4

Fan Speed/Damper Position 5

Fan Speed/Damper Position 6

Fan Speed/Damper Position 7

Aux 1

X

X

X

X

Aux 2

X

X

X

X

Aux 3

X

X

X

X

31

Unit Options

Building Signal Damper Control

When this option is ordered, the outdoor air (supply) and return dampers will modulate based on a 0-10V

DC signal from the Building automation system. 0V = max outside air, 10V = max return air. Direct fired units cannot go below 20% outside air, maximum output voltage may differ.

Electric Cabinet Heater

Units can be shipped with an optional 120V electric cabinet heater powered from the MUA board. There is a temperature sensor built onto the MUA board that will regulate when the cabinet heater activates. To enable this option go to Factory Settings > Unit Options > Cabinet Heater > Enable . Temperature readings and adjustments can be made through the HMI. Go to User Settings > Temp Set Points >

Option Set Points > Cab Heat Set Points .

Motorized Intake Damper

On units shipped with the optional motorized intake damper, a power transformer is supplied with the unit if the main incoming voltage is greater than 120V. No external wiring to the damper motor is required.

Mixing Box Control Unit Options

Manual Control - The dampers can be controlled from the HMI in the unit or from a space HMI if one is provided to any position from 20% to 100% fresh air. This is a 0-10V setting, which is available under user settings, 100% Outdoor Air (0 volts), 80% Return Air (equivalent voltage). This will allow to manually set the dampers to match the building ventilation requirements. On a power failure, the return air damper will close by spring return.

Two Position Control - The dampers can be controlled by a two-position switch (a field-supplied switching device) to open the fresh air to 100%. The MUA board sends out a constant voltage. The field supplied switch will cut or allow the signal from the MUA board to the mixing box damper. On opening of the circuit, power failure, or if the unit is shut off, the return air damper will close by spring return. If the circuit is closed, the MUA board will allow the return air damper to open per the setpoint.

Outdoor Air % - The dampers can be controlled from the HMI in the unit or from a space HMI if one is provided to any position from 20% to 100% fresh air. There is an outdoor air percentage setting which is available under user settings. This will allow the user to manually set the dampers to match the building ventilation requirements.

• When preset OA is On, the unit will use preset values for mixing box OA% by directly associating

OA voltage to OA percentages. A calibration can be run from the service menu to store and use real-world results rather than provided defaults.

• When preset OA is Off, the MUA board utilizes an internal algorithm to alter its 0-10V output to the mixing box damper in order to maintain an exact outdoor air percentage. When this mixing box option is selected, a mixing box dead-band comes into play. This setting checks the delta T between outdoor and return air. If the difference between these two temperatures is less than or equal to the mixing box dead-band setting, the MUA board will not alter its output to the mixing box damper (default setting is 5 degrees). On a power failure, or if the unit is turned off, the return air damper will close by spring return.

Analog Control - When this is set to ON, a 0-10V input will drive the damper output to modulate linearly between the min and max OA voltage for both occupied and unoccupied modes.

Static Pressure Control - Damper position will modulate to maintain building pressure. Building pressure below the setpoint will increase the amount of outdoor air supplied to increase pressure. Building pressure above the setpoint will decrease the amount of outdoor air supplied to decrease pressure.

CO2 Control - When the unit senses the CO2 input to be above the threshold setting, the unit will decrease mixing box output until the CO2 falls below threshold setting.

32

Menu Descriptions

NOTE: Refer to “Menu Tree” on page 41 through page 48 for default/range settings.

User settings: Allows the user to change or set certain temperatures and configurations on the unit.

Factory settings: Requires a password (1111) to enter this menu. Factory settings are job-specific and configured from the plant. Any changes to the factory settings will require the user to save the updated changes.

Service: Requires a password (1234) to enter this menu. Allows a certified technician to monitor the unit and test components in the system.

User Settings

Temp Set Points - Some or all of these setpoints may not be available based on settings. If scheduling is enabled, there will be occupied and unoccupied values for each setpoint. The user will be allowed to check or adjust the setpoints/limits.

Dry Mode Config - The user will be allowed to view or adjust dry mode setpoints/limits when the option is enabled.

Scheduling - This menu will only show when the scheduling option is set to On.

• Scheduling Times - Each day contains the option for three occupied time periods. Time periods cannot overlap.

