advertisement

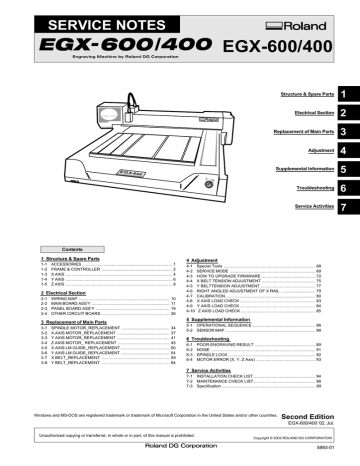

SERVICE NOTES

EGX-600/400

Structure & Spare Parts

1

Electrical Section

2

Replacement of Main Parts

3

Adjustment

4

Supplemental Information

5

Troubleshooting

6

Service Activities 7

Contents

1 Structure & Spare Parts

1-1 ACCESSORIES ............................................................................ 1

1-2 FRAME & CONTROLLER ............................................................ 2

1-3 X AXIS .......................................................................................... 4

1-4 Y AXIS .......................................................................................... 6

1-5 Z AXIS .......................................................................................... 8

2 Electrical Section

2-1 WIRING MAP ............................................................................. 10

2-2 MAIN BOARD ASS’Y .................................................................. 11

2-3 PANEL BOARD ASS’Y ............................................................... 19

2-4 OTHER CIRCUIT BOARS .......................................................... 26

3 Replacement of Main Parts

3-1 SPINDLE MOTOR_REPLACEMENT ......................................... 34

3-2 X AXIS MOTOR_REPLACEMENT ............................................. 37

3-3 Y AXIS MOTOR_REPLACEMENT ............................................. 41

3-4 Z AXIS MOTOR_ REPLACEMENT ............................................ 45

3-5 X AXIS LM GUIDE_REPLACEMENT .......................................... 50

3-6 Y AXIS LM GUIDE_REPLACEMENT .......................................... 54

3-7 X BELT_REPLACEMENT .......................................................... 59

3-8 Y BELT_REPLACEMENT .......................................................... 64

4 Adjustment

4-1 Special Tools ............................................................................. 68

4-2 SERVICE MODE ........................................................................ 69

4-3 HOW TO UPGRADE FIRMWARE ............................................. 72

4-4 X BELT TENSION ADJUSTMENT ............................................. 75

4-5 Y BELTTENSION ADJUSTMENT .............................................. 77

4-6 RIGHT ANGLED ADJUSTMENT OF X RAIL ............................. 79

4-7 CALIBRATION ............................................................................ 80

4-8 X AXIS LOAD CHECK ................................................................ 83

4-9 Y AXIS LOAD CHECK ................................................................ 84

4-10 Z AXIS LOAD CHECK ............................................................... 85

5 Supplemental Information

5-1 OPERATIONAL SEQUENCE ..................................................... 86

5-2 SENSOR MAP ............................................................................ 88

6 Troubleshooting

6-1 POOR ENGRAVING RESULT ................................................... 89

6-2 NOISE ........................................................................................ 91

6-3 SPINDLE LOCK .......................................................................... 92

6-4 MOTOR ERROR (X, Y, Z Axis) .................................................. 93

7 Service Activities

7-1 INSTALLATION CHECK LIST .................................................... 94

7-2 MAINTENANCE CHECK LIST .................................................... 98

7-3 Specification ............................................................................... 99

Windows and MS-DOS are registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

Second Edition

EGX-600/400 ‘02. Jul.

Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

Copyright © 2002 ROLAND DG CORPORATION

5893-01

Revision Record

Revision

No.

0

1

Date Description of Changes

First Edition

Approval Issued by

Inagaki Tamaki

2002.5.28

2002.7.11

Sect1. [Structure & Parts List] has been added. Inagaki Tamaki

To Ensure Safe Work

To Ensure Safe Work

About and Notices.

Used for instructions intended to alert the operator to the risk of death or severe injury should the unit be used improperly.

Used for instructions intended to alert the operator to the risk of injury or material damage should the unit be used improperly.

* material damage refers to damage or other adverse effects caused with respect to the home and all its furnishings, as well to domestic animals or pets.

About the Symbols

The symbol alerts the user to important instructions or warnings. The specific meaning of the symbol is determined by the design contained within the triangle.

The symbol at left means danger of electrocution.

The symbol alerts the user to items that must never be carried out (are forbidden). The specific thing that must not be done is indicated by the design contained within the circle.

The symbol at left means not to touch.

The symbol alerts the user to things that must be carried out. The specific thing that must be done is indicated by the design contained within the circle. The symbol at left means the power-cord plug must be unplugged from the outlet.

1 Structure & Spare Parts

1 Structure & Spare Parts

1-1 ACCESSORY

9

18

17

14

13

JAPANESE

10

20

11

21

12

ENGLISH

19

6

4

3 1 2

5 8

7

S1

16 accessory

PARTS LIST -Main Parts-

Parts No.

Parts Name

1 23495124 AC CORD 3ASL/100 240VA 10A SAA

2 13499111 AC CORD H05VV-F 240VE 10A S

3 13499109 AC CORD SJT 117V 10A 3PVC

4 23495214 AC CORD VCTF 100V 7A 3P-S

5 23495125 AC-CORD H05VV 230V 10A S

6 13499209 ADAPTER PLUG (100V)

7 21815108 BOLT,T-SLOT EGX-600

8 13439801 CABLE-AC 3P CHINA 10A/250V S

9 13509781 CABLE-ASSY HCL-T5-1MP-BL 1M

10 12569515 HEXAGONAL WRENCH

11 21655242 HOLDER,COLLET 4.36 EGX-600

12 26015374 MANUAL,USE EN EGX-600

13 26015373 MANUAL,USE JP EGX-600

14 21575104 NUT,KNURLED RETAINER PNC-2300

15 22055278 PLATE,CLAMP PNC-2300

16 21515102 RING,DEPTHNOSE PNC-2300

17 21515101 RING,MICROMETER DIAL PNC-2300

18 12569304 SPANNER 17MM

19 21935130 TOOL,HEXAGON 3 ZN

20 11939106 TOOL,SPANNER 10

PARTS LIST -Supplemental Parts-

Parts No.

Parts Name

S1 31099108 NUT,WING 2SYU M6 BC

1

1

1

1 Structure & Spare Parts

1-2 FRAME & CONTROLLER

33

9

22

34

30

2

S2

31

S2

21

6

S7

16

S6

S3

19

S1

13

35

S8

8

S7 29

19

S7

25

S7

10

18

S9

S1 11

27

5

32

3

S1

4

S10

1

S11

20

S1

12

S1

S7

26

35

2

23

15

S7

28

24

S7

35

14

S1

35

S4

S1

7

S4

1 Structure & Spare Parts

EGX-400

EGX-600

PARTS LIST -Main Parts-

Parts No.

1 13429701

Parts Name

AC INLET SUP-J15G-E

2 22805450

3 23505780

ASS'Y,CONTROLER EGX-600

CABLE-ASSY GND EGX-600

4 23505776

5 23505777

6 22815146

22025642

7

22025643

CABLE-ASSY JUNBI1 EGX-600

CABLE-ASSY JUNBI5 EGX-600

CHASSIS,CONTROLLER EGX-600

COVER,CABLE GUIDE EGX-400

8

22025641

22025635

9 22025625

10 22025666

11 22025667

12 22025664

COVER,CABLE GUIDE EGX-600

COVER,CONTROL CHASSIS EGX-400

*

COVER,CONTROL CHASSIS EGX-600 *

COVER,CONTROLLER EGX-600

COVER,MAIN BOARD EGX-600

COVER,Y FRAME CORNER 2 EGX-600

COVER,Y FRAME CORNER EGX-600

*

*

PARTS LIST -Supplemental Parts-

Parts No.

