advertisement

▼

Scroll to page 2

of

64

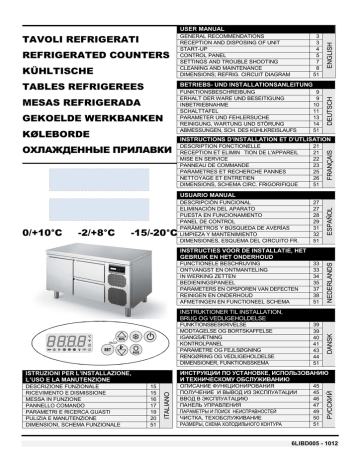

TAVOLI REFRIGERATI REFRIGERATED COUNTERS KÜHLTISCHE TABLES REFRIGEREES 3 3 4 5 7 8 51 USER MANUAL MESAS REFRIGERADA GEKOELDE WERKBANKEN KØLEBORDE 9 9 10 11 13 14 51 ОХЛАЖДЕННЫЕ ПРИЛАВКИ DESCRIPTION FONCTIONELLE RECEPTION ET ELIMIN TION DE L'APPAREIL MISE EN SERVICE PANNEAU DE COMMANDE PARAMETRES ET RECHERCHE PANNES NETTOYAGE ET ENTRETIEN DIMENSIONS, SCHEMA CIRC. FRIGORIFIQUE 21 21 22 23 25 26 51 0/+10°C -2/+8°C -15/-20°C DESCRIPCIÓN FUNCIONAL ELIMINACIÓN DEL APARATO PUESTA EN FUNCIONAMIENTO PANEL DE CONTROL PARÁMETROS Y BÚSQUEDA DE AVERÍAS LIMPIEZA Y MANTENIMIENTO DIMENSIONES, ESQUEMA DEL CIRCUITO FR. 27 27 28 29 31 32 51 USUARIO MANUAL 33 33 34 35 37 38 51 NEDERLANDS INSTRUCTIES VOOR DE INSTALLATIE, HET GEBRUIK EN HET ONDERHOUD ITALIANO 15 15 16 17 19 20 51 45 45 46 47 49 50 51 РУССКИЙ ИНСТРУКЦИИ ПО УСТАНОВКЕ, ИСПОЛЬЗОВАНИЮ И ТЕХНИЧЕСКОМУ ОБСЛУЖИВАНИЮ ISTRUZIONI PER L’INSTALLAZIONE, L’USO E LA MANUTENZIONE DESCRIZIONE FUNZIONALE RICEVIMENTO E DISMISSIONE MESSA IN FUNZIONE PANNELLO COMANDO PARAMETRI E RICERCA GUASTI PULIZIA E MANUTENZIONE DIMENSIONI, SCHEMA FUNZIONALE 39 39 40 41 43 44 51 DANSK 6LIBD005 - 1012 TECHNISCH LABEL 2 DANSK 2 Matrikelnr. 4 Model РУССКИЙ РУССКИЙ ТЕХНИЧЕСКАЯ ТАБЛИЧКА PLAQUE SIGNALÉTIQUE ITALIANO NEDERLANDS TARGHETTA TECNICA MATRIKELANGABEN 1. Manufacturer 2. Serial number 3. Code 4. Model 5. Voltage 6. Running absorbed current 7. Max refrigerant power 8. Running absorbed power 9. Defrost heating element power 10. Other elements nominal power 11. Lamp power 12. Max and min. pressure 13. Refrigerant, type and q.ty 14. Net capacity 15. Insulation expanding gas 16. Manufacture year 17. Climatic class Translation of the original instructions General reccomendations, reception and disposing of unit KEEP DRY INTENDED USE This appliance is designed for indoor use and should only be used to store food and beverages. Conservation models (low temperature) have been realized to store only pre-frozen products. The device should not be used by people (including children) of limited physical or motor capacity, or who lack the necessary skill or expertise, unless aided or instructed by another person responsible for their safety. STACKING OF OTHER OBJECTS ON THE APPLIANCE MUST BE ABSOLUTELY AVOIDED. UNPACKING Remove the protection without using tools that may damage the surface. Keep the packing out of the reach of children as it could be a danger hazard. Dispose of the packing to the specialized collection or recycling points (respect existing regulations). Children should be supervised to ensure they do not play with the device. Check that the serial number corresponds to the transport documents. Never place liquids or hot food into the appliance and do not fill lidded containers to the top. RESIDUAL RISKS Never place carbonated beverages into the low-temperature compartment. They may explode. In all appliances there are surfaces subject to frosting. Depending on the model, frost may be melted away either automatically (automatic defrost) or manually. Never attempt to remove frost using a pointed object You could irreparably damage the appliance. Do not use any mechanical device or other artificial means to accelerate the defrost process. The Manufacturer declines all responsibility, and the warranty shall be null and void, if electrical and/or mechanical alterations are made to the product. CONTROLS AT RECEPTION On arrival, check that the appliance has not incurred transport damage and that it is complete according to the order. In the event of visible damage immediately note the damage on the transport documents with the following wording: “RECEIVED WITH RESERVE FOR EVIDENT DAMAGE OF PACKING”. cALL THE OPERATIONS INDICATED BELOW MUST BE PERFORMED IN RESPECT OF EXISTING SAFETY REGULATIONS, BOTH FOR THE EQUIPMENT IN USE AND FOR THE OPERATING PROCEDURES BEFORE BEGINNING HANDLING OPERATIONS ENSURE THAT THE LIFTING CAPACITY IS SUFFICIENT FOR THE APPLIANCE IN QUESTION HANDLING HANDLING with FORK LIFT or SIMILAR Insert the forks into the side of back of the wooden pallet supplied with the appliance. Begin lifting checking that the appliance is in stable equilibrium. DURING HANDLING OPERATIONS DO NOT TIP OR TURNOVER IF IT’S NECESSARY TO TRANSPORT APPLIANCE DIFFERENTLY AS IN ITS WORKING POSITION, YOU HAVE TO WAIT AT LEAST 2 HOURS BEFORE OPERATING. The refrigerator equipment has been designed and manufactured with the appropriate devices to guarantee the health and safety of the user and does not contain dangerous edges, sharp surfaces or protruding elements. The stability of the machine is guaranteed even when the doors are open; however, do not pull on the doors. In the case of refrigerators with drawers, do not open more than one drawer at a time and do not lean or sit on an open drawer, so as to avoid overturning or damaging the refrigerator. N.B.: In refrigerators with glass doors do not extract more than one basket or rack at a time so as not to compromise the stability of the refrigerator. In case of appliance with wheels, when moving, take care not to forcefully push the refrigerator so as avoid overturning and damage. Also note any unevenness of the surface on which the refrigerator is being pushed. ALWAYS BLOCK THE WHEELS WITH THE STOPS PROVIDED. NOISE LEVEL The A-weighted emission sound pressure level at workstations NOT exceeds 70 dB(A); DISPOSAL OF UNIT Our appliances contain the refrigerant shown on the corresponding rating plate as per Regulation (EC) No. 2037/2000 of 29 June 2000; in addition, the appliance is composed of reusable or recyclable parts and materials. Therefore, at the end of its lifetime, the appliance should be delivered to a specific disposal center. The best method to ensure that no one will remain trapped inside is to take off the door completely. The appliance must not be disposed of together with household waste and metal scrap. Absolutely avoid damaging the refrigeration circuit, particularly near the heat exchanger. COMPLY WITH LOCAL REGULATIONS IN FORCE CONCERNING THE FINAL DISPOSAL OF THIS TYPE OF EQUIPMENT. 3 Translation of the original instructions Start-Up IMPORTANT BEFORE CONNECTING THE APPLIANCE CHECK THAT THE DATA ON THE SERIAL PLATE CORRESPOND TO THE ACTUAL ELECTRICAL SUPPLY. THE SERIAL PLATE GIVING THE ELECTRICAL DATA REQUIRED IN THE INSTALLATION IS FOUND ON THE RIGHT SIDE OF THE COMPARTMENT. An incorrect power supply could be cause of fire, electric shake or accident. THE INSTALLATION MUST BE MADE ACCORDING TO THE INSTRUCTIONS GIVEN IN THIS SECTION, BY PROFESSIONALLY QUALIFIED PERSONNEL. THE ELECTRICAL SAFETY OF THIS APPLIANCE IS ONLY GUARANTEED WHEN IT IS CONNECTED TO AN EFFICIENT EARTHING PLANT AS PRESCRIBED BY EXISTING ELECTRICAL SAFETY REGULATIONS. A connection to a defective earthing plant would be cause of short-circuit or electric shake in the case of malfunction. THE APPLIANCE MUST ALSO BE FITTED WITH AN EQUIPOTENTIAL SYSTEM WHOSE EFFICIENCY MUST BE VERIFIED ACCORDING TO EXISTING REGULATIONS. THE USE OF ADAPTERS, MULTI-PLUGS, AND/OR EXTENSION LEADS IS STRICTLY PROHIBITED PRELIMINARY GENERAL CHECKS Check that the floor is able to support the weight of the appliance and that it is level. Control the appliance is perfectly level. Regulate the adjustable feet if necessary. Use a level, if needed. The maximum permissible deviation from the horizontal plane is +/-0.5 degrees. All four feet should rest on the floor. Appliances fitted with wheels cannot be leveled, therefore, ensure that the surface on which they rest is perfectly horizontal and level. Check that the socket is suitable for the appliance plug. If necessary, the socket should be replaced with an appropriate one by qualified personnel. These personnel should also make sure that the socket cable section is appropriate to the power absorbed by the appliance. Check that the plug is plugged into the socket Otherwise the stability of the equipment is compromised and can cause the fall of it; The proper operation of the doors could be compromised. After the above controls have been thoroughly completed the appliance may be started-up: To avoid possible forming of condensate or ice, there should be a free space of at least 5cm between the appliances. On models with built-in refrigerating unit, there has to be a free space of at least 50cm in front (tables) or