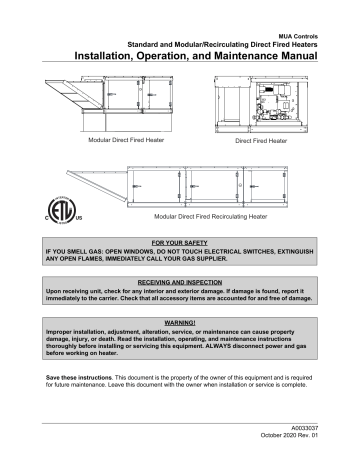

advertisement

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in accordance with this manual. If there are any questions about any items, please call the service department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE UNIT BY THE INTAKE HOOD, BLOWER, MOTOR SHAFT, OR

BEARINGS. USE ALL LIFTING LUGS PROVIDED WITH A SPREADER BAR OR SLING UNDER THE

UNIT.

Clearance

The top, back, and front surfaces of this heater may not be installed less than 6” from combustible materials. The heater base may be installed on combustible surfaces. Allow 24” minimum service clearance on both sides of this heater.

Site Preparation

Figure 1 - Spreader Bar

1. Provide clearance around installation site to safely rig and

lift equipment into its final position ( Figure 1 ). Supports

must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Locate unit close to the space it will serve to reduce long, twisted duct runs.

3. Consider general service and installation space when locating unit.

4. Do not allow air intake to face prevailing winds. Support unit above ground or at roof level high enough to prevent precipitation from being drawn into its inlet. The inlet must also be located at least 10 feet away from any exhaust vents. The fan inlet shall be located in accordance with the applicable building code provisions for ventilation air.

5. All air to the heater must be ducted from the outdoors.

Recirculation of room air is not permitted. If in doubt regarding the application, consult the manufacturer.

6. Recirculation of room air may be hazardous in the presence of:

• Flammable solids, liquids, and gases

• Explosive materials (e.g., grain dust, coal dust, gun powder, etc.)

• Substances which may become toxic when exposed to heat (e.g, refrigerants, aerosols, etc.)

7. Recirculation is not recommended in uninsulated buildings where outside temperatures fall below 32 ° F (0°C).

8. Excessive recirculation or insufficient ventilation air, which results in inadequate dilution of the combustion products generated by the heater, may create hazardous concentrations of carbon dioxide, carbon monoxide, nitrogen dioxide, and other combustion products in the heated space. Refer to Table 1 for ventilation requirements.

Spreader

Bar

Lifting Lugs

Lifting Lugs

4

9. If gas fork trucks or other fossil fuel powered equipment are utilized in the conditioned area, additional ventilation requirements for the facility must be addressed separately.

10. If the heater utilizes room sensors for limiting room CO

2

concentration:

• The CO

2 control set-point shall be no greater than the maximum allowable room concentration of

5000 ppm less the sensor’s published accuracy tolerance. The control shall prevent the CO

2 concentration in room air from exceeding 5000 ppm.

• A minimum of one sensor shall be installed per room served by the heater.

• When a room area, served by a single heater, does not exceed 10,000 ft 2 (929 m 2 ) and height does not exceed 20 ft. (6 m), a duct sensor may be installed in the return air opening of the heater.

• Sensors shall be calibrated per the sensor manufacturer’s recommended procedure and frequency or annually, whichever is more frequent.

• Each heater shall require CO

2

sensor(s).

• Sensors shall not be placed near sources of CO

2

.

%

Natural

Gas

Propane

Gas

Table 1 - Minimum Ventilation Requirements for Heaters that Recirculate

5

12.2

(6.8)

10.6

(5.9)

Minimum Ventilation Rate (as % of Total Air Throughput)

10 15 20 25 30 40

Maximum Equivalent Temp. Rise Through Heat for CO 2 °F (°C)

24.5

(13.6)

21.1

(11.7)

36.7

(20.4)

31.7

(17.6)

49.0

(27.2)

42.2

(23.5)

61.2

(34.0)

52.8

(29.3)

73.5

(40.8)

63.4

(35.2)

98.0

(54.4)

84.5

(46.9)

50

122.5

(68.0)

105.6

(58.7)

60

146.9

(81.6)

126.7

(70.4)

5

Intake Assembly

) are shipped on a separate skid. Upon unit arrival, perform the following steps to assemble the intake to the unit.