S1 31019115

S2 31019709

S3 31019702

S4 31049111

S6 31329601

S7 31289105

S8 31279183

S9 31279116

S10 31279195

S11 31079101

Parts Name

SCREW,BINDING M3*4 BC

SCREW,BINDING P-TIGHT 2.6*4 BC

SCREW,BINDING P-TIGHT 3*6 BC

SCREW,CAP M4*8 BC

CLAMP,INSULOK T-18S

CUPSCREW, M3*6 BC

LABEL,CATION AIRGUN No.473

LABEL,EARTH MARK-1 NO.E-580

LABEL,NAME EXPRESSION No.450

SCREW,OVAL M3*8 BC

*

13

14

15

16

18

22025650

22025649

22025662

22025663

22025658

22025653

22025659

22025654

22025660

22025655

COVER,Y FRAME L EGX-400

COVER,Y FRAME L EGX-600

COVER,Y FRAME R EGX-400

COVER,Y FRAME R EGX-600

COVER,Y-BASE FRONT EGX-400 (3/5)

COVER,Y-BASE FRONT EGX-600 (3/5)

COVER,Y-BASE L EGX-400 (4/5)

COVER,Y-BASE L EGX-600(4/5)

COVER,Y-BASE R EGX-400 (5/5)

COVER,Y-BASE R EGX-600(5/5)

19 12239406 CUSHION,TM-96-6

7589418000 EGX-400 FRAME-ASSY

20

7589318000 EGX-600 FRAME-ASSY

*

*

*

*

*

*

21 W589356020 EGX-600 JOG BOARD ASS'Y

22 22475110 KNOB,L MCG MDX-500

23 22535349

24 22535352

LABEL,CARD SLOT EGX-600 #LA425

LABEL,EMERGENCY EGX-600 #LA428

25 22535348

22535351

26

22535350

LABEL,INTERFACE EGX-600 #LA424

LABEL,LOGO EGX-400 #LA427

27 22535117

28 22535362

29 22535123

LABEL,LOGO EGX-600 #LA426

LABEL,POWER CM-500 NO.893

LABEL,RISK WARN EGX-600 #LA454

LABEL,STANDARD(131)No.910

30 W589356090 EGX-600 LCD BOARD ASS'Y

31 W589356030 EGX-600 PANEL BOARD ASS'Y

32 13129171 POWER-SW AJ8201B

33 21475137

34 22255217

35 11879126

SHEET,CONTROLLER EGX-600

SHIELD,JOG MDX-500

ABSORBER,C-30-RK-3225

*

*

*

*

*

*

*

1

3

1 Structure & Spare Parts

1-3 X AXIS

23

1

S4

23

S3

S9

S4

12

S4

39

S10

43

S5

S9

S6

21

S4

S4

S8

41

S9

14

30

S4

25

5

4

40

S4

40

38

S13

S4

10

19

31

18

S4

10

S6

S12

S9

29

3

S4

1

37

S10

34

S4

10

19

S12

19

10

S4

S10

S10

S12

S11

S1

32

S4

35

S12

17

27

S12

36

33

S9

16 S4

9

S4

S13

S2

S9

S4

28

2

S7

S9

S12

42

S9

20

22

S4

S9

S4

8

7

13

26

15

S4

S14

S4

24

S11

6

S4

11

4

1 Structure & Spare Parts

EGX-600

PARTS LIST -Main Parts-

Parts No.

1 22805454

2 22355794

3 22175815

Parts Name

ASS'Y,HOLDER BEARING EGX-600

BASE,X-MOTOR EGX-600

BEARING F8-16ZZ

4 11929132

5

11929136

11929134

6 21985135

23475182

7

23475180

8

23475181

23475179

9 11769118

10 22025646

11 22025636

BELT,100S2M240UG

BELT,150S2M555LW-C

BELT,150S2M755LW-C

BRACKET,Y-CABLE EGX-600

CABLE-CARD 28P 1100L BB HIGH-V

CABLE-CARD 28P 1300L BB HIGH-V

CABLE-CARD 28P 1380L BB HIGH-V

CABLE-CARD 28P 1740L BB HIGH-V

CLAMP,FCM2-S6-14

COVER,BELT HOLDER EGX-600

COVER,BRACKET Y-CABLE EGX-600

*

*

*

12 22025448

13

22025657

22025652

COVER,SIDE L EGX-600

COVER,SIDE R EGX-400 (2/5)

22025639

COVER,SIDE R EGX-600 (2/5)

COVER,TOP EGX-400

14

22025637

22025640

COVER,TOP EGX-600

COVER,X-FRONT EGX-400

15

22025638 COVER,X-FRONT EGX-600

16 W589356010 EGX-600 XY BOARD ASS'Y

17 7589317000

18 21655237

EGX-600 CHASSIS,X-Y BOARD ASSY

HOLDER,BEARING X EGX-600

19 21655232

20

21 21655239

21655236

22

21655235

21655233

21655234

23 22535347

24 22535356

25

21895144

21895143

26 22435425

HOLDER,BELT EGX-600

HOLDER,X-CABLE EGX-400

HOLDER,X-CABLE EGX-600

HOLDER,X-IDLE PULLEY EGX-600

HOLDER,Y-CABLE EGX-400

HOLDER,Y-CABLE EGX-600

LABEL,CAUTION PINCH-2 #LA423

LABEL,CORPORATE LOGO TYPE#LA437

L-BEARING,HSR15R2SSE+580L-2

L-BEARING,HSR15R2SSE+760L-1

MOTOR,XY EGX-600

27 21975151

28 21975152

29 21975153

22185429

30

22185428

31 12179721

32 11889127

33 22295259

34 22185123

35 22185124

PULLEY,100S2M0100 EGX-600

PULLEY,20S2M0100SF EGX-600

PULLEY,30S2M0150SF EGX-600

RAIL,X EGX-400

RAIL,X EGX-600

R-BEARING JIS6000ZZ (B8)

R-BEARING,DDLF-1910ZZ

SHAFT,X-DRIVE EGX-600

SLIDER,Y L EGX-600

SLIDER,Y R EGX-600

36 22175318

37 22715310

38 22715307

39 22715300

40 22135430

41 22135428

42 22135431

43 22175687

SPRING,X-DRIVE EGX-600

STAY,SIDE L EGX-600

STAY,X-BELT HOLDER EGX-600

STAY,X-IDLE PULLEY EGX-600

STOPPER,CABLE2 EGX-600

STOPPER,CARRIAGE EGX-600

STOPPER,X-DRIVE EGX-600

X-IDLE PULLEY

*

*

*

*

*

*

*

EGX-400

*

*

*

*

*

*

*

*

*

*

PARTS LIST -Supplemental Parts-

Parts No.

Parts Name

S1 31029817 BUSH,ROLL 4*15

S2 31029823 BUSH,ROLL 4*2,5

S3 31329601 CLAMP,INSULOK T-18S

S4 31289105 CUPSCREW, M3*6 BC

S5 31109802 NUT,HEXAGON M4 C

S6 31119902 PIN,SPRING 4*16 SUS JAG

S7 31149709 RING,E-RING CONIC BETW-7 SUS

S8 31049167 SCREW,CAP M4*35BC ALL THREADED

S9 31049111 SCREW,CAP M4*8 BC

S10 31049169 SCREW,CAP M4*8 BC+PW4*10*0.8

S11 31139101 SCREW,PLAPOINT M3*6 BK FE

S12 31199703 SCREW,SET WP M3*6 BC

S13 31049136 SCRWE,CAP M4*20 BC

S14 31249225 WASHER,3*12*1 BC

1

5

1

1 Structure & Spare Parts

1-4 Y AXIS

S18

25

33

34

35

S16

S11

36

S11

37

6

S2

24

50

S18

9

S6

S3

18

S17

S6

S3

S15

S10

44 2

S20

14

15

12

17

S3

S3

4

S19

41

43

39

S16

42

54

48

S16

S19

S16

42

S16

42

1

45

3

S1

S19

40

30

29

S4

26

S16

S19

41

11

S19

S10

13

32

S3

5 S9

38

S17

22

53

S21

S7

S9

S3

S5

52

S6

7

28

16

27

51

8

S14

47

5

S9

53

S17

26

S9

31

31

S21

19

20

21

S3

29

S3

S15

10

S3

S16

49

S4

S12

46

6

1 Structure & Spare Parts

EGX-600

PARTS LIST -Main Parts-

Parts No.

1 22805453

Parts Name

ASS'Y,BASE Y-DRIVE EGX-600

2

22805452

22805451

3 22355795

ASS'Y,STAY Y-DRIVE EGX-400

ASS'Y,STAY Y-DRIVE EGX-600

BASE,Y-MOTOR EGX-600

4 11929132

5

11929135

11929133

6

23505767

23505768

BELT,100S2M240UG

BELT,150S2M467LW-C

BELT,150S2M569LW-C

CABLE-ASSY EMG EGX-400

7 23505778

8 23505779

9 23505773

10

11

23505765

23505766

23505774

23505775

12 23475138

13 23475184

14 22335145

15 22025644

CABLE-ASSY EMG EGX-600

CABLE-ASSY JUNBI6 EGX-600

CABLE-ASSY JUNBI7 EGX-600

CABLE-ASSY POWER2

CABLE-ASSY Y LIMIT EGX-400

CABLE-ASSY Y LIMIT EGX-600

CABLE-ASSY YM EGX-400

CABLE-ASSY YM EGX-600

CABLE-CARD 20P 1120L BB HIGH-V

CABLE-CARD 30P 120L BB

CAP,MEMORYSLOT EGX-600

COVER,MEMORY SLOT EGX-600

16 W589356050 EGX-600 IF BOARD ASS'Y

17 W589356080 EGX-600 MMC BOARD ASS'Y

18 W589356060 EGX-600 TRANS BOARD 1 ASS'Y

19 7589350000 EGX-600 MAIN BOARD ASS'Y

20 7589353000 EGX-600 SPINDLE BOARD ASS'Y

21 12399313 FILTER(E) TR-20-10-10

22

24

12559570

12559444

22135613

22135611

FUSE 5X20 CEE-2AT WICKMANN

FUSE 5X20 SB4 (4A)