above (cupboards); Turn the main switch, connected to the power cable plug, to the ON position. Do not place the appliance close to heat sources (such as Press the key “ON/STAND BY” of the control panel to switch on the appliance. After about 1 minute, the compressor will start cycling until internal temperature reaches the factory-set value. Not to respect these norms can cause serious damages to the refrigerating circuit or to products contained in the equipment. To modify the factory setting of this value consult the CONTROL PANEL section. ovens, radiators, etc.) or exposed to direct sunlight; do not prevent air from circulating inside the engine compartment. If the appliance has been moved, wait for a while before switching it on again. In particular, if the handling was made differently as in it’s working position, you need to wait at least 2 hours. Remove the plastic protection from the external surfaces and wash the inside part with warm water and mild soap. Keep away from children the closing keys (if available). PRELIMINARY ELECTRICAL CHECKS AND START-UP. The network voltage and frequency values should be the same of those reported on the appliance part number plate (point 6 of the "Rating Plate" paragraph). An incorrect power supply could be cause of fire, electric shake or accident. • Fit a 16A fuse upstream from the socket. • Switch the main switch that will be connected to the power lead plug to the OFF position. CONNECT THE DEVICE TO THE MAINS USING THE PLUG PROVIDED. 4 THE PLUG MUST BE EASY TO ACCESS WHEN THE DEVICE IS INSTALLED DO NOT LOAD THE APPLIANCE UNTIL THE SET TEMPERATURE VALUE HAS BEEN REACHED NEVER EXCEED THE MAX. LOADING LIMIT SHOWED ON THE STICKER PLACED INSIDE THE COMPARTMENT OPERATION Proper storage of foodstuffs is a relevant factor in the safe and sanitary production of food; in addition, it improves the efficiency of foodservice activities and positively affects energy consumption. Follow the directions below to obtain the highest performance possible out of your appliance. Products should always be stored on the shelves; do not place any products on the cabinet’s bottom. PRODUCTS SHOULD BE PLACED INTO THE APPLIANCE IN SUCH A WAY AS TO ALLOW UNOBSTRUCTED AIRFLOW. ALWAYS LEAVE SOME FREE SPACE BETWEEN THE PRODUCTS AND PREVENT THEM FROM COMING IN CONTACT WITH THE WALLS. IF NEEDED, ADJUST THE DISTANCE BETWEEN SHELVES. Translation of the original instructions KEYPAD and ASSOCIATED FUNCTIONS The keypad is blocked by keeping and pressed simultaneously for a few seconds: "Loc" will appear on the display. INDICATORS LED ON: The compressor is on FLASHING: The working Set Point is being changed Compressor protection in progress Pressing them once again will unblock the keypad: "UnL" will appear on the display. ON: Defrosting in progress FLASHING Defrosting requested but compressor protection is in progress Dripping in progress; Heating coolant in progress ON/STAND BY Press this button for a few seconds to switch the appliance into status ON or STAND BY. MANUAL DEFROSTING Press this button for a few seconds to activate manual defrosting, if the temperature of the evaporator allows it and provided that the Overcooling function is not activated. If the defrosting time interval elapses while Overcooling is in progress, the former will be activated upon conclusion of the latter. CHAMBER LIGHT if parameter u1=0 Press the auxiliary button to switch the chamber light on and off manually (only glass door version) DOWN button This scrolls the menu items and decreases the values. When pressed for a few seconds, the Overcooling function is activated unless defrosting or dripping is not in progress or the evaporator fan is stopped. During Overcooling, the working set point is decreased to the temperature and for the time set by the parameters. UP button This scrolls the menu items and increases the values. When pressed for a few seconds, the low RH% function ("rhL" appears on the display) or the high RH% function ("rhH" appears on the display) is activated for 10 seconds. If the function is not available and the button is pressed, "----" will appear on the display. SET POINT This provides access to the set point edit function. STOPPING THE BUZZER (IF PRESENT) Briefly press any button. SETTING THE SET POINT MEANING ON The evaporator fan is on FLASHING The evaporator fan is being stopped ON : Chamber light switched on manually FLASHING Chamber light switched on automatically ON The anti-steaming up resistors will be switched on Auxiliary output switched on manually Alarm output activated The door resistors will be switched on The evaporator valve will be activated FLASHING : Auxiliary output switched on remotely ON Overcooling in progress ON Alarm or error in progress ON: Not all the information regarding the HACCP alarms has been displayed FLASHING : At least one new alarm has been saved OFF : All the information regarding the alarms has been displayed List of the HACCP alarms has been deleted ON Energy Saving in progress ON Compressor maintenance required ON The temperature measurement unit will be degrees Celsius ON The temperature measurement unit will be degrees Fahrenheit ON: The instrument is on stand-by INDICATIONS CODE MEANING rhL Press the SET () button: the compressor LED will flash. Low RH% function selected rhH High RH% function selected Press the UP () or DOWN () button within 15 seconds. Loc The keypad is blocked; The working Set Point is blocked Press the SET () button or do not operate for the compressor LED to go off, after which the instrument will exit from the procedure. ---- Requested function is not available DO NOT PERFORM ANY MAINTAINANCE WHEN THE APPLIANCE IS IN ON OR STAND BY DISCONNECT FROM ELECTRICAL POWER SUPPLY NET. 5 Translation of the original instructions DISPLAYS CHAMBER TEMPERATURE Displayed with the instrument on, during normal operation. EVAPORATOR TEMPERATURE (with the evaporator sensor present) Press the DOWN () button for a few seconds, then press the UP () or DOWN () button to select "Pb2". Press the SET () button for the evaporator temperature to appear on the display. Press SET () once again or do not operate to return to the chamber temperature. CONDENSER TEMPERATURE (with the condenser sensor present) Press the DOWN () button for a few seconds, then press the UP () or DOWN () button to select "Pb3". Press the SET () button for the condenser temperature to appear on the display. Press SET () once again or do not operate to return to the chamber temperature. COMPRESSOR OPERATION TIMER (“HACCP EXTENDED” version) Press the DOWN () button for a few seconds, then press the UP () or DOWN () button to select "CH". Press the SET () button for the compressor operation hours to appear on the display. Press SET () once again or do not operate to return to the chamber temperature. SETTING THE DATE AND TIME (IF PRESENT) Press the DOWN () button for a few seconds, then press the UP () or DOWN () button to select "rtc". Press the SET () button for the following to appear on the display in sequence: "yy", "nn", "dd", "hh" and "nn" followed by 2 numbers that correspond respectively to the year, month, day, hour and minutes; values that can be adjusted by acting on the UP () or DOWN () button. To exit from the procedure press ON/STAND-BY(). HACCP FUNCTIONS The instrument can save up to 3 HACCP alarms (“HACCP BASIC” version) or 9 allarms (“HACCP EXTENDED” version). The HACCP LED provides information regarding the memory status of the HACCP alarms: if it is on, not all the information regarding the HACCP alarms have been displayed, if it flashes, the instrument has saved at least one new HACCP alarm. DISPLAYED INFORMATION REGARDING THE HACCP ALARMS To access the procedure: - press the DOWN () button for 2 seconds: the first label appears on the display. - press and release the UP () or DOWN () button to select "LS". - press and release the SET () button: either of the "AL", "AH" or "id" codes will appear on the display. To select an alarm: - press and release the UP () or DOWN () button (e.g. to select "AH"). To display the information regarding the alarm: - press and release the SET () button: the HACCP LED will stop flashing and the following information will appear on the display in sequence (“#:” only for “HACCP EXTENDED” version): INFO 8,0 StA # y07 n03 d26 h16 n30 Dur h01 n15 AH3 # # # # # MEANING the critical value is 