• Schedule Copy - This will allow the user to copy an existing schedule from one day of the week to individual days in the week, to Week Days, or All.

Fan Speed - Enabled when the supply fan is controlled by a VFD or ECM. The range of this menu is limited by the min and max setpoints under factory settings. When the fan is set to VFD, the settings will be displayed in Hertz. When the fan is set to ECM, the PWM percentage will be displayed. When occupied scheduling is set to On, occupied and unoccupied settings are available.

Mixing Box Setting - Mixing box will allow outdoor air in vs. return air. 0V out is equal to 100% OA and

0% RA.

Pressure Config - Adjustable pressure setpoints for static pressure control.

Active Faults Contains the current faults on the board.

Fault History Displays time-stamped history of the last 20 faults. The most recent fault will show first.

Reset Lockouts - Reset lockout faults.

Dynamic SP Diff - Temperature differential for dynamic setpoint change.

Dynamic SP Offset - Temperature amount that will change per differential.

Dynamic Heat OA - Outdoor air dynamic heat setpoint.

Dynamic Cool OA - Outdoor air dynamic cool setpoint.

CO2 Control Config - CO2 Parts Per Million (PPM) setpoints and sensor settings.

• PPM Low/High - CO2 Parts Per Million (PPM) threshold setpoints for the space.

• PPM Limit - CO2 Parts Per Million (PPM) threshold limit setpoints.

• Sensor Min/Max - Set minimum and maximum range setting for CO2 sensor.

33

Factory Settings Password to enter factory menu is 1111.

NOTE: Refer to “Menu Tree” on page

41 through page 48 for default/range settings.

Heating Type - Unit heating type is set from the factory.

Temperature Control - The MUA board monitors temperature control setpoints and components.

• Tempering Mode - The options for controlling the output of the tempering mode in heat/cool (if equipped). Available options are Intake/Discharge/Space/Analog Control/Direct Digital Control (DDC).

• Activate Based On - Select how the unit will activate based on temperature readings: Intake/Space/

Both/Either/Stat (field installed thermostat). These settings can be altered for occupied and unoccupied preferences.

• Activation Sensor - Allows selection of intake or outdoor sensor for unit to activate.

• Construction Mode - Configurable option for units used in construction settings.

Heating Config - Allows the user to set various heating configurations.

• # of Heat Stages - Default is set to 0 for units without gas heat. If the unit is equipped with gas heat, select 1.

• Gas Type - Select gas type, natural gas or propane, for the unit.

• Gas Valve Limits - This setting adjusts the unit’s gas valve range. You may adjust the Min or Max percentage range.

• Heat Hyst - Intake or Space tempering sensor must go this amount of degrees above the setpoint before heating turns off.

• Input Source - This lets the board know what signal (volts or milliamps) to expect from the analog control system. Only valid for analog tempering mode.

• 2nd Disch Sensor - On/Off selection. When an additional thermistor is added, the two thermistor readings will be averaged together. Default Off.

• Average High Temp - On/Off. When the “2nd Disch Sensor” is On, this menu will be available. When

“Average High Temp” is Off, if either discharge sensor goes above high temp limit the unit will go into high temp lockout. When “Average High Temp” is On, both thermistors readings will be used to determine high temp lockout. Default Off.

• Pre Purge Config - When enabled, this option will purge any gas that may not have combusted in the unit before the unit lighting off. You may set the amount of time the purge cycle will operate.

• Cabinet Hyst - The cabinet temp must reach this many degrees above the activation setpoint to turn off.

• Freezestat Timer - If the discharge temperature is below the freezestat setpoint for half the duration of the freezestat timer, the heat will shut off momentarily. If the freezestat trips for a second time, the heat will shut down immediately. Reset the lockout manually on the HMI.

• Construction Heater - When this option is set to On, settings will override any other airflow proving values and high-temperature setting.

• Max Temp Rise Limit - Compares max rise limit to calculated max temp rise. Software will always utilize the lower of the two values.

• Blwr Off Flame Fail - When enabled On, the blower will shut down if a flame lockout occurs. The blower may go back into operation after the fault is cleared.

34

Factory Settings Password to enter factory menu is 1111.

NOTE: Refer to “Menu Tree” on page 41 through page 48 for default/range settings.

Cooling Config - Allows the user to set various cooling configurations.

• Cooling Type - Selections are None, DX, Evap, Both. If “None” is selected, all cooling options under user settings are hidden.