1. Apply silicone or weather-proof gasket on the backside of the flanges of the intake hood or V-bank intake.

2. Secure the flanges of the intake hood to the unit with the supplied sheet metal screws.

3. Use caulk on the outside of the screws to prevent water leaks.

4. If the unit is a modular unit with a V-bank or evaporative cooler section, the V-bank or evaporative cooler will bolt to the heater with the bolts provided.

5. Slide the filters down the filter track.

Figure 2 - Intake and Curb Assembly

Direct Fired

1

2

3

4

Direct Fired Recirc

1

2

3

1. Unit

2. Intake Housing

3. Intake Filter(s)

4

5

4. Curb

5. Mixing Box Curb

6

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will significantly affect airflow performance. When using rectangular ductwork, elbows must be radius throat, radius back with turning vanes. Flexible ductwork and square elbows should not be used. Any transitions and/or turns in the ductwork near the fan outlet will cause system effect. System effect will drastically increase the static pressure and reduce airflow.

•

fan performance. Table 2 displays recommended return ductwork sizes for recirculating units.

• Do not use the unit to support ductwork in any way. This may cause damage to the unit.

• Follow SMACNA guides and manufacturer's requirements for the remaining duct run. Fans designed for rooftop installation should be installed on a prefabricated or factory-built roof curb.

• Follow curb manufacturer’s instructions for proper curb installation.

• The unit should be installed on a curb and/or rail that meets local code height requirements.

• Make sure the duct connection and fan outlet are properly aligned and sealed.

• Secure fan to curb through vertical portion of the ventilator base assembly flange. Use a minimum of eight (8) lug screws, anchor bolts, or other suitable fasteners (not furnished). Shims may be required depending upon curb installation and roofing material.

• Verify all fasteners are secure.

through Figure 8 show different mechanical installations.

• Adequate building relief shall be provided so as not to over pressurize the building when the heating system is operating at its rated capacity. This can be accomplished by taking into account, through standard engineering methods, the structure’s designed infiltration rate; by providing properly-sized relief openings; or by interlocking a powered exhaust system; or by a combination of these methods.

• Heaters installed with intake ductwork must be purged to replace at least four air changes of the volume of the intake duct.

• If the failure or malfunction of this heater creates a hazard to other fuel-burning equipment in the building (e.g., when the heater is providing makeup air to a boiler room), the unit is to be interlocked to open inlet air dampers or other such devices.

• On outdoor installations, it is recommended that the discharge duct be insulated to prevent condensation during the “OFF” cycle in cold weather.

• Flexible connectors should be used on all ductwork connections. Vibration isolators are optional and can be supplied in the loose parts package.

• Units that are installed in airplane hangars should be installed in accordance with the Standard for

Aircraft Hangars, ANSI/NFPA 409. Units that are to be installed in public garages should be installed in accordance with the Standard for Parking Structures, ANSI/NFPA 88A, or the Standard for Repair

Garages, ANSI/NFPA 88B, and with CAN/CGA B149 Installation Codes.

Table 2 - Recommended Return Ductwork Sizes

Mixing Box

3

4

1

2

5

Duct Size (Inches)

19 x 15

25 x 24

31 x 29

37 x 34

44 x 44

7

Blower Size (Inches)

10

15D, 16Z, 18Z

12

15

20D, 20Z, 22Z

18

24D, 25Z

20

30D, 28Z

25

36D

Table 3 - Required Supply Ductwork

Discharge

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Side

Up/Down

Duct Size

14” x 14”

20” x 20”

14” x 14”

16” x 16”

20” x 20”

26” x 26”

20” x 20”

24” x 24”

30” x 30”

24” x 24”

26” x 26”

32” x 32”

26” x 26”

32” x 32”

36” x 36”

32” x 32”

WARNING!

Failure to properly size ductwork may cause system effects and reduce the performance of the equipment.

Straight Duct Length

48”

72”

48”

54”

168”

108”

168”

189”

168”

72”

108”

72”

86”

108”

86”

108”

8

Roof Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 3 - Roof Mount Details

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit Located in Curb Area for Field

Wiring

1

4. Intake Housing

5. Lifting Lugs

6. Direct Fired Module

7. Service Disconnect Switch

8. Blower/Motor Access Door

9. Curb (20” High)

10. Control Drop

11. Motor Drop

12. Gas Connection

Max. Roof Opening 2” Smaller than Curb

Outside Dimension.

8

3

7

2

12

6

Installation with Exhaust Fan

Note: Refer to submittal drawings for specific unit dimensions.

