advertisement

7

7 Service Activities

7 Service Activities

7-1 INSTALLATION CHECK LIST

EGX-600/400 INSTALLATION CHECK LIST

Model

EGX-600/400

Serial No.

User Name Date

Minimum Space Required

EGX-600 EGX-400

995mm(W) X 820mm(L) X 521mm(H) 795mm(W) X 719mm(L) X 521mm(H)

Classification

Purcahse Loan Unit Demo Unit Replacement

Unpacking Take the unit out of the carton box.

Accesorry box

94

7 Service Activities

Accessories

Follow the steps in "Unpacking and Repacking" on the packing carton to take out the included items and accessories. Before you attempt installation, make sure all the included items are present.

Operation panel : 1

Operation-panel connector cable : 1

Power cord : 1

Depth regulator nose unit : 1

Solid collet : 1 (*1) Clamps : 4 (*2)

Wrenches

(17 mm : 1, 10 mm : 1)

Hexagonal screw driver (2 mm) : 1

Hexagonal wrench

(3 mm) : 1

7

Remove the retainers.

Roland Software Package

CD-ROM : 1

User's Manual : 1

*1 This is for diameter 4.36 mm character cutters and flat cutters. It cannot be used with diamond scrapers or end mills.

*2 The bolts and nuts are installed on the machine. (They are used for attaching the packing retainers.)

1. Use the included wrench (10mm) and hexagonal wrench (3mm) to remove the retainers on the side of the unit. Then, lower the unit from the base.

95

7 Service Activities

2. Remove the four nuts and the retainer shown in the figure.

3. Loosen the three screws shown in the figure and remove the guide temporarily

7

4. Slide the bolts left on the table in step 2 to detach them.

5. Mount the guide at its original location.

6. Use the included hexagonal wrench (3mm) to remove the retainers for the spindle head. Then secure the screw on the left side of the head at its original location.

96

EGX-600/400

User

Explanation

Operation

7 Service Activities

Emergency Stop to Ensure Safety

The machine immediately stops operating and quits engraving by pressing the emergency stop switch.

Switching the Power On and Off

Moving the Spindle Head

The speed of movement is determined by how you press the movement buttons.

This machine has the function that moves the spindle head directly to the back-left position of the table (the VIEW position).

Starting and Stopping Spindle Rotation

To adjust the spindle rotating speed, you use the dial on the operation panel.

Menu Operations

Selecting the Cutter Installation Method

1. Character cutter , Flat cutter (with nose unit)

2. Character cutter , Flat cutter (without withoutse unit)

3. Diamond scraper (without withoutse unit)

4. End mill (without withoutse unit)

Loading Material and Setting the Reference Point for Cutting

1. Clamp

2. Adhesive sheet

3. Center vice

The reference point for engraving is the location where the X- and Y-axis coordinates are both (that is, the X- and Y-axis origin point).

Setting the Cutting Parameters

There are five kinds of settings and you can make the settings for these either on the machine by using the menus, or by using the program.

1. Spindle rotating speed

2. Feed rate in the X- and Y- axis directions

3. Feed rate in the Z-axis direction

4. Cutting depth (Z1)

5. Amount of cut-out during feed while raised (Z2)

Installation and Setup the Software

Coordinate Systems

Detailed Description of the Menus

7

EGX-600/400

User

Explanation

Maintenance

Daily Care

Clean the table, bed, the spindle head and the X-axis rail.

Maintenance and Inspection

Spindle Maintenance

Others Examples of Setting for Engraving Parameters

The Nose Unit

Optional Items

97

advertisement

* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Related manuals

advertisement

Table of contents

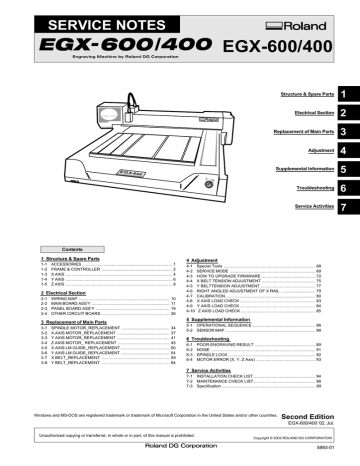

- 4 ACCESSORIES

- 5 FRAME & CONTROLLER

- 7 X AXIS

- 9 Y AXIS

- 11 Z AXIS

- 13 WIRING MAP

- 14 MAIN BOARD ASS’Y

- 22 PANEL BOARD ASS’Y

- 29 OTHER CIRCUIT BOARS

- 37 SPINDLE MOTOR_REPLACEMENT

- 40 X AXIS MOTOR_REPLACEMENT

- 44 Y AXIS MOTOR_REPLACEMENT

- 48 Z AXIS MOTOR_ REPLACEMENT

- 53 X AXIS LM GUIDE_REPLACEMENT

- 57 Y AXIS LM GUIDE_REPLACEMENT

- 62 X BELT_REPLACEMENT

- 67 Y BELT_REPLACEMENT

- 71 Special Tools

- 72 SERVICE MODE

- 75 HOW TO UPGRADE FIRMWARE

- 78 X BELT TENSION ADJUSTMENT

- 80 Y BELTTENSION ADJUSTMENT

- 82 RIGHT ANGLED ADJUSTMENT OF X RAIL

- 83 CALIBRATION

- 86 4-8 X AXIS LOAD CHECK

- 87 4-9 Y AXIS LOAD CHECK

- 88 4-10 Z AXIS LOAD CHECK

- 89 OPERATIONAL SEQUENCE

- 91 SENSOR MAP

- 92 POOR ENGRAVING RESULT

- 94 NOISE

- 95 SPINDLE LOCK

- 96 MOTOR ERROR (X, Y, Z Axis)

- 97 INSTALLATION CHECK LIST

- 101 MAINTENANCE CHECK LIST

- 102 Specification