advertisement

Should the motor not function normally, it is possible that it has become clogged with sawdust, in which case it will be necessary to disassemble the motor in order to clean the various components. Contact your CLARKE dealer for advice.

2. Changing the Saw Blade

IMPORTANT: Exercise extreme care when handling the saw blade. The teeth are extremely sharp and careless handling could result in severe personal injury.

2.1 Open the Lower Guard Box door to reveal the saw blade.

2.2 Using a 13mm spanner remove the blade securing bolt, noting that it has a

LEFT HAND THREAD , followed by the outer flange and the saw blade.

NOTE: Flats are milled on the motor shaft, on to which a 17mm spanner may be fitted, in order to hold the shaft when removing the blade securing bolt.

2.3 Reassemble in reverse order, ensuring: a.

the blade teeth are the correct way round, i.e. facing down at the front of the table.

b.

the flange is correctly mounted, with the flat in the bore of the flange mating correctly with the flat on the motor shaft.

c.

the blade securing bolt is tightened to no more than 25 lbf ft.

2.4 Finally, check to ensure the correct clearance is set between the riving knife and the blade. Adjust as necessary (See page 12).

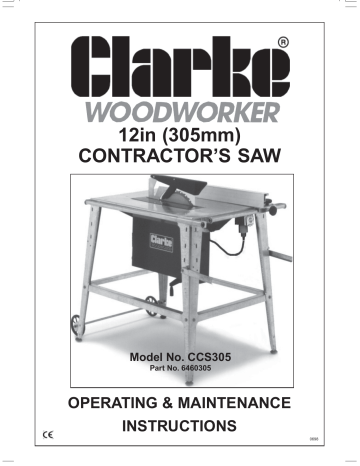

SPECIFICATIONS

Motor - Voltage:

Input Current Rating

Fuse Rating

Power Rating:

Speed:

Capacitor

Duty cycle

Blade - Size:

Bore

230V 50Hz 1 phase.

10 Amps

13 Amps

2.2Kw

2,830RPM

25uF 450V

S6 60%

12” (300mm) TCT (24 teeth)

30mm

Noise level

Gross weight

Min 88dB Max 115dB

59 kg

Dimensions (at table - incl guides) L900xW710xH800mm (To table top)

Dimensions at base 895x660mm

Max Depth of cut

Max width of cut with Rip Fence

Cross cut mitre angle

Rip cut bevel angle

70mm

280mm (high) 220mm (low)

0 - 45°

0 - 45°

20

advertisement