Figure 4 - Exhaust Fan Details

2

1

11

AIRFLOW

10

9

AIRFLOW

5

4

8

3

7

6 5

4

9

10

1. Discharge Opening

2. Curb Outer Wall

3. Flex Conduit Located in

Curb Area for Field Wiring

4. Intake Housing

5. Lifting Lugs

6. Direct Fired Module

7. Service Disconnect Switch

Max. Roof Opening 2” Smaller than Curb Outside Dimension.

8. Blower/Motor Access Door

9. Curb with Support Legs or

Rail (20” High)

10. Gas Connection

9

Duct Mount Installation

Note: Refer to submittal drawings for specific unit dimensions.

Figure 5 - Duct Mount Details

1. Control/Valve Access Door

2. Gas Connection

3. Optional Unistrut Base

4. Lifting Lugs

AIRFLOW

1

2

4

3

Indoor (Inline) Installation

Note: Refer to submittal drawings for specific unit dimensions.

1. Flex Conduit for Field Wiring

2. Optional Unistrut Base

3. Lifting Lugs

4. Control/Filter Access Door

5. Control/Valve Access Door

6. Gas Connection

7. Blower/Motor Access Door

8. Service Disconnect Switch

Figure 6 - Indoor Installation Details

8

1

AIRFLOW

2

3

7

6

5 4

10

Roof Mount Installation - Recirculation Unit

Note: Refer to submittal drawings for specific unit dimensions.

Figure 7 - Roof Mount Details

1. Discharge Opening

2. Curb Outer Wall

3. Curb

4. Return Damper

5. Intake Damper

6. Intake Filter

7. Direct Fired Module

8. Control Drop

9. Motor Drop

10. Blower/Motor Access

Door

11. Flex Conduit for Field

Wiring

12. Service Disconnect

Switch

13. Optional Filters

14. Lifting Lugs

1

9

10

11

8

2

12

13

7

AIRFLOW

3

4

4

AIRFLOW

5

6

14

Indoor (Inline) Installation Recirculation Unit

Note: Refer to submittal drawings for specific unit dimensions.

Figure 8 - Indoor Installation Details

1. Flex Conduit for Field

Wiring

2. Optional Filters

3. Return Damper

4. Intake Damper

5. Direct Fired Module

6. Blower/Motor Access

Door

7. Service Disconnect

Switch

8. Lifting Lugs

9. Optional Uni-Strut Base

AIRFLOW

7

1

2

AIRFLOW

6 5

3

3

4

8

9

11

Heat Module Add-On Installation

require field mechanical and wiring installation.

1. Remove existing intake housing and lifting lugs from the blower section intake side.

2. Attach heat module to blower intake using the provided sheet metal screws and bolts. Tighten screws and bolts to compress the gasket between the heat module and the blower module.

3. Support and level the end of the heat module (end opposite the blower) with the provided equipment legs/rails.

4. Attach the intake housing to the intake side of the heater module.

5. Drill a hole in the discharge of the blower large enough to insert the discharge control sensor (if provided). Install the sensor through the hole.

6. Wire the sensor and coil as indicated on the supplied wiring schematic. Route all wiring through metal conduit.

7. After the add-on installation is complete, refer to

“Start-up Procedure” on page 53 .

Figure 9 - Heat Module

4

1 2

3

1. Blower

2. Direct Fired Module

3. Intake Housing

4. Filters

7

6

5

5. Equipment Legs

6. Conduit

7. Curb

12

Gas

Installation of gas piping must conform with local building codes, or in the absence of local codes to the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, installation must be in accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane units.

WARNING: INLET GAS PRESSURE MUST NOT EXCEED PRESSURE INDICATED ON NAMEPLATE.

SEE UNIT NAMEPLATE FOR PROPER GAS SUPPLY PRESSURE AND GAS TYPE.

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect switch or breaker to prevent accidental power-up.

2. Piping to the unit should conform to local and national requirements for type and volume of gas handled, and pressure drop allowed in the line. Refer to the Gas Engineer’s Handbook for gas line capacities.

3. The incoming pipe near the heater should be sized to match the connection on the outside of the unit.

Unit inlet sizes are shown in

Table 4 . The unit requires a steady supply of gas at all times, avoid

multiple taps in the gas supply line.

4. Install a ground joint union with brass seat and a manual shut-off valve external to the unit casing.

Install shut-off valve adjacent to the unit for emergency shut-off and easy servicing of controls. Refer to

.

5. Provide a sediment trap, as shown in

Figure 10 on page 14 , before each unit and where low spots in

the pipeline cannot be avoided.