GUIDE,X-SCALE EGX-400

GUIDE,X-SCALE EGX-600

25

22135612

22135609

GUIDE,Y-SCALE EGX-400

GUIDE,Y-SCALE EGX-600

26 21655240 HOLDER,Y-IDLE PULLEY EGX-600

27 7559306100 JACK ASS'Y EGX-300

28 22535361

21895145

29

21895144

LABEL,N EGX-600 #LA453

L-BEARING,HSR15R2SSE+460L-2

30 22435425

L-BEARING,HSR15R2SSE+580L-2

MOTOR,XY EGX-600

31 2215352600 NUT

32 22055522

22055530

33

22055523

PLATE,INTERFACE EGX-600

PLATE,T-SLOT 1 EGX-400

34

35

22055531

22055524

22055532

22055525

36 22055526

37 22055527

PLATE,T-SLOT1 EGX-600

PLATE,T-SLOT 2 EGX-400

PLATE,T-SLOT2 EGX-600

PLATE,T-SLOT 3 EGX-400

PLATE,T-SLOT3 EGX-600

PLATE,T-SLOT4 EGX-600

PLATE,T-SLOT5 EGX-600

38 12429113U0 POWER UNIT,ZWS120PPF-36

39 21975151

40 21975152

PULLEY,100S2M0100

PULLEY,20S2M0100SF

41 21975153

42 12179721

43

22295261

22295260

PULLEY,30S2N0150SF

R-BEARING JIS6000ZZ (B8)

SHAFT,Y-DRIVE EGX-400

SHAFT,Y-DRIVE EGX-600

44 22175217

45 22175316

46 22715299

47 22715311

SPRING,SOLENOID MDX-500

SPRING,Y-DRIVE EGX-600

STAY,EMARGENCY SW EGX-600

STAY,TERMINAL BLOCK EGX-600

48

22715301

22715302

STAY,Y-DRIVE EGX-400

STAY,Y-DRIVE EGX-600

49 22135430

21965146

50

21965145

STOPPER,CABLE2 EGX-600

TABLE,T-SLOT EGX-400

51 12729102

TABLE,T-SLOT EGX-600

TERMINAL-BLOCK BTBH15LC2P

52 22455116U0 TRANSFORMER-PW1 EGX-600

53 22175687

54 22355796

X-IDLE PULLEY

BASE,Y-DRIVE EGX-600

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

EGX-400

*

*

*

*

*

*

*

*

*

*

*

*

*

*

PARTS LIST -Supplemental Parts-

Parts No.

S1 31029823

S2 31329601

S3 31289105

S4 31059110

S5 31279191

S6 31279121

31279124

S7

31279127

S9 31109802

S10 31149705

S11 31019117

S12 31049106

S14 31049113

S15 31049167

S16 31049111

S17 31049169

S18 31139101

S19 31199703

S20 31179907

S21 31049136

Parts Name

BUSH,ROLL 4*2,5

CLAMP,INSULOK T-18S

CUPSCREW, M3*6 BC

CUTION,COVER CABLE 519M0433

LABEL,CAUTION FUSE #347

LABEL,FLASH-LIGHTING NO.E-582

LABEL,FUSE 4.0A 125V NO.E-575

LABEL,FUSE T2A/250V NO.E-574

NUT,HEXAGON M4 C

RING,E-RING ETW-7 SUS

SCREW,BINDING M3*8 BC

SCREW,CAP M3*8 BC

SCREW,CAP M4*12 BC

SCREW,CAP M4*35BC ALL THREADED

SCREW,CAP M4*8 BC

SCREW,CAP M4*8 BC+PW4*10*0.8

SCREW,PLAPOINT M3*6 BK FE

SCREW,SET WP M3*6 BC

SCREW,UREA M3*20 N-1 BK

SCRWE,CAP M4*20 BC

1

7

1 Structure & Spare Parts

1-5 Z AXIS

S5

23

20

S5

S4

1

15

S5

S5

44

8

36

S16

1

2

28

7

34

40

S9

S11

35

S17

S10

3

27 S5

9

S5

19

S19 11

39

S5

S3

S14

26

A

B

5

S1

S12

29

S7

S12

41

S5

16

17

32

33

S2

S5

S13

45

31

S5 S18

S8

A

S6

43

38

S5

S5

21

S5

S2

18

33

24

22

S5

17

13

S5

10

12

25

S13

S14

S20

6

S12

S15

S5

4 37

B

S12

42

30

S13

8

1 Structure & Spare Parts

PARTS LIST -Main Parts-

Parts No.

1 22805456

Parts Name

ASS'Y,BASE Z SLIDE EGX-600

2 22805455

3 22355793

4 22355800

5 22355798

6 22355799

ASS'Y,SLIDER Z EGX-600

BASE,MICROMETER DIAL EGX-600

BASE,MOTOR Z EGX-600

BASE,SPINDLE MOTOR EGX-600

BASE,Z EGX-600

EGX-600

7 22355792

8 22355797

9 11929131

10 21985134

11 23505771

23475182

12

23475180

13 22025647

15 22025648

16 22025645

17 12239406

BASE,Z SLIDE EGX-600

BASE,Z0 SENSOR EGX-600

BELT,A-1CEBRF 5*170

BRACKET,X-CABLE EGX-600

CABLE-ASSY SENS EGX-600

CABLE-CARD 28P 1100L BB HIGH-V

CABLE-CARD 28P 1300L BB HIGH-V

COVER,BRACKET X-CABLE EGX-600

COVER,X-Z JUNCTIONBOARD EGX-600

COVER,Z-CABLE EGX-600

CUSHION,TM-96-6

18 W589356040 EGX-600 BRAKE BOARD 2 ASS'Y

19 7589320000 EGX-600 PULLEY M PP

20 7589359000 EGX-600 SPINDLE CABLE ASSY

21 W589356070 EGX-600 XZ BOARD ASS'Y

22 7589360000 EGX-600 BRAKE ASSY

23

7589407000 EGX-400 COVER,Z ASSY(1/5)

7589307000 EGX-600 COVER,Z ASSY(1/5)

24 7589319000 EGX-600 STAY,X-Z BOARD ASSY

25

21655235 HOLDER,X-CABLE EGX-400

21655233 HOLDER,X-CABLE EGX-600

26 22535213 LABEL,CAUTION TOOL MDX-15#LA58

27 22535355

28 22395130

29 22435427

30 22435426

31 22055535

LABEL,COVER LOCK EGX-600 #LA436

MAGNET PR1008P157B

MOTOR,SPINDLE EGX-600

MOTOR,Z EGX-600

PLATE,RUBBER Z EGX-600

32 11889107

33 11519107

34 21495140

35 21495141

36 25095116

37 22295262

38 22185125

39 22175309

40 22175311

41 22175320

42 22715304

43 22715305

44 22715303

45 22325440

R-BEARING,D10S6(B3FL)

RING,O P4

SCREW,Z ADJUST EGX-600

SCREW,Z-AXIS ASSY EGX-600

SENSOR,HALL AN9153 ASSY

SHAFT,Z EGX-600

SLIDER,X EGX-600

SPRING,MICROMETER DIAL EGX-600

SPRING,NOSE GUARD EGX-600

SPRING,SP MOTOR EGX-600

STAY,COVER SW EGX-600

STAY,COVER Z EGX-600

STAY,SENSOR EGX-600

SUPPORT,Z-SCREW EGX-600

*

*

*

EGX-400

*

*

*

PARTS LIST -Supplemental Parts-

Parts No.

Parts Name

S1 31029820 BUSH,ROLL 3*2

S2 31029802 BUSH,ROLL 3*3.5

S3 31499101 CLAMP,BASE SKM-1

S4 31329601 CLAMP,INSULOK T-18S

S5 31289105 CUPSCREW, M3*6 BC

S6 31059110 CUTION,COVER CABLE 519M0433

S7 31279106 LABEL,CAUTION HOT SURF No.778

S8 31119115 PIN,PARALLEL 6*25 SUS H7

S9 31149503 RING,C CTW-14 SUS

S10 31049102 SCREW,CAP M2*6 BC

S11 31049103 SCREW,CAP M2*8 BC

S12 31049106 SCREW,CAP M3*8 BC

S13 31049113 SCREW,CAP M4*12 BC

S14 31049167 SCREW,CAP M4*35BC ALL THREADED

S15 31049111 SCREW,CAP M4*8 BC

S16 31169115 SCREW,FLAT M2*8 BC

S17 31199710 SCREW,SET WP M3*3 BC

S18 31199703 SCREW,SET WP M3*6 BC

S19 31199711 SCREW,SET WP M4*8 BC

S20 31049136 SCRWE,CAP M4*20 BC

1

9

2-1 WIRING MAP

2

CN6 CN3 CN5

CN1 CN2 CN4

CN2 CN3 CN12 CN1 CN6

CN25

CN8 CN9

CN1 1 CN1 0 CN7

CN1 6

CN23

CN2 1

CN1 CN3

CN1 1

CN14

10

CN15 3 CN1 CN12

D A T A

A D D R E S S

C O N T R O L L

CN8 CN1 1

RD BOA

00

S AN

EGX

TR

2-2 MAIN BOARD ASS'Y

Main Board_Arrangement Diagram / component side

2 Electrical Section

Indicates revision of the circuit board.