• Min Cool OA Temp - When the space temperature is calling for cooling, and the outdoor air temperature is below the setpoint, the unit will shut the condensers off. The blower will start and use outdoor air to cool the space.

• Condenser Staging - Selections None, 1, 2, or 3 condensers. Within the 2 and 3 condenser selection, there is another sub-menu which allows for 2 or 3 stages. For 2 condenser units, 3 stages should only be selected when the condensers are of unequal tonnages.

• Cool Hyst - Intake or Space tempering sensor must fall this many degrees below the setpoint for cooling turns off.

• Condenser Min Times - Minimum time each condensing stage must remain on after becoming activated. This is to prevent stage cycling. A “C” will be present in the lower-left corner of the home screen when any of the condensers are in a MIN ON/OFF TIME.

• Evap Config

• Sprayer Times

• Time On - Time the evaporative cooler will spray in the cycle.

• Time Off - Time the evaporative cooler will be idle in the cycle.

• Evap Drain - Units that use evap drain should be set to On.

• Drain Hyst - Temperature differential setting before the drain shuts off.

• Evap Hyst - Temperature differential before the evap cooling shuts off.

Occupancy Config - Allows access to setting scheduling and/or override On or Off.

• Scheduling - This menu is where the scheduling can be turned On or Off. Default is Off.

• Override - This menu is where the occupancy override can be turned On or Off.

Unit Options - Allows user access to various options included with the unit.

• Board Config

• Unit Address - Modbus address of the MUA Board.

• Startup Timer - Time upon power-up where the board will sit idle.

• Temp Readings - Allows user to set temperature readings between Fahrenheit or Celsius.

Changing between the two will reset all setpoints.

• HMI Config - Allows access to adjust HMI settings and options.

• Number - Set the number of HMIs connected to the MUA board.

• Screensaver - Default is set to On. If set to Off, the home screen will not time out to the screensaver.

• Average HMI - If there are multiple space HMIs connected, this menu allows you to select which will be included in the space temperature and relative humidity averaging. If a thermistor or relative humidity sensor is connected into the ST screw terminals, it will automatically be averaged into any HMIs included. When in Space Tempering Mode, a minimum of one HMI must have Average HMI set to On, or a separate remote sensor must be used that is wired back to the MUA board.

• Lock Screen - If the option is set to On, a password (9999) will be required when; screensaver option is enabled or if any button functions are not pressed for 5 minutes.

• Scnsvr Disp - Displays date, time, and/or temperature when screensaver is active.

35

Factory Settings Password to enter factory menu is 1111.

NOTE: Refer to “Menu Tree” on page 41 through page 48 for default/range settings. Refer to

for Aux pin settings .

• Blower Config

• Blower Control - Allows user to select between 120V Contactor, VFD Manual, VFD Preset, VFD

Jog, VFD 0-10V, ECM, ECM 0-10V, ECM Preset, ECM Pressure, ECP.

• 120V Contactor - 120V output on the MUA board to energize the coil of a contactor. This option should be selected when the MUA is used in conjunction with a DCV package.

• VFD Manual - HMI selectable VFD frequency.

• VFD Preset - HMI selectable fan preset speeds. Fan speed is determined by Aux pins.

• VFD Jog - For use with VFDs using photohelic control. Aux pins are used to control the VFD.

Powering aux 1 will speed the fan up, powering aux 2 will slow the fan down. When aux 1 or aux

2 are not powered, the VFD will hold current speed.

• VFD 0-10V - For use when an external 0-10V signal is being provided to control the speed of the

VFD. The VFD output from this input will be based on the VFD min and max freq set under protected params in factory settings. 0 Volts will equal VFD min, 10V will equal VFD max, and all voltages in between will be scaled linearly. This option will utilize 0-10V J14-(6) and 0-10V common J14-(7) screw terminals, and will require field wiring.

• VFD Pressure - For use with VFDs that use a pressure transducer (0-10V output).

• Electronically Commutated Motor (ECM) - HMI selectable PWM rate.

• ECM 0-10V - For use when an external 0-10V signal is being provided to modulate the ECM supply output between min and max speed.

• ECM Preset - HMI selectable PWM fan preset speeds. Fan speed is determined by Aux pins.

• ECM Pressure - For use with ECMs that use a pressure transducer (0-10V output).