6. Clean out the gas line to remove debris before making connections. Purge gas line to remove air before attempting to start unit. Purging air from gas lines should be performed as described in ANSI

Z223.1-latest edition “National Fuel Gas Code,” or in Canada as described in CAN/CGA-B149.

7. All field gas piping must be pressure/leak tested before unit operation. Use a non-corrosive bubble forming solution or equivalent for leak testing. The heater and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psi.

8. This unit requires the gas pressure to be within the unit’s minimum and maximum gas pressure ratings. If the pressure is greater than the maximum, the internal valve components will be damaged. If the pressure is below the minimum, the heater will not perform to specifications. Refer to

Table 5 on page 14 for gas pressure ratings.

Unit Size

Size 1

Size 2

Size 3

Size 4

Size 5

Table 4 - Gas Connection Sizes

Gas Pipe Size (NPT)

3/4”

1”

1”

1-1/4”

1-1/2”

13

1

Figure 10 - Gas Connection Diagram

1

2

3

4

A

5

1. Gas Supply Line Connection

2. Manual Gas Shut-off Valve

3. Ground Joint Union with Brass Seat

4. Plugged 1/8” NPT Test Gauge Connection

5. Sediment Trap

A. Minimum Depth = 3”

Table 5 - Gas Pressure

Gas Pressure Type

Size 1-3 Inlet

Size 4-5 Inlet

Maximum Manifold Pressure - Natural Gas

Maximum Manifold Pressure - Propane

Gas Pressure

7 -14 Inches WC

7 Inches WC - 5 psi

5 Inches WC Maximum

2.5 Inches WC Maximum

NOTICE

Refer to the heater’s rating plate for determining gas supply pressures and requirements.

14

advertisement

Related manuals

advertisement

Table of contents

- 3 WARRANTY

- 3 Listings

- 3 Patents

- 4 INSTALLATION

- 4 Mechanical

- 7 Curb and Ductwork

- 9 Roof Mount Installation

- 9 Installation with Exhaust Fan

- 10 Duct Mount Installation

- 10 Indoor (Inline) Installation

- 11 Roof Mount Installation - Recirculation Unit

- 11 Indoor (Inline) Installation Recirculation Unit

- 12 Heat Module Add-On Installation

- 13 Gas

- 15 ELECTRICAL

- 16 Fan to Building Wiring Connection

- 17 Make-up Air (MUA) Board Connectors

- 27 HMI and Remote Room Sensor Installation

- 28 Temperature Control

- 28 ECM (Electronically Commutated Motor) Speed Control

- 28 External PWM Signal

- 29 OPERATION

- 29 Accessing Menu Configurations

- 29 Remote (HMI) Control Panel

- 29 HMI Notification Letters

- 30 HMI Configuration Menu

- 30 Communication

- 30 Advanced Options

- 30 Status

- 30 About

- 31 Scheduling

- 31 Fan Speed and Damper Position Presets

- 32 Unit Options

- 32 Building Signal Damper Control

- 32 Electric Cabinet Heater

- 32 Motorized Intake Damper

- 32 Mixing Box Control Unit Options

- 33 Menu Descriptions

- 41 Menu Tree

- 49 Variable Frequency Drive (VFD)

- 50 VFD Installation

- 50 Input AC Power

- 50 VFD Output Power

- 51 VFD Programming

- 52 ACTECH SMV VFD

- 53 START-UP OPERATION

- 53 Start-up Procedure

- 54 Pulley Adjustment

- 55 Pulley Alignment/Proper Belt Tension

- 56 Pulley Combination Chart

- 57 Air Flow Sensor

- 58 Modulating Gas System

- 58 High Temperature Limit

- 58 Pilot Adjustment

- 59 Main Burner Adjustment

- 60 Final Start-up Procedure

- 61 Sequence of Operation

- 61 Flame Safety Control

- 63 Components

- 64 Network

- 64 BACnet

- 65 LonWorks

- 66 Device Instance, MAC Address, Baud Rate

- 67 Changing the IP Address

- 68 DDC Control Points

- 72 DDC Fault List

- 73 Troubleshooting

- 74 Burner Troubleshooting

- 75 HMI Fault Codes

- 78 VFD Fault List

- 78 Resetting Unit

- 79 MAINTENANCE

- 79 General Maintenance

- 79 2 Weeks After Start-up

- 79 Every 3 Months

- 79 Yearly

- 80 Burner Maintenance

- 80 Unit Filters

- 81 Emergency Shutdown of Unit

- 81 Prolonged Shutdown of Unit

- 84 Start-Up Documentation