2

11

2

2 Electrical Section

Main Board_Component Diagram / component side

12

Main Board_Arrangement Diagram / soldering side

2 Electrical Section

2

13

2

2 Electrical Section

Main Board_Component Diagram / soldering side

14

Main Board_1/4 Circuit Diagram

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

C101 CE0.1u

2

1

CE0.22u/50V

C43

3

18

16

17

VCP

VBOOT

VREF

SENSE2

SENSE1

GND

GND

GND

GND

11

1

10

20

19

2

R61 100k 0.1%

11 4

100k 0.1%

EXBA10E103J

RA5

EXBA10E103J

RA6

1

6

8

4

9

2

3

7

5

10

R243.3k

C38CE1.0u

1

6

1

6

RA4 EXBA10E103J

RA3 EXBA10E103J

8

4

9

2

3

7

5

10

10

8

4

9

2

3

7

5

R

IT

RES

PLLVCC

PLLVSS

STBY

GND

EXTAL

XTAL

VCC3

PG0/CS0

PG1/CS1

PG2/CS2

PG3/CS3

PH0/CS4

PH1/CS5

PF6/AS

PF5/RD

PF4/HWR

PF3/LW

PF0/WA

PF7/CLKOUT

105

104

103

102

108

107

106

101

100

88

87

86

85

81

82

83

84

74

75

73

77

76

78

79

80

93

92

91

90

89

97

96

98

99

94

95

PD3/D11

GND

PD2/D10

PD1/D9

PD0/D8

PD4/D12

PD5/D13

PD6/D14

P50/TXD2/IRQ0

P51/RXD2/IRQ1

PF2/LCAS/IRQ15

PF1/UCAS/IRQ14

P65/TMO1/DACK1/IRQ13

P64/TMO0/DACK0/IRQ12

P63/TMCI1/TEND1/IRQ11

P62/TMCI0/TEND0/IRQ10

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

R50 560

R40 0.1/1W

2

1

CE0.22u/50V

C47

3

18

16

17

VCP

VBOOT

VREF

R39 0.1/1W

SENSE2

SENSE1

GND

GND

GND

GND

11

1

10

20

19

2

R65 47k 0.1%

P71/EDREQ1/(DREQ1)

P70/EDREQ0/(DREQ0)

P72/ETEND0/(TEND0)

P85/EDACK3/(IRQ5)

P84/EDACK2/(IRQ4)

P83/ETEND3/(IRQ3)

PB7/A15

PB6/A14

PB5/A13

PB4/A12

PB2/A10

MD2

PA7/A23

PA6/A22

PA5/A21

PA4/A20

PA2/A18

PA3/A19

NC

PA0/A16

PA1/A17

GND

7

6

5

9

8

4

3

1

2

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PC6/A6

PC7/A7

PB1/A9

PB0/A8

PC5/A5

PC4/A4

GND

PC3/A3

PC2/A2

PC1/A1

PC0/A0

VCC3

GND

PB3/A11

8

4

9

2

3

7

5

10

RA7 EXBA10E103J

6

1

R26 3.3k

R109 22k

8

7

6

5

8

7

6

5

1

2

3

4

1

2

3

4

3

8

4

9

2

3

7

5

10

RA8 EXBA10E103J

6

1

1

R55

R54

R53

R56

C67

330

CE0.022u

330

C68

330

C69

C66

CE0.022u

CE0.022u

CE0.022u

330

1 10K

2 Electrical Section

2

15

2

2 Electrical Section

Main Board_2/4 Circuit Diagram

2

3

1

16

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

Z0

/DSR

A_LIM

Z_LIM

Y_LIM

X_LIM

/DACK1

/DACK0

T STAR

Cmd_HS

T STAR

/LESSTHAN_ZA

/DACK1

/DACK0

Cmd_HS

/RAS

/CASL

/CASU

/LESSTHAN_XY

PTF7

PTF6

PTF5

PTF4

PTF3

PTF2

PTF1

PTF0

X_LIM

Z_LIM

A_LIM

/DSR

Z0

Y_LIM

136

137

138

139

143

144

142

141

140

133

132

135

134

128

127

125

126

130

129

131

148

147

145

146

150

149

151

153

154

152

156

155

109

108

107

106

105

110

111

115

114

112

113

119

118

116

117

120

124

123

122

121

GND

VCC3

PTG[3]

PTG[4]

PTG[2]

PTG[5]

PTG[6]

GND

PTG[0]

VCC1.9

PTG[1]

WAIT

BREQ

BACK

PTE[0]

RESETM

IOIS16/PTG[7]

EXTAL

XTAL

VCC1.9

GND

GND

PTH[6]

Vcc-PLL2

CAP2

Vss-PLL2

Vss-PLL1

CAP1

Vcc-PLL1

MD0

PTF[0]/PINT[8]

PTF[1]/PINT[9]

CKE/PTK[5]

RAS3L/PTJ[0]

RAS2L/PTJ[1]

CAS2H/PTE[3]

CAS2L/PTE[6]

CASHH/PTJ[5]

CASHL/PTJ[4]

RAS3U/PTE[2]

RAS2U/PTE[1]

DACK0/PTD[5]

DACK1/PTD[7]

PTF[3]/PINT[11]

PTF[2]/PINT[10]

ADTRIG/PTH[5]

PTF[4]/PINT[12]

PTF[5]/PINT[13]

PTF[6]/PINT[14]

PTF[7]/PINT[15]

CASLL/CASL/PTJ[2]

CASLH/CASU/PTJ[3]

3

8

7

6

5

8

7

6

5

1

2

3

4

1

2

3

4

1

EXBA10E103J

RA10

EXBA10E103J

RA12

EXBA10E103J

RA13

IRQ0/IRL0/PTH[0]

IRQ1/IRL1/PTH[1]

IRQ2/IRL2/PTH[2]

IRQ3/IRL3/PTH[3]

IRQ4/PTH[4]

D29/PTB[5]

D28/PTB[4]

D27/PTB[3]

D26/PTB[2]

D31/PTB[7]

D30/PTB[6]

[1]

[0]

[2]

[3]

[7]

[6]

[5]

[4]

D24/PTB[0]

D25/PTB[1]

MD2

MD1

VCC3

NMI

GND

EXTAL2

XTAL2

6

5

3

4

2

1

8

7

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

D17/PTA

D16/PTA

D18/PTA

GND

D15

VCC3

GND

D5

D13

D12

D14

D11

D10

D9

D8

D7

D6

D3

D2

D4

D1

D0

VCC3

GND

D19/PTA

D23/PTA

D22/PTA

D21/PTA

D20/PTA

VCC1.9

VCC3

GND

D23

D22

D24

D21

D20

D19

D17

D16

D18

D13

D12

D14

D11

D10

D9

D8

D7

D6

D5

D3

D2

D4

D1

D0

D15

D29

D28

D27

D26

D31

D30

D25

8

4

9

2

3

7

5

10

D31

D30

D29

D28

D27

D26

D25

D24

D23

D22

D21

D20

D19

D18

D17

D16

D13

D12

D11

D10

D9

D8

D15

D14

D7

D6

D5

D4

D3

D2

D1

D0

8

4

9

2

3

7

5

10

8

4

9

2

3

7

5

10

8

4

9

2

3

7

5

10

8

4

9

2

3

7

5

10

RA18 NOT 6

1

RA17 NOT 6

1

RA16 NOT

1

6

1

6

1

6

R130 10k

2 Electrical Section

Main Board_3/4 Circuit Diagram

8

7

6

5

8

7

6

5

1

2

3

4

1

2

3

4

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

R44 0.1/1W

CE0.22u/50V

2

1

C55

3

18

16

17

VBOOT

VREF

VCP

R43 0.1/1W

SENSE2

SENSE1

GND

GND

GND

GND

11

1

10

20

19

2 C50 CE0.22u/50V

2

1

CE0.22u/50V

C51

3

18

16

17

VBOOT

VREF

VCP SENSE2

SENSE1

GND

GND

GND

GND

11

1

10

20

19

2

11 4

EXBA10E103J

RA21

EXBA10E103J

RA22

1

6

8

4

9

2

3

7

5

10

R28

C39CE1.0u

1

6

1

6

RA20 EXBA10E103J

RA19 EXBA10E103J

8

4

9

2

3

7

5

10

10

8

4

9

2

3

7

5

3.3k

105

104

103

102

108

107

106

101

100

88

87

86

85

81

82

83

84

74

75

73

77

76

78

79

80

93

92

91

90

89

97

96

98

99

94

95

RES

PLLVCC

PLLVSS

EXTAL

XTAL

VCC3

STBY

GND

PG0/CS0

PG1/CS1

PG2/CS2

PG3/CS3

PH0/CS4

PH1/CS5

PF6/AS

PF5/RD

PF4/HWR

PF3/LWR

PF7/CLKOUT

PF0/WAIT

P50/TXD2/IRQ0

P51/RXD2/IRQ1

PF1/UCAS/IRQ14

PF2/LCAS/IRQ15

PD3/D11

GND

PD2/D10

PD1/D9

PD0/D8

PD4/D12

PD5/D13

PD6/D14

P65/TMO1/DACK1/IRQ13

P64/TMO0/DACK0/IRQ12

P63/TMCI1/TEND1/IRQ11

P62/TMCI0/TEND0/IRQ10

8

4

9

2

3

7

5

10 1

6

P71/EDREQ1/(DREQ1)