• Blower Mode :

- If “Occ” is set to On, the menu screen for the blower mode will allow you to choose ON/AUTO

OFF for Occupied or Unoccupied.

- If “Occ” is set to Off, the menu screen for the blower mode will allow you to choose MANUAL/

AUTO/INTERLOCK. In blower auto mode, the blower will only run when it gets a call for heating/ cooling.

- In blower manual/on mode, the blower will run as long as the fan button is enabled regardless of whether the unit is heating/cooling. In blower off mode, closing contacts J16-5 (unit intlk) and

J16-6 (24V AC) will cause the blower to run.

• Blower Presets - User may set blower preset option On/Off.

• Post Purge Config - When enabled, this option will run the blower for the set time after heating has shutdown.

• Door Interlock - When enabled, if the door is open, the supply fan will shut down immediately.

• Fan Proving Config - To set fan proving, the Exhaust Contactor must be set to Before Airflow or

After Airflow. When enabled, the user may set the number of contactors used. Contactor 1 = Aux 2.

Contactor 2 = Aux 3.

• VFD Direction - Sends a command to the VFD to run in forward or reverse.

• VFD Freq Limits - Min to Max range settings for fan speed.

• VFD Volt Limits - Min to Max range settings for third party VFDs.

• PWM Rate Limits - Range Min to Max settings for fan speed.

• Occ Fan Presets - After the blower has started, the blower setting will use the aux pins to drive the preset occupied value.

• Unocc Fan Presets - After the blower has started, the blower setting will use the aux pins to drive the preset unoccupied value.

36

Factory Settings Password to enter factory menu is 1111.

NOTE: Refer to “Menu Tree” on page 41 through page 48 for default/range settings. Refer to

for Aux pin settings .

• Occ PWM Presets - After the blower has started, the blower setting will use the aux pins to drive the preset unoccupied value.

• Unocc PWM Presets - Allows user to set unoccupied preset blower speed value.

• VFD By Others - This option will be used when a factory provided Modbus control VFD is not utilized. A start command, as well as a 0-10 V output will be provided to the VFD.

• Pressure Config

• Sensor Range - Menu is available when any blower pressure or mixing box pressure option is selected.

• Static PS KP - Proportionally constant value for static pressure measured in V/sec.

• Cycle Time - Cycle time is the time between two consecutive readings.

• PS Hysteresis - Percentage band between high and low static setpoints. This will reduce cycling of blower or damper. Increase this value if the blower speed or damper does not settle into a setpoint.

• Airflow Proving - User can set unit to prove with airflow sensor located on the board.

• Purge Config

• Purge Button - When the purge button is pressed, the damper will open to max outdoor air and turn on the exhaust contactor, if enabled. Purge Button must be enabled for Dry Mode use.

• Purge Time - This is the amount of time that the unit will run the purge process if the user does not stop the purge manually.

• Purge Speed - Adjustable between VFD or ECM. Min and Max frequency the fan will run during the purge cycle.

• Dry Mode Config - When this option is set to On, there are three separate ways to initiate dry mode. Through the HMI home screen, through a hardwired input, or automatic activation. When dry mode is activated:

- The unit will go to Dry Mode Discharge when there is a call for heat.

- Space dewpoint is the average of the Space RH input with any additional HMI inputs.

- If OA dewpoint < Space dewpoint, the mixbox should go to mix box outdoor air. This should override any other mixbox functionality. The exhaust contactor should turn on.

- If OA dewpoint > Space dewpoint, the mixbox should go to min OA%. The exhaust contactor should not turn on.

- Purge should run until the purge timer expires or the user cancels the purge.

• Space DP SP - Dewpoint threshold for automatic dry mode activation.

• Monitoring Sensors - Smoke Detector, Filter Monitor, Intake Firestat, Discharge Firestat, Freezestat,

Low Gas Switch, High Gas Switch, CO Shutdown.

• Mixing Box Config

• Mixing Box - Off, Manual, 2 Position, Outdoor Air %, Analog Control, Pressure, CO2.

• Mixing Box Deadband - If the temperature difference between the outdoor and return sensor is less than or equal to this setpoint, the MUA board will not attempt to adjust the output voltage until it matches the outdoor air percentage setpoint. This setting only takes effect when either outdoor air

% or schedule is selected.

• Return As Space - Setting this to On will not require a space sensor or HMI. This setting will use the return air thermistor (RT) in place of the space sensor.

