- No category

advertisement

CHAPTER 2 MACHINE INSTALLATION

2-1 Fundamental Locating of the Machine

The machine should be fixed on working with four Hexagon bolts.

Please install it an appropriate location in order to demand the precision requirements of the machine.

The Selection of The Installing Location

(1) The working table should have a flat surface.

(2) Avoid the place with direct sunshine, heavy moisture and dust.

Method of Fundamental Locating

(1)Please drill 4 locating holes on working table,

The dimensions should as same as the holes on the machine’s base.

(Attention: the machine’s position, You had better consider Y-axis hand wheel will benefit later on.)

(2) Please adjust the machine to horizon and

Fix the worktable with 4 M10 bolts and nuts.

2-2 Check the Follow Items Before Switching On the Machine:

1. Remove all of fixtures which used foxing the machine when you equipped the machine.

2. Check whether the power voltage is suited to the machine.

(see label in front of the machine.)

3. Remove all obstacle which are around the machine.

4. remove anti-rust protection which were used before you fixed the machine.

5. Check the angle of the pillar and adjust the bolts to see if they are unloaded.

6. Check the chuck, chuck holder and fixing pin on spindle to make sure they are unloaded.

7. Check the High-Low speed on spindle to see if it sets on right speed.

8. Turn on the machine and check the direction of spindle rotating (clockwise).

9. Operate Longitudinal Axis (Working table),Cross Axis (Saddle seat),Vertical Axis (Fuselage) to ensure it’s in normal condition.

10. During the operation, watch out while you’re manipulating the machine.

If there is any unusual situation, stop operating and repair immediately.

5

CHAPTER 3 PREVENTION AND MAINTENANCE

3-1 Prevention And Maintenance

3-1.1 Daily Maintenance

(1) Inspect each operating part to ensure the condition of lubrication.

(2) To examine each component if the part is fixed and no other abnormal situations.

(3) Please clean and remove the obstacles around the machine in order to prevent

Machine damage and safety of the operator.

(4) Please keep the machine clean after daily use lubricate the movement parting to prevent rust.

(5) Please watch out the operation while you’re manipulating the machine.

In case that there is any unusual phenomena, please stop and repair immediately.

3-1.2 Seasonal Maintenance

(1) Please use clean cotton or soft gauze to clean each part of the machine.

(2) Please confirm whether the motion of machine’s head fixed are smooth or loosen.

(3) Check whether the spindle is over-swing.

(4) Check whether each bolt and nut is loosen.

(5) Examine the overall circuit (contact points conductor, plugs and switches…) to ensure its normal condition.

3-1.3 Seasonal Maintenance

(1) Please perform the maintenance on each level and make record.

(2) Please stop the machine before replacing the part or maintenance in order to avoid danger.

(3) Maintenance and repair showed be done regularity. If any abnormal situation occurs, stop the machine and repair immediately.

(4) If the abnormal situation is beyond the regular maintenance. Please contact our service engineer nearest to you in order to avoid further damage and safety.

3-2 Maintenance of Accessories

3-2.1 Maintenance of Cutter

(1) Use rag while install or unload the cutter to prevent the cutter falling and cause the split of blade as hurt the figures.

(2) Keep the cutter in wooden or plastic box when you don’t need it, In order to maintain the sharp blade, the cutter should be kept respectively.

(3) Pay extra attention on cutter rotating direction. Wrong rotating direction might cause sharpness and blade direction in high speed revolving, please turn off the machine, during the process, in decelerating speed, easier to it will be identify the blade direction.

(4) Put the cutter and working piece (or chuck piece) in right places before you turn on the machine. After turn on the machine, the cutter will get close to the working

6

piece and mill it.

(5) Sharpen the cutter as soon as it gets sharpness. Sharpness cutter is not only hard to do the milling work but also easy to cause damage on blade.

3-2.2 Attention Items For Accessories

(1) Please keep the taper shank clean.

(2) Please keep the taper shank and cutter in order and keep the same cutter together.

Next time when you use them ,you will feel more convenient.

(3) Draw bar and chuck have their own wrenches. For your convenience, please keep the wrenches near by the machine with inappropriate tools.

(4) Please use wrench to tight the nuts and never use other tools such as steel hammer to do so.

3-3 Mechanics Lubrication

In order to ensure the precision ,keep lubrication on contact face.

In accessories, there is an oil-can, use it to lubricate. Please inject some lubricant to all of contact face before operating.

The following are the item that needs to make lubrication on machine.

□

USE LUBRICATING OIL □ USE LUBRICATING GREASE

(1) Basement and saddle face (1) X-Axis feeding screw(saddle seat).

(2)Saddle seat and connecting strut (2) Y-Axis feeding screw(working table). slide face.

(3)Fuselage sear and connecting strut (3) Z-Axis feeding gear rack(fuselage). slide face.

(4)Fuselage and spindle box slide face.

Lubricating grease

Lubricating oil

After working, clean the work table and lubricate with a lubricate to protect the worktable.

7

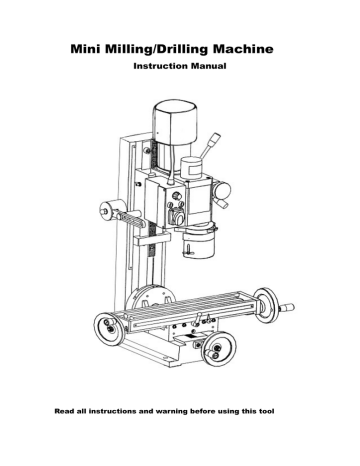

CHAPTERR 4 MACHINE STRUCTURE

4-1 External Feature

8

4-2 Assembly and Part

Longitudinal(Y)Axis Cross (X)Axis

9

Vertical (Z) Axis

10

advertisement