8.0 °C/8 °F the date and time when the alarm was triggered are about to appear on the display the alarm was triggered in 2007 (continues) the alarm was triggered in March (continues) the alarm was triggered on 26 March 2007 the alarm was triggered at 16 hrs (continues) the alarm was triggered at 16:30 hrs the alarm duration is about to appear on the display the alarm lasted 1 hr (continues) the alarm lasted 1 hr and 15 min the selected alarm To exit from the information sequence: - press and release the the key ON/STAND-BY(): the selected alarm appears on the display (in the "AH3" example). The instrument provides the following information: • the critical value • the date and time when the alarm was triggered (only “HACCP EXTENDED” version) • • the alarm duration (from 1 min to 99 hr and 59 min, partial if the alarm is still active). To exit from the procedure: - exit from the information sequence - press and release the key UP () or the key DOWN () until the display shows the compartment temperature or do not operate for 60 s. CODE AL If the instrument has no alarm saved, the "LS" label will not be displayed. Id TYPE OF ALARM minimum temperature alarm maximum temperature alarm micro port input alarm PF power failure alarm AH CRITICAL VALUE the minimum chamber temperature during this type of alarm the maximum chamber temperature during this type of alarm the maximum chamber temperature during this type of alarm the chamber temperature when the power is restored (parameter AA) “HACCP BASIC” VERSION: The device updates the information if the new alarm is worse than the one stored or provided that the information have already been shown. If the device is switched off, no alarm will be stored. “HACCP EXTENDED” VERSION: the most recent alarm will overwrite the oldest. If the duration of the “PF” alarm causes a clock error, the instrument will not provide any information regarding the alarm duration. 6 When the cause that triggered the alarm is resolved, the display restores normal operation, except for the power failure alarm, which requires the normal display to be restored manually. DELETING THE LIST OF HACCP ALARMS - Keep the DOWN () button pressed for 2 seconds: the first available label will appear on the display. - Press the UP () or DOWN () button to select "rLS". - Press the SET () button. - Press the UP () or DOWN () button within 15 seconds to set "149". - Press the SET () button or do not operate for 15 seconds: "----" will flash on the display for a few seconds and the HACCP LED will go off, after which the instrument will exit from the procedure. If the instrument has no alarm saved, the "rLS" label will not be displayed. Translation of the original instructions Settings and Troubleshooting CONFIGURATION To enter the procedure: • make sure no processes are in progress • press UP () and DOWN () for 4 s: “PA” appears on the display • press SET () • press UP () or DOWN () within 15 s to set “-19” • press SET () or wait for 15 s • press UP () and DOWN () for 4 s: “SP” appears on the display. To select a parameter: • press UP () or DOWN () To modify a parameter: • press SET () • press UP () or DOWN () within 15 s • press SET () or wait for 15 s. To exit the procedure: • press UP () and DOWN () for 4 s or wait for 60 s. Turn off the instrument after modifying the parameters. ALLARMS AND ERRORS CODE TYPE OF ALARM Solutions Consequences iA MULTIFUNCTION INPUT ALARM Verify what caused the input activation / See the i5 and i6 parameters Effect established by the i5 parameter / Alarm output activated with u1=3 iSd PRESSURE SWITCH ALARM Verify what caused the input activation / See the i5, i6, i7, i8 and i9 parameters / Switch the instrument off and on again or disconnect the power supply The regulators go off / Alarm output activated with u1=3 COH Verify the condenser temperature / See C6 parameter Alarm output activated with u1=3 CSd COMPRESSOR BLOCKAGE ALARM Verify the condenser temperature / See the C7 parameter / Switch the instrument off and on again: if the condenser temperature is still > parameter C7 when it is switched on again, disconnect the power supply and clean the condenser The evaporator compressor and fan go off / Alarm output activated with u1=3 Pr1 Verify the type of sensor / Verify the integrity of the sensor / Verify the instrument-sensor connection / Verify the chamber temperature Compressor on or off for 10 m / Defrosting will not be activated / Relè alarm activated if u1=3 / Door resistors off if u1=4 / Disabling evap. valve if u1=5 Pr2 Verify the type of sensor / Verify the integrity of the sensor / Verify the instrument-sensor connection / Verify the evaporator sensor temperature Defrosting activated for 30 min with P3=1 / Defrosting at intervals with P3=1 and d8=2 / The evaporator fan operates in parallel with the compressor with F0=3 or 4 / Alarm output activated with u1=3 Pr3 Verify the type of sensor / Verify the integrity of the sensor / Verify the instrument-sensor connection / Verify the condenser sensor temperature Condenser overheating alarm ("COH") will not be activated / Blocked compressor alarm ("CSd") will not be activated / Alarm output activated if u1=3 rtc Defrosting at intervals with d8=3; The HACCP will not provide information regarding the date and time when the alarm was triggered / The Energy Saving function is not available in real time / Alarm output activated if u1=3 Once the cause that triggered the alarm is resolved, the instrument restores normal operation, except for the following alarms that require: • “PF" any button to be pressed; • “iSd"- the instrument to be switched off or the power supply to be disconnected • “CSd" the instrument to be switched off or the power supply to be disconnected FAULT The following items will help you find possible solutions to some troubles the unit could be subject to. It is understood that the information given here does not cover all possible cases. Whenever a safety device triggers, it means that there is a malfunction; before resetting it, check and remove the cause. After making the above checks, if the fault persist contact your aftersales service. Remember to specify the nature of the defect, the appliance’s code and serial number(you will find on its nameplate). PROBLEM Possible cause What to do 1 1.1 2 2.1 2.2 2.3 2.4 2.5 2.6 3 3.1 3.2 4 4.1 4.2 4.3 CLOCK ERROR Set the date and time 4.4 APPLIANCE DOESN’T START Appliance isn’t connected to the power supply Check that the plug is fitted into the mains power supply socket correctly. COMPRESSOR RARELY STOPS Room temperature is too high Ensure proper ventilation to the room Refrigerated cabinet condenser is dirty Check it on a regular basis and clean it thoroughly. Low refrigerant charge Call an authorised technical support centre to find and repair any leaks and to recharge the compressor with refrigerant. Door gaskets do not ensure proper seal Call an authorised technical support centre to perform the necessary replacement Frost build-up on the evaporator Do not place hot or high water content foodstuffs into the appliance and, if needed, perform a manual defrost cycle Evaporator motor fan(s) damaged Call an authorised technical support centre to perform the necessary replacement OVERFLOWING OF SELF-EVAPORATING CONDENSATE TRAY Hot or high-water content foodstuffs are being introduced into the appliance too often. Do not introduce hot or high water content foodstuffs into the appliance Doors and/or drawers are opened too often. Pay attention to the conditions of use of your appliance COMPARTMENT TEMPEATURE TOO HIGH Refrigerated cabinet condenser is dirty Check it on a regular basis and clean it thoroughly. Feeble aeration of the zone around the technical compartment. Remove any obstructions for a correct airflow Hot air entering the compartment. Check the correct closure of the door and the gasket to be proper. If it’s not possible to adjust functioning, call a technical support centre to perform replacement and regulations Frost build-up on the evaporator Perform a manual defrost cycle 7 Translation of the original instructions Cleaning and maintenance YOU MUST FOLLOW THE INSTRUCTIONS BELOW ESPECIALLY WHEN USING R290 COOLANT (see reference 13 on page 2 of this manual and the data plate on the device) KEEP THE VENTS FREE ON THE BODY OF THE DEVICE OR ON THE MODULAR STRUCTURE. DO NOT USE MECHANICAL EQUIPMENT OR SIMILAR