• Off Position - Allows user to select how the dampers will be positioned when the supply fan is off.

Standard (default), Max Outdoor Air %, or Min Outdoor Air %.

• Mixing Box Limits - Minimum and maximum settings for mixing box. Percentage or voltage based on mixing box selection.

• Preset OA Values - On/Off option. If set to On, the voltage values equivalent to air percentage.

• Edit OA% Table - User may edit voltages for the equivalent to outdoor air percent table.

37

Factory Settings Password to enter factory menu is 1111.

NOTE: Refer to “Menu Tree” on page 41 through page 48 for default/range settings. Refer to

for Aux pin settings .

• Damper Presets - This allows the user to set damper preset option On or Off.

• Preset Volts - Uses aux pins to control damper actuator.

• Occ/Unocc Preset Volts - When scheduling is On, Occ Preset Volts and Unocc Preset Volts with be available.

• Intake Damper - User can adjust intake damper to be On or Off.

• Discharge Damper - User can adjust discharge damper to be On or Off.

• Room Override - Uses room override SP rather than Discharge SP. This setting will only have an effect when the heat tempering mode setting is discharge and activate based on is not set to intake.

• Exhaust Contactor - This allows the user to assign a contactor for an interlocked exhaust fan. There are occupied and unoccupied settings.

• None

• Before airflow - Exhaust fan will start before the airflow proving switch has been activated.

• After airflow - Exhaust fan will start after the airflow proving switch has proved there is airflow.

• Exhaust On Smoke - Input that when enabled, if it receives a 24VAC signal from a fire system, this will shut down the supply fan and enable the exhaust contactor. The 24VAC signal must originate from the MUA Board.

• Cabinet Heater - This allows the user to enable the cabinet heater, if applicable. If enabled, the temperature sensor on MUA board controls the cabinet heater. When this option is enabled, to adjust setpoints, go to User Settings > Temp Set Points > Option Set Points > Cab Heat Set Points .

• Blower Throttle - The throttle function is to maintain profile pressure across the burner.

• Throttle Volt Step - Increases/decreases fan speed when a third party VFD is used.

• Proof of Closure - For gas valves that contain a proof of closure switch, the user may set this option

On. Before heating occurs, a 24V AC input must be present at connector J32 pin 12.

• No FSC Reset - When this option is set to On, the flame safety control will not reset on a failure to prove flame. If the flame fails, a manual reset is required immediately via the push button or HMI.

• Warm Liquid Bypass - Prevents freezing of condensing coil in low ambient temperatures.

• Trouble Input - While connector J28 pin 3 receives 24 volts, the unit will act based on one of the following settings:

• Unit Off - Shuts down blower (heating/cooling will also shutdown). Timers will be bypassed.

• Both Off - Turn off/lockout heating and cooling. Bypass min on/off timers.

• Heat Off - Turns off/lockout heating.

• Cool Off - Turns off/lockout cooling. Bypass min on/off timers.

• Set Back - Forces unit to unoccupied state.

• DD Wheel Size - Direct drive wheel size selection. The wheel size selection will be utilized for CFM monitoring. Models available are 11,13, 15, 18, 20, 24, 30, 36, 16Z, 18Z, 20Z, 22Z, 25Z, 28Z.

• CO2 Control Config - Mixing box settings for CO2 control.

• Override - If CO2 exceeds override setting, the blower will speed up incrementally from PPM low

(speed when override started or damper position when override started) to PPM high (max speed or max outside air). Accepts 0-10V DC input to determine CO2 level.

• Threshold - If CO2 exceeds CO2 threshold, the blower will speed up, or the damper will open

(depending on selection). Accepts 0-10V DC input to determine CO2 level.

38

Factory Settings Password to enter factory menu is 1111.

NOTE: Refer to “Menu Tree” on page 41 through page 48 for default/range settings.

• Outdoor Reset - Allows access to setting option On/Off. Below are scenarios for Outdoor Reset functionality.

- Discharge Heat Tempering: If outside air is below OA Reset Low setpoint, heat will discharge to

Reset Heat Discharge setting.

- Space Heat Tempering: If outside air is below OA Reset Low setpoint, space setpoint will adjust to

Reset Heat Space setting.

- Intake Cool Tempering: If outside air is above OA Reset High setpoint, cooling will go to max staging. If both evap and dx are present, unit will run all.