P70/EDREQ0/(DREQ0)

P72/ETEND0/(TEND0)

P84/EDACK2/(IRQ4)

P83/ETEND3/(IRQ3)

P85/EDACK3/(IRQ5)

PB7/A15

PB6/A14

PB5/A13

PB4/A12

PB2/A10

MD2

PA7/A23

PA6/A22

PA5/A21

PA4/A20

PA2/A18

PA3/A19

NC

PA0/A16

PA1/A17

GND

7

6

5

9

8

4

3

1

2

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PC6/A6

PC7/A7

PB1/A9

PB0/A8

PC5/A5

PC4/A4

GND

PC3/A3

PC2/A2

PC1/A1

PC0/A0

VCC3

GND

PB3/A11

R30 3.3k

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

3

8

4

9

2

3

7

5

10

RA24 EXBA10E103J 6

1

1

2

R59

R58

R57

R60

C72

330

C73

CE0.022u

330

C71

CE0.022u

CE0.022u

330

C70

CE0.022u

330

17

2

2 Electrical Section

Main Board_4/4 Circuit Diagram

3

1 2

K A

2

18

BHEU

BLEU

BLEL

BHEL

DQMLL

DQMLU

DQMUL

DQMUU

DQMUL

DQMUU

BLEU

BHEU

BHEL

BLEL

DQMLL

DQMLU

VCC

GND

I/O5

I/O4

I/O3

I/O2

I/O1

I/O0

I/O7

I/O6

VCC

I5

GND

GND

GND

I/O63

I/O62

I/O61

I/O60

I/O59

I/O58

GND

GND

I/O56

I/O57

92

91

90

89

87

86

88

85

84

83

82

81

80

79

78

77

76

98

97

99

96

95

94

93

100

I/O39

I/O38

GND

GND

I/O36

I/O35

I/O37

I/O34

I/O33

I/O29

I/O28

I/O27

I/O26

I/O25

I/O24

GND

GND

GND

GND

VCC

VCC

I2

I/O32

I/O31

I/O30

41

40

42

39

38

37

36

35

34

33

32

31

30

29

28

27

26

50

49

48

47

46

45

44

43

ZACLK

XYCLK

EXTOUT

EXTIN

IOPORT

/CS4

/RD

RD/WR

A5

A4

A6

EXTOUT

EXTIN

IOPORT

/CS4

/RD

RD/WR

ZACLK

XYCLK

2-3 SPINDLE BOARD ASS'Y

Spindle Board_Arrangement Diagram / component side

2 Electrical Section

2

19

2

2 Electrical Section

Spindle Board_Component Diagram / component side

20

Spindle Board_Arrangement Diagram / soldering side

2 Electrical Section

2

21

2

2 Electrical Section

Spindle Board_Component Diagram / soldering side

22

2 Electrical Section

Spindle Board_1/3 Circuit Diagram

R35 4.7k/0.25W

CE0.1u

C53

CE0.1u

C11

R13 10

R73 4.7k/0.1W

BUPWM

/BUPWM

BSD

3 1

R55 330

BVPWM

/BVPWM

BSD

R39 4.7k/0.25W

CE0.1u

C57

CE0.1u

C14

R15 10

C23 CE0.1u

R96 4.7k/0.1W

INT4K

250K

BZ0

HolePulse

BUCRNT

BVCRNT

BWCRNT

BAD

78

79

80

81

82

83

84

85

87

88

IRQ0

IRQ1

AN2

AN3

AN1

AN4

AN5

DA0

DA1

AN0

94

95

93

96

76

77

68

1

35

97

98

99

100

TP4

TP5

TP7

TCLKA

TCLKB

TCLKC

TCLKD

VCC

VCC

VCC

AVCC

VREF

TIOCA2/TP6

P31

P30

P33

P32

P34

P26

P25

P27

P24

P23

P21

P20

P22

VSS

VSS

AVSS

VSS

VSS

VSS

VSS

P16

P15

P17

P13

P12

P14

P11

P10

P36

P35

P37

28

27

29

48

47

46

45

50

49

51

52

92

65

22

11

57

44

86

42

41

43

40

39

37

36

38

33

32

34

31

30

R59 1.2k/0.1W

R77 1.8k/0.1W

R38 4.7k/0.25W

BWPWM

/BWPWM

BSD

CE0.1u

C54

C20 CE0.1u

R14 10

C18 CE0.1u

R95 4.7k/0.1W

C19 CE0.1u

11 4

18k/0.1W

R60 1.2k/0.1W

R41 4.7k/0.25W

R42 1k/0.25W

2

C83 CE0.1u

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

23

2

2 Electrical Section

Spindle Board_2/3 Circuit Diagram

I/O

I/O

I/O

I/O

I/O

GND

NC

VCC

I/O

I/O

I/O

I/O

46

45

47

43

44

48

41

42

39

40

37

38

NC

VCC

GND

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

22

21

20

19

23

24

16

17

18

15

14

13

ACOUNT5

ACOUNT4

ACOUNT6

ACOUNT7

ACOUNT2

ACOUNT1

ACOUNT3

ACOUNT0

3 1

C85 CE0.1u

7 14

1 3

C86 CE0.1u

1 3

C34 CE0.1u

C84 CE0.1u

24

2 Electrical Section

Spindle Board_3/3 Circuit Diagram

2

BBOOT

3

K A

2

3 1

RCH895-680

L3

4

VCC

RESET

Cd

GND

6

7

2

D13 D1FL20U

4

5

3

2

2

3

4

5

R110

R107 15k

CE2200p

4.7k

C64

C65

2.2u/50V

C56

C50 100u/63V

R93 10K 1W

3

CE0.033u

1

D12 D1FL20U

D15 D1FL20U

R100 33/0.1W

3

4

2

5

2

3

4

5

R120

R123

C72

CE1000p

15k C68

4.7k

CE2200p

C67

2.2u/50V

C66

CE0.033u

1 2

R92 10K 1W

R126 100

RCH895-680

L4

3 1

3 1

1 2

13 12

3 1

1

C87 CE0.1u

2

3

1 2

R94 10K 1W

2

2

25

2

2 Electrical Section

2-4 OTHER CIRCUIT BOARD

Other Circuit Board_Arrangement Diagram / component side

26

Other Circuit Board_Component Diagram / component side

2 Electrical Section

2

27

2

2 Electrical Section

Other Circuit Board_Arrangement Diagram / soldering side

28

Other Circuit Board_Component Diagram / soldering side

2 Electrical Section

2

29

2

2 Electrical Section

Other Circuit Board_1/4 Circuit Diagram

30

C20 47u/16V

Other Circuit Board_2/4 Circuit Diagram

R3 330

D26 D1FL20U

2 Electrical Section

2

R58 2/3W R59 2/3W

31

2

2 Electrical Section

Other Circuit Board_3/4 Circuit Diagram

8

7

6

5

8

7

6

5

1

2

3

4

1

2

3

4

8

7

6

5

8

7

6

5

1

2

3

4

1

2

3

4

3

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4 3

3

3

3

3

1

1

1

1

1

1

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4 3

3 1

1

R18 560 R19 560 R20 560 R21 560 R22 560 R23 560 R24 560 R25 560

9

VCC

R5 10k

DGND

8

32

Other Circuit Board_4/4 Circuit Diagram

8

7

6

5

1

2

3

4

8

7

6

5

1

2

3

4

R37 1k

R38 1k

C25 47u/16V

2 Electrical Section

2

R36 1k

3

Q9 DTC114EK

1

R34 10k R35 10k

33

3

3 Replacement of Main Parts

3 Replacement of Main Parts

Following table describes the necessary adjustment after the replacement of each parts.

Replacement Parts

X MOTOR

Necessary Adjustment

1. X Axis Load Check

Y MOTOR

Z MOTOR

1. Y Axis Load Check

1. Z Axis Load Check

X AXIS LM GUIDE 1. X Axis Load Check

1. Right Angle Adjustment of X Axis

Y AXIS LM GUIDE

2. Y Axis Load Check

X BELT

1. X Belt Tension Adjustment

2. X Axis Load Check

Y BELT

1. Right Angle Adjustment of X Axis

2. Y Belt Tension Adjustment

3. Y Axis Load Check

3-1 Spindle Moter_Replacement (Referential Time : 20 minutes)

1

Remove the Spoindle Cover.