OTHER THAN THAT RECOMMENDED BY THE MANUFACTURER TO SPEED UP THE DEFROSTING PROCESS. DO NOT TAMPER WITH THE COOLANT CIRCUIT DO NOT USE ELECTRICAL EQUIPMENT IN THE COMPARTMENTS TO PRESERVE FOOD FROZEN BY THE DEVICE, UNLESS RECOMMENDED BY THE MANUFACTURER This section has been dedicated to the end-user and is extremely important for the appliance to work correctly in the long-term. A few simple operations conscientiously carried out at set periods can avoid the need of servicing by specialized personnel. The operations to be made do not require any particular technical knowledge IMPORTANT BEFORE BEGINNING ANY TYPE OF MAINTENANCE OR CLEANING WORK ON THE APPLIANCE DISCONNECT THE MAINS POWER SUPPLY. DO NOT WASH THE APPLIANCE DIRECTLY WITH HIGH PRESSURE WATER JETS. AVOID SPRAYING WATER DIRECTLY ONTO ELECTRICAL PARTS. CLEANING How often you will need to clean the appliance depends largely on how often you use it. Analyze the use and schedule the required cleaning operations. To clean the appliance’s inside and outside, use a neutral or slightly alkaline detergent. For gaskets cleaning, all neutral agents on water base, commonly employed for domestic use, are suggested. NEVER REMOVE GASKETS FOR CLEANING ! We recommend that you clean the inside with a disinfectant every once in a while. Impurities may be removed using a damp cloth. Removing the shelves makes cleaning the inside easier. Never use metallic tools for clearing appliance; it could be damaged. For a deeper cleaning of the compartment, remove the shelf guide. IMPORTANT THE APPLIANCES ARE MADE OF STEEL WHICH IS CORROSION PROOF UNDER NORMAL USE. AVOID USING AGGRESSIVE DETERGENTS OR CLEANERS THAT MAY DAMAGE ITS PROTECTION. 8 ROUTINE MAINTENANCE CONDENSING COIL It is important that the coil can offer the maximum possible heat exchange. Use a vacuum cleaner and soft bristled brush to remove all the impurities such as paper or dust that may have deposited on the coil. When brushing the condenser, exercise great care so as to avoid damaging the aluminum grid or the fans. If a filter is present, remove and clean it. Afterwards, put it in the original position. If damaged or too dirty, ask for its replacement and change it. Not to respect these norms can cause serious damages to the refrigerating circuit or to products contained in the equipment. To ensure a perfect seal, it’s important to check the gaskets to be undamaged and perfectly closing. POWER CABLE Check that the power cable that connects the appliance to the mains socket is not cut, cracked or altered in such a way as to compromise the insulation. Contact your authorised service centre if this requires maintenance. If the cable is damaged, have this replaced by the manufacturer or it’s an authorized technical assistance service, or by someone with similar competence. A damaged electric cable could be cause of fire, electric shake or accident LONG SHUTDOWNS If the appliance is inactive for long periods of time proceed as follows: Turn the main switch to the OFF position. Remove the plug from its socket. Empty the appliance and clean as in point CLEANING. Leave the door ajar to avoid bad odours from forming. Protect the compressor group from dust. CHANGING LIGHT BULB [IF PRESENT] To change the light bulb, perform the following steps: • Switch off the appliance and disconnect the power cord; • Open the appliance door; and remove the protective glass shield; • Unscrew the light bulb located in the instrument panel and replace it with an identical component (voltage of the light bulb is shown on the sticker); • Refit the glass shield. MAX LOADING CAPACITY OF PROVIDED GRIDS THE GRILLS PROVIDED ARE ABLE TO WITHSTAND A MAX LOAD OF 50 kg EACH. THE LOAD MUST BE DISTRIBUTED EVENLY ON THE GRILL AND POSITIONED IN SUCH A WAY AS NOT TO OBSTRUCT THE VENTS OF THE DEVICE. 9 KONTROLLEN ELEKTRISCHEN TEILS 10 ANZEIGEN LED HINWEISE CODE rhL rhH Loc ---- 11 12 ALARME UND FEHLER PROBLEM iA ALARM AN MULTIFUNKTIONSEINGANG iSd COH ALARM: VERFLÜSSIGER ÜBERHITZT 1 1.1 2 2.1 2.2 2.3 CSd Pr1 Pr2 Pr3 rtc 2.4 2.5 2.6 4 4.1 4.2 4.3 4.4 RAUMTEMPERATUR IST UNGENÜGEND 13 14 ITALIANO 15 Istruzioni originali / Original instructions bibite gassate. Possono esplodere. SE SI RENDE INDISPENSABILE IL TRASPORTO IN POSIZIONE DIVERSA DA QUELLA DI LAVORO; ATTENDERE ALMENO 2 ORE PRIMA DI METTERLO IN FUNZIONE. TENERE ALL’ASCIUTTO E EVITARE NEL MODO PIÙ ASSOLUTO DI SOVRAPPORRE ALL’APPARECCHIO ALTRI OGGETTI. 15 16 ITALIANO L’APPARECCHIO DEVE ESSERE INOLTRE INCLUSO IN UN SISTEMA EQUIPOTENZIALE LA CUI EFFICIENZA DEVE ESSERE VERIFICATA SECONDO LE NORME IN VIGORE. È VIETATO L’USO DI ADATTATORI, PRESE MULTIPLE, E/O PROLUNGHE. 16 QUEST’APPARECCHIO VA COLLEGATO ALLA RETE DI ALIMENTAZIONE UTILIZZANDO LA SPINA IN DOTAZIONE. ITALIANO 17 NON ESEGUIRE NESSUNA MANUTENZIONE QUANDO L’APPARECCHIATURA È IN “ON” O IN “STAND BY”. per TACITAZIONE BUZZER (se presente) Premere brevemente un tasto qualsiasi. IMPOSTAZIONE DEL SET POINT INDICAZIONI CODE SIGNIFICATO rhL rhH Loc ---- 17 18 ITALIANO Istruzioni originali / Original instructions 18 ITALIANO 19 TIPO DI ALLARME Pr1 ERRORE SONDA CELLA Pr2 ERRORE SONDA EVAPORATORE Pr3 ERRORE SONDA CONDENSATORE rtc 1 1.1 2 2.1 2.2 2.3 2.4 2.5 2.6 3 3.1 3.2 4 4.1 4.2 4.3 ERRORE OROLOGIO 4.4 19 20 ITALIANO IMPORTANTE PRIMA DI DAR CORSO A QUALSIASI OPERAZIONE DI MANUTENZIONE O PULIZIA DELL'APPARECCHIO DISINSERIRLO DALLA RETE DI ALIMENTAZIONE ELETTRICA. NON LAVARE L’APPARECCHIO CON GETTI D’ACQUA DIRETTI E AD ALTA PRESSIONE. EVITARE DI INDIRIZZARE L’ACQUA SULLE PARTI ELETTRICHE. IMPORTANTE GLI APPARECCHI SONO REALIZZATI IN ACCIAIO RESISTENTE ALLA CORROSIONE DERIVANTE DA NORMALE UTILIZZO. EVITARE L’USO DI SOSTANZE DETERGENTI O SISTEMI DI PULIZIA AGGRESSIVI CHE NE POSSANO COMPROMETTERE L’INTEGRITÀ. 20 MASSIMO CARICO DELLE GRIGLIE FORNITE IN DOTAZIONE LE GRIGLIE FORNITE IN DOTAZIONE SONO ADATTE A SOPPORTARE UN CARICO MASSIMO DI 50 kg CIASCUNA. IL CARICO DEVE ESSERE DISTRIBUITO IN MODO UNIFORME SULLA GRIGLIA, POSTO IN MODO DA NON OSTRUIRE LA VENTILAZIONE NELL'APPARECCHIATURA . PENDANT LES OPERATIONS DE MOUVEMENT, NE PAS RETOURNER NI RENVERSER L’APPAREIL. S’IL FAUT TRASPORTER L’APPAREIL EN POSITION DIFFERENTE DE CELLE DE TRAVAIL, ATTENDRE AU MOINS 2 HEURES AVANT DE METTRE EN FONCTION. L’INSTALLER L’APPAREIL DANS UN ENDROIT SEC. EVITER ABSOLUMENT D’INSTALLER D’AUTRES OBJETS AU-DESSUS DE L’APPAREIL. 21 Traduction de la notice originale 22 ECLAIRAGE CELLULE si par. u1=0 ACCES: Fonction Overcooling en cours touche HAUT ACCES: Fonction Energy Saving en cours POINT DE CONSIGNE ACCES: L'instrument est en stand-by INDICATIONS CODE SIGNIFICATION IMPOSTATION DU SET POINT rhL rhH Loc ---- 23 REGLAGE DATE ET HEURE (SI PRÉSENT) 24 INFO 8,0 StA y07 n03 d26 h16 n30 Dur h01 n15 AH3 # # # # # # sera pas affiché. Traduction de la notice originale ALARMES ET ERREURS CODE TYPE D'ALARME Solutions Consequences iA iSd ALARME PRESSOSTAT 1 1.1 2 ALARME CONDENSATEUR SURCHAUFFÉ 2.1 2.2 CSd 2.3 COH ALARME COMPRESSEUR BLOQUÉ Pr1 ERREUR SONDE CELLULE Pr2 ERREUR SONDE ÉVAPORATEUR Pr3 ERREUR SONDE CONDENSATEUR rtc 2.4 2.5 2.6 4 4.1 4.2 4.3 4.4 25 IMPORTANT AVANT TOUTE OPERATION D’ENTRETIEN OU DE NETTOYAGE DE L'APPAREIL, NE PAS OUBLIER DE LE DEBRANCHER. NE PAS LAVER L’APPAREIL DIRECTEMENT AU JET D’EAU A HAUTE PRESSION. FAIRE ATTENTION A NE PAS MOUILLER LES PARTIES ELECTRIQUES. 26 En el caso de daños visibles apuntar enseguida sobre el documento relativo al transporte el daño hallado reconduciendo la dicción : "RETIRO CON RESERVA POR EVIDENTES DAÑOS A EMBALAJE". TODAS LAS OPERACIONES EN SEGUIDA INDICADAS DEBEN SER EJECUTADAS EN CONFORMIDAD A LAS NORMAS DE SEGURIDAD VIGENTES, SEA POR CUÁNTO RELATIVO A EL APAREJO USADO SEA POR CUÁNTO RELATIVO A LAS MODALIDADES OPERATIVAS ANTES DE DAR CURSO A OPERACIONES DE MANUTENCIÓN CERCIORARSE QUE LA CAPACIDAD DE LEVANTAMIENTO SEA ADECUADA A EL PESO DEL APARATO EN CUESTIÓN. MANEJO SI SE HACE INDISPENSABLE EL TRANSPORTE EN POSICIÓN DIFERENTE DE AQUEL DE TRABAJO, ESPERAR AL MENOS 2 HORAS ANTES DE PONERLO EN FUNCIÓN. TENER A LA SEQUEDAD. EVITAR EN EL MODO MÁS ABSOLUTO DE SUPERPONER A EL APARATO OTRO OBJETOS. EN EL CURSO DEL MANEJO NO VOLCAR O VOLTEAR. 27 EL APARATO TIENE QUE ADEMÁS SER INCLUSO EN UN SISTEMA EQUIPOTENCIAL CUYA EFICIENCIA TIENE QUE SER AVERIGUADA SEGÚN LAS NORMAS EN VIGOR. ES PROHIBIDO EL EMPLEO DE ADAPTADORES, TOMAS MÚLTIPLES O ALARGADORES. 