Spindle Cover

2 Remove the Z Cable Cover, cut off the INSULOCK TIE and disconnect the Spindle Motor Cable.

Spindle Motor Cable

Z Cable Cover

34

3 Replacement of Main Parts

Spindle Belt

3

Loosen the screws fixing the Flange and remove the Spindle

Belt.

There is the collar on the lower right side of the flange. Be careful not to lose it.

4

Remove the Spring and the Screws, and then remove

Spindle Motor with the Flange.

Screws

Spring

Screw with collor

3

5

Loosen the Set screw and remove the Spindle Motor Pulley.

Remove the Spindle Motor from the Flange and change it to the new one.

Screws Flange

Set Screw

Flange

Spindle Motor

Pulley

When fixing the Motor Flange, be careful with the direction of the Spindle Motor and the Flange.

Fix the Flange to the Spindle Motor following to the figure.

Screw with collar

<Bottom View>

Spindle Motor

Cable

Cable Direction

Flange Spindle Motor

35

3 Replacement of Main Parts

3

6

Fix the Spindle Motor Pulley to the Spindle Motor with the

Set Screw.

When fixing the Spindle Motor Pulley, it is necessary to align the top end of the Spindle

Motor Pulley and the top end of the Motor Shaft.

It is necessary to fix the Set Screw against the D-

Cut part of the Motor Shaft.

<Side View of the Spinlde Motor Pulley>

Top Part

Motor Shaft

Spindle

Motor

Pulley

<Top View of the Spinlde Motor Pulley>

Set Screw

Motor Shaft

Pulley

D-cut part

7

Tighten up the screw with the collar and tighten the other screws temporarily to the Flange and put the Spring.

Spring

8

Attach the Spindle Belt and tighten up the screws of the

Flange.

Flange

Spindle Belt

Screw with the collar

9

Connect the Spindle Motor Cable and pack it with

INSULOCK TIE, and fix the Z Cable Cover.

Screws

Please be careful not to pinch the Cable by the Z

Cable Cover.

Spindle Motor

Cable

36

Z Cable Cover

3 Replacement of Main Parts

3-2 X Axis Motor_Replacement (Referential Time : 20 minutes)

1

Remove the X Axis Rail Cover, Rail Cover and Right

Side Cover.

X Axis Rail Cover

Right Side Cover

2

Move the Head Carriage to the left end.

Remove the X Motor Cable from the XY Junction

Board.

Rail Cover

XY Junction Board

3

X Motor

Cable

Flange

Spring

3

Remove the Spring and after that remove the screws fixing the Flange.

Drive Belt

There are the collars on the lower left and upper right side of the screws. Be careful not to lose them.

Screws with the collar

4

Remove the X Motor together with the Flange from the Drive

Belt.

Drive Belt

X Motor

Screws

37

3

3 Replacement of Main Parts

5

Loosen the Set Screws and remove the X Motor Pulley from the X Motor. Then, remove the X Motor from the Flange and change it to the new one.

X Motor

Pulley

X Motor

When fixing the Motor Flange, be careful with the direction of the X Motor and the Flange.

Fix the Flange to the X Motor while taking care with the cable direction and the bending part of the Flange as the figure.

Set Screws

Flange

<Bottom View>

Cable Direction

Bending

Part

X Motor Cable

X Motor

Flange

X Motor Pulley

It is necessary to press the X Motor Pulley downward against the X Motor Shaft as the figure.

X Motor Shaft

6

Fix the X Motor Pulley to the X Motor with the Set Screw.

It is necessary to fix the Set Screw against the D-

Cut part of the X Motor Shaft.

X Motor

Pulley

<Top View>

Set Screws

D-Cut part

X Motor Shaft

38

3 Replacement of Main Parts

7

Put through the X Motor Pulley to the Drive Belt.

Then, tighten up the Screws with the collar and the other

Screws temporarily to the Motor Flange.

Drive Belt

Flange

8

Attach the Spring and tighten up the screws.

Screws with the collar

Flange

Screws

3

Drive Belt

9

Connect the X Motor Cable to the XY Junction Board.

Spring

XY Junction

Board

<X Axis Load Check>

10

Turn on the Power while pressing the [ ], [ ], [ ] keys to enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

X Motor Cable

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

39

3 Replacement of Main Parts

11

Select the [AXIS X] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 500 and press the [ENTER] key.

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 500

[ENTER] key

AXIS X Y Z S

VALUE 500 OK

3

12 After setting the value, the load check starts.

The Carriage moves in the X direction to check the load.

40

3 Replacement of Main Parts

3-3 Y Axis Motor _Repalcement (Referential Time : 20 minutes)

1 Remove the Front Cover.

Front Cover

2

Disconnect the Y Motor Cable.

3

Remove the Spring and the screws fixing the Flange.

Then, remove the Y Motor together with the Flange from the

Drive Belt.

Y Motor Cable

Drive

Belt

Spring

Screws

Screw with the collar

There is the collar on the lower right side of the flange. Be careful not to lose it.

When it is difficult to remove the lower right screw, you can remove it from the base of the machine.

Flange

Y Motor

41

3

3 Replacement of Main Parts

4

Loosen the Set Screw and remove Y Motor Pulley from the Y

Motor.

Remove the Y Motor from the Flange and change it to the new one.

Y Motor

3

5

Set Screws

Y Motor Pulley

Flange

When fixing theFlange, be careful with the direction of the Motor and the Flange.

Fix the Flange to the Y Motor while taking care with the cable direction and the projection part of the Flange as the figure.

Projection

Part

<Front View>

Cable Direction

Flange

Y Motor Cable

Fix the Y Motor Pulley to the Y Motor with the Set Screws.

Y Motor

Y Motor Pulley

It is necessary to press the Y Motor Pulley downward against the Y Motor Shaft as the figure.

Y Motor Shaft

42

It is necessary to fix the Set Screws against the

D-Cut part of the Y Motor Shaft.

Y Motor

Pulley

<Top View>

Set Screws

D-Cut part

Y Motor Shaft

3 Replacement of Main Parts

6

Put through the Y Motor Pulley to the Drive Belt and tighten the Flange with the Motor temporarily.

Drive

Belt

3

7

Attach the Spring and tighten up the screws.

Then, connect the Y Motor Cable.

<Y Axis Load Check>

8

Turn on the Power while pressing the [ ], [ ], [ ] keys too enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

Spring

9

Select the [AXIS Y] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 500 and press the [ENTER] key.

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 500

[ENTER] key

AXIS X Y Z S

VALUE 500 OK

43

3

3 Replacement of Main Parts

10

After setting the value, the load check starts.

The Carriage moves in the Y direction to check the load.

44

3 Replacement of Main Parts

3-4 Z Axis Motor_Replacement (Referential Time : 30 minutes)

1

Remove the Spindle Cover.

Spindle Cover

2

Remove the Junction Board Cover.

Disconnect the Z Motor Cable, Z Limit Cable and Spindle

Motor Cable from the XZ Junction Board.

3

Remove the Limit SW and loosen the Spindle Cable Bush.

Then, cut off the INSULOCK TIEs and remove the Sponge.

Sponge and

INSULOCK TIE

Spindle

Motor

Cable

Spindle

Cable Bush

INSULOCK

TIEs

4

Loosen the 4 screws on the Z Motor Base by rotating the Z

Screw and making the Z Slider up and down.

3

45

3 Replacement of Main Parts

5

Remove the 4 screws fixing the Carriage Unit.

And loosen the 2 Set Screws on the Boss Part of the Z

Screw.

Then, Loosen the 2 Screws on the Z Screw Support.

3

6

Detach the Carriage Unit from the Carriage Base.

Screws

Boss Part of the

Z Screw

Carriage Unit

7

Remove the Z Motor and change it to the new one. Then tighten up the screws for fixing the Z Motor.

46

Z Motor

Screws

When fixing the Z Motor, be careful with the direction.

Fix the Z Motor Shaft to the Boss part of the Z

Screw while taking care with the cable direction as the figure.

<Bottom View>

Z Motor Cable

<View Point>

Cable Direction

Screws

3 Replacement of Main Parts

8

Tighten up the Set Screw on the Boss part of the Z Screw.

It is necessary to fix the Set Screw against the

D-Cut part of the Z Motor Shaft.

At the same time, please be careful if the top of the Z Motor Shaft hit the Z Screw.

Set Screw

<Top View>

D-Cut Part

Boss Part of the

Z Screw

<View Point>

Z Motor Shaft

3

9

Tighten the 2 Screws on the Z Screw Support temporarily.

Then, tighten up the 2 Screws on the upper part of the Z

Motor Base by rotating the Z Screw and making the Z Slider downward.

10

Tighten up the 2 Screws on the lower part of the Z Motor

Base by rotating the Z Screw and making the Z Slider upward.

11

Tighten up the 2 Screws on the Z Screw Support by rotating the Z Screw and making the Z Slider downward.

Then, apply the grease on the Z Screw and make sure that the Z Slider moves smoothly.

Screws

47

3 Replacement of Main Parts

12

Tighten up the screws fixing the Carriage Unit.

Screws

3

13

Connect the INSULOCK TIEs and the Sponge as the figure.