28 NO EJECUTES NINGUNA MANUTENCIÓN CUANDO LA INSTRUMENTACIÓN ESTÁ EN ON O EN STAND BY. INDICACIONES LED PONER A SILENCIO ÉL ALARMA (SI PRESIENTE) Pulsar brevemente una tecla cualquiera. INDICACIONES CÓD rhL rhH Loc ---- 29 # # # # # CODE AL AH Id PF 30 iA ALARMA DE ENTRADA MULTIFUNCIÓN iSd ALARMA DE PRESOSTATO COH ALARMA CONDENSADOR SOBRECALENTADO CSd ALARMA DE COMPRESOR BLOQUEADO Pr1 ERROR SONDA CELDA Pr2 Pr3 ERROR SONDA CONDENSADOR rtc 1 1.1 2 2.1 2.2 2.3 2.4 2.5 2.6 3 DERRAME DE LA BANDEJA DE EVAPORACIÓN DE CONDENSADOS 3.1 3.2 4 4.1 4.2 4.3 EL APARATO NO PARTE 4.4 31 Limpieza y mantenimiento LOS SIGUIENTES AVISOS SON ESPECIALMENTE IMPORTANTES EN CASO QUE EL FLUIDO REFRIGERANTE UTILIZADO SEA DE TIPO R290 (véase la referencia 13 en la página 2 de este manual y la chapa técnica del aparato) MANTENER LIBRES DE OBSTRUCCIONES LAS APERTURAS DE VENTILACIÓN EN EL ENVOLTORIO DEL APARATO O EN LA ESTRUCTURA DE ENCASTRE. NO USAR DISPOSITIVOS MECÁNICOS U OTROS MEDIOS PARA ACELERAR EL PROCESO DE DESESCARCHE DIFERENTES DE LOS RECOMENDADOS POR EL FABRICANTE. NO DAÑAR EL CIRCUITO DEL REFRIGERANTE NO USAR APARATOS ELÉCTRICOS EN EL INTERIOR DE LOS COMPARTIMENTOS PARA LA CONSERVACIÓN DE LAS COMIDAS CONGELADAS DEL APARATO, SI ÉSTOS NO SON DEL TIPO RECOMENDADO POR EL FABRICANTE IMPORTANTE ANTES DE DAR CURSO A CUALQUIERA OPERACIÓN DE MANUTENCIÓN O LIMPIEZA DEL APARATO DESCONECTARLO DE LA RED DE ALIMENTACIÓN ELÉCTRICA. NO LAVES EL APARATO CON CHORROS DE AGUA DIRIGIDOS Y A ALTA PRESIÓN. EVITAR DIRIGIR EL AGUA SOBRE LAS PARTES ELÉCTRICAS. IMPORTANTE LOS APARATOS SON REALIZADOS DE ACERO INOXIDABLE RESISTENTE A LA CORROSIÓN CONSIGUIENTE DE NORMAL EMPLEO EVITAR EL EMPLEO DE SUSTANCIAS DETERGENTE O SISTEMAS DE LIMPIEZA AGRESIVA QUE PUEDAN COMPROMETER DE ELLO LA INTEGRIDAD. 32 MÁXIMA CARGA DE LAS REJILLAS INCLUIDAS LAS REJILLAS INCLUIDAS SON ADECUADAS PARA SOPORTAR UNA CARGA MÁXIMA DE 50 KG CADA UNA. LA CARGA DEBE DISTRIBUIRSE DE MANERA UNIFORME EN LA REJILLA Y SER COLOCADA DE MANERA QUE NO OBSTRUYA LA VENTILACIÓN EN EL APARATO. NEDERLANDS 33 MOET MEN MINSTENS 2 UUR WACHTEN VOORALEER HET TOESTEL IN WERKING TE STELLEN. OP EEN DROGE PLAATS HOUDEN; ABSOLUUT VERMIJDEN OM OP HET APPARAAT ANDERE VOORWERPEN TE PLAATSEN. 33 34 NEDERLANDS 34 NEDERLANDS 35 Bedieningspaneel STILLEGGEN BUZZER (indien aanwezig) Druk kort op een willekeurige toets. AAN: Het instrument is in stand-by INDICATIES COD. rhL rhH Loc Het toetsenbord is geblokkeerd Het werk-Setpoint is geblokkeerd ---- 35 36 NEDERLANDS WEERGAVE TYPE ALARM alarm minimumtemperatuur alarm maximumtemperatuur alarm ingang micro deur alarm onderbreking van de voeding 36 # # # # # NEDERLANDS 37 Vertaling van de oorspronkelijke gebruiksaanwijzing iA ALARM INGANG MULTIFUNCTIE iSd COH ALARME CONDENSATOR OVERVERHIT CSd ALARM COMPRESSOR GEBLOKKEERD Pr1 FOUT CELSONDE Pr2 Pr3 FOUT SONDE CONDENSATOR rtc 1 HET APPARAAT START NIET 1.1 2 2.1 2.2 2.3 2.4 2.5 2.6 3 3.1 3.2 4 TEMPERATUUR VAN DE CEL IS ONVOLDOENDE 4.1 4.2 4.3 FOUT UURWERK 4.4 37 38 NEDERLANDS BELANGRIJK VOORALEER OM HET EVEN WELK ONDERHOUD OF REINIGING VAN HET APPARAAT UIT TE VOEREN, MOET MEN HET TOESTEL LOSKOPPELEN VAN HET ELEKTRISCHE STROOMNET. HET TOESTEL NIET SPOELEN MET RECHTSTREEKSE WATERSTRALEN ONDER HOGE DRUK. VERMIJDT DAT WATER IN CONTACT KOMT MET DE ELEKTRISCHE DELEN. 38 DANSK 39 temperatur. SKAL HOLDES TØR UNDGÅ ABSOLUT AT STILLE ANDRE GENSTANDE OVENPÅ APPARATET. 39 40 DANSK Igangsætning VIGTIGT INDEN MAN TILSLUTTER APPARATET SKAL MAN SIKRE SIG AT SKILTETS DATA MODSVARER DEN DER FINDES I STRØMNETTET. TYPESKILTET DER VISER DEN ELEKTRISKE DATA DER ER NØDVENDIG TIL INSTALLATIONEN FINDES PÅ KØLERUMMETS HØJRE SIDE. En ikke korrekt strømforsyning kunne blive årsag til brand, elektriske stød og ulykker. En ikke korrekt elektrisk forsyning kunne forårsage brand, elektriske stød eller ulykker. 40 stik er DANSK 41 Kontrolpanel FRAKOBL DEN EL-FORSYNINGEN. FINDES) Tryk kort en hvilken som helst taste. INDSTILLING AF SÆTPUNKT Valgt funktionen til lav RF% tryk og slip tasten UP () eller tasten DOWN () indenfor 15 s. rhH Loc ---- tryk og slip tasten SET(): kompressorens LED vil blinke 41 42 DANSK KODE AL Hvis instrumentet ikke har nogen alarm i hukommelsen, vil label "LS" ikke blive visualiseret. AH Id PF 42 DANSK 43 Pr1 FEJL KØLERUMSSONDE Pr2 FEJL FORDAMPERENHEDSSONDE Pr3 FEJL KONDENSATORSONDE rtc 1 1.1 2 2.1 2.2 2.3 2.4 2.5 2.6 3 3.1 3.2 4 4.1 4.2 4.3 FEJL UR 4.4 APPARATET STARTER IKKE Apparatet er ikke korrekt tilsluttet strømforsyningen. Kontrollér at stikket er korrekt sat i strømudtaget 43 44 DANSK VIGTIGT INDEN MAN STARTER ENHVER VEDLIGEHOLDELSESELLER RENGØRINGSOPERATION PÅ APPARATET SKAL MAN FRAKOBLE DET EL-TILFØRSLEN. SKYL IKKE APPARATET MED DIREKTE VANDSPRØJT ELLER MED HØJTRYK. UNDGÅ AT RETTE VANDET MOD DE ELEKTRISKE DELE. 44 РУССКИЙ 45 РАБОТУ ДОЛЖНО ПРОЙТИ НЕ МЕНЕЕ 2 ЧАСОВ. ХРАНИТЬ В СУХОМ МЕСТЕ КАТЕГОРИЧЕСКИ ЗАПРЕЩАЕТСЯ УСТАНОВКА НА АГРЕГАТ ДРУГИХ ПРЕДМЕТОВ 45 46 РУССКИЙ 46 НЕ ЗАГРУЖАТЬ АГРЕГАТ ДО ТЕХ ПОР, ПОКА ТЕМПЕРАТУРА НЕ ДОСТИГНЕТ ЗАДАННОГО ЗНАЧЕНИЯ. НИКОГДА НЕ ПРЕВЫШАТЬ ПРЕДЕЛЬНУЮ НАГРУЗКУ, УКАЗАННУЮ НА ТАБЛИЧКЕ ВНУТРИ КАМЕРЫ. РУССКИЙ 47 ИНДИКАТОРЫ СИД ЗНАЧЕНИЕ УКАЗАНИЯ КОД ЗНАЧЕНИЕ rhL rhH Loc ---- 47 48 РУССКИЙ 48 РУССКИЙ 49 rtc 1 АГРЕГАТ НЕ ЗАПУСКАЕТСЯ 1.1 2 2.1 2.2 2.3 2.4 2.5 2.6 3 3.1 3.2 4 4.1 4.2 4.3 4.4 49 50 РУССКИЙ ВАЖНО ПРИБОРЫ ИЗГОТОВЛЕНЫ ИЗ НЕРЖАВЕЮЩЕЙ СТАЛИ, УСТОЙЧИВОЙ К КОРРОЗИИ, ВОЗНИКАЮЩЕЙ ПРИ НОРМАЛЬНОМ ИСПОЛЬЗОВАНИИ. НЕ ИСПОЛЬЗОВАТЬ МОЮЩИЕ СРЕДСТВА ИЛИ АГРЕССИВНЫЕ СИСТЕМЫ ОЧИСТКИ, КОТОРЫЕ МОГУТ НАРУШИТЬ ЦЕЛОСТНОСТЬ ОБОРУДОВАНИЯ. 50 CONTROL PANEL RATING PLATE SCHALTTAFEL MATRIKELANGABEN PANNELLO COMANDI TARGHETTA MATRICOLARE PANNEAU DE COMMANDE PLAQUE SIGNALÉTIQUE PANEL DE CONTROL DATOS DE MATRÍCULA BEDIENINGSPANEEL TECHNISCH LABEL ПАНЕЛЬ УПРАВЛЕНИЯ ТЕХНИЧЕСКАЯ ТАБЛИЧКА 51 52 CONTROL PANEL RATING PLATE SCHALTTAFEL MATRIKELANGABEN PANNELLO COMANDI TARGHETTA MATRICOLARE PANNEAU DE COMMANDE PLAQUE SIGNALÉTIQUE PANEL DE CONTROL DATOS DE MATRÍCULA BEDIENINGSPANEEL TECHNISCH LABEL ПАНЕЛЬ УПРАВЛЕНИЯ ТЕХНИЧЕСКАЯ ТАБЛИЧКА CONTROL PANEL RATING PLATE SCHALTTAFEL MATRIKELANGABEN PANNELLO COMANDI TARGHETTA MATRICOLARE PANNEAU DE COMMANDE PLAQUE SIGNALÉTIQUE BEDIENINGSPANEEL TECHNISCH LABEL ПАНЕЛЬ УПРАВЛЕНИЯ ТЕХНИЧЕСКАЯ ТАБЛИЧКА 53 54 54 55 55 56 56 57 57 58 58 59 PARAMETERS / PARAMETER / LISTA PARAMETRI / PARAMÈTRES PARÁMETROS / PARAMETERS / LISTE OVER PARAMETRE / ПАРАМЕТРЫ КОНФИГУРАЦИИ PAR Description / Descrizione / Beskrivelse H+H+ = HACCP EXTENDED working setpoint / Betriebssollwert / SET point di lavoro / point de consigne / punto de ajuste de trabajo / arbejdssætpunkt / рабочая установка температуры. cabinet probe offset / Offset Zellensonde / calibr. sonda / offset sonde chambre / offset sonda cámara / sondekalibrering / CA1 отклонение датчика холодильной камеры. evaporator probe offset / Offset Verdampfersonde / offset sonda evaporatore (°C) / offset sonde évaporateur / offset sonda CA2 evaporador / offset fordamperenhedssonde (°C) / Отклонение датчика испарителя. CA3 Offset condenser probe / / Offset sonda condensatore decimal point Celsius degree (0 = no) / Dezimalpunkt Grad Celsius (0 = Nein) / Punto decimale, (0 = no) / point décimal degré P1 Celsius (0 = no) / punto decimal grado Celsius (0 = no) / Decimalpunkt, (0 = nej) / визуализация значений температуры (0=1°С) unit of measure temperature (0 = °C) / Maßeinheit Temperatur (0 = °C) / unità di misura (0 = °C) / unité de mesure température (0 P2 = °C) / unidad de medida temperatura (0 = °C) / måleenhed (0 = °C) / единицы измерения температуры (0=°С) evaporator probe function / Funktion der Verdampfersonde / funzione sonda evap / fonction de la sonde évaporateur / función P3 de la sonda evaporador / fordamperenhedssonde funktion / функция датчика испарителя P4 Enabling of condenser probe/ / Abilitazione sonda condensatore delay in display of variations in temperature detected by the probes / ritardo visualizzaz (ds) / forsinkelse af visualisering (ds) / P8 / задержка показа температуры working setpoint differential / Differentialbetriebssollwert / differenziale del setpoint di lavoro / différentiel du point de consigne / r0 diferencial del punto de ajuste de trabajo / arbejdssætpunkts differentiale / дифференциал рабочей установки minimum working setpoint / Mindestbetriebssollwert / minimo setpoint di lavoro / point de consigne minimum / mínimo punto de r1 ajuste de trabajo / minimum arbejdssætpunkt / минимальное значение рабочей установки maximum working setpoint / Maximalbetriebssollwert / massimo setpoint di lavoro / point de consigne maximum / máximo r2 punto de ajuste de trabajo / maksimum arbejdssætpunkt / максимальное значение рабочей установки locking the working setpoint modification / Blockierung der Änderung des Betriebssollwerts / blocco della modifica del setpoint r3 di lavoro / blocage de la modification du point de consigne / bloqueo de la modificación del punto de ajuste de trabajo / blokering af arbejdssætpunktets ændring / блокировка изменения рабочей установки r4 Increase in temperature during Energy Saving function / / Incremento di temperatura in funzione Energy Saving r5 decrease in temperature during Overcooling function / decremento in overcooling / formindskelse i overcooling r6 duration of Overcooling function / durata overcooling / overcoolingvarighed r7 Min (Ti-SET) @ON -> NO defrost compressor delay since you turn on the instrument / Verspätung nach der Inbetriebnahme des Gerätes / ritardo compressore dall’accensione dello strumento / retard compresseur après la mise en marche de l’appareil / retardo compresor del encendido C0 del instrumento / kompressorforsinkelse fra instrumentets tænding / задержка между включением прибора и первой активацией компрессора minimum time between 2 activations in succession of the comp./ Mindestzeit zwischen 2 aufeinanderfolgenden Einschaltvorgängen des Verdichters / tempo minimo tra 2 accensioni successive del comp / temps minimum entre 2 mises en C1 marche consécutifs du compresseur / tiempo mínimo entre 2 encendidos consecutivos del compresor / minimumtid mellem 2 tændinger der efterfølger kompr / минимальная задержка между двумя последовательными активациями компрессора Minimum time the compressor remains turned off / Mindestdauer des Abschaltens des Verdichters / durata minima dello C2 spegnimento del compressore / durée minimum de l’arrêt du compresseur / duración mínima del apagamiento del compresor / minimum varighed af kompressors slukning / минимальное время, когда компрессор остается выключенным Minimum time the compressor remains turned on / Mindestdauer des Einschaltens des Verdichters / durata minima C3 dell’accensione del compressore / durée minimum de la marche du compresseur / duración mínima del encendido del compresor / minimum varighed af kompressors tænding / минимальное время, когда компрессор остается включенным time the comp. remains turned off during the cabinet probe error / Abschaltdauer des Verdichters während Fehler Zellensonde / durata dello spegnimento del comp. durante l’errore sonda cella / durée de l’arrêt du comp. pendant l’erreur sonde chambre / C4 duración del apagamiento del comp. durante el error sonda cámara / varighed af slukning af kompr. under fejl i kølerumssonde / время, когда компрессор остается выключенным во время неисправности датчика холодильной камеры time the comp. remains turned on during the cabinet probe error / Einschaltdauer des Verdichters währen Fehler Zellensonde / durata dell’accensione del compr. durante l’errore sonda cella / durée de la marche du compresseur pendant l’erreur sonde C5 chambre / duración del encendido del compresor durante el error sonda cámara / varighed af tænding af kompr. under fejl i kølerumssonde / время, когда компрессор остается включенным во время неисправности датчика холодильной камеры Condenser temperature is higher than that at which the condenser overheating alarm is activated (COH code) / / Temperatura C6 condensatore oltre la quale è attivato l’allarme condensatore surriscaldato Condenser temperature is higher than the limit at which the compressor blocked alarm is activated (CSd code) / / Temperatura C7 condensatore oltre la quale è attivato l’allarme compressore bloccato C8 Compressor alarm delay locked (CSd code) / / Ritardo allarme compressore bloccato Number of operating hours in higher than the limit at which the need for maintenance is signaled / / Ore di funzionamento del CA compressore oltre cui viene segnalata la richiesta di manutenzione defrost interval / Abtauinterval / intervallo tra sbrinamenti / intervalle de dégivrage / intervalo de desescarche / interval mellem d0 afrimninger / интервал между процессами оттайки d1 type of defrosting / Abtautyp / tipo sbrinamento / type de dégivrage / tipo de descongelación / afrimningstype / Вид оттайки temperature at end of defrosting / Temperatur bei Abtauende / T fine def / température de fin dégivrage / temperatura de final d2 de descongelación / T afrimningsslut / Температура завершения процесса оттайки defrost duration / Abtaudauer / durata sbrinamento / durée du dégivrage / duración del desescarche / afrimningsvarighed / d3 длительность процесса оттайки defrost when you turn on the instrument (0=no) / Abtauung bei Inbetriebnahme des Gerätes (0=nein) / sbrinamento d4 all'accensione (0 = no) / dégivrage après la mise en marche de l’appareil (0=no) / desescarche al encendido del instrumento (0=no) / afrimning ved tænding (0 = nej) / процесс оттайки будет каждый раз активироваться при включении прибора d5 defrost delay when you turn on the instrument (if d4 = 1) / Abtauungverspätung bei Inbetriebnahme des Gerätes / ritardo SP 0 -2 +10 +8 H+ H+ -20 0 -2 -15 +10 +8 H+ -20 PAR -15 2 -2 -20 2 -2 -20 SP 0 0 0 0 0 0 CA1 0 0 0 0 0 0 CA2 0 0 0 0 0 0 0 0 0 P1 0 0 0 0 0 0 P2 0 1 1 0 1 1 P3 1 1 1 5 5 5 5 5 5 P8 2 2 2 2 3 2 r0 0 -2 -20 0 -2 -20 r1 10 8 -15 10 8 -15 r2 0 0 0 0 0 0 r3 0 3 30 10 0 3 30 10 0 3 30 10 0 3 30 10 0 3 30 10 0 3 30 10 r4 r5 r6 r7 1 1 1 1 1 1 C0 1 1 1 1 1 1 C1 1 1 1 1 1 1 C2 0 0 0 0 0 0 C3 4 4 4 4 4 4 C4 5 5 6 5 5 6 C5 80 80 80 C6 90 90 90 C7 1 1 1 C8 0 0 0 CA 6 14 14 CA3 P4 6 14 14 d0 2 0 0 2 0 0 d1 21 10 7 21 7 7 d2 30 30 30 30 30 30 d3 0 0 0 0 0 0 d4 0 0 0 0 0 0 d5 59 d6 d7 d8 A1 A2 A4 A5 A6 A7 A8 A9 AA 60 sbrinamento all'accensione (se d4 = 1) / retard dégivrage après la mise en marche de l’appareil (si d4 = 1) / retardo desescarche del encendido del instrumento (si d4 = 1) / afrimning ved tænding (hvis d4 = 1 / задержка между включением прибора и началом процесса оттайки (только, если d4 = 1) temperature shown during the defrost / Während des Abtauvorgangs angezeigte Temperatur / visualizzazione temperatura durante sbrinamento / température visualisée pendant le dégivrage / temperatura visualizada durante el desescarche / visualisering af temperatur under afrimning / фиксация на дисплее значения температуры в процессе оттайки dripping duration / Abtropfdauer / durata gocciolamento / durée d'égouttage / duración del goteo / dryppevarighed / время стекания конденсата. kind of defrost interval (0 = will be activated when the instr. Turned on the time d0) / Typ des Abtauintervalls / tipo intervallo sbrinamento (0 = strumento acceso per il tempo d0) / Type de intervalle de dégivrage (0=le dégivrage sera activé quand l’appareil sera resté en marche pour le temps d0) / tipo de intervalo de desescarche (0=el desescarche será activado cuando el instrumento haya quedado encendido por el tiempo d0) / type afrimningsinterval (0 = tændt instrument i tiden d0) / тип интервала между процессами оттайки (0=процесс оттайки будет активирован в течение работы прибора, после завершения времени, установленного параметром d0) evaporator temp. is higher than that at which the defrost interval counter is suspended / Temp. des Verdampfers bei deren Überschreiten das Zählen des Abtauvorgangs unterbrochen wird / conteggio d0 se tevap < d9 / temp. de l'évaporateur audessus de laquelle le comptage de l'intervalle de dégivrage est arrêté / temp. del evaporador por encima de la cual se suspende el cómputo del intervalo de descongelación / tælling d0 hvis fordamperenh < d9 / температура испарителя, выше которой отсчет интервала оттайки приостанавливается All se stop sbrinamento per timeout minimum compressor on duration on activation of defrosting so that they may be activated / Mindestdauer des Einschaltens des Verdichters bei Aktivierung des Abtauvorgangs, damit dieser aktiviert wird / min ON comp x def / durée min. de la mise sous tension du compresseur à l'activation du dégivrage afin que celui-ci puisse être activé / duración mínima del encendido del compresor cuando se activa la descongelación, para que se pueda activar / минимальное время, в течение которого компрессор должен работать (к моменту активации процесса оттайки), чтобы процесс оттайки мог быть активирован durata pregocciolamento n° valori per calcolo