Tighten up the Spindle Motor Cable Bush.

Spindle Cable Bush

Sponge and

INSULOCK TIE

Be careful with the position of the Sponge.

It is necessary to put it beside the Cable Holder.

Cable

Holder

14

Connect the Z Motor Cable, Z Limit Cable and Spinle Motor

Cable to the XY Junction Board.

Then, fix the Limit Switch and the Junction Board Cover.

Carriage Unit

INSULOCK

TIEs

<Z Axis Load Check>

15

Turn on the Power while pressing the [ ], [ ], [ ] keys to enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

48

3 Replacement of Main Parts

16 Select the [AXIS Z] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 350 and press the [ENTER] key.

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 350

[ENTER] key

AXIS X Y Z S

VALUE 350 OK

3

17 After setting the value, the load check starts.

The Carriage moves in the Z direction to check the load.

If the check is OK, fix the Cover.

If the check is NG, repeat 8 to 10 and 14 to 15 .

49

3

3 Replacement of Main Parts

3-5 X Axis LM Guide_Repalcement (Referential Time : 35 minutes)

NOTES

1. LM GUIDE has the direction for fixing. Bottom side of the LM GUIDE has the line that indicates its direction and the side plane of the bottom part will be the standard plane.

Push the standard plane of the LM GUIDE against the standard plane of the machine when fixing the

LM GUIDE.

STANDARD PLANE of LM GUIDE

Top Side

Bottom Side

Line

Standard Plane

1

Remove the X Axis Rail Cover, Rail Cover and Right

Side Cover.

X Axis Rail Cover

Right Side Cover

Rail Cover

2

Remove the Junction Board Cover.

Then, remove the Limit Switch.

50

3 Replacement of Main Parts

3

Disconnect the Z Limit Cable, Z Motor Cable and

Spindle Motor Cable from the XZ Junction Board.

3

4

Remove the Screws fixing the Carriage Unit and detach it from the Main Unit.

Screws

Carrige Unit

5

Remove the Carriage Base from the LM Block.

6

Remove the LM Guide and change it to the new one.

51

3 Replacement of Main Parts

When fixing the X LM Guide, be careful with the direction.

Fix the X LM Guide fitting the standard plane with the Pins as the figure.

<Right>

Pin

<Left>

3

7

Tighten the screws fixing the LM Guide temporarily.

Then, tighten up the screws for fixing the LM Guide by pushing to the Pins.

<Right>

LM Guide

<Left>

8

At first, tighten the Screws fixing the Carriage Base to the

LM Block temporarily.

And next, tighten up the Screws fixing the Carriage Base to the LM Block by pushing Carriage Base to the LM Block.

Carriage Base

Pin

LM Guide

Standard

Plane

LM Guide

Standard

Plane

Pin

LM Block

Scews

9

Tighten up the screws fixing the Carriage Unit.

Screws

Carriage Unit

52

3 Replacement of Main Parts

10

Connect the Z Motor Cable, Z Limit Cable and Spindle

Motor Cable to the XZ Junction Board.

Then, fix the Limit Switch and Junction Board Cover.

<X Axis Load Check>

11 Turn on the Power while pressing the [ ], [ ], [ ] keys to enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

12 Select the [AXIS X] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 500 and press the [ENTER] key.

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 500

[ENTER] key

AXIS X Y Z S

VALUE 500 OK

13 After setting the value, the load check starts.

The Carriage moves in the X direction to check the load.

If the check is OK, fix the Covers.

If the check is NG, repeat 6 to 11 .

3

53

3 Replacement of Main Parts

3

3-6 Y Axis LM Guide_Repalcement (Referential Time : 35 minutes)

NOTES

1. LM GUIDE has the direction for fixing. Bottom side of the LM GUIDE has the line that indicates its direction and the side plane of the bottom part will be the standard plane.

Push the standard plane of the LM GUIDE against the standard plane of the machine when fixing the

LM GUIDE.

STANDARD PLANE of LM GUIDE

Top Side

Bottom Side

Line

Standard Plane

1

Remove the Right Side Cover and Y Rail Cover.

Right Side Cover

2

Then, disconnect the Flexible Cables and open the Clamp.

Remove the screws fixing the Plate and remove the Plate.

Y Rail Cover

Flexible Cables

Clamp

Plate

Screws

54

3 Replacement of Main Parts

3

Remove the screws fixing the LM Guide.

4

Remove the screws fixing the LM Block on the Carriage Rail and loosen the Set Screws.

Set

Screws

5

Hold the Carriage Rail up and take the LM Guide off. Then, fix the new LM Guide by tightening screws temporarily.

LM Guide

Carriage

Rail

3

LM Block

Y LM

Guide

When fixing the Y LM Guide, be careful with the direction.

Fix the Y LM Guide fitting the standard plane with direction as the figure.

Carriage Rail

Standard Plane

Carriage Rail

Y LM Guide

55

3 Replacement of Main Parts

When fixing the Y LM Guide, be careful with the position of the Screws as the figure.

<Rear Side>

3

6

Fix the Carriage Rail to the LM Block and tighten up the Set

Screws and Screws.

<Front Side>

7

Push the Carriage Rail to the back side of the Machine and tighten up the screws of the front side.

Set

Screws

Y LM

Guide

Y LM Guide

LM Block

Carriage Rail

8

Move the Carriage Rail to the front side of the machine and tighten the screws of the rear side.

Y LM Guide

Carriage Rail

56

3 Replacement of Main Parts

9

Tighten up the Screws for fixing the Plate and connect the

Flexible Cables. Then, close the Clamp.

Fix the Right Side Cover.

Flexible Cables

Clamp

Plate

<Right Angle Adjustment of X Axis>

10

Loosen the Set Screws of the Y Drive Pulley.

Screws

Y Drive Pulley

Right Side

Cover

3

Set Screws

11

Move the X-Rail to the Rear side frame.

12

Tighten the Set Screws by pushing the X Rail to rear side frame.

Make sure that the Y Drive Pulley won't idle.

Y Drive Pulley

Set Screws

57

3

3 Replacement of Main Parts

<Y Axis Load Check>

13 Turn on the Power while pressing the [ ], [ ], [ ] keys too enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

14

Select the [AXIS Y] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 500 and press the [ENTER] key.

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 500

[ENTER] key

AXIS X Y Z S

VALUE 500 OK

15 After setting the value, the load check starts.

The Carriage moves in the Y direction to check the load.

If the check is OK, fix the Covers.

If the check is NG, repeat 6 to 13 .

58

3 Replacement of Main Parts

3-7 X Belt_Repalcement (Referential Time : 30minutes)

1 Remove the X Axis Rail Cover, Rail Cover and Right

Side Cover.

X Axis Rail Cover

Right Side Cover

2

Move the Carriage to the Right side by hands.

Spindle Cover

Carriage

Rail Cover 3

3

Remove the Junction Board Cover.

Junction Board

Cover

4

Remove the screws as the figure and after that, shift the

Junction Board Base behind from the Carriage.

Screws

Be careful the Limit SW. It is possible to break it when you shift the Junction Board Base.

Junction

Board

Base

59

3 Replacement of Main Parts

5

Loosen the Screw1 and remove the Screw2 and then loosen the Nut2.

3

6

Move the Z Slider to the bottom part by rotating the Z

Screws.

Nut2

Nut1

Frame

Screw2

Screw1

7

Loosen the screws from the Belt Holder and after that, remove the X Belt.

Z Screw

X Belt

8

Put the new belt through the Belt Holder and tighten up the

Screws.

X Belt

Belt Holder

Screws

Belt Holder

Screws

60

3 Replacement of Main Parts

X Belt

When fixing the X Belt, be careful not to overlap the both end of the Belts.

9

Tighten up the Screws as the figure for fixing the Junction

Board Base.

Be careful the Limit SW. It is possible to break it when you put the Junction Board Base.

Screws

Belt Holder

Junction

Board

Base

3

10

Fix the Screw2 temporarily.

<X Belt Tension Adjustment>

11

Tighten up the Nut2 so that there is no gap between the

Frame and the Nut1.

Nut2

Nut1

Frame

Screw2

Screw1

Nut2

Nut1

Frame

Screw2

Screw1

61

3 Replacement of Main Parts

12 Push the X-Belt with the Tension Gauge (ST-001) at the center position of the X Belt and check the bending amount with the ruler.

Confirm that the Pressing Force matches with the Bending

Amount in reference to the next table.

ST-001

X Belt

3

EGX-600

EGX-400

<Reference Table>

Pressing Force Bending Amount

720gf 10.0mm

720gf 7.0mm

13

When the Pressing Force matches with the Bending

Amount, tighten up the Screw1 and Screw2. Then, carry out the X Axis Load check.

If the Pressing Force does not match with the Bending

Amount, adjust the Belt Tension by Nut1 and 2 again. After that, measure the tension and when the Belt Tension becomes to the proper value, tighten up the Nut1 and 2.