Tevap media intervallo sbrinamento adattativo T evap sbrinamento adattativo minON comp => sbrinamento minON comp & ON frigo & dopo overcooling => sbrinamento Tevap + d22 => d18 sospeso Tevap in energy saving = Tevap + d23 Temp. associated with the minimum temperature alarm / Temperaturwert, der dem Mindesttemperaturalarm zugeordnet ist / Temp. associata ad allarme min / température associée à l'alarme de température minimum / temp. asociada a la alarma de temperatura de mínima / tilknyttet min alarm / Температура, для которой срабатывает сигнал тревоги при достижении нижнего критического значения temperature below which the lower temperature alarm is activated; / Schwelle fur den Tief-Temperatur-Alarm / allarme temperatura di minima / température en dessous de laquelle l’alarme de température basse est active / temperatura por debajo de la cual es activada la alarma de temperatura de mínima / temperaturalarm for minimum / Нижняя граница температуры для активации сигнала тревоги kind of lower temp. alarm (0=alarm not enabled) / Alarmtyp Mindesttemperatur (0 = Alarm fehlt) / tipo di allarme di temp. di minima (0=allarme assente) / type de alarme de temp. basse (0=alarme absent) / tipo de alarma de temp. de mínima (0=alarma ausente) / alarmtype for minimtemperatur (0=fraværende alarm) / вид срабатывания сигнала тревоги при достижении нижней границы температуры (0=сигнал тревоги не включается) temperature above which the upper temperature alarm is activated / Temperaturwert, über dem der Maximaltemperaturalarm aktiviert wird / temperatura al di sopra della quale viene attivato l’allarme di temperatura di massima / empérature en dessus de laquelle l’alarme de température haute est activée / temperatura por encima de la cual es activada la alarma de temperatura de máxima / temperatur er over grænse hvortil alarmen vil aktiveres for maksimum temperatur / верхняя граница температуры для активации сигнала тревоги kind of upper temp. alarm (0=alarm not enabled) / Alarmtyp Maximaltemp. (0 = Alarm fehlt) / tipo di allarme di temp. di massima (0=allarme assente) / type de alarme de temp. haute (0=alarme absent) / tipo de alarma de temp. de máxima (0=alarma ausente) / alarmtype for maksimum temperatur (0=fraværende alarm) / вид срабатывания сигнала тревоги при достижении верхней границы температуры (0=сигнал тревоги не включается) upper temp. alarm delay since you turn on the instrument / Verspätung Hoch-Temperatu-Alarm nach der Inbetriebnahme des Gerätes / ritardo allarme di temp. di massima dall’accensione dello strumento / retard alarme de temp. haute après la mise en marche de l’appareil / retardo alarma de temp. de máxima del encendido del instrumento / forsinkelse af alarm for maksimum temperatur fra instruments tænding / задержка срабатывания сигнала тревоги при достижении верхней границы температуры после включения прибора temperature alarm delay / Verspätung Temperatur-Alarm / ritardo allarme temperatura / retardo alarma de temperatura / retard alarme de température / Forsinkelse af temperaturalarm / время задержки сигнала температурной тревоги upper temperature alarm delay since the end of the defrost / Verzögerung Maximaltemperaturalarm nach Ende der Abtauvorgang / ritardo allarme temperatura dopo sbrinamento / retard alarme de température haute après la fin du dégivrage / retardo alarma de temperatura de máxima del fin del desescarche / forsinkelse af temperaturalarm efter afrimning / задержка срабатывания сигнала тревоги при достижении верхней границы температуры после окончания задержки включения вентилятора испарителя по окончании стекания конденсата delay in maximum temperature alarm / Verzögerung Alarm Maximaltemperatur nach Deaktivierung des Mikrotüreingangs / rit ALL / retard de l'alarme de température maximum à partir de la conclusion de l'arrêt de l'évaporateur / retardo de alarma de temperatura de máxima desde la desactivación de la entrada microinterruptor puerta / задержка срабатывания сигнала тревоги при достижении верхней границы температуры после деактивации открывания двери Durat. of interruption in the power supply when instr. is switch on Alarm stored when the power supply is restored (PF code) / / 0 +10 -2 +8 -20 0 -2 -15 +10 +8 -20 PAR -15 1 1 1 1 1 1 d6 0 0 2 0 2 2 d7 0 3 3 0 3 3 d8 0 0 0 0 0 0 d9 0 0 0 0 0 0 d11 0 0 0 0 0 0 dA 0 0 0 0 0 0 4 4 4 4 4 4 40 40 40 40 40 40 3 3 3 3 3 3 180 180 180 180 180 180 200 200 200 200 200 200 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 -10 -20 -20 1 1 1 1 20 20 20 1 1 1 0 0 A0 -20 A1 1 1 A2 20 20 20 A4 1 1 1 A5 -10 -20 240 240 240 240 240 240 A6 15 15 15 15 15 15 A7 15 15 15 15 15 15 A8 15 15 15 15 15 15 A9 5 5 5 AA 0 +10 -2 +8 -20 0 -2 -15 +10 +8 -20 PAR -15 4 1 5 1 4 1 4 5 4 Ab 1 5 5 1 5 5 F0 15 15 15 15 15 15 F1 2 1 0 2 0 0 F2 0 0 4 0 6 4 F3 40 40 40 40 40 40 F4 20 20 20 20 20 20 F5 1 0 2 0 33 0 40 20 0 0 2 0 33 0 40 20 0 5 2 0 33 0 40 20 1 0 2 0 0 4 2 0 0 5 2 0 F6 F7 40 20 0 40 20 0 40 20 0 0 0 i0 0 0 0 i1 -1 -1 -1 i2 -1 -1 -1 i3 0 0 0 i4 F1 i3 i4 i5 i6 i7 i8 i9 i10 i11 i12 i13 i14 u0 u1 u2 u4 u5 Differential of parameters A1, A4 and F1 / / diff ALL e vent evap (°C) tipo segnalazione black-out evaporator fan activity during normal operation / Aktivität des Verdampferventilators während des Normalbetriebs / Fan COMP acceso / activités du ventilateur de l'évaporateur pendant le normal fonctionnement / actividad del ventilador del evaporador durante el funcionamiento normal / Tændt COMP ventilator / работа вентилятора испарителя при нормальной работе evaporator temperature above the limit at which the evaporator fan is switched off / Verdampfertemperatur bei deren Überschreiten der Verdampferventilator abgeschaltet wird / T max ON ventola evap / température de l'évaporateur en dessus de laquelle le ventilateur de l'évaporateur est arrêté / temperatura del evaporador por encima de la cual se apaga el ventilador del evaporador / T max ON ventilator fordamperenh / Температура испарителя, при превышении которой вентилятор выключается evaporator fan activity during defrosting and dripping / Aktivität des Verdampferventilators während des Abtauens und Abtropfens / vent in def / activité du ventilateur de l'évaporateur pendant le dégivrage et l'égouttage / actividad del ventilador del evaporador durante la descongelación y el goteo / работа вентилятора испарителя во время оттайки и стекания конденсата maximum duration of evaporator fan disactivation / Dauer des Stillstands des Verdampferventilators / gocciolamento (min) / durée de l'arrêt ventilateur de l'évaporateur / duración de la parada del ventilador del evaporador / dryppen (min) / время задержки включения вентилятора испарителя после стекания конденсата time duration that evaporator fan is switched off during operation for a low percentage of relative humidity when the compressor is switched off / sec OFF in UR bassa (s) / sek OFF i lav RF (s) time duration that evaporator fan is switched on during operation for a low percentage of relative humidity when the compressor is switched off / sec ON in UR bassa (s) / Sek ON i lav RF (s) operation for low or high percentage of relative humidity / alta o bassa umidità relative / høj eller lav relativ fugtighed evaporator temperature below limit at which the evaporator fan is disactivated / T evap < x e gocciolante / T fordamperenh < x drypper diff di F1 rit OFF ventilatore evap a stop compressore Tcond > F11+2 => ventilatorecond = ON con cpmp ON rit OFF ventilatore comd a stop compressore OFF vent evap in energy saving ON vent evap in energy saving effect caused by the activation of the door microswitch input / durch die Aktivierung des Mikrotüreingangs verursachte Wirkung / effetto micro porta / effet provoqué par l'activation de l'entrée micro porte / efecto provocado por la activación de la entrada de 0 0 0 microinterruptor de puerta / dørmikroafbryders effekt / тип цифрового входа type of door microswitch input contact / Typ von Kontakt der Mikrotür / tipo contatto / type de contact de l'entrée micro porte / 0 0 0 tipo de contacto de la entrada de microinterruptor de puerta / kontakttype / тип контакта цифрового входа delay in signaling of door microswitch input alarm / Verzögerung Alarmanzeige Eingang Mikrotür / rit ALL micro / retard signalisation alarme entrée micro porte / retardo de señalización de la alarma de entrada de microinterruptor de puerta / -1 -1 -1 задержки сигнала на входе сигнала тревоги от открывания двери maximum duration of the effect caused by activation of the door microswitch on the compressor and the evaporator fan / Maximaldauer der durch die Aktivierung des Mikrotüreingangs verursachten Wirkung auf Verdichter und Verdampferventilator / T max effetto micro / durée maximum de l'effet provoqué par l'activation de l'entrée micro porte sur le compresseur et sur le -1 -1 -1 ventilateur de l'évaporateur / duración máxima del efecto provocado por la activación de la entrada del microinterruptor de puerta en el compresor y en el ventilador del evaporador / T max effekt mikroafbryder / максимальное время действия, вызванного активацией выхода открывания двери storage of door microswitch input alarm / Speicherung des Alarms Mikrotüreingang / memorizzazione ALL micro / mémorisation de l'alarme d'entrée micro porte / memorización de la alarma de entrada microinterruptor de puerta / Oplagring i 0 0 0 hukommelse ALL mirkoafbryder Effect caused by the activation of the multifunction input / / Effetto provocato dall’attivazione dell’ingresso multifunzione 0 0 0 Type of multifunction input contact / / Tipo di contatto dell’ingresso multifunzione 0 0 0 if i5=2 → multif. input alarm delay (iA code), if i5=3 → delay in compressor switching on after the disactivation of the multifunction / / se i5=2 → ritardo segnalazione allarme ingresso multif. (cod. iA), se i5=3 → ritardo compressore dalla 0 0 0 disattivazione dell’ingresso multifunzione Number of multifunction input alarms (iA code) such to cause a pressure switch alarm (iSd code) / / Numero di allarmi ingressi 0 0 0 multifunzione (cod. iA) che provocano l’allarme pressostato (cod. iSd) Time that must pass in absence of multifunction output alarms (iA code) so that the alarm counter is reset / / Tempo che deve 240 240 240 trascorrere in assenza di allarmi ingresso multif. (cod. iA) affinché sia azzerato il contatore allarmi 0 0 0 t no ON micro => energy saving ON 15 15 15 secondi minimi ON micro per non calcolare Tmedia evap 60 60 60 min(secondi complessivi) ON micro per non calcolare Tmedia evap 0 0 0 n° ON micro => sbrinamento 0 0 0 durata min ON micro => sbrinamento funzione 2° relé (per prodotto 3 relè) Operation controlled by fourth output / / Utenza gestita dalla quarta uscita 4 4 4 Enabling of manual switch on/off of the cell light or the auxiliary output when the instrument is switched off (only if u1=0 or 2) / / Abilitazione dell’accensione/spegnimento manuale luce cella o uscita ausiliaria con strumento spento (solo se u1=0 o 2) / 0 0 0 Aktivering af manuel tænding/slukning af kølerumslys eller hjælpeudgang med slukket instrument (kun hvis u1=0 eller 2) Enabling of alrm output diactivation with the silencing of the buzzer (only if u1=3) / / Abilitazione della disattivazione uscita di 1 1 1 allarmi + tacitazione buzzer (solo se u1=3) Cell temperature below that at which the door resistors are switched on (only if u1=4) / / Temperatura cella oltre la quale le 2 2 2 resistenze della porta vengono spente (solo se u1=4) i5 i6 i7 i8 i9 0 15 60 0 0 0 0 0 15 60 0 0 0 15 60 0 0 4 4 u1 0 0 u2 1 1 u4 2 2 u5 61 62 PARAMETERS / PARAMETER / LISTA PARAMETRI / PARAMÈTRES PARÁMETROS / PARAMETERS / LISTE OVER PARAMETRE / ПАРАМЕТРЫ КОНФИГУРАЦИИ 0 +10 Operating time of demistor resistors (only if u1=1) / / Durata dell’accensione delle resistenze antiappannamento (solo se u1=1) 5 PAR Description / Descrizione / Beskrivelse u6 u7 u8 u9 HE1 HE2 Hd1 Hd2 Hd3 Hd4 Hd5 Hd6 LA Lb LP 62 -2 +8 5 -20 0 -2 -15 +10 +8 5 5 -20 PAR -15 u6 5 Cell temperature below that at which the evaporator valve is disactivated (relating to Setpoint + u7) (only if u1=5) / / 2 2 2 2 2 Temperatura cella sotto la quale la valvola dell’evaporatore viene disattivata (relativa a Setpoint + u7) (solo se u1=5) Tipe of evaporator valve contact (only if u1=5) / / Tipo di contatto della valvola dell’evaporatore (solo se u1=5) 0 0 0 0 0 Enabling of buzzer / / Abilitazione buzzer 1 1 1 1 1 Time of activation of the Energy Saving function in real time / / Ora di attivazione della funzione Energy Saving in tempo reale 0 0 0 Duration of the Energy Sav. function in real time (see also r4 and HE1) - 00:00 = the ES function in real time will not be activated / / 0 0 0 Durata della funz. Energy Sav. in tempo reale (vedi anche r4 e HE1) - 00:00 = la funzione ES in tempo reale non verrà attivata Time of activation of first defrosting period in real time (only if d8=3) --:-- = the first defrosting in real time will not be activated / / 0 0 0 Ora attivazione primo sbrinamento in tempo reale (solo se d8=3) (--:-- = il primo sbrinamento non verrà attivato) Time of activation of second defrosting period in real time(only if d8=3) (--:-- = the second defrosting in real time will not be 0 0 0 activated) / / Ora attivazione secondo sbrinamento in tempo reale (solo se d8=3) (--:-- = il secondo sbrinamento non verrà attivato) Time of activation of third defrosting period in real time(only if d8=3) (--:-- = the second defrosting in real time will not be 0 0 0 activated) / / Ora attivazione terzo sbrinamento in tempo reale (solo se d8=3) [--:-- = il terzo sbrinamento non verrà attivato] Time of activation of fourth defrosting period in real time(only if d8=3) (--:-- = the second defrosting in real time will not be 0 0 0 activated) / / Ora attivazione quarto sbrinamento in tempo reale (solo se d8=3) [--:-- = il quarto sbrinamento non verrà attivato] Time of activation of fifth defrosting period in real time(only if d8=3) (--:-- = the second defrosting in real time will not be 0 0 0 activated) / / Ora attivazione quinto sbrinamento in tempo reale (solo se d8=3) [--:-- = il quinto sbrinamento non verrà attivato] Time of activation of sixth defrosting period in real time(only if d8=3) (--:-- = the second defrosting in real time will not be 0 0 0 activated) / / Ora attivazione sesto sbrinamento in tempo reale (solo se d8=3) [--:-- = il sesto sbrinamento non verrà attivato] instrument address / Geräteadresse / indirizzo strumento / dirección instrumento / adresse appareil / instrumentadresse / адрес прибора 247 247 247 247 247 247 baud rate / baud rate / baud rate / baud rate / baud rate / baud rate / скорость передачи сигнала 2 2 2 2 2 2 Parity / Parität / Parità / paridad / parité / Четность 2 2 2 2 2 2 u7 u8 u9 HE1 HE2 Hd1 Hd2 Hd3 Hd4 Hd5 Hd6 LA Lb LP 63 63 64 1 Compressor 2 Condensator 3 Filter dehydrateerder 4 Capillair 4 Ventiel 5 Verdamper 6 4 Tube capillaire 4 Vanne 5 Evaporateur 6 A charge de l’installateurr (pour groupe a distance) 1 Компрессор 2 Конденсатор 3 Обезвоживающий фильтр 4 Капилляр 4 Клапан 5 Испаритель ITALIANO 1 Compresseur 2 Condenseur 3 Filtro secador sucio РУССКИЙ DANSK NEDERLANDS 4 Capillary tube 4 Valve 5 Evaporator 6 Will be borne by the installer (remote unit versions) 1 Compressor 2 Condenser 3 Filter drier dirty REFRIGERATION CIRCUIT DIAGRAM / SCHEMA DES KÜHLKREISLAUFS / SCHEMA CIRCUITO FRIGORIFERO / SCHÉMA CIRCUIT FRIGORIFIQUE / ESQUEMA CIRCUITO FRIGORÍFICO / SCHEMA CIRCUIT KOELKAST / SKEMA OVER KØLEKREDSLØB / КОНТУРНАЯ СХЕМА ХОЛОДИЛЬНИКА All specifications and data are subject to change without notice. Copyright Die Daten des vorliegenden Handbuchs sind nicht bindend und können vom Erbauer ohne Vorankündigungspflicht geändert werden. Unerlaubte Abdrücke verboten. I dati contenuti nel presente manuale non sono impegnativi e possono essere cambiati dal costruttore senza obblighi di preavviso. Riproduzione anche parziale vietata Des modifications aux prodiuts peuvent être apportées sans préavis du constructeur. Reproduction même partielle interdite Los datos contenidos en el presente manual no constituyen una obligación para el fabricante, que puede modificarlos sin previo aviso. Queda prohibida la reproducción total o parcial. De gegevens van deze handleiding zijn niet bindend en kunnen door de constructeur gewijzigd worden zonder verplichting vooraf te verwittigen. Reproductie, ook gedeeltelijk, verboden Dataen der findes i manualen er ikke forpligtende og kan ændres af fabrikanten uden forvarselspligt. Reproduktion selv delvis er forbudt Данные, содержащиеся в данном руководстве, не являются обязательными и могут быть изменены изготовителем без предварительного уведомления. Воспроизведение, даже частичное, запрещено 64

advertisement

Related manuals

advertisement

Languages

Only pages of the document in English were displayed