<X Axis Load Check>

14

Turn on the Power while pressing the [ ], [ ], [ ] keys to enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

Nut2

Nut1

Frame

Screw2

Screw1

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

62

3 Replacement of Main Parts

15

Select the [AXIS X] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 500 and press the [ENTER] key.

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 500

[ENTER] key

AXIS X Y Z S

VALUE 500 OK

3

16 After setting the value, the load check starts.

The Carriage moves in the X direction to check the load.

If the check is OK, fix the Covers.

If the check is NG, repeat 10 to 14 .

63

3 Replacement of Main Parts

3-8 Y Belt_Repalcement (Referential Time : 30 minutes)

Remove the Y Rail Cover and the Front Cover.

1

Y Rail Cover

Front Cover

3

2

Loosen the Screw1 and remove Screw2 and then loosen the

Nut2.

Then, remove the Belt from the Idle Pulley.

Belt

Frame

3

Loosen the 4 screws and remove the Belt from the Carriage

Rail Base.

Put the new Belt through the Belt Holder and tighten up the

Screws.

Screw1

Screw2

Nut1 Nut2

Screws

When putting the new Belt, be careful not to overlap the both end of the Belt.

Belt

Holder

Belt

64

3 Replacement of Main Parts

4

Fix the Screw2 temporarily.

Belt

Frame

<Y Belt Tension Adjustment>

5

Tighten up the Nut2 so that there is no gap between the

Frame and the Nut1.

Screw1

Screw2

Nut1 Nut2

Frame

3

Screw1

Screw2

Nut1 Nut2

6

Push the Y-Belt with the Tension Gauge (ST-001) at the middle position between the Y-Drive Pulley and check the bending amount with the ruler.

Confirm that the Pressing Force matches with the Bending

Amount in reference to the next table.

ST-001

Y Belt

EGX-600

EGX-400

<Reference Table>

Pressing Force Bending Amount

720gf 8.0mm

720gf 6.0mm

65

3 Replacement of Main Parts

7 When the Pressing Force matches with the Bending

Amount, tighten up the Screw1 and Screw2. Then, carry out the X Axis Load check.

If the Pressing Force does not match with the Bending

Amount, adjust the Belt Tension by Nut1 and 2 again. After that, measure the tension and when the Belt Tension becomes to the proper value, tighten up the Nut1 and 2.

Frame

3

<Right Angle Adjustment of X Axis>

8

After carrying out the Y Belt Tension Adjustment, carry out the Right Angle Adjustment of X Rail.

Loosen the Set Screws of the Y Drive Pulley.

Screw1

Screw2

Nut1 Nut2

Y Drive Pulley

Set Screws

9

Move the X-Rail to the Rear side frame.

10

Tighten the Set Screws by pushing the X Rail to rear side frame.

Make sure that the Y Drive Pulley won't idle.

Y Drive Pulley

Set Screws

66

3 Replacement of Main Parts

<Y Axis Load Check>

11

Turn on the Power while pressing the [ ], [ ], [ ] keys to enter the Service Mode.

Select the [LOAD] menu by pressing the [MENU] key and press [ENTER] key.

[ ], [ ], [ ] + POWER ON

[MENU] key

CHECK MODE

LOAD CON. CARD

[ENTER] key

3

12 Select the [AXIS Y] in the [LOAD] menu and press [ENTER] key. Then, Carriage moves to the Limit Position.

Enter the value 500 and press the [ENTER] key.

AXIS X Y Z S

[ENTER] key

AXIS X Y Z S

VALUE 500

[ENTER] key

AXIS X Y Z S

VALUE 500 OK

13 After setting the value, the load check starts.

The Carriage moves in the Y direction to check the load.

If the check is OK, fix the Covers.

If the check is NG, repeat 4 to 11 .

67

4

4 Adjustment

4 Adjustment

4-1 Special Tool

Table shown below is a list of special tools recommended by Roland DG Corporation.

Tool No.

Tool Name

ST-001

TENSION GAUGE 2000g (2N)

Purpose Belt Tension Adjustment

68

4-2 Service Mode

4 Adjustment

4

69

4

4 Adjustment

70

4 Adjustment

4

71

4 Adjustment

4-3 HOW TO UPGRADE FIRMWARE (Referential Time : 5 minutes)

1

Connect PC and EGX-600/400 with the PARALLEL CABLE.

It is necessary to prepare the followings to upgrade the FIRMWARE.

1. FIRMWARE DISK

2. PC with MS-DOS

3. PARALLEL CABLE

4

2

Turn on the power while pressing [ ], [ ] and [ ] keys.

Press [ENTER] key when the right message appears.

[ ],[ ],[ ] + POWER ON

UPDATE B.1.10

Are you sure?

[ENTER ] key

UPDATE B.1.10

Send new program

3

Open the [download.bat] in the FIRMWARE DISK.

BAT FILE can not be used on some PCs. Please refer to the ReadMe File in the FIRMWARE DISK.

4

Turn off the power when completed.

Version [ A1.2]

UPDATE Complete!

72

4 Adjustment

Booter is included in the Firmware.

When the Booter version in the Firmware is upgraded to the new one, carry out the following operation.

5

In order to enter the Service Mode, turn on the power while pressing [ ], [ ] and [ ] keys.

Check Mode

DIP VOLT BOOT

6

Select the [BOOT] and press the [Enter] key for three seconds.

When the "Booter Update Are you sure?" appears, press the [Enter] key.

Check Mode

DIP VOLT BOOT

Booter update

Are you sure?

7 When the message "Now processing" appears, the program update is carried out.

When the message "Already latest " appears after this sequence, the same version of the

Booter has already been installed.

Booter update

Are you sure?

Booter Update

*Now Prosessing

Booter update

Already latest

73

4

4

4 Adjustment

8

When the program update is finished, "Finished" is appeared. Then turn off the Main power Switch.

Confirm the current Booter version by turning on the power while pressing the [ ] key.

Booter Update

*Now Prosessing

Booter update

Finished

ROM Ver 1.20

BOOT Ver 1.20

74

4-4 X BELT TENSION ADJUSTMENT (Referential Time : 10min.)

2

Remove the Rail Cover.

Rail Cover

4 Adjustment

2

Loosen the Screw1 and 2 and then, loosen the Nut1 and 2.

Tighten up the Nut2 so that there is no gap between the

Frame and the Nut1.

It is possibe to adjust the X Belt Tension by changing the position of the Nuts.

Nut2

Nut1

Frame

Screw2

Screw1

3

Push the X-Belt with the Tension Gauge (ST-001) at the middle position between the X-Drive Pulley and check the bending amount with the ruler.

Confirm that the Pressing Force matches with the Bending

Amount in reference to the next table.

ST-001

4

X Belt

EGX-600

EGX-400

<Reference Table>

Pressing Force Bending Amount

720gf 10.0mm

720gf 7.0mm

75

4

4 Adjustment

4

When the Pressing Force matches with the Bending

Amount, tighten up the Screw1 and 2.

If the Pressing Force does not match with the Bending

Amount, adjust the Belt Tension by Nut1 and 2 again. After that, measure the tension and when the Belt Tension becomes to the proper value, tighten up the Nut1 and 2.

Nut2

Nut1

Frame

Screw2

Screw1

76

4-5 Y BELT TENSION ADJUSTMENT (Referential Time : 10min.)

1

Remove the Y Rail Cover.

Y Rail Cover

4 Adjustment

2

Loosen the Screw1 and 2 and then, loosen the Nut1 and 2.

Tighten up the Nut2 so that there is no gap between the

Frame and the Nut1.

Frame

It is possibe to adjust the X Belt Tension by changing the position of the Nuts.

Screw1

Screw2

Nut1 Nut2

3

Push the Y-Belt with the Tension Gauge (ST-001) at the middle position between the Y-Drive Pulley and check the bending amount with the ruler.

Confir that the Pressing Force matches with the Bending

Amount in reference to the next table.

ST-001

4

Y Belt

EGX-600

EGX-400

<Reference Table>

Pressing Force Bending Amount

720gf 8.0mm

720gf 6.0mm

77

4

4 Adjustment

4

When the Pressing Force matches with the Bending

Amount, tighten up the Screw1 and 2.

If the Pressing Force does not match with the Bending

Amount, adjust the Belt Tension by Nut1 and 2 again. After that, measure the tension and when the Belt Tension becomes to the proper value, tighten up the Nut1 and 2.

Frame

Screw1

Screw2

Nut1 Nut2

78

4-6 RIGHT ANGLED ADJUSTMENT OF X-RAIL (Referential Time : 5min.)

1

Remove the Front Cover.

4 Adjustment

2

Loosen the Set Screws of the Y Drive Pulley.

Front Cover

Y Drive Pulley

4

Set Screws

3 Move the X-Rail to the Rear side frame.

4

Tighten the Set Screws by pushing the X Rail to rear side frame.

Make sure that the Y Drive Pulley won't idle.

Y Drive Pulley

Set Screws

79

4 Adjustment

4-7 CALIBRATION (Referential Time : 20 minutes)

1

Attach the ZEC-A2025 and ACRYLIC PLATE (over 25cm x

